Integrated automatic alarm device of hydraulic system

An automatic alarm device and hydraulic system technology, applied in the direction of fluid pressure actuation device, fluid pressure actuation system safety, fluid pressure actuation system components, etc., can solve the problem of slow movement of actuators, reduction of performance and service life of hydraulic components, Large resistance and other problems, to prevent misjudgment troubleshooting, to protect the effect of safe operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

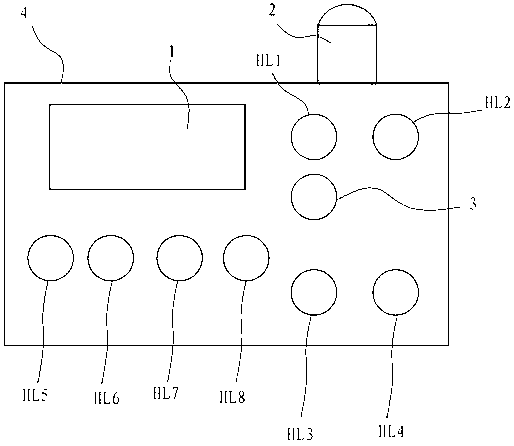

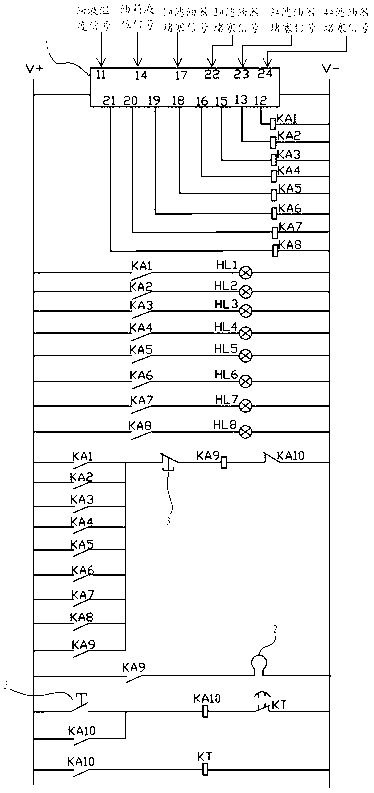

[0020] The hydraulic system integrated automatic alarm device provided in this embodiment includes a control box 4, and XMT is arranged in the control box. * -908 series control digital display meter 1, various fault signal indicators, alarm 2, reset switch 3, the display part of control digital display meter 1, various fault signal indicator lights, and reset switch 3 are exposed on the front of the control box, The alarm 2 is exposed on the top of the control box, such as figure 1 shown. The internal circuit of the control box 4 is:

[0021] Control the positive input terminal of the power supply of the digital display meter 1 and the positive terminal V of the external regulated power supply. + Connect and control the negative input terminal of the power supply of the digital display meter 1 and the negative terminal V of the external re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com