Corrosive granular waste carbon regeneration method

A corrosive and granular technology, applied in the field of corrosive granular waste carbon regeneration, can solve the problem of inability to adapt to the corrosive granular waste carbon regeneration treatment, and achieve the effect of prolonging the lifting and ventilation time, increasing the volume, and rationally configuring

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In order to describe the technical content, structural features, achieved goals and effects of the present invention in detail, the following will be described in detail in conjunction with the embodiments and accompanying drawings.

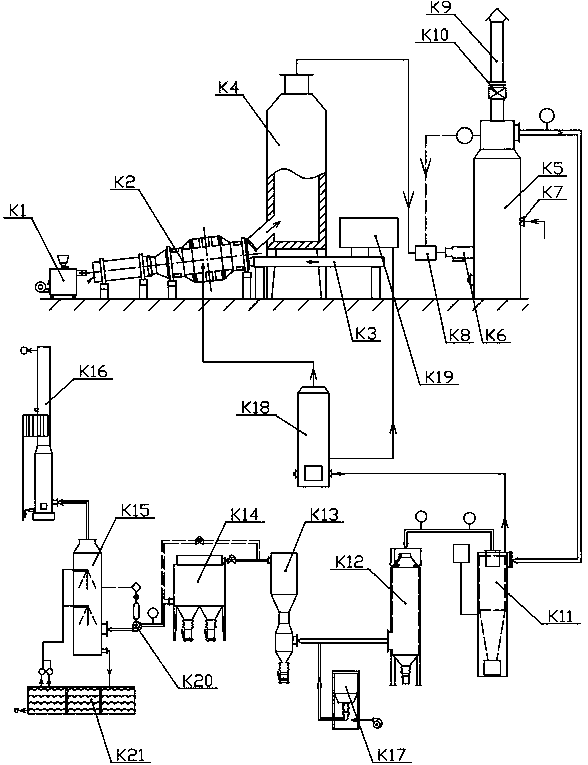

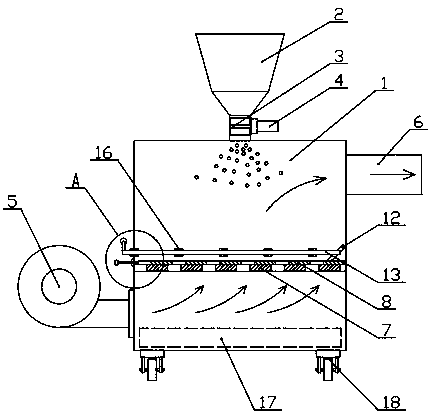

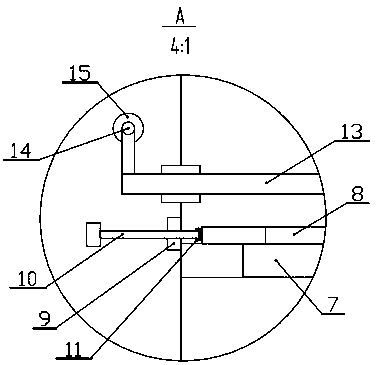

[0034] Such as figure 1 As shown, the corrosive granular waste carbon regeneration method of the present invention is: firstly dry the corrosive granular waste carbon, and then use the carbon activation integrated rotary kiln to carbonize and activate the corrosive granular waste carbon, thereby obtaining the regenerated activated carbon product ;The high-temperature tail gas produced by the carbon activation integrated rotary kiln is collected and dried by a corrosion-resistant tail gas collection tower, and then the high-temperature tail gas is sent to the secondary combustion chamber for combustion treatment. Neutralization treatment, dioxin absorption treatment, dust removal treatment and lye spray treatment for harmless treatment of h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com