Lightweight early-strength magnesium-based cement concrete mixing equipment and application thereof

A cement concrete and lightweight technology, which is applied in the direction of cement mixing equipment, clay preparation equipment, chemical instruments and methods, etc., can solve the problems of insufficient carbonation and inability to meet the mixing of cement concrete in extreme climate areas, so as to improve the compactness and improve the The effect of microstructure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

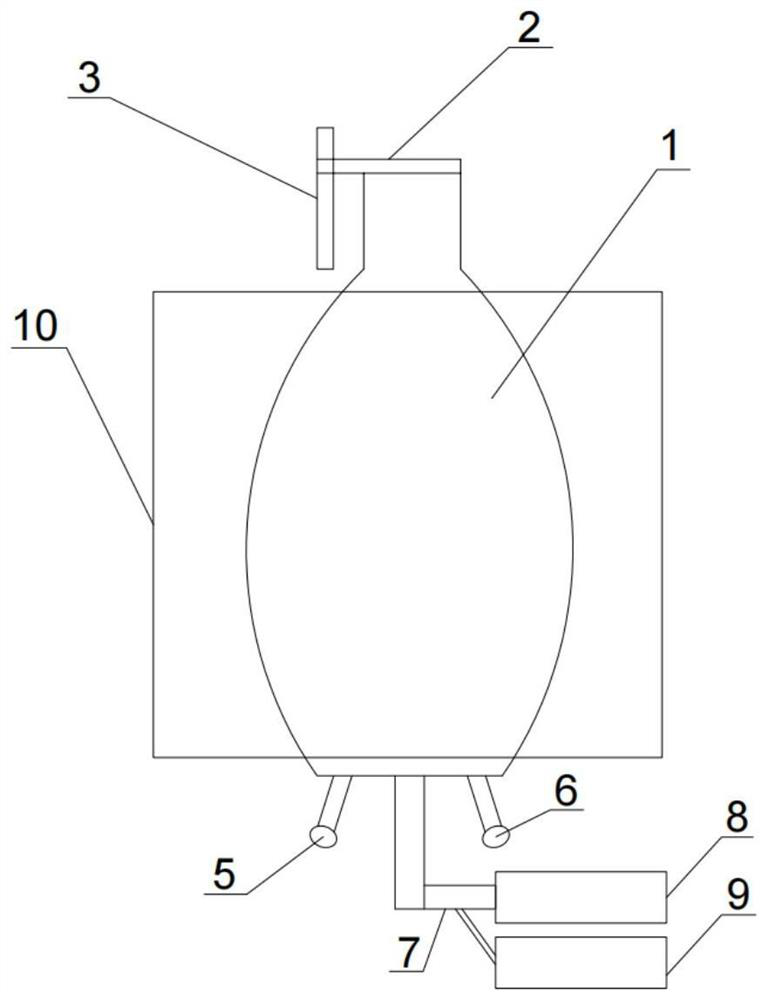

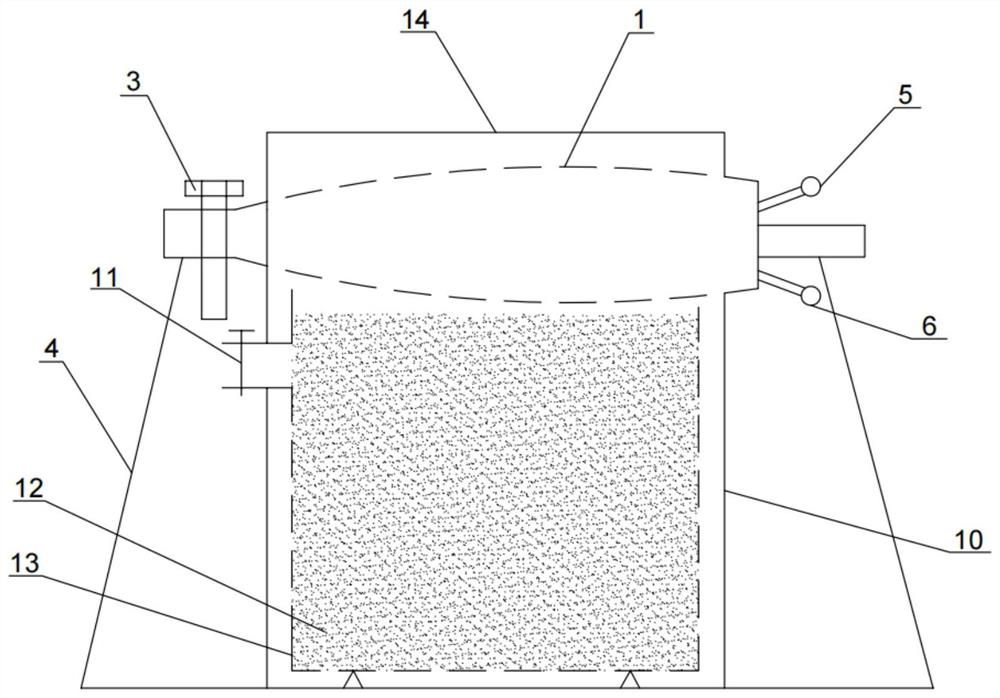

[0032] The airtight mixing equipment for lightweight early-strength magnesium-based cement concrete disclosed in Example 1 includes a sealable hopper, and a temperature control facility is provided at the lower part of the hopper, and the temperature control facility can regulate the temperature in the hopper.

[0033] In this embodiment, cement concrete raw materials can be placed in the hopper, and the temperature and pressure of the hopper can be adjusted by using temperature control facilities, so that the temperature and pressure of the hopper are suitable for cement concrete mixing. This embodiment solves the problems of insufficient hydration and early carbonation of cement concrete. Free water volatilizes, suitable for extreme climate environment, wide area of use.

[0034] Preferably, the hopper is spindle-shaped and can rotate axially.

[0035] Wherein, the lower part of the hopper is provided with a frame, and this embodiment is also provided with a control device...

Embodiment 2

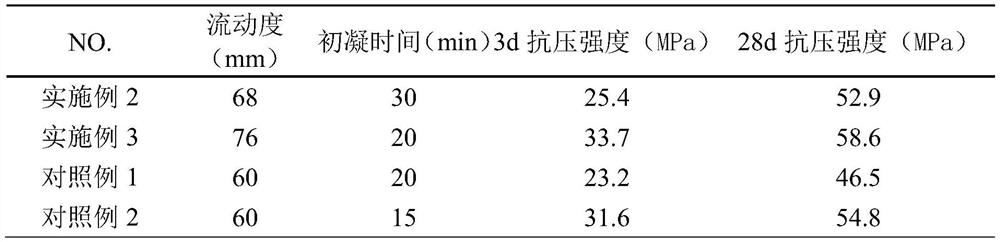

[0046] Embodiment 2,3 The application of light early strength magnesium-based cement concrete airtight mixing equipment comprises the following steps:

[0047] S101, weighing the powder particles with a particle size less than 2.36mm in the magnesium-based cement concrete raw material according to the proportion, and then stirring evenly;

[0048] S102, adding S101 powder to the closed mixing equipment of lightweight early-strength magnesium-based cement concrete for closed mixing;

[0049] S103, add the S102 slurry, water, and particles with a particle size greater than 2.36 mm to the light early-strength magnesium-based cement concrete closed mixing equipment and mix evenly. The slurry stirred in this embodiment can be poured or 3D printed.

[0050] Comparative example 1 and comparative example 2 use traditional concrete mixer mixing equipment, and mix according to conventional methods.

[0051] Embodiment 2, Comparative Example 1 Magnesium-based cement concrete raw materia...

Embodiment 3

[0052] Embodiment 3, comparative example 2 magnesium-based cement concrete formula, comprise following raw materials in parts by weight: 100 parts of magnesia, 50 parts of phosphate, 100 parts of magnesium salt, 8 parts of citric acid monohydrate, 70 parts of phosphogypsum, magnesium-based standard sand 150 parts, 50 parts water slag sand, 50 parts gravel, 40 parts engineering dregs, 20 parts dry ice, 20 parts water;

[0053] Wherein, magnesia described in embodiment 2-3, comparative example 1-2 comprises light-burned magnesia and dead-burned magnesia;

[0054] The magnesium-based standard sand is composed of light-burned magnesia and dead-burned magnesia of different particles.

[0055]The fineness modulus of the magnesium-based standard sand is 3.5; the fineness modulus of the water slag sand is 3.8; the sand content of the engineering dregs is 23.16%, and the fineness modulus of the contained sand is 1.2; The magnesium sulfate heptahydrate has a content of 98% and a finene...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com