Method for synthesizing chloromethane from gas-state hydrogen chloride

A technology of methyl chloride and hydrogen chloride, applied in the methods of chemically changing substances by atmospheric pressure, chemical instruments and methods, pressure vessels used in chemical processes, etc. speed, the effect of reducing environmental pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

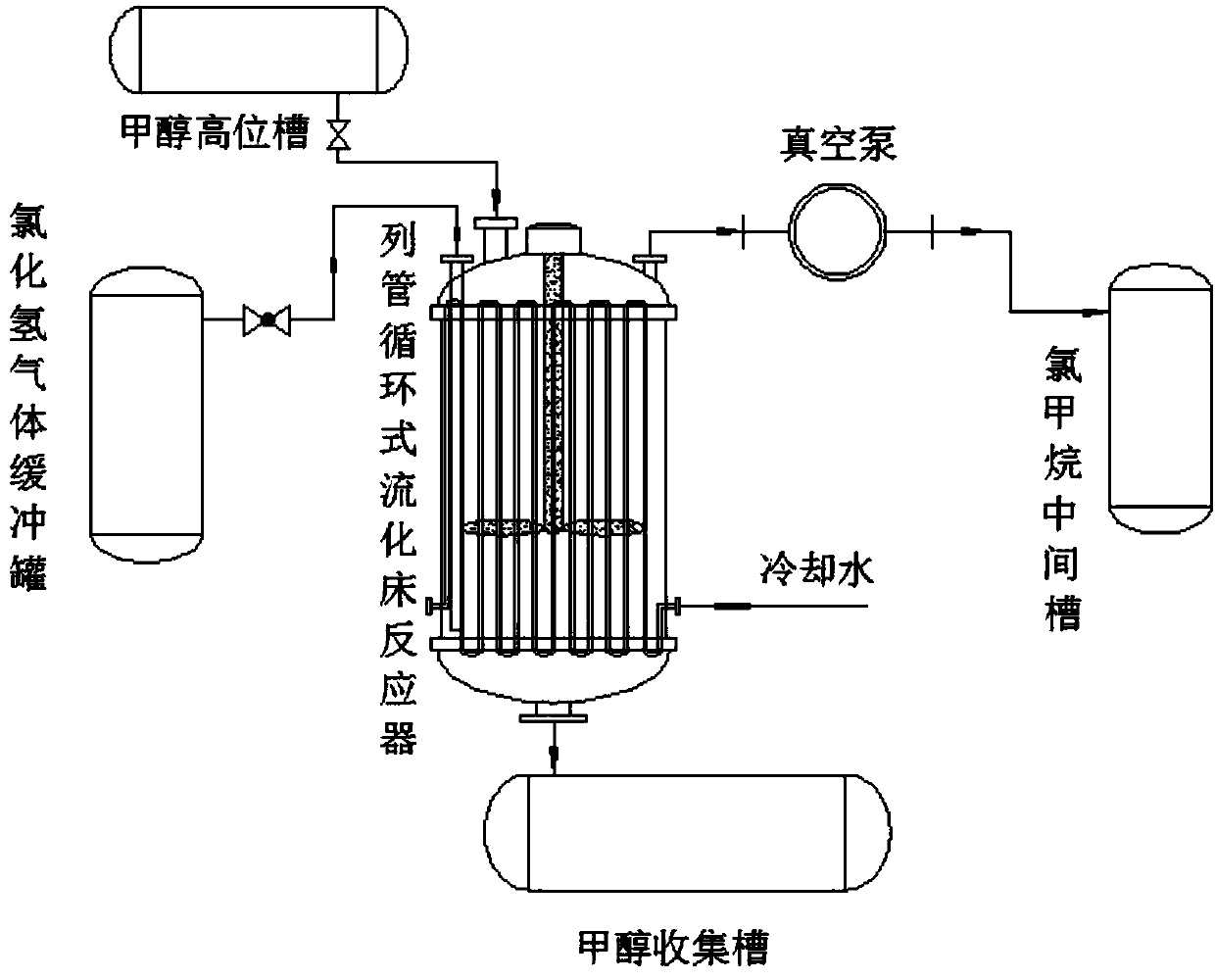

[0027] see figure 1 As shown, the technical solution adopted in the present invention is: a method for synthesizing methyl chloride from gaseous hydrogen chloride, and the method for synthesizing methyl chloride from gaseous hydrogen chloride specifically comprises the following steps:

[0028] 1).Assembly: There is a discharge pipe at the bottom of the tubular circulating fluidized bed reactor, the discharge pipe is connected to the methanol collection tank, the top of the reactor is equipped with stirring, gas phase outlet, vent port and feed port, and the gas phase outlet is connected Vacuum pump, the vent port is connected to the hydrogen chloride gas buffer tank, the feed port is connected to the methanol high tank, and the inlet and outlet provided on the lower side of the reactor body are respectively connected to the condensed water inlet and outlet;

[0029] 2). Feeding: Add 10mol of hydrogen chloride gas and 15mol of methanol as raw materials into the reactor accordi...

Embodiment 2

[0037] see figure 1 As shown, the technical solution adopted in the present invention is: a method for synthesizing methyl chloride from gaseous hydrogen chloride, and the method for synthesizing methyl chloride from gaseous hydrogen chloride specifically comprises the following steps:

[0038] 1).Assembly: There is a discharge pipe at the bottom of the tubular circulating fluidized bed reactor, the discharge pipe is connected to the methanol collection tank, the top of the reactor is equipped with stirring, gas phase outlet, vent port and feed port, and the gas phase outlet is connected Vacuum pump, the vent port is connected to the hydrogen chloride gas buffer tank, the feed port is connected to the methanol high tank, and the inlet and outlet provided on the lower side of the reactor body are respectively connected to the condensed water inlet and outlet;

[0039] 2). Feeding: Add 10mol of hydrogen chloride gas and 20mol of methanol as raw materials into the reactor accordi...

Embodiment 3

[0047] see figure 1 As shown, the technical solution adopted in the present invention is: a method for synthesizing methyl chloride from gaseous hydrogen chloride, and the method for synthesizing methyl chloride from gaseous hydrogen chloride specifically comprises the following steps:

[0048] 1).Assembly: There is a discharge pipe at the bottom of the tubular circulating fluidized bed reactor, the discharge pipe is connected to the methanol collection tank, the top of the reactor is equipped with stirring, gas phase outlet, vent port and feed port, and the gas phase outlet is connected Vacuum pump, the vent port is connected to the hydrogen chloride gas buffer tank, the feed port is connected to the methanol high tank, and the inlet and outlet provided on the lower side of the reactor body are respectively connected to the condensed water inlet and outlet;

[0049] 2). Feeding: Add 15mol of hydrogen chloride gas and 30mol of methanol as raw materials into the reactor accordi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com