Patents

Literature

72results about How to "Shorten carbonization time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

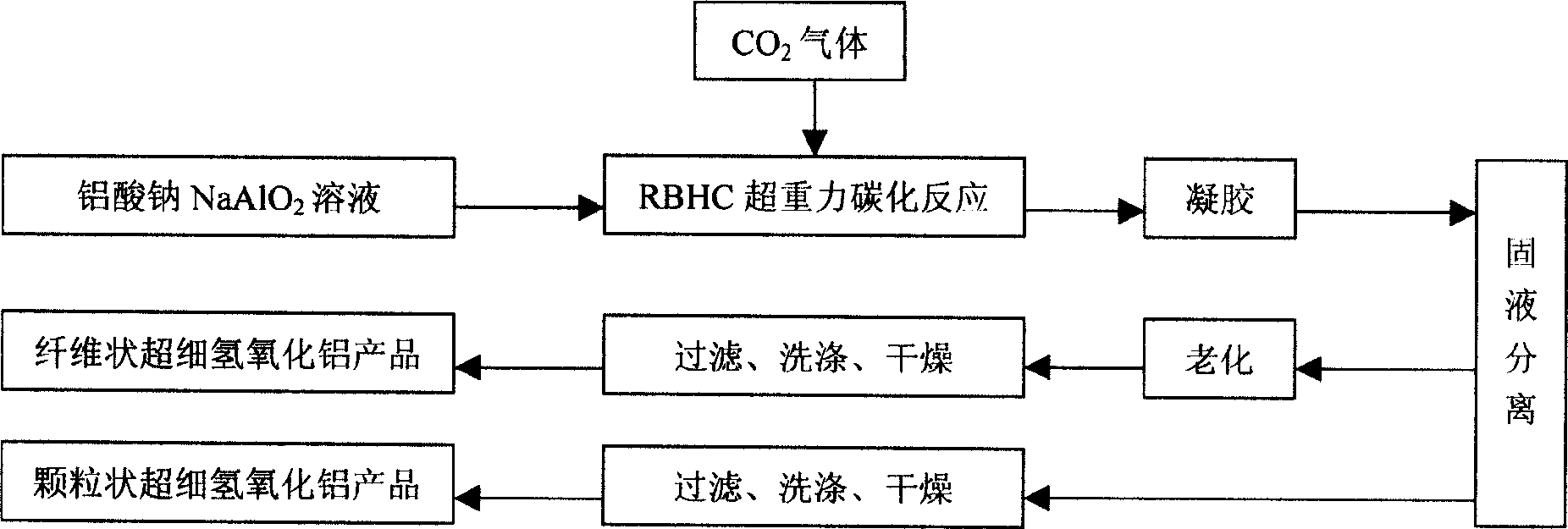

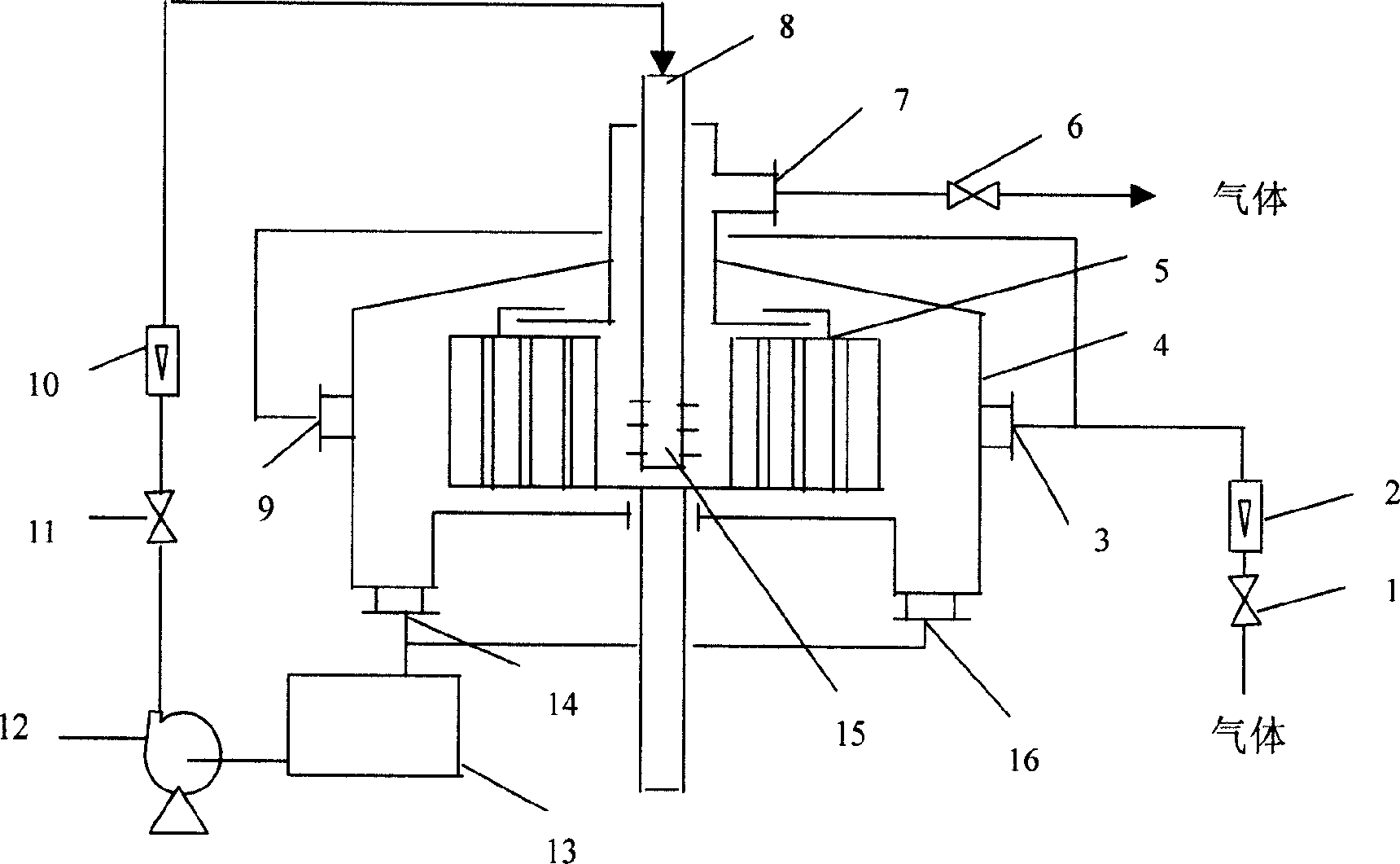

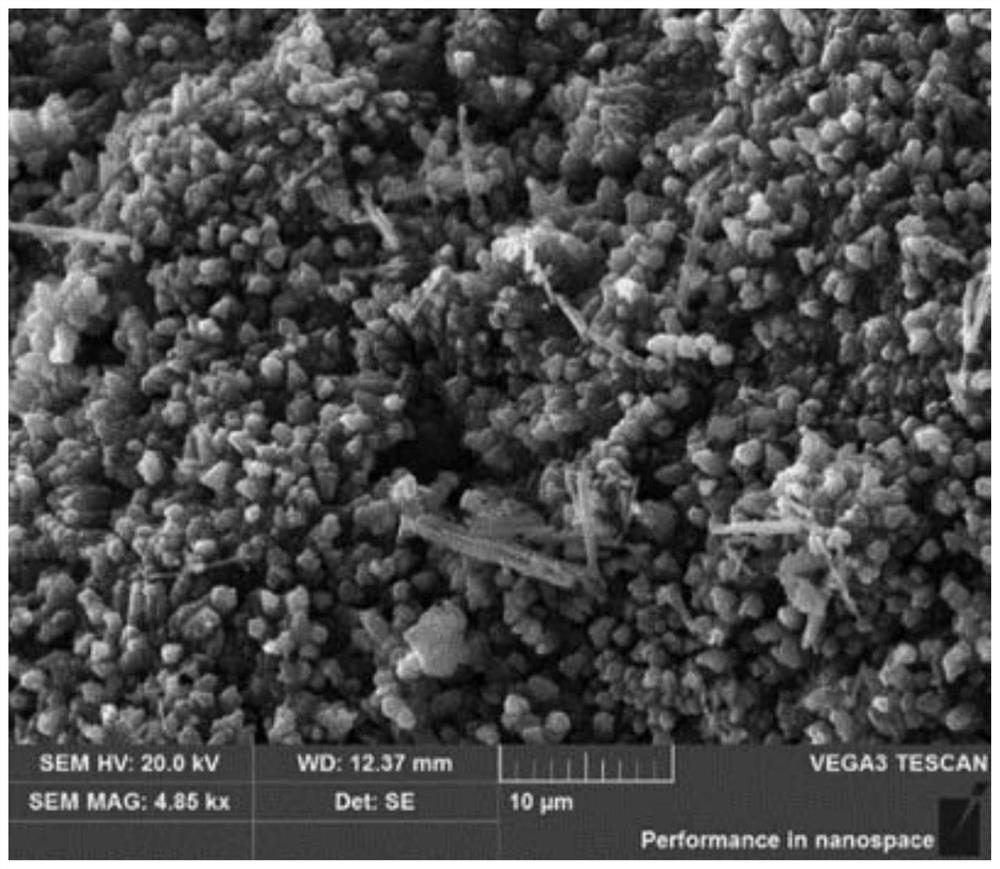

Preparation method of ultrafine aluminium hydroxide

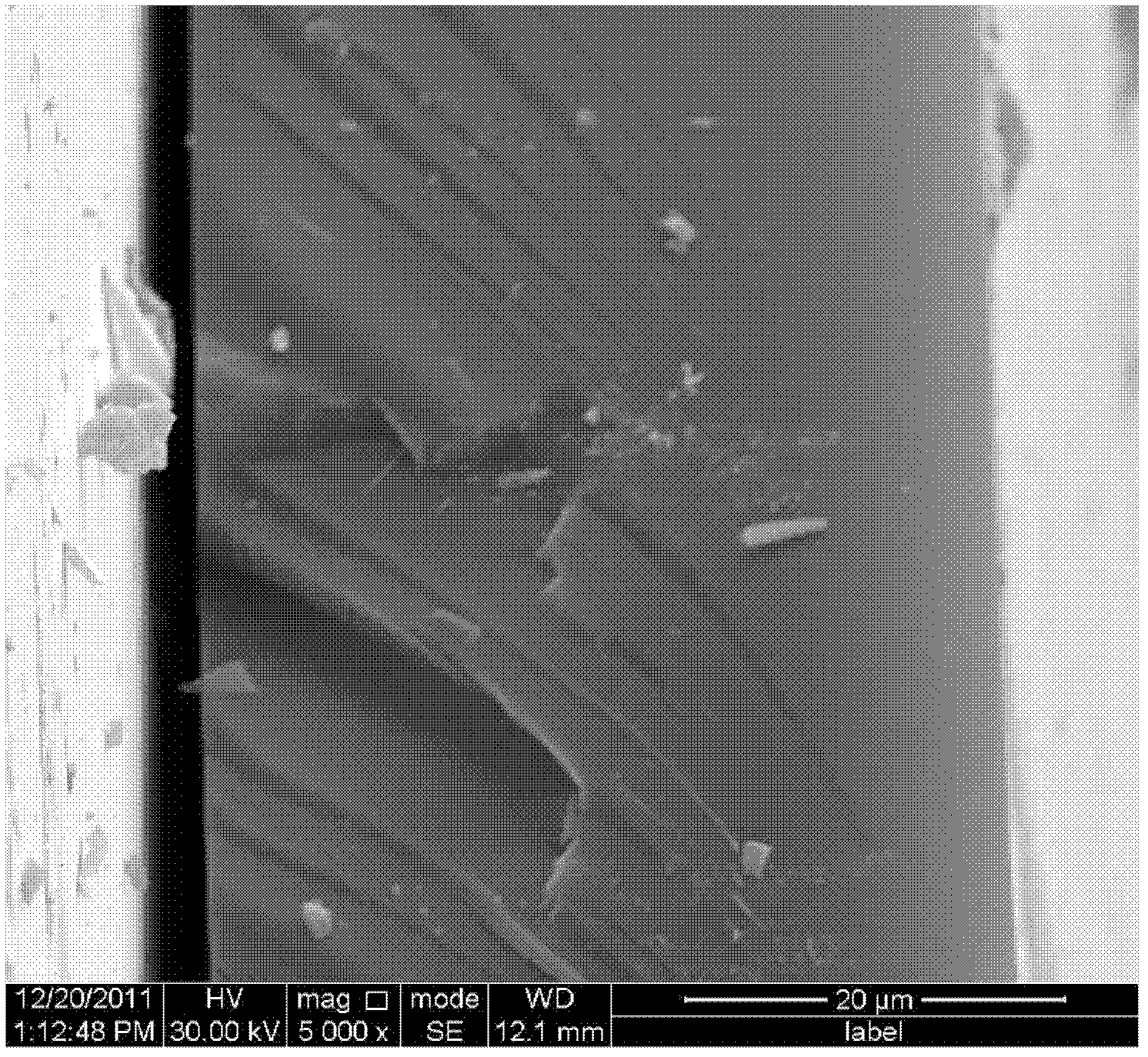

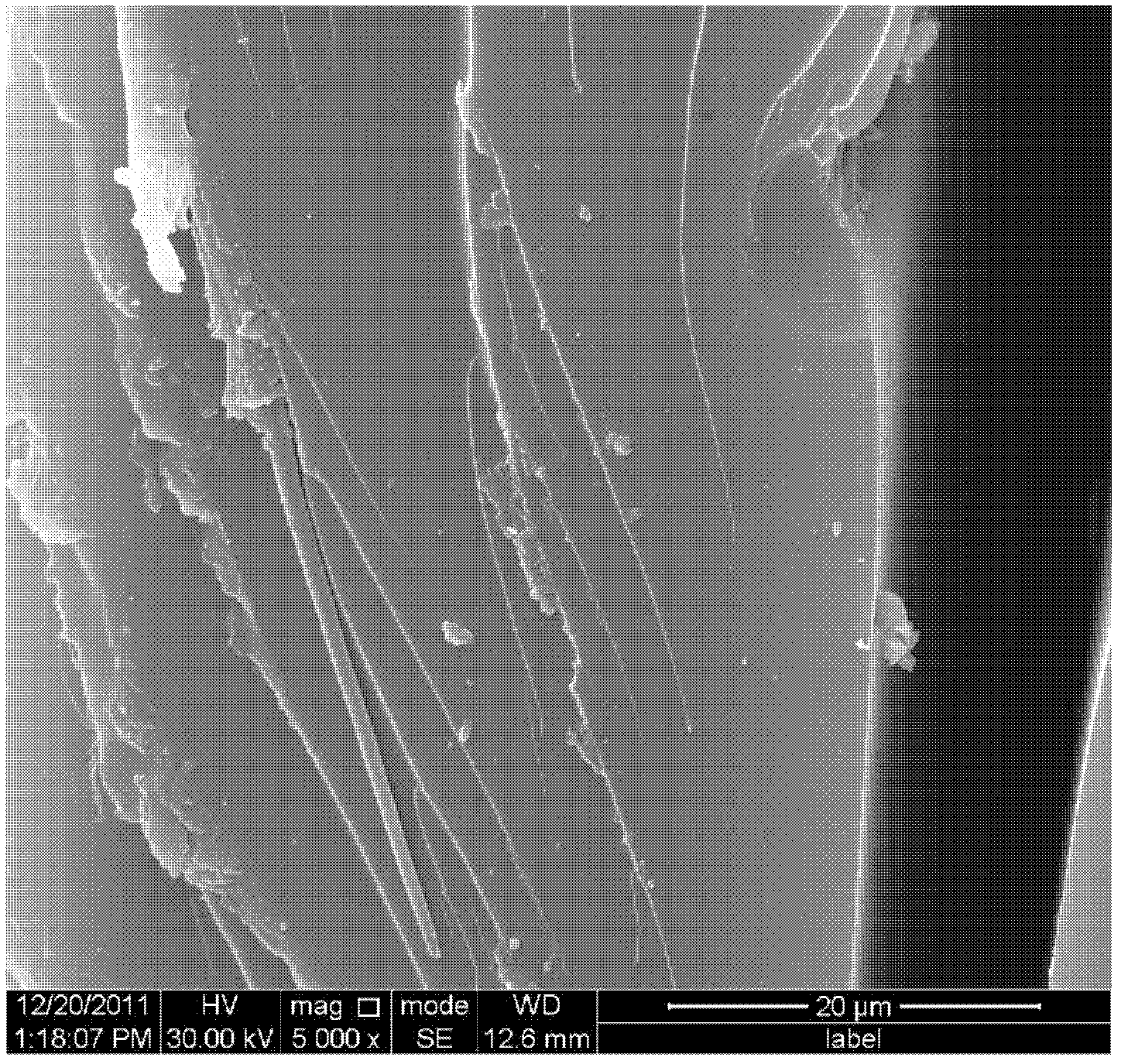

InactiveCN1752006ASolve defects that are prone to clogging equipmentLow miscellaneous crystal contentAlkali-metal aluminates/aluminium-oxide/aluminium-hydroxide preparationNanoparticleAluminium hydroxide

A process for preparing superfine aluminium hydroxide includes such steps as carbonifying reaction between NaAlO2 solution and the gas containing CO2 in gravitation condition to obtain aluminium hydroxide gel, preparing superfine aluminium hydroxide, filtering, washing, and drying. The product (nanofibers or nanoparticles of aluminium hydroxide) can be used as inorganic flame-retarding agent or for preparing catalyst.

Owner:XIANGTAN UNIV

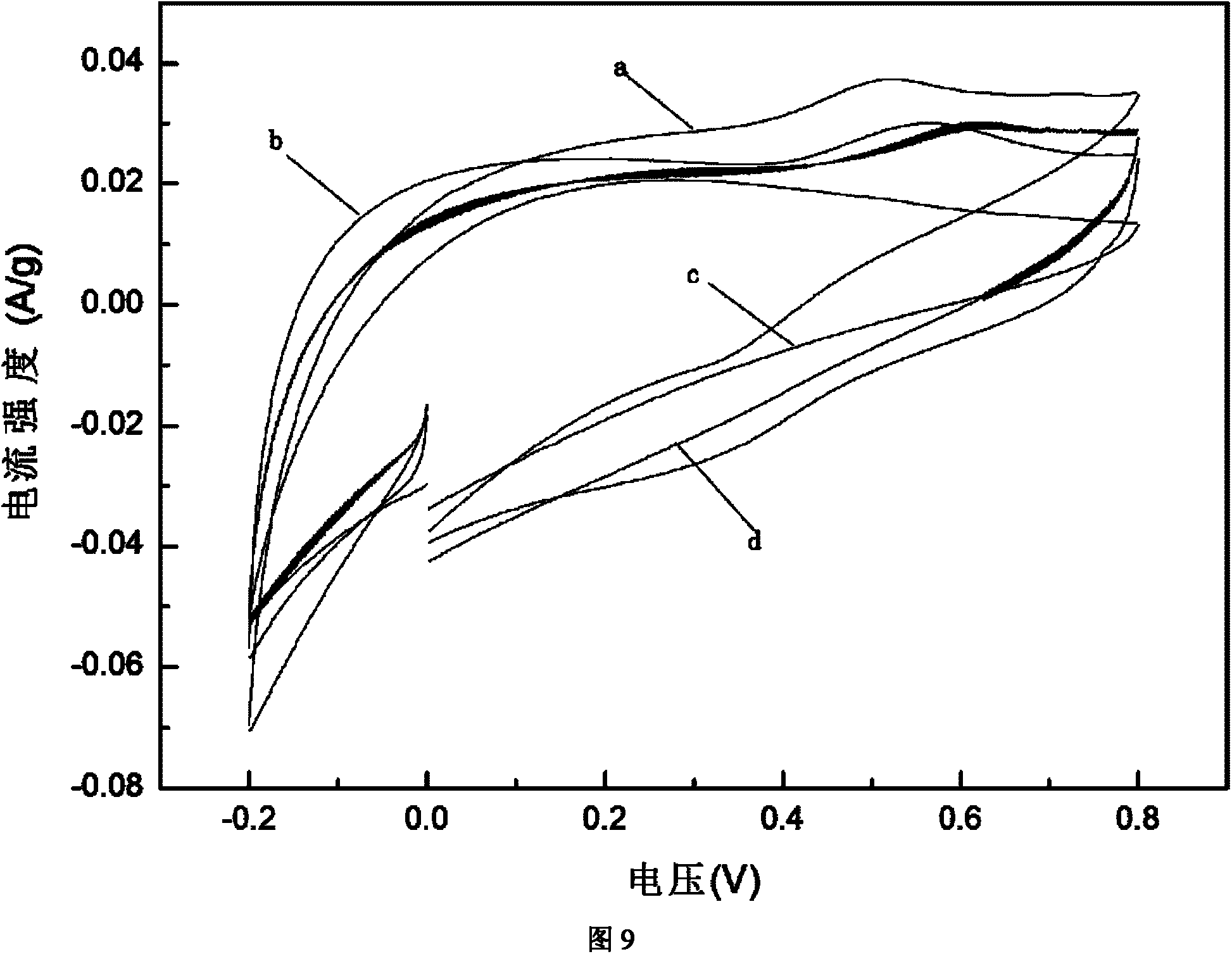

Method for preparing carbide film by carbonizing graphene reinforced polyimide resin

ActiveCN102560453AIncrease internal stressReduce brittlenessSolid/suspension decomposition chemical coatingCapacitancePolymer science

The invention discloses a method for preparing a carbide film by carbonizing graphene reinforced polyimide resin, and relates to a method for preparing a carbide film. The method solves the technical problems of high carbonizing temperature, high energy consumption, long carbonizing period and low carbonizing rate and low strength of the carbide film in the conventional method for preparing the carbide film. The method comprises the following steps of: 1, adding 4,4'-diamino diphenyl ether (ODA) and 3,3',4,4'-benzophenonetetracarboxylic dianhydride (BTDA) into N,N-dimethyl acetamide (DMAC), and performing mechanical stirring to obtain a polyamide acid (PAA) solution; 2, adding graphene into the PAA solution, and performing in-situ polymerization reaction to obtain a solution A; 3, spreading the solution A on a clean glass plate, heating to the temperature of 60 DEG C and preserving the heat for 2 hours, heating to the temperature of 100 DEG C and preserving the heat for 1 hour, heating to the temperature of 200 DEG C and preserving the heat for 1 hour, heating to the temperature of 300 DEG C and preserving the heat for 1 hour, and thus obtaining a composite film; and 4, carbonizing, naturally cooling to room temperature, and thus obtaining the carbide film. The carbide film has excellent mechanical properties; and because the adding proportion of the graphene is increased, the mechanical properties of the carbide film are improved, the specific capacitance of the graphene is also improved, and the carbide film is suitable to be used as an electrode material.

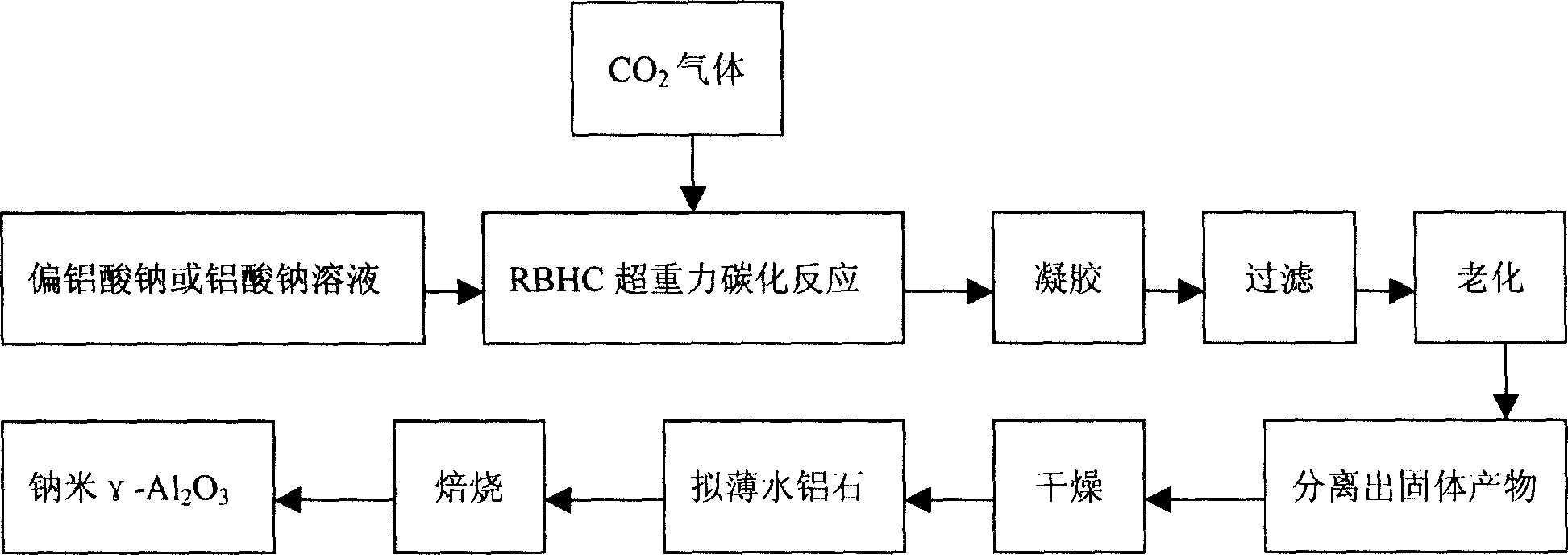

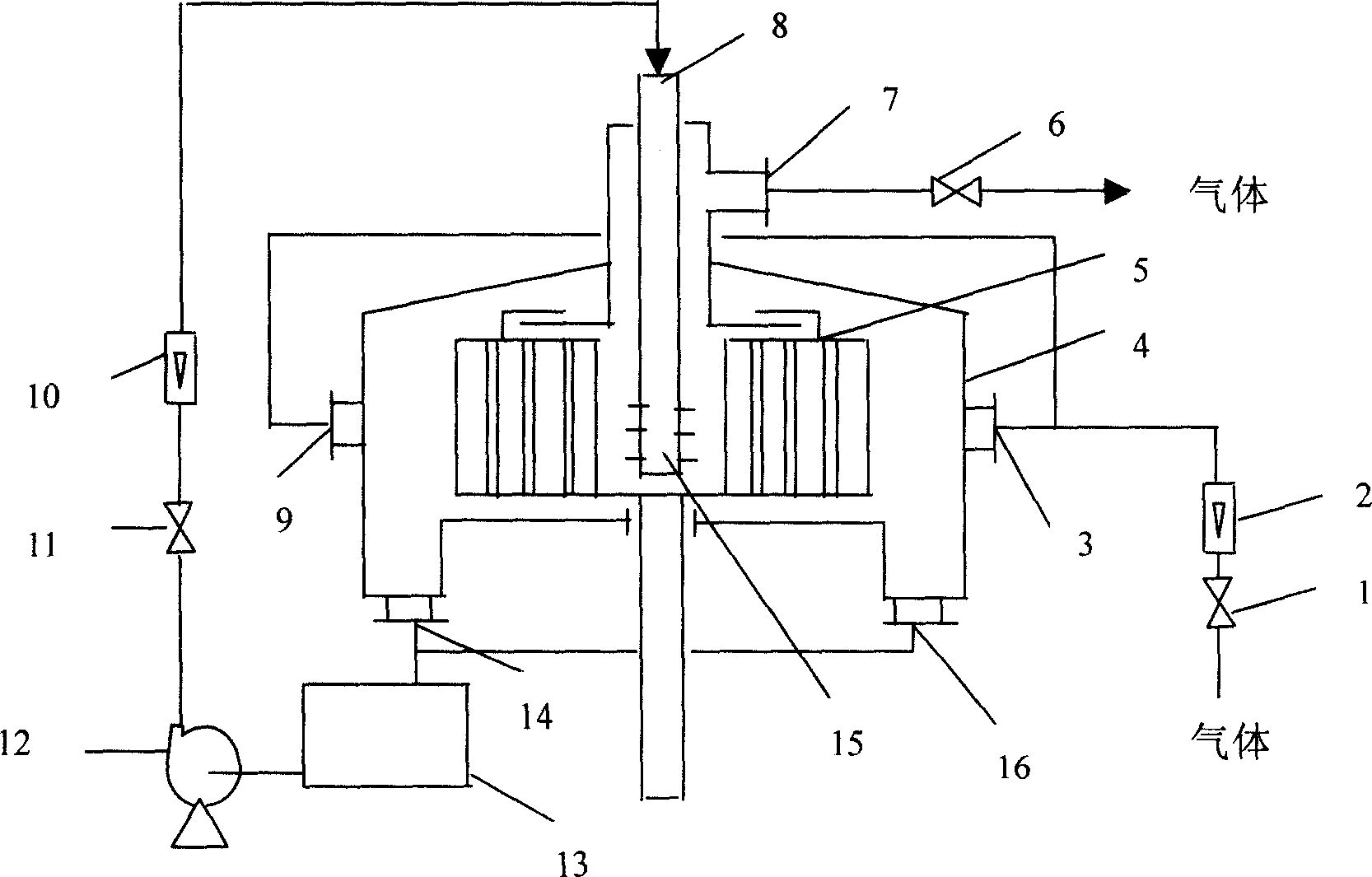

Preparation method of ultrafine active aluminium oxide

InactiveCN1752005ASolve defects that are prone to clogging equipmentLow miscellaneous crystal contentAlkali-metal aluminates/aluminium-oxide/aluminium-hydroxide preparationAluminateNanofiber

A process for preparing superfine active alumina includes such steps as carbonifying reaction between the solution of sodium metaaluminate (or aluminate) and the gas containing CO2 in gravitation condition to obtain alpha-AlO(OH) gel, filtering, ageing, separating solid, drying and calcining. Said product has high pore volume, large specific surface area and large average pore diameter, and can be used to prepare reforming catalyst and hydrocracking catalyst.

Owner:XIANGTAN UNIV

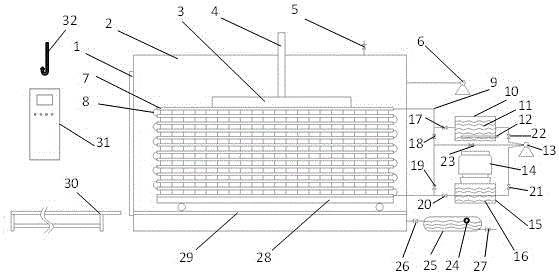

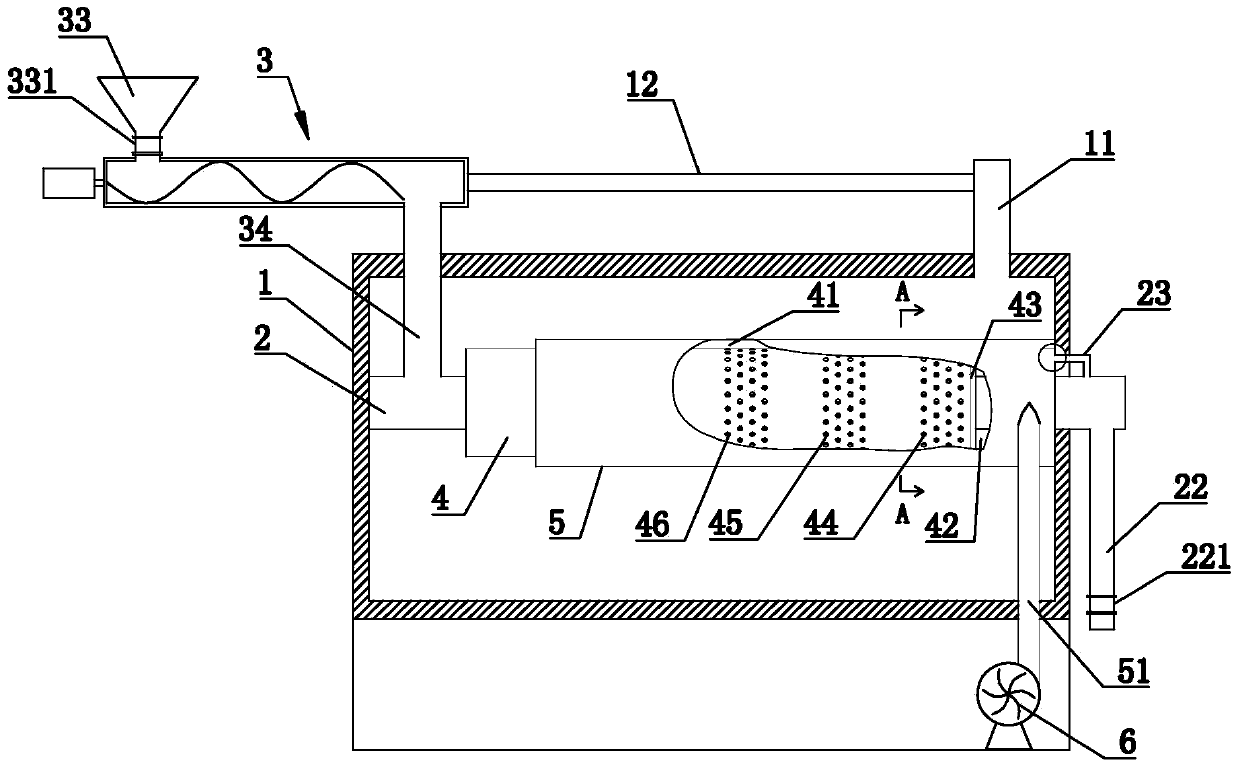

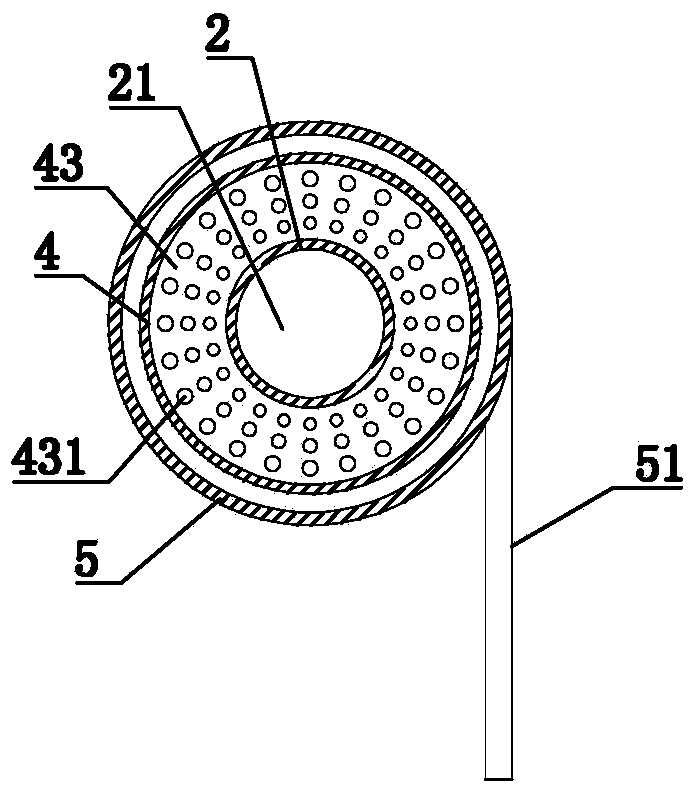

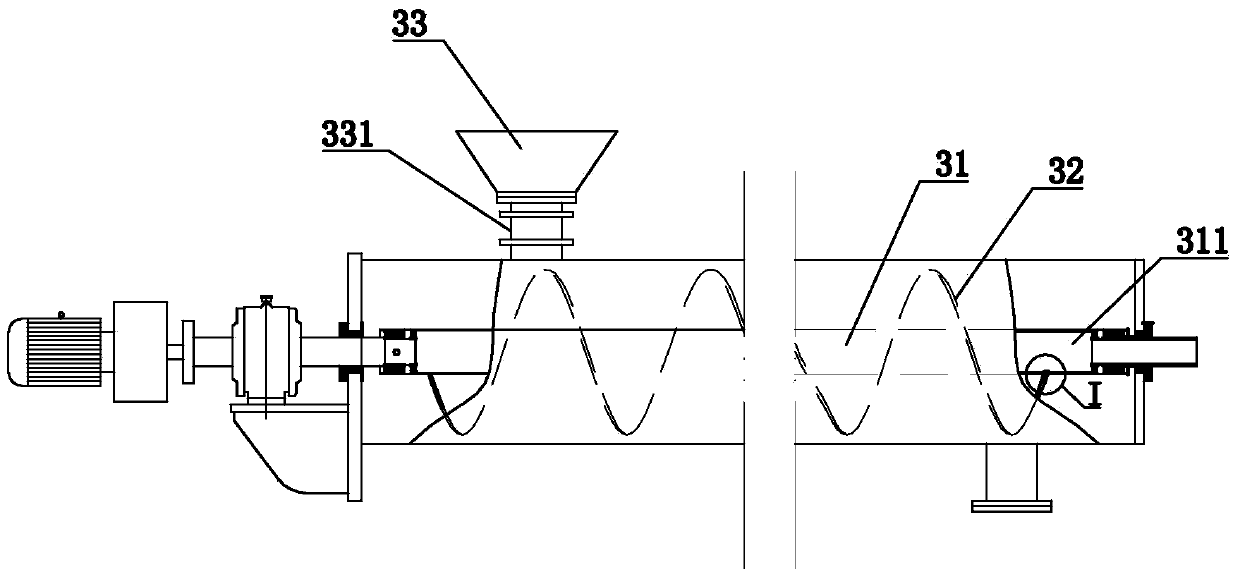

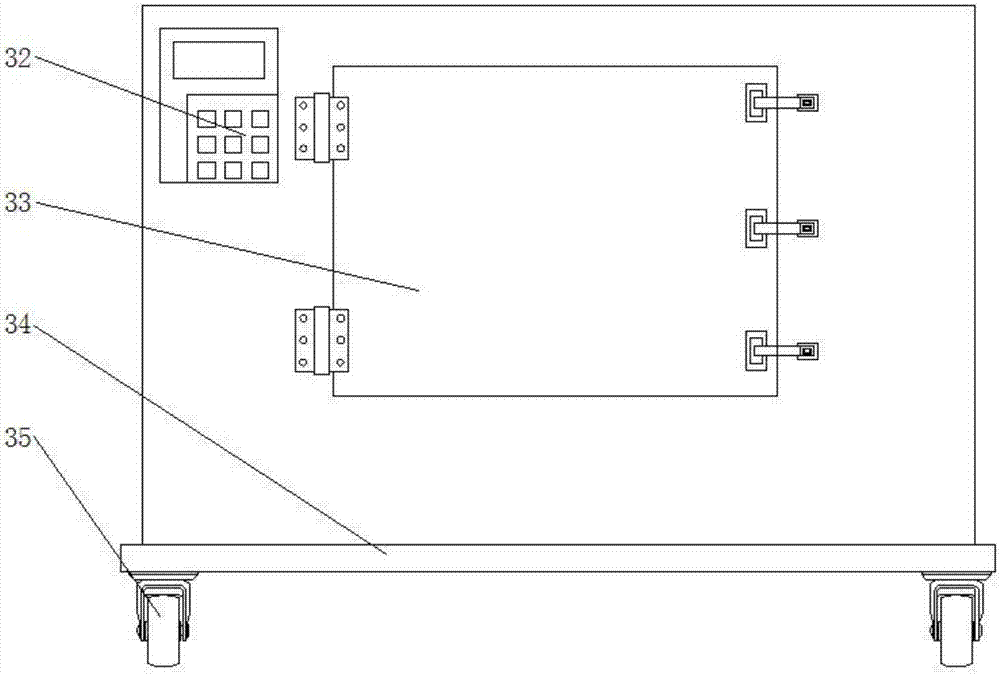

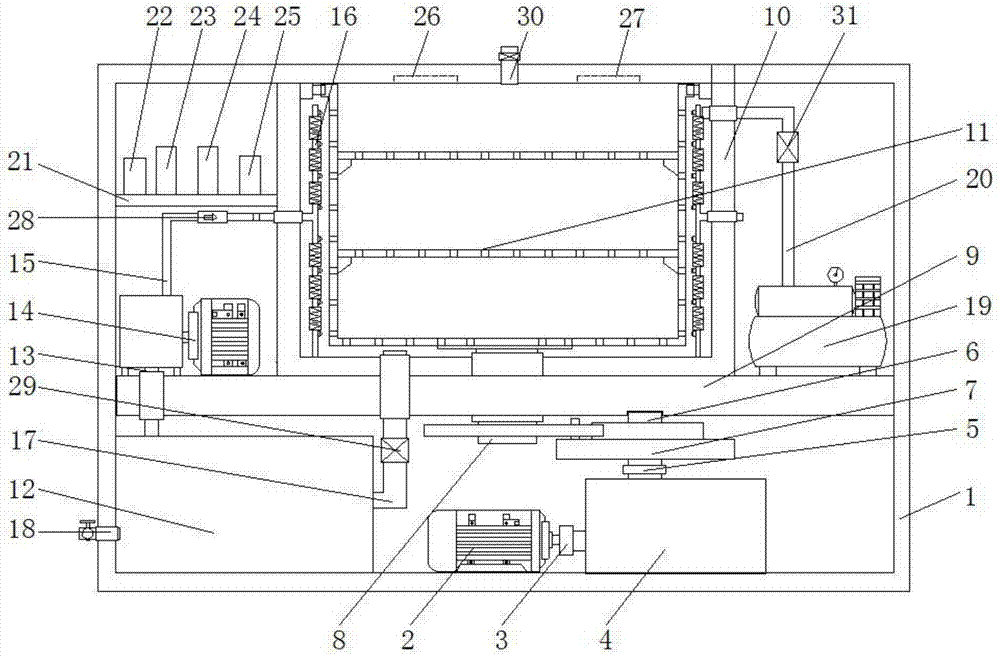

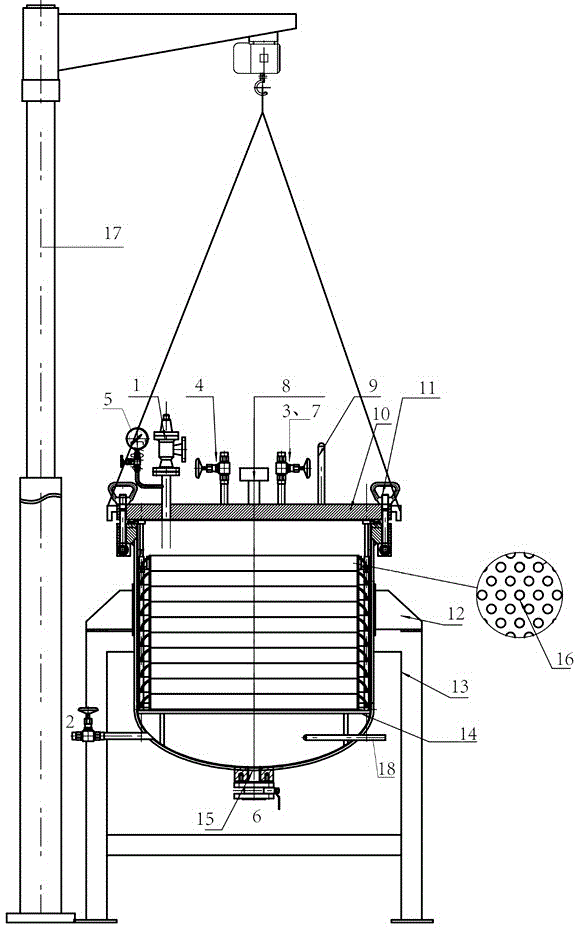

Method and equipment for drying and carbonizing wood integrally on vacuum condition

InactiveCN106426473AShorten carbonization timeImprove processing efficiencyDrying solid materials without heatWood treatment detailsWood dryingHeating cooling

The invention provides equipment for drying and carbonizing wood integrally. The equipment comprises a pressure adjusting system, a heating and cooling system, a material loading, transporting and pressurizing system and a water drainage system; an exo-box heat conduction oil pipe of the heating and cooling system penetrates through a treatment box and is welded to a wall of the treatment box for being sealed; a water inlet valve of the water drainage system is connected to the treatment box and a water drainage box through connection pipelines; and an outer wall of a hydraulic cylinder of the material loading, transporting and pressurizing system is welded to the treatment box in a sealed mode. The equipment has the advantages that the repeated loading, stacking, heating and cooling steps of the drying and heat treating steps of wood are reduced, so that the processing efficiency is improved, and the energy consumption is lowered; a processing method is flexible and multipurpose and the equipment is multifunctional; the whole drying and carbonizing treatment is carried out on the vacuum and negative pressure conditions, the content of air in the treatment box is small, and the oxygen content is low; carbonized wood making contact with a hot plate can be fast cooled; and the wood can be prevented from being deformed, warped and cracked in the vacuum drying and vacuum carbonizing stages.

Owner:GUANGDONG YIHUA TIMBER IND

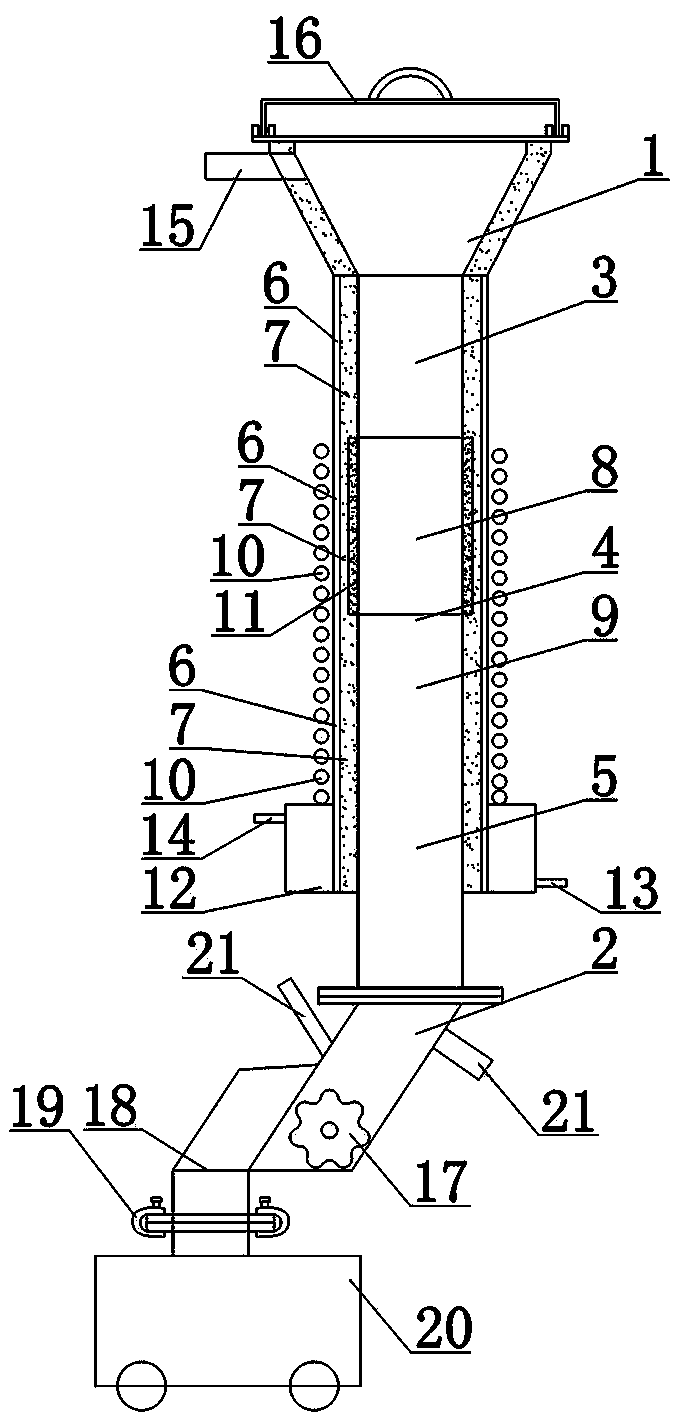

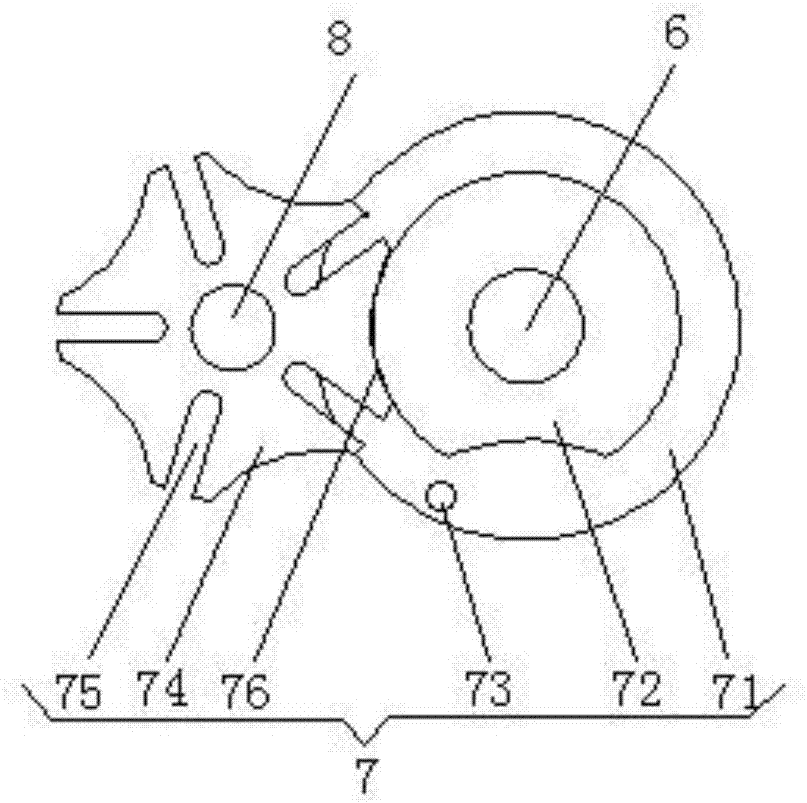

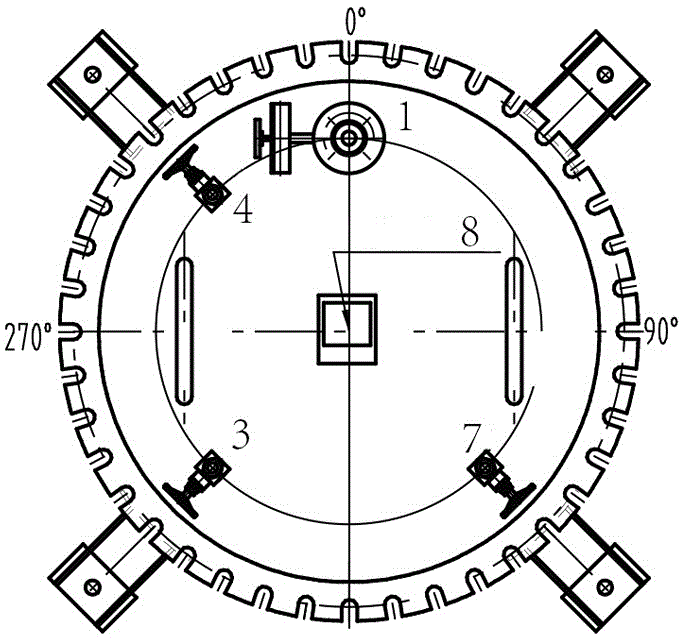

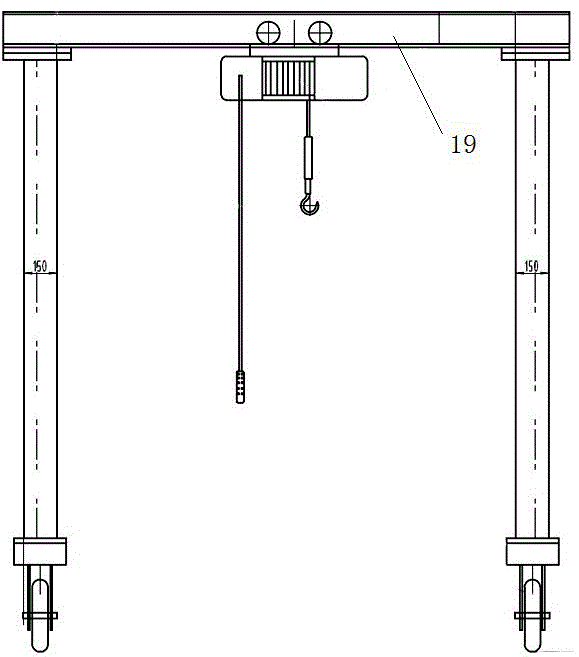

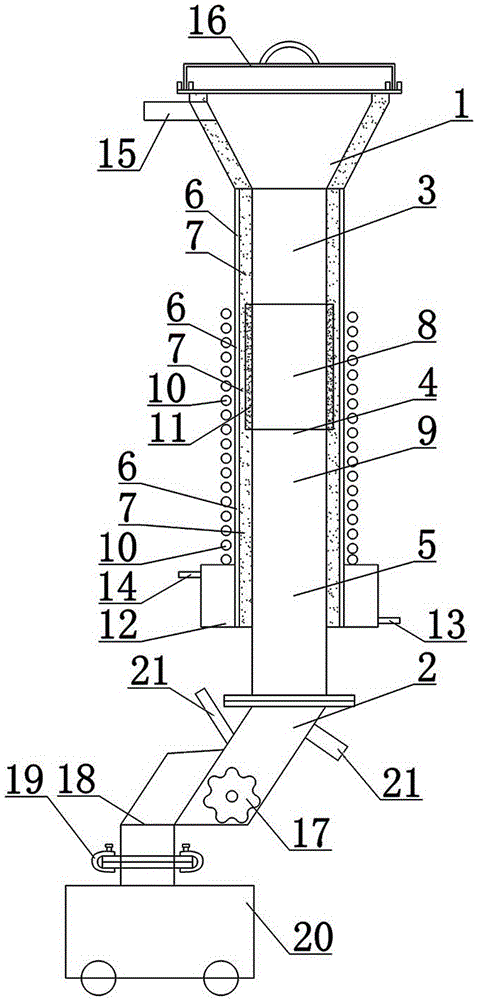

Method and device for continuously preparing vanadium-nitrogen alloy

The invention discloses a method for continuously preparing vanadium-nitrogen alloy. The method includes the first step of preparation, the second step of blending and blank manufacturing, the third step of adding, the fourth step of preheating and prereduction, the fifth step of carbonization and nitridation sintering, and the sixth step of discharging. A device for preparing vanadium-nitrogen alloy according to the method comprises a vertical boiler, a top feeding bin (1) and a continuous automatic discharging device (2), wherein the vertical boiler is composed of a preheating section (4), a calcination section (4) and a cooling section (5); the lower end of the vertical boiler is connected with the continuous automatic discharging device (2) through a pipeline; the tail end of the continuous automatic discharging device is connected with a finished product trolley (20) through a discharge pipe (18); the bottom of the vertical boiler is provided with a nitrogen inlet (21). The method has the advantages that the process and the device are compact, the production process is short, electric energy is saved, little investment is required, yield is high, continuous production is really achieved, and the industrialized and scale production requirement is met.

Owner:SICHUAN ZHANXIANG SPECIAL ALLOY TECH

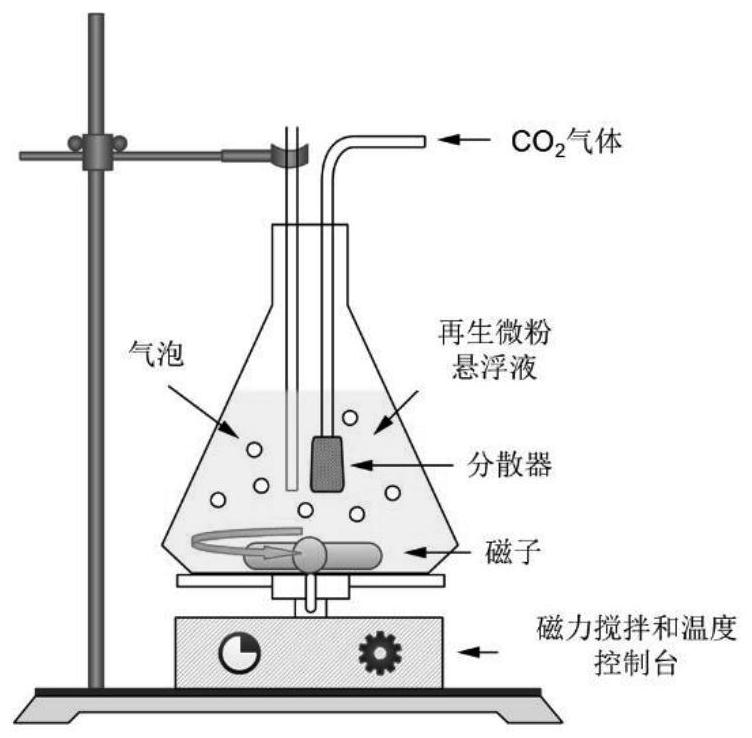

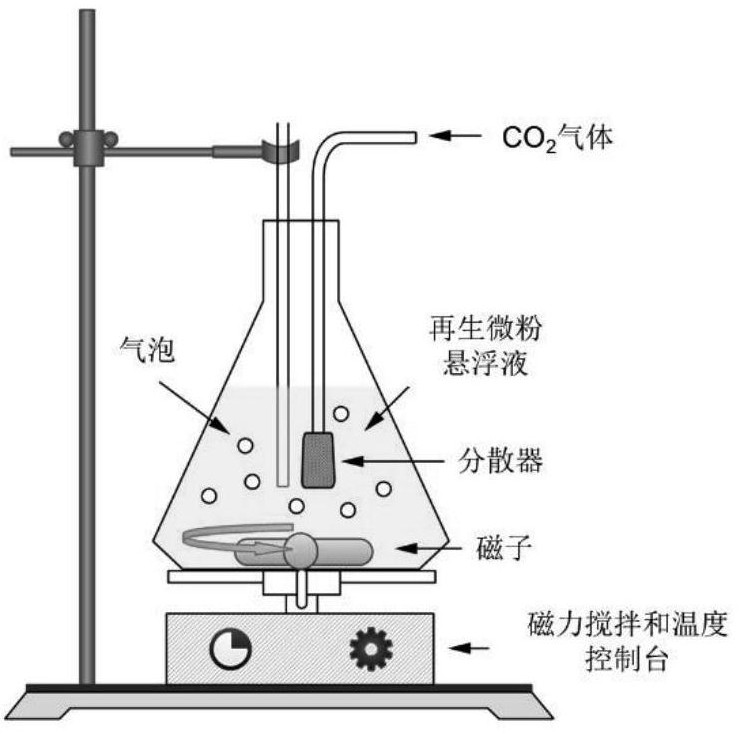

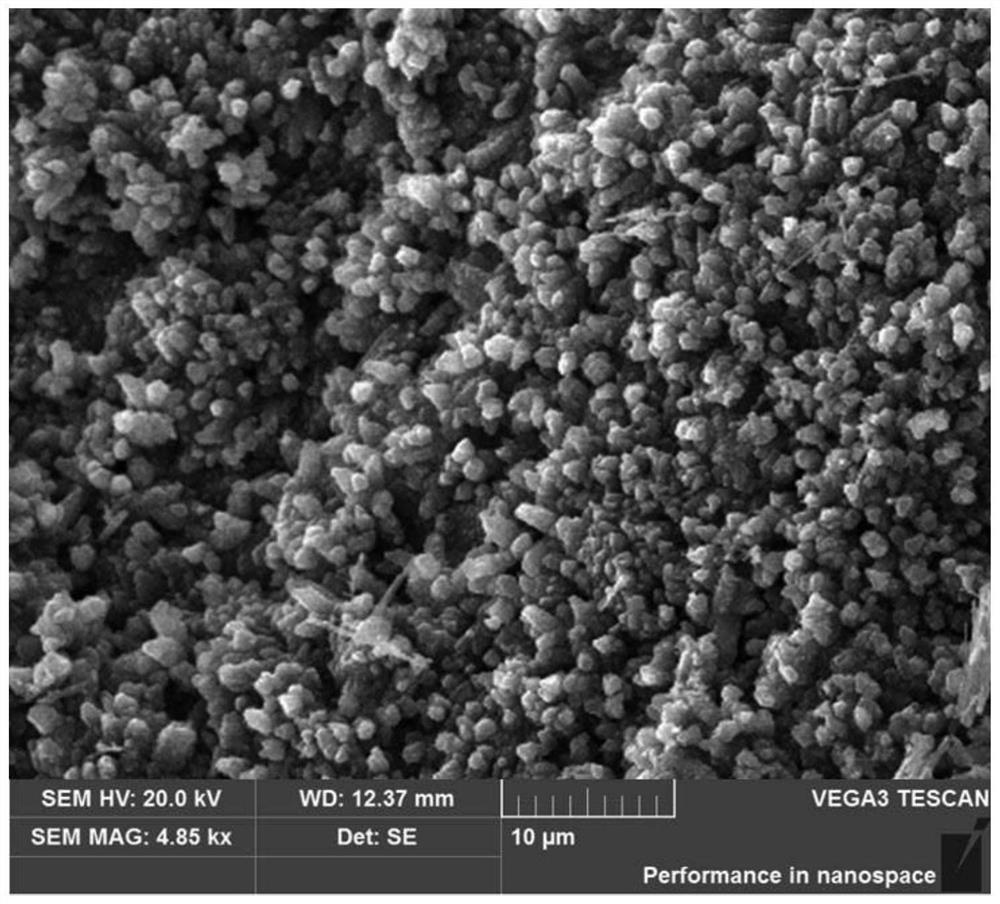

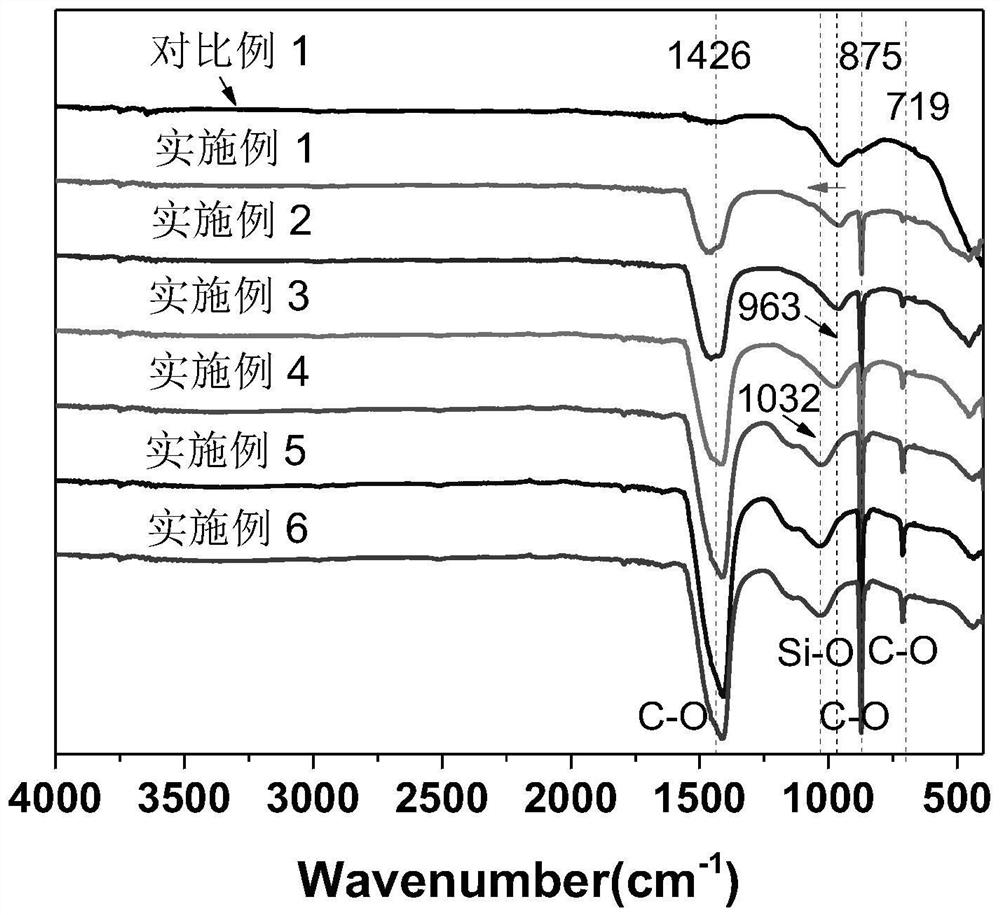

Method for carbonizing and activating waste concrete recycled micro powder by wet process and application of regenerated micro-powder

ActiveCN112125541AHigh activityEasy to achieve continuous productionCement productionSilica fumeIndustrial waste

The invention provides a method for carbonizing and activating waste concrete recycled micro powder by a wet process, which comprises the following steps of: taking powder generated in the process ofproducing recycled aggregate by crushing waste concrete as recycled micro powder, dispersing the recycled micro powder into water to form mixed slurry, and continuously introducing industrial waste gas containing carbon dioxide into the mixed slurry, in the process, carbon dioxide contained in the industrial waste gas and the regenerated micro powder are subjected to a carbonization reaction. According to the invention, the regenerated micro-powder is subjected to the carbonization reaction in an aqueous solution, the activity of calcium carbonate and silicon dioxide generated by carbonizationis higher, the volcanic ash activity is superior to that of common auxiliary cementing materials such as fly ash and silica fume, and the regenerated micro-powder can be used as an auxiliary cementing material.

Owner:HENAN POLYTECHNIC UNIV

Modified bio-carbon and preparation method thereof

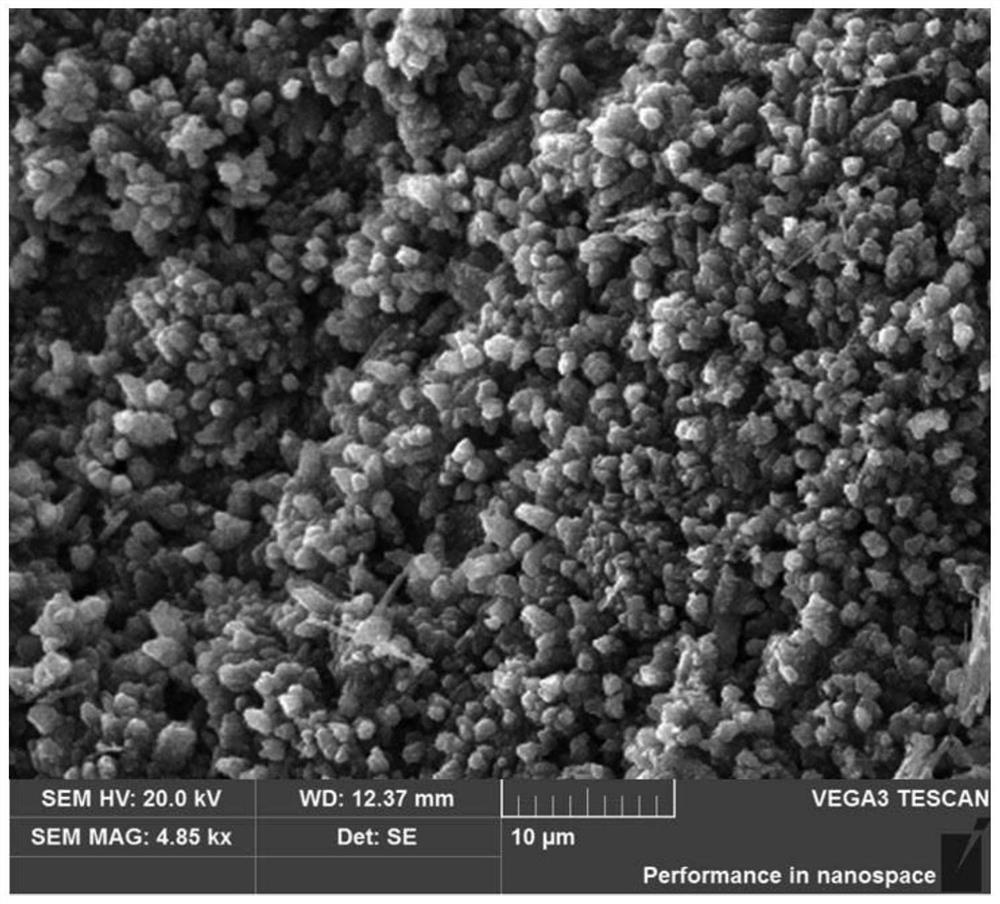

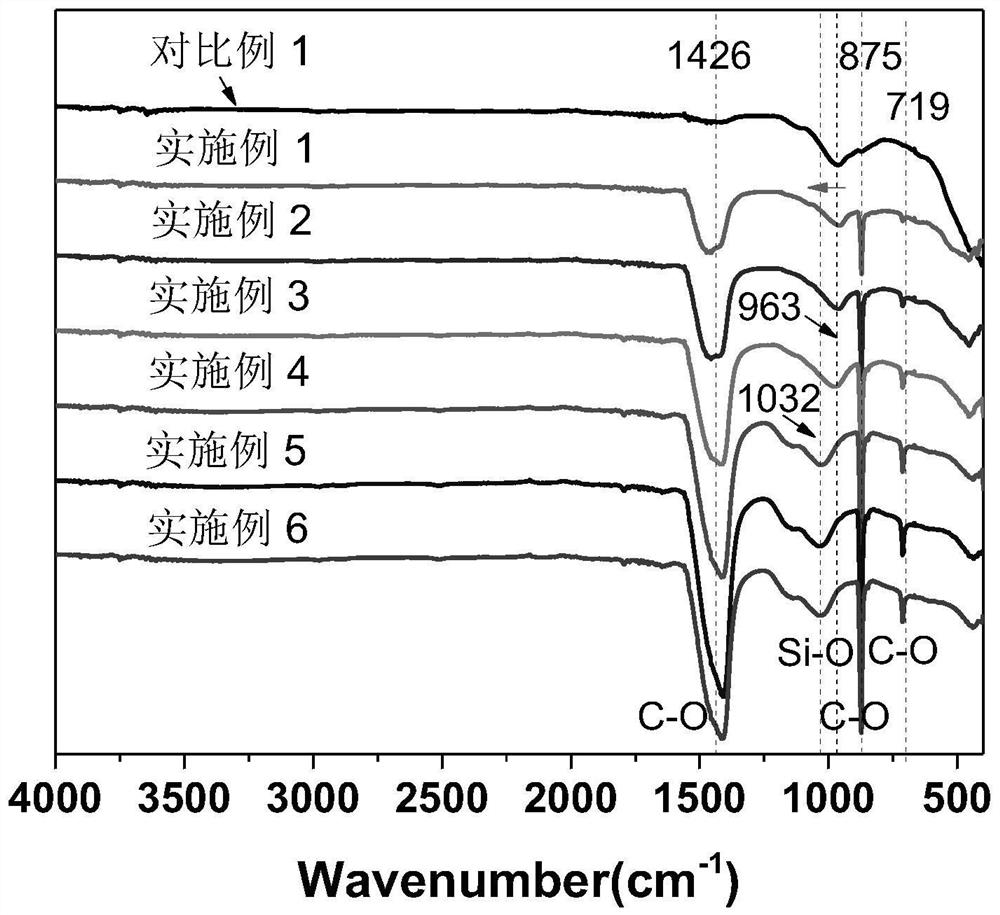

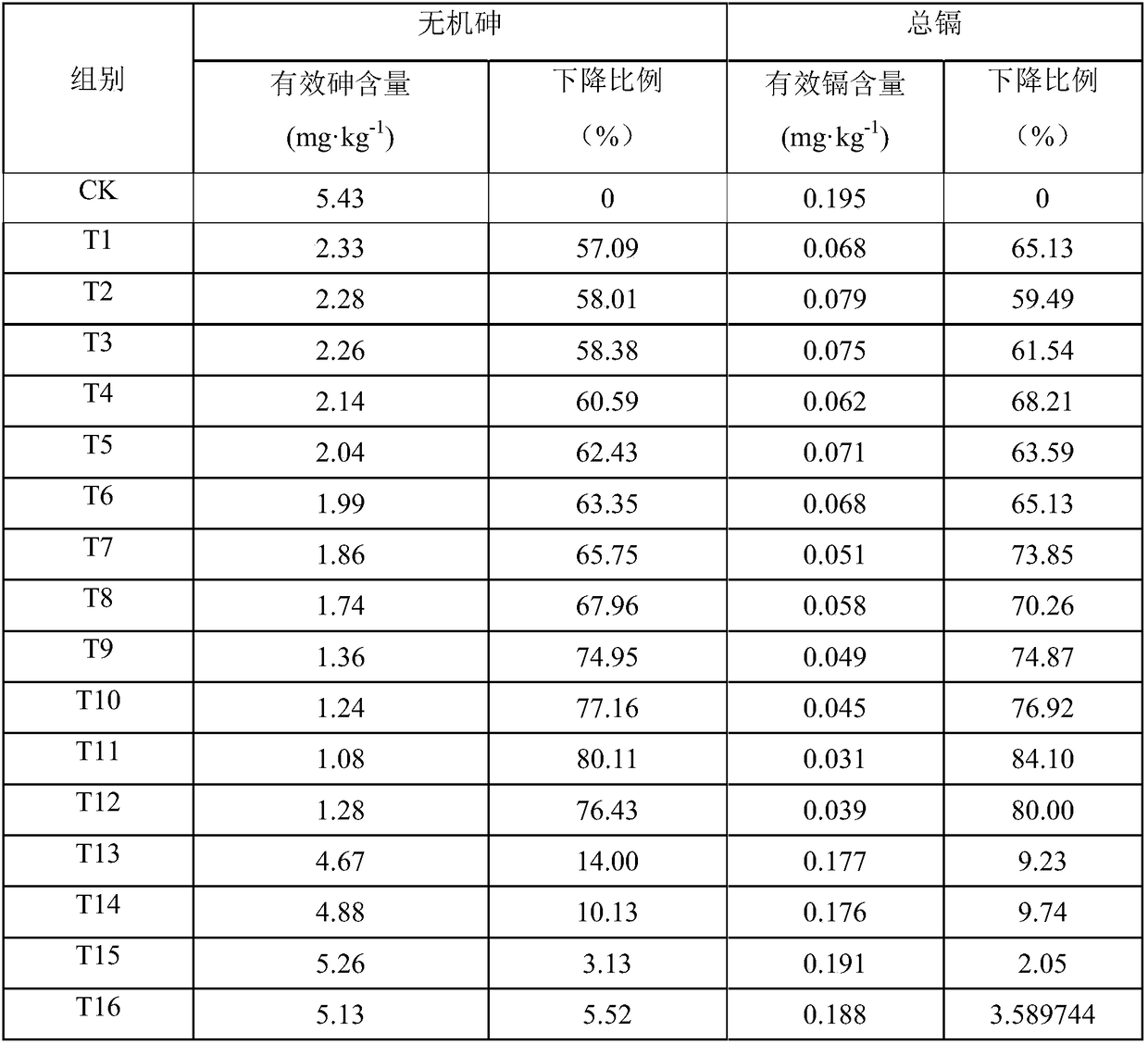

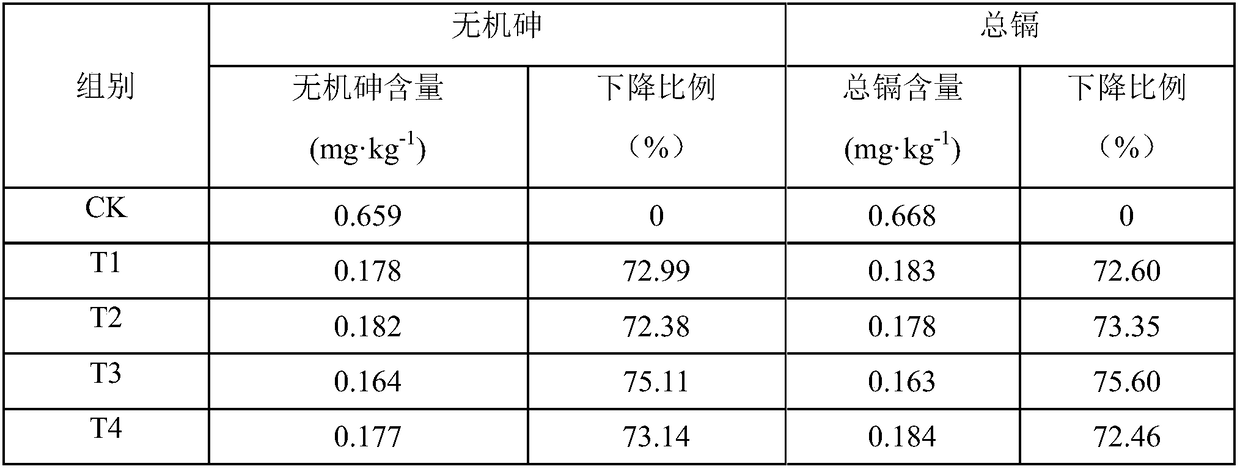

ActiveCN108262022ASmall particle sizeLarge specific surface areaOther chemical processesContaminated soil reclamationResource utilizationPotassium

The invention discloses a modified bio-carbon preparation method thereof. The preparation method takes bagasse as a raw material, bagasse is subjected to resource utilization, the bagasse is used forpreparing the modified bio-carbon with characteristics of small particle size, large specific surface area, and prominent micropore structure, more nutrition ions such as iron, nitrogen, phosphor, potassium and silicon are absorbed in micropore, the nutrition ions in the micropore can be displaced to cadmium and arsenic ions, and the cadmium and arsenic content in soil can be reduced. The modifiedbio-carbon has the advantages of simple component and low cost, contains nutrient elements required by plant, contains components for solidifying cadmium and arsenic, can reduces absorption of cadmium and arsenic by the plant, and increases the plant output.

Owner:IRONMAN ENVIRONMENTAL TECH CO LTD

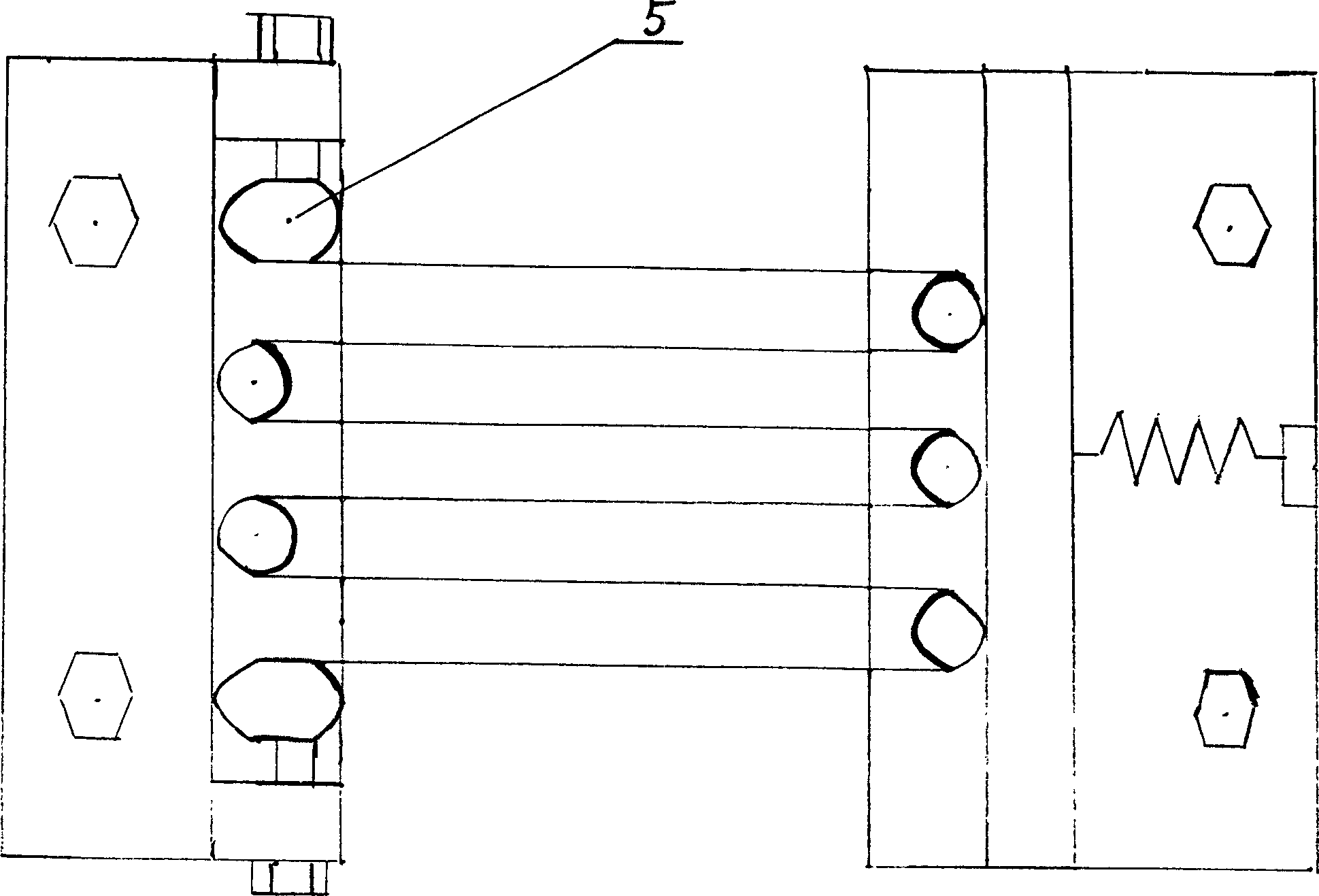

Hot wire for diamond film growth device and electrode structure thereof

InactiveCN1844450AReduced blocking cross sectionEasy to pass throughOhmic-resistance electrodesChemical vapor deposition coatingEngineeringProduct gas

This invention relates to the heater and electrode structure of diamond film growth device. This invention mainly includes a fixing electrode, a mobile electrode and corresponding heater, the character as follows: the fixing electrode is arranged with a group of electrode poles in equal space; and the mobile electrode is also arranged with a group of electrode poles, and the space is equal to the electrode pole space of the fixing electrode, the electrode pole is half space away from the electrode pole on the fixing electrode; the heater is a flat-shape heater, which is wrapped around the electrode pole of the fixing electrode and mobile electrode to form heater array. Comparing to the circular silk, the flat-shape structure increases the contact area and time of the reaction gas and heater, and improves the reaction gas decomposing rate, and save electric energy to decrease the growth cost of the diamond film.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

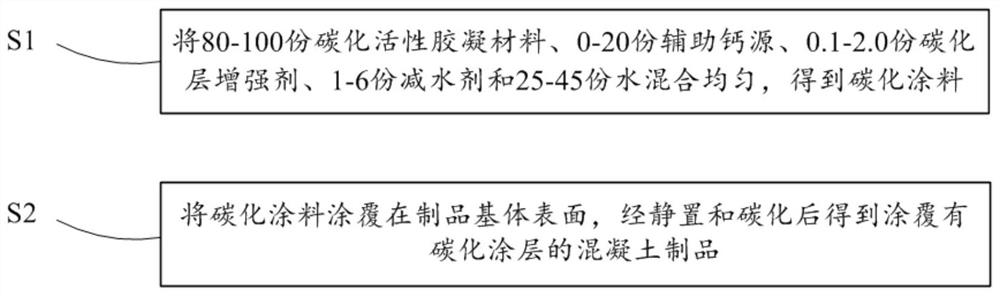

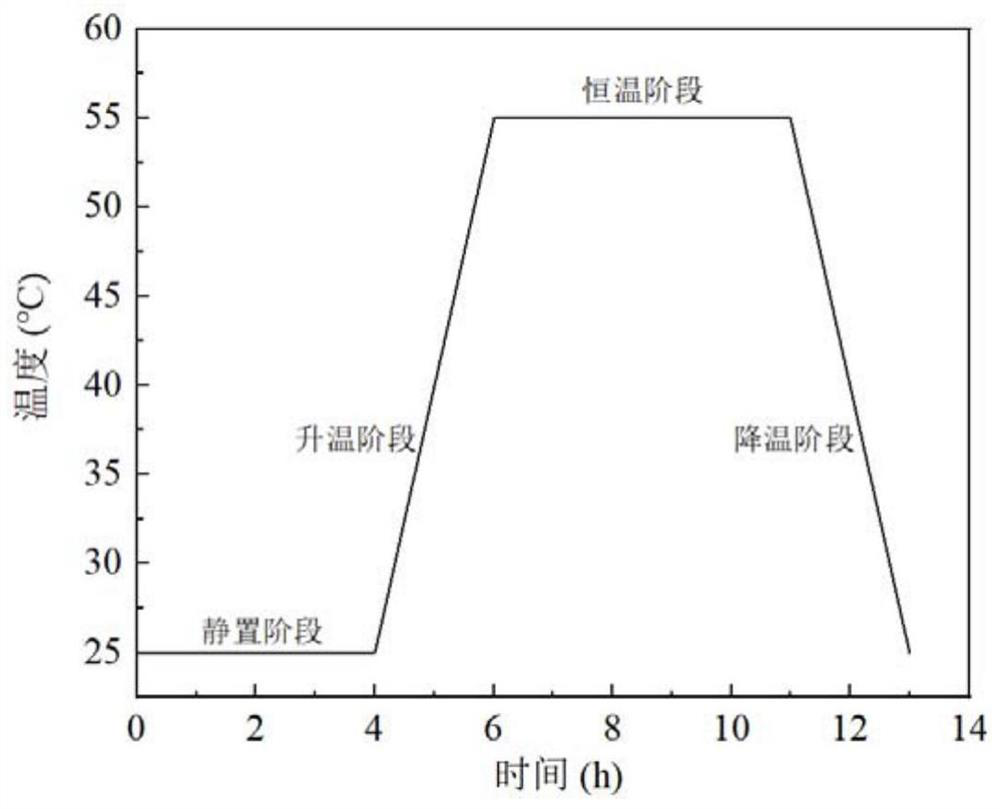

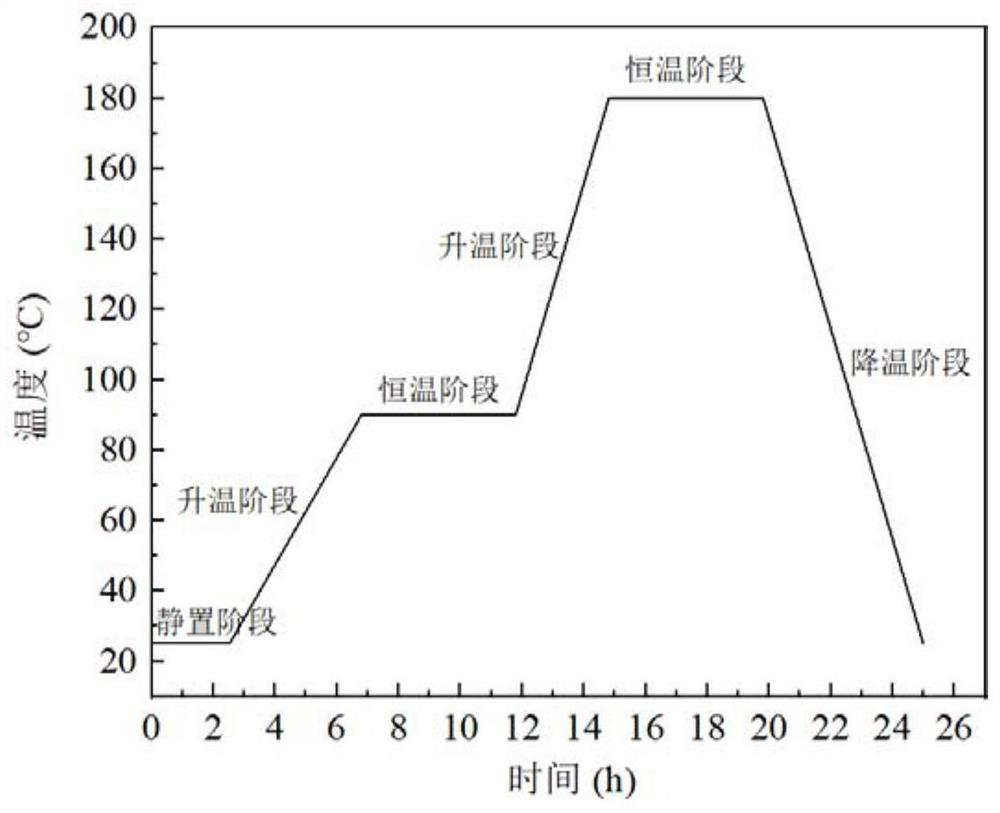

Method for improving durability of concrete product by using carbonized coating

The invention discloses a method for improving durability of a concrete product by using a carbonized coating, which comprises the following steps: uniformly mixing 80-100 parts of a carbonized active cementing material, 0-20 parts of an auxiliary calcium source, 0.1-2.0 parts of a carbonized layer reinforcing agent, 1-6 parts of a water reducing agent and 25-45 parts of water to obtain a carbonized coating; and coating the carbonized coating on the surface of a product matrix, and standing and carbonizing to obtain the concrete product coated with the carbonized coating. By introducing the auxiliary calcium source, the carbonization time can be shortened, the utilization rate and the production efficiency of the carbonization device can be improved, and the requirements of a product production process are met; and by applying the carbonized coating prepared from the carbonized active cementing material such as the steel slag to the surface of the concrete product, the purpose of economically, conveniently and effectively improving the durability of the concrete product through the calcium carbonate coating is achieved, meanwhile, the application range of the carbonized active cementing material is widened, a large amount of carbon dioxide can be immobilized, and the method has obvious environmental benefits.

Owner:WUHAN UNIV OF TECH

Preparation method of tungsten carbide-cobalt cemented carbide

The invention discloses a method for preparing tungsten carbide-cobalt cemented carbide by one step through discharge plasma in-situ synthesis. The method comprises the steps that tungsten powder, cobalt powder, carbon black, glucose and paraffin are used as raw materials, and the tungsten powder, the cobalt powder, the carbon black and the glucose are subjected to ball milling and mixing in proportion and then are dried and sieved for standby application; the paraffin is heated and dissolved through anhydrous ethyl alcohol and poured into ultrafine-grain tungsten-cobalt mixed powder and is continuously subjected to water-bath heating and stirring until the anhydrous ethyl alcohol is volatilized; the obtained product is dried, sieved and charged into a high-strength graphite mold and is subjected to discharge plasma sintering, and the WC grain controllable compact tungsten carbide-cobalt cemented carbide is prepared by controlling the processes such as the heating rate, the pressurization rate and the heat holding time. Through the method, the preparation process of the cemented carbide can be effectively shortened, and the comprehensive performance of the cemented carbide can be improved.

Owner:KUNMING UNIV OF SCI & TECH

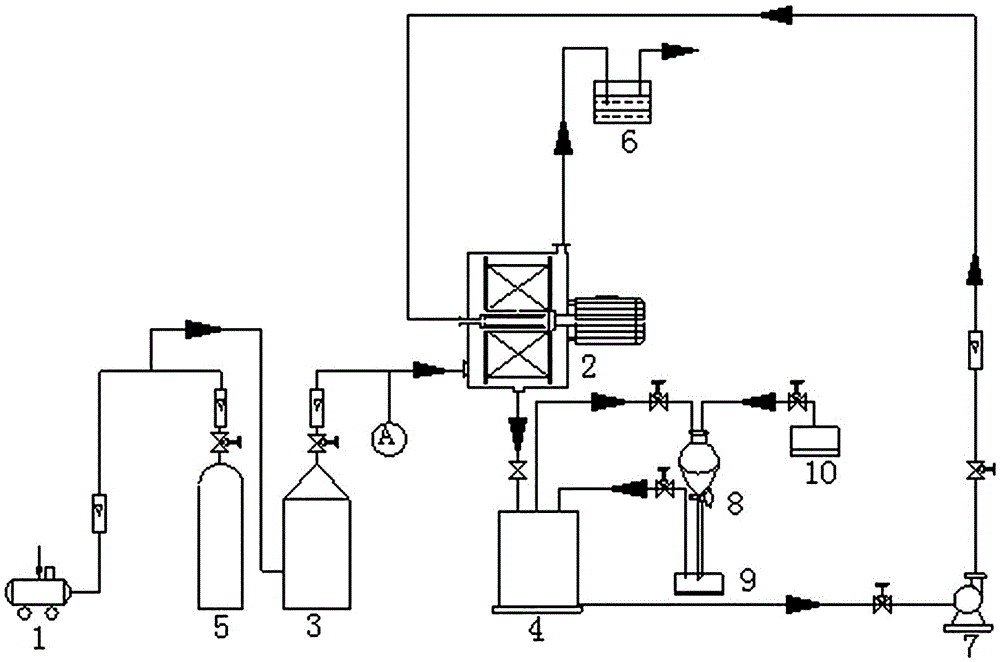

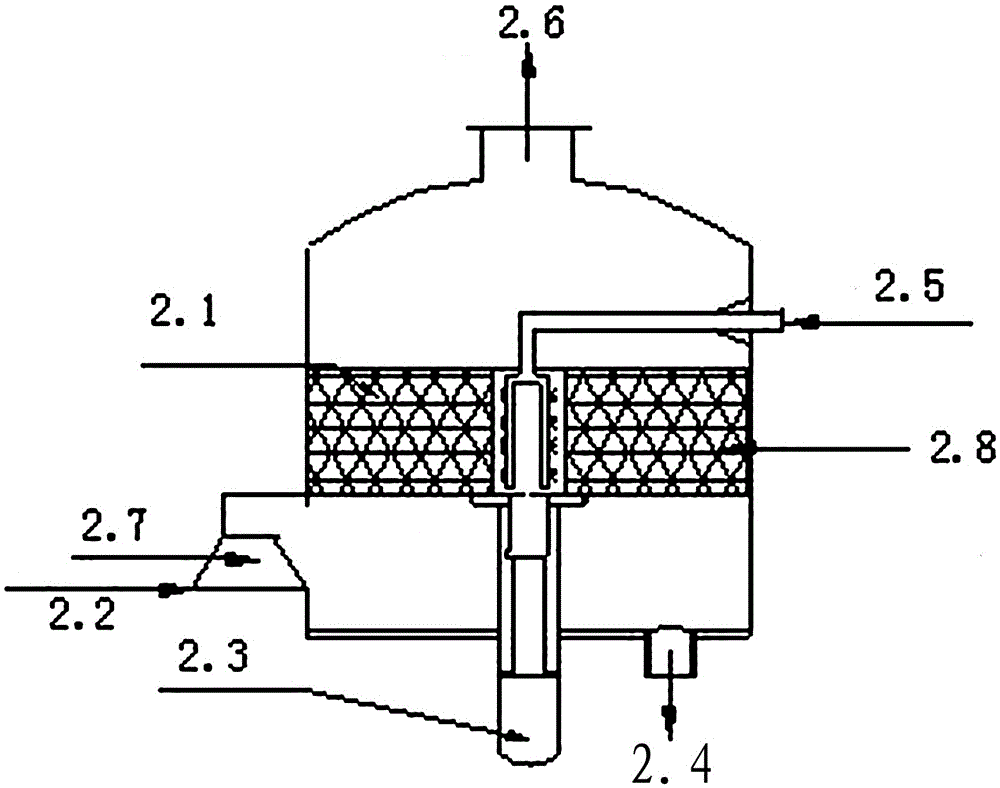

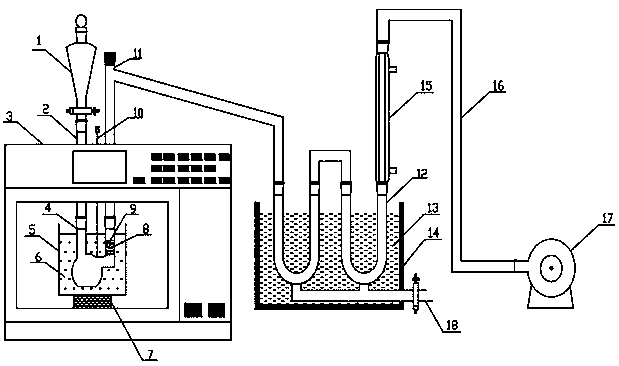

Device and process for treating ammonium chloride wastewater by supergravity carbonization reaction

ActiveCN105668753AIncrease contact areaEnhanced mass transferWater contaminantsWater/sewage treatmentHigh concentrationFiltration

The invention belongs to the technical field of treating industrialammonium chloride wastewater, and provides a device and a process for treating the ammonium chloride wastewater by a supergravity carbonization reaction, aiming at solving the problems that the current common electro-osmotic method for treating the ammonium chloride wastewater cannot realize an electrodialysis technology which is not only economical but also effective, the high-concentration ammonium chloride wastewater is hardly treated in an effective way by a membrane separation technology, and the cost is overhigh, etc. Ammonium chloride, organic amine and carbon dioxide react in a supergravity rotary packed bed to generate a mixed hydrochloric acid solution of ammonium bicarbonate and organic amine; after the ammonium bicarbonate and the organic amine are separated in a separating funnel, an organic amine solution reacts with ammonium hydroxide to regenerate organic amine; an obtained ammonium chloride solution through the regeneration is subjected to concentration, crystallization, filtration, and drying to obtain industrial grade ammonium chloride. The carbonization effect is improved; the carbonization reaction time is shortened; the treatment effect is improved; energies are saved; environment protection is realized; by adopting the method provided by the invention, reaction equipment can be minimized, the carbonization time can be shortened, the treatment effect can be improved, and the operation cost can be reduced.

Owner:ZHONGBEI UNIV

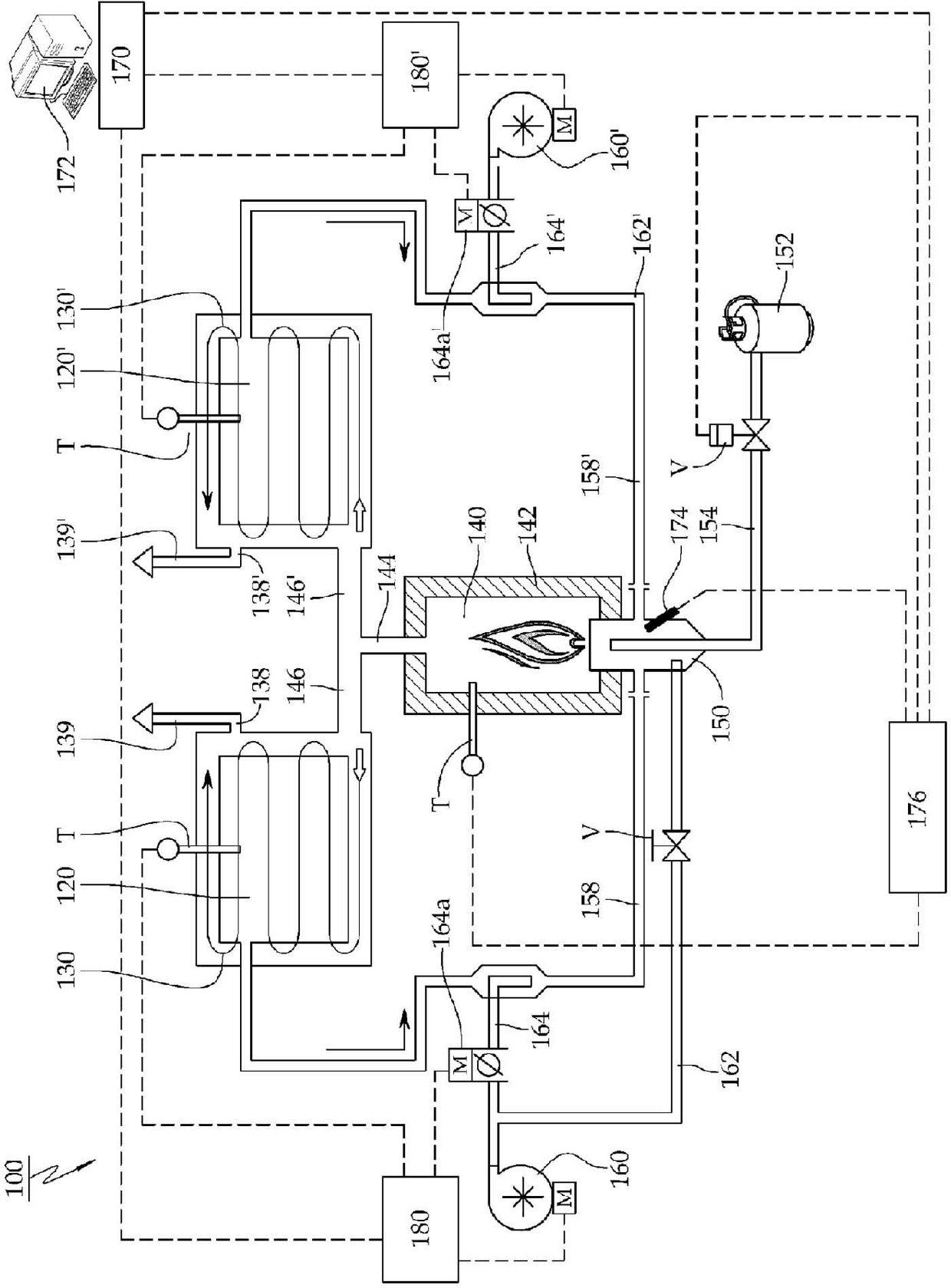

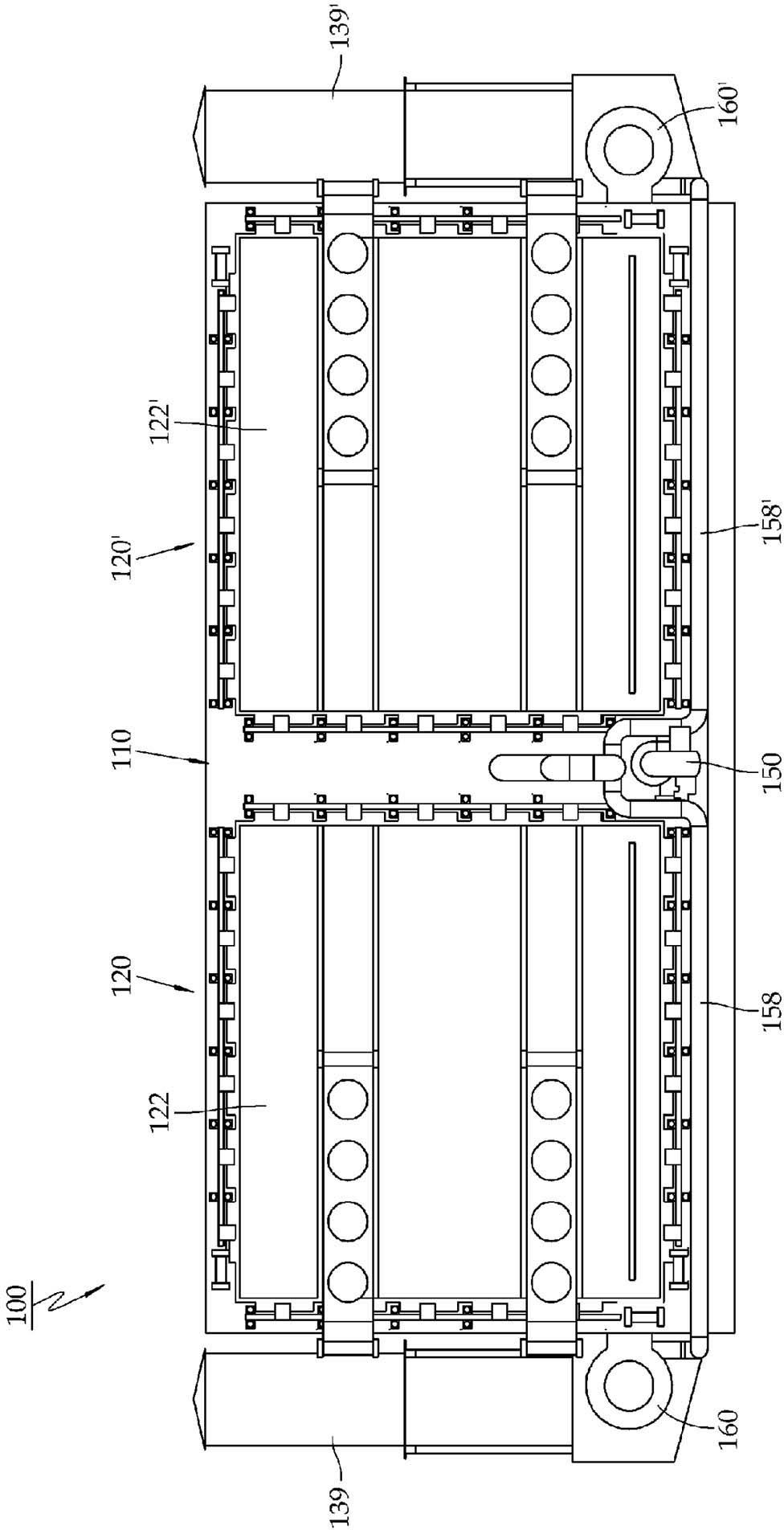

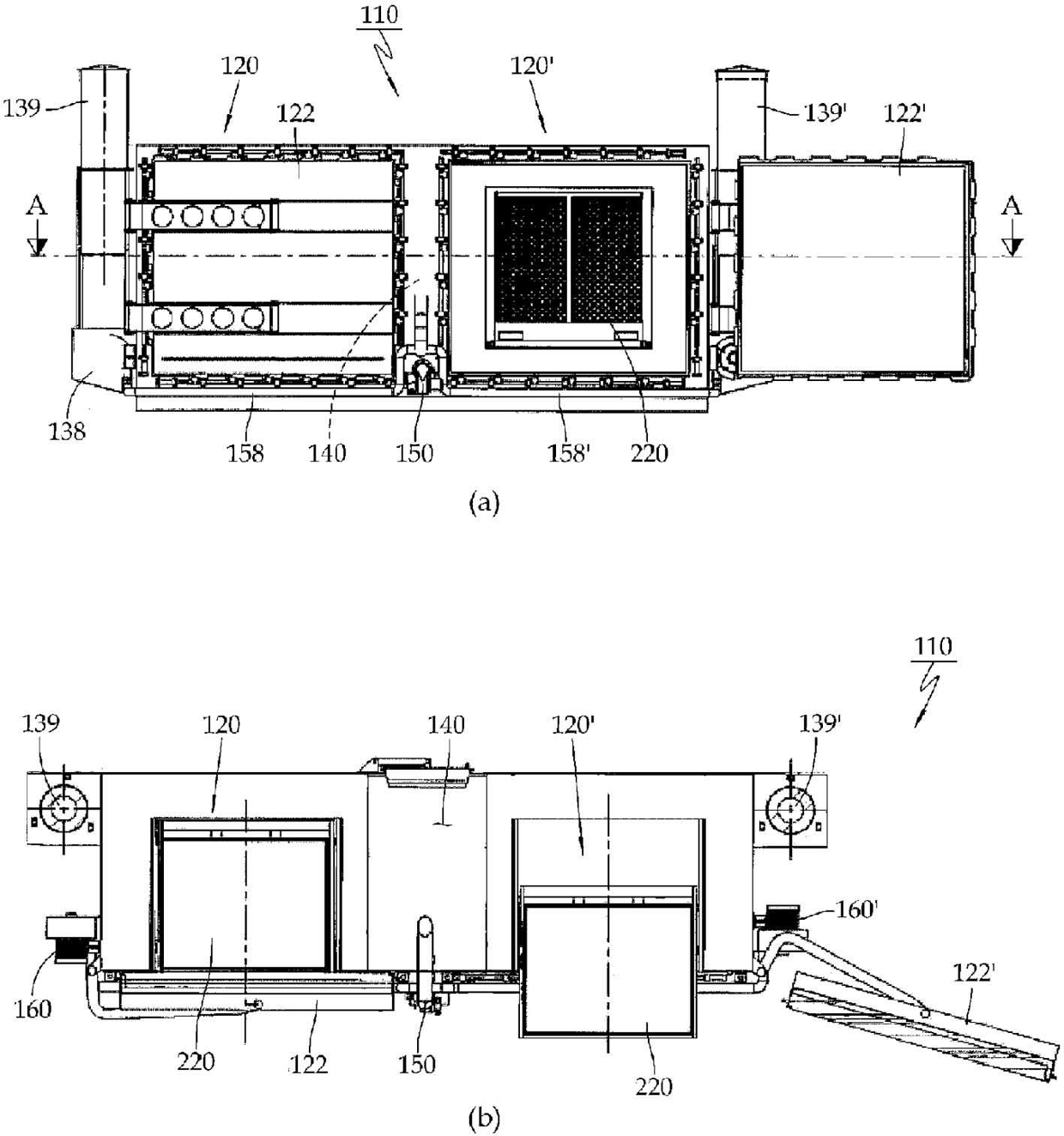

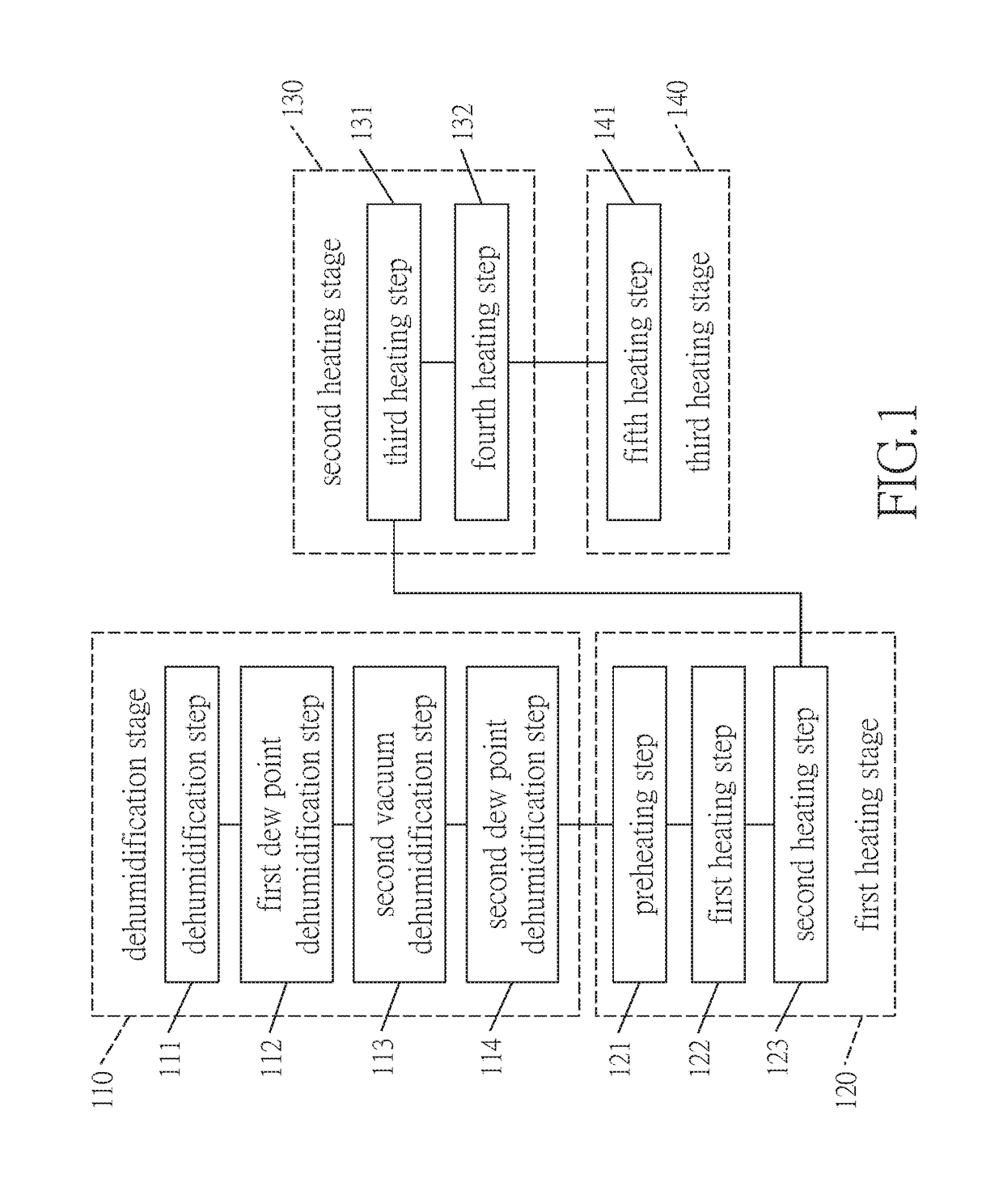

Indirect-heating-type carbonization treatment system for waste, and carbonization treatment vehicle using same

ActiveCN102667340AShorten carbonization timeRun automationCremation furnacesRefuse gatheringMedical wasteCarbonization

The present invention relates to an indirect-heating-type carbonization treatment system for waste, which disposes of organic industrial, livestock, and medical wastes generated by the industrial, livestock farming, and medical fields by collecting and effectively carbonizing the wastes, and to a carbonization treatment vehicle using same. According to the present invention, the waste generated by the industrial, livestock farming, and medical fields is carbonized at a location close to the location at which the waste is generated or is continuously disposed of while the vehicle is moving, in order to enable the complete carbonization of the waste and the effective protection of the surrounding environment.

Owner:株式会社福村

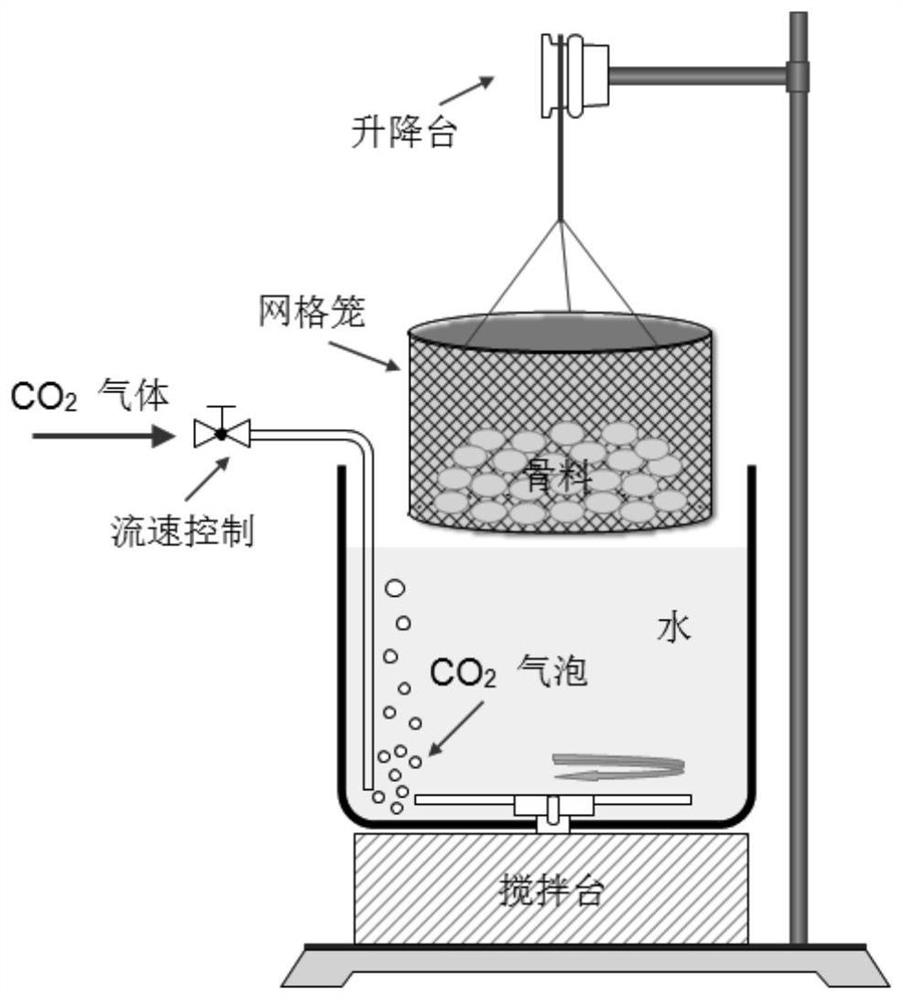

Method for open type carbonization strengthening of waste concrete recycled aggregate

ActiveCN112125550AImprove efficiencyEasy to achieve continuous productionSolid waste managementCarbonizationExhaust fumes

The invention provides a method for open type carbonization strengthening of waste concrete recycled aggregate, which comprises the following steps: crushing waste concrete to obtain granular recycledaggregate, soaking the granular recycled aggregate in water, continuously introducing industrial waste gas containing carbon dioxide, in the soaking process, performing a carbonization reaction on carbon dioxide contained in the industrial waste gas and mortar attached to the surface of the granular recycled aggregate. A carbon dioxide sealing carbonization device is not needed, continuous production is easy, and carbon dioxide industrial waste gas with different concentrations can be utilized.

Owner:HENAN POLYTECHNIC UNIV

High-temperature hearth carbonizing furnace

InactiveCN103420553AAvoid it happening againBurn fullySludge treatment by pyrolysisByproduct vaporizationCombustion chamberSludge

The invention discloses a high-temperature hearth carbonizing furnace which comprises a furnace body casing. A carbonizing chamber is arranged in a hearth, a feeding device is further connected to the furnace body casing, the feeding device is connected with a carbonizing pipe through a feeding pipe, a combusting pipe is annularly arranged on the outer side of the carbonizing pipe, a cavity between the combusting pipe and the carbonizing pipe is divided into a combusting pipe and a pyrolysis gas distributing chamber, pyrolysis gas inlets are formed in a pyrolysis gas distributing plate, a pyrolysis gas access pipe access to the pyrolysis gas distributing chamber is arranged on the carbonizing pipe, an air pipe is annularly arranged on the outer side of the combusting chamber, and air inlets for combustion air to enter the combusting pipe are formed in the combusting pipe. The high-temperature hearth carbonizing furnace uses pyrolysis gas generated in a carbonizing process to continuously heat the carbonizing pipe, so that byproducts generated in the carbonizing process are fully utilized, waste of energy gas generated in the carbonizing process is avoided, carbonizing innocent treatment on sludge is further achieved, pollution of the sludge to the environment is avoided, energy consumption of the carbonizing furnace is reduced, and energy is saved.

Owner:SHANDONG HONGLI HEAT PUMP ENERGY

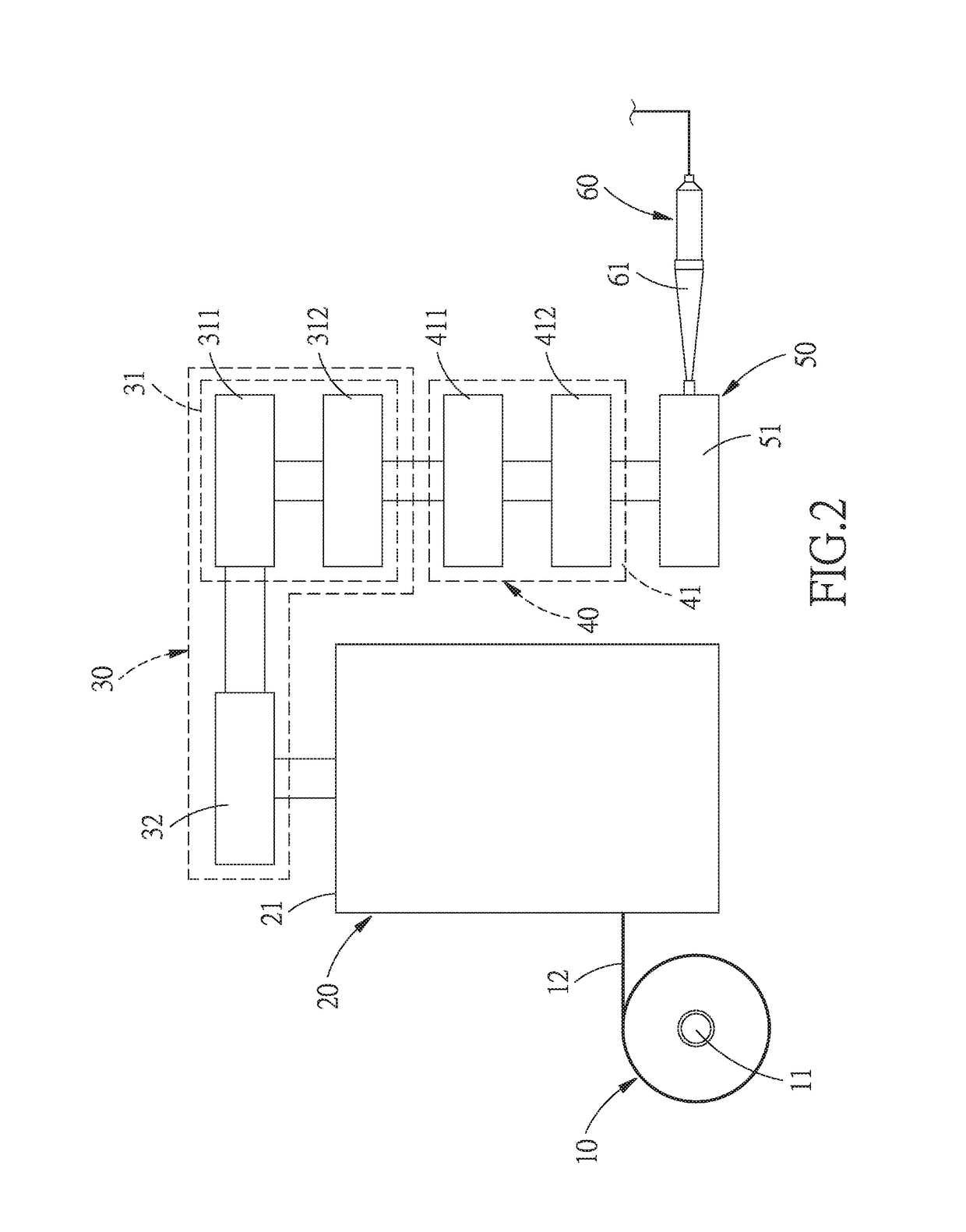

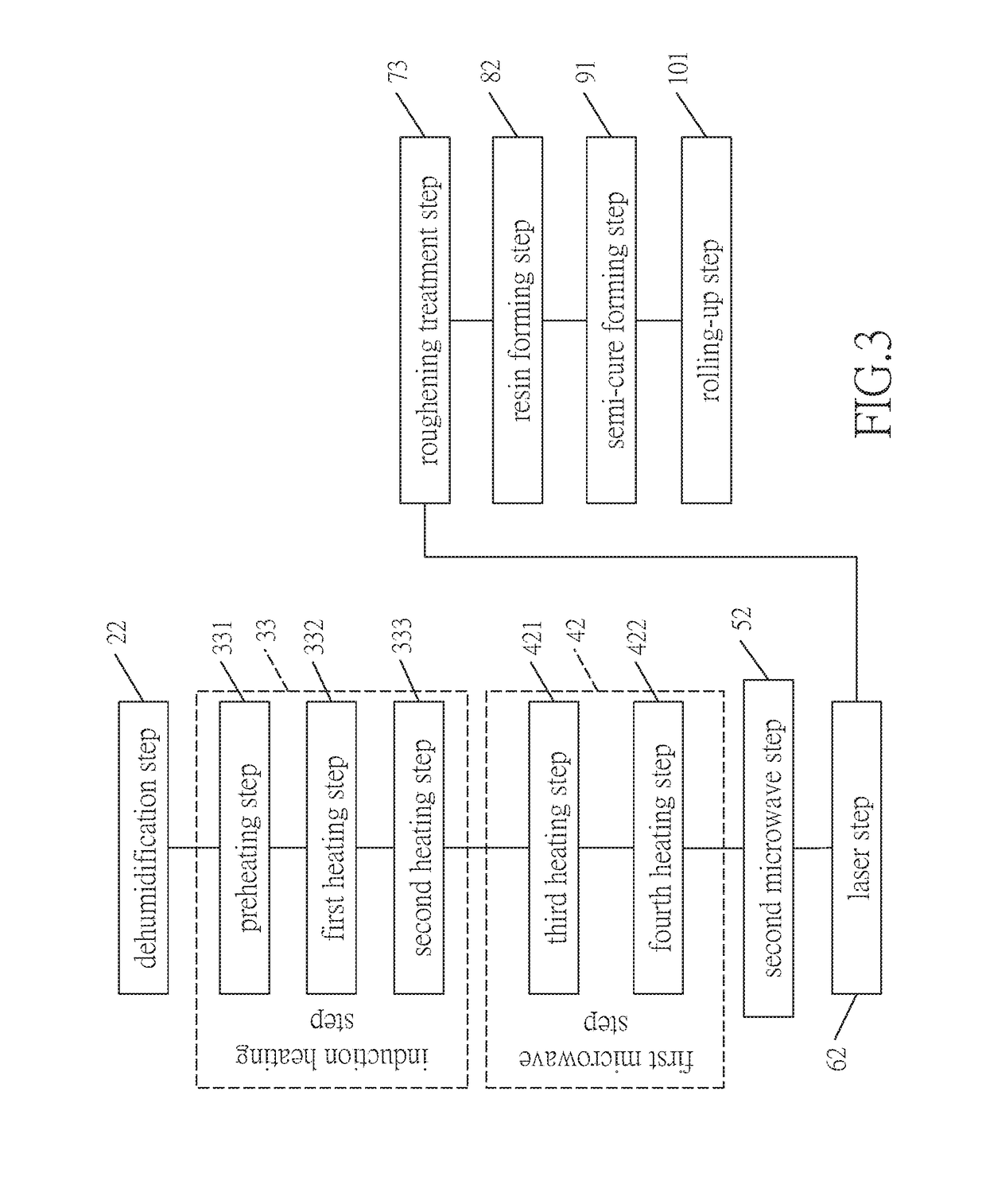

Carbon fiber bundle forming device and method

InactiveUS20190048493A1Uniform carbonizationShorten carbonization timeGlass making apparatusFibre treatmentFiber bundleMicrowave

A carbon fiber bundle forming method, wherein the at least one carbon fiber bundle can be evenly heated since it is heated with microwave in the first and second microwave steps. Besides, the at least one carbon fiber bundle is treated in the laser step, laser can reach into the interior of the at least one carbon fiber bundle to enable the carbonization and graphitization to take place more evenly, then the carbon fiber bundle is treated in the subsequent roughening treatment step, the resin forming step and the semi-cure forming step, so that the interior of the at least one carbon fiber bundle can be heated evenly, which allows the at least one carbon fiber bundle to be carbonized evenly.

Owner:ONG CHING LONG

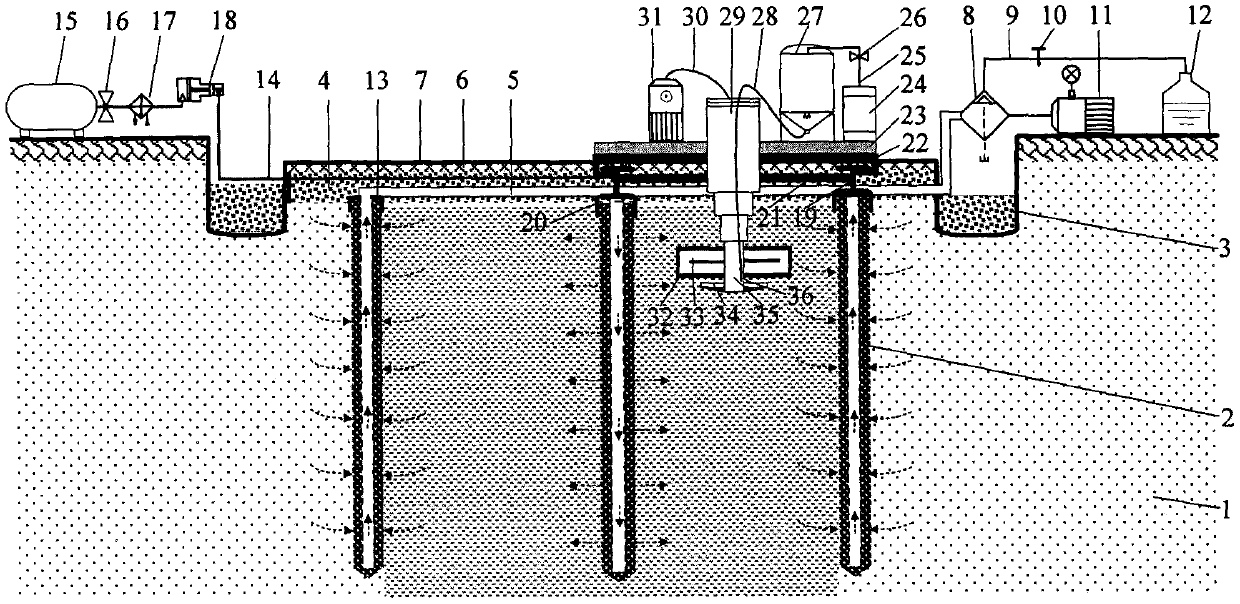

Reinforcing method of vacuum preloading lead pipe pile gas injection carbonized super-soft foundation

ActiveCN110512591AImprove compactionImprove displacement effectSoil preservationSites treatmentResource utilization

The invention discloses a reinforcing method of a vacuum preloading lead pipe pile gas injection carbonized super-soft foundation, and belongs to the technical field of super-soft foundation reinforcing treatment of geotechnical engineering. The reinforcing method comprises the steps of site treatment and exploration, first pile group construction and beating, spraying mixing equipment placement and debugging, curing agent spraying and mixing, first treatment system layout, vacuum preloading-gas injection carbonized treatment, first site treatment completing, continuous construction, final treatment and the like. The reinforcing method has the advantageous of a vacuum preloading method, a magnesium oxide carbonization curing method and a pipe pile composite foundation, the drainage efficiency and the infiltration diffusion efficiency of carbon dioxide are greatly improved through coordination work of vacuum preloading and pipe pile gas injection, the compacting displacement action of apipe pile on soft soil is fully utilized, mud soil is effectively glued through hydration products and carbonization products, thus the intensity of the soft soil composite foundation is enhanced, and the stability is improved. The reinforcing method has the characteristics that the treatment effect is good, the period is short, and low-carbon and environmentally-friendly and economic efficiencyare achieved, and resource utilization of industrial waste in soft foundation treatment is achieved.

Owner:NANJING FORESTRY UNIV

Method for preparing hydrocarbon-rich bio-oil and biochar through microwave-assisted double bed co-catalytic rapid pyrolysis of soybean soap stock

InactiveCN107903931AShorten carbonization timeImprove yield and qualityBiofuelsLiquid hydrocarbon mixture productionMolecular sieveChemistry

Owner:NANCHANG UNIV

Method and device for producing calcium carbonate through dynamical carbonation method

ActiveCN108101091AIncrease profitEmission reductionCalcium/strontium/barium carbonatesHydrogenSlurry

The invention relates to the technical field of production of calcium carbonate and in particular discloses a method and a device for producing the calcium carbonate through a dynamical carbonation method. The method comprises the following steps: suspending and limiting a dynamic reactor provided with a reaction cavity and a downward opening in a reaction tank; adding prepared Ca(OH)2 slurry intothe reaction tank and immersing the opening of the dynamic reactor; pumping the Ca(OH)2 slurry in the reaction tank through a reflowing pump and spraying and reflowing in a reaction cavity of the dynamic reactor; meanwhile, introducing CO2-containing mixed gas into the reaction cavity; monitoring the pH (Potential of Hydrogen) value of reaction slurry in the reaction tank; when the pH value is 7to 8, stopping the reflowing of the slurry to prepare a calcium carbonate crude product. According to the method and the device for producing the calcium carbonate through the dynamical carbonation method, provided by the invention, the carbonation speed is improved by 60 percent and the carbonation time is shortened by 37.5 percent; the grain diameter of the generated calcium carbonate is 2 to 4microns and the utilization rate of the carbon dioxide is improved to 69 percent from original 50 percent.

Owner:石家庄市红星钙业有限公司

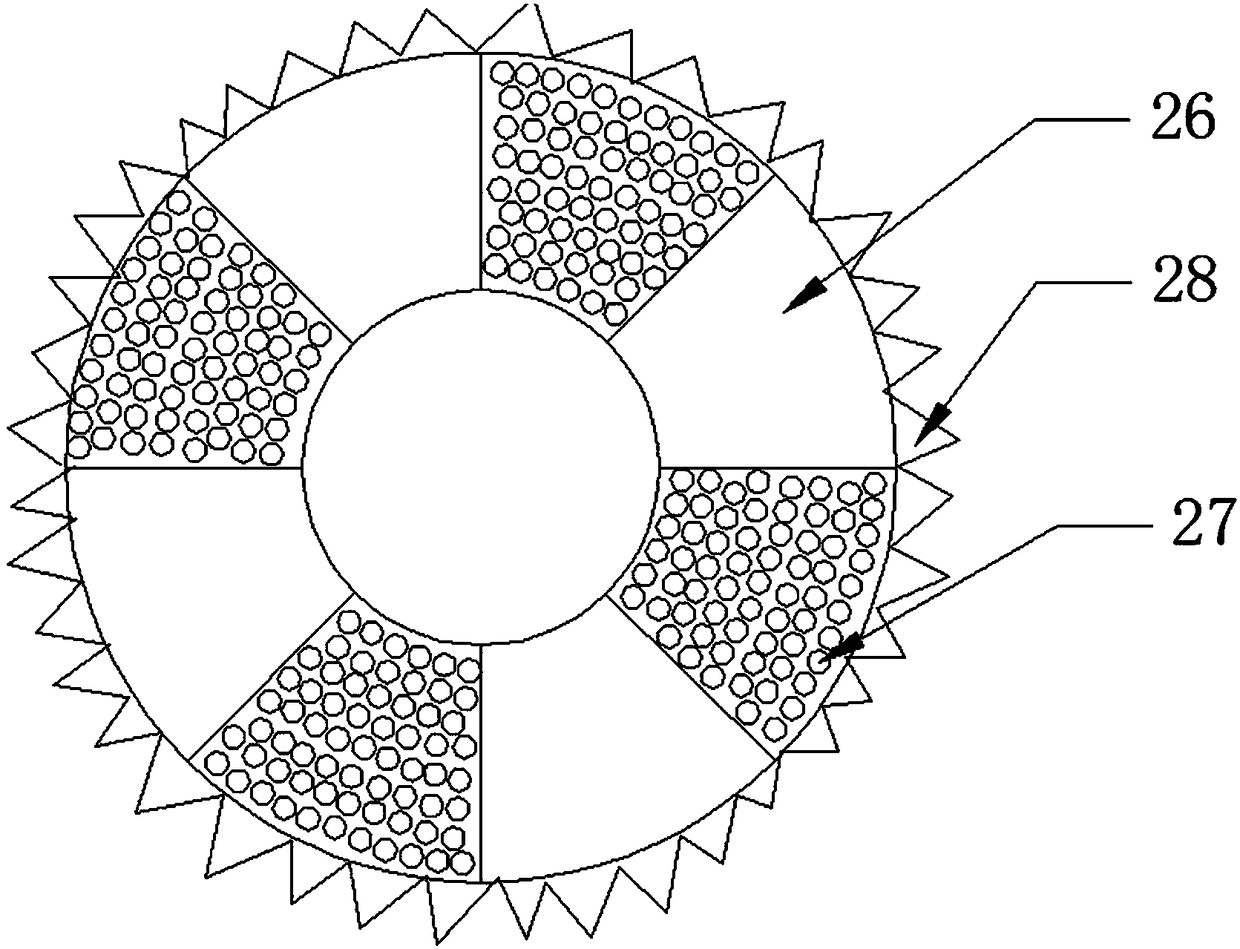

Carbonizing device for bamboo wood processing

InactiveCN107310005AFully carbonizedShorten carbonization timeWood charring/burningSimultaneous control of multiple variablesClutchCarbonation

The invention discloses a carbonization device for bamboo and wood processing, comprising a box body, a motor is fixedly connected to the bottom of the inner wall of the box, the output shaft end of the motor is fixedly connected to a transmission through a first coupling, and the output shaft end of the transmission The first rotating shaft is fixedly connected through the second coupling, and the surface of the first rotating shaft is fixedly connected with the second rotating shaft through the rotating device. A steam boiler is fixedly connected, an air pump is fixedly connected to one side of the top of the fixed plate, an air compressor is fixedly connected to the side far from the air pump on the top of the fixed plate, and an air pipe is connected to the air outlet of the air compressor. The invention relates to bamboo and wood field of processing technology. The carbonization device for bamboo and wood processing solves the problem of the lack of intelligence of the existing carbonization device, and at the same time solves the problem of slow decomposition of traditional organic matter, ensures the carbonization effect and improves work efficiency.

Owner:安吉县瑞旺竹木制品厂

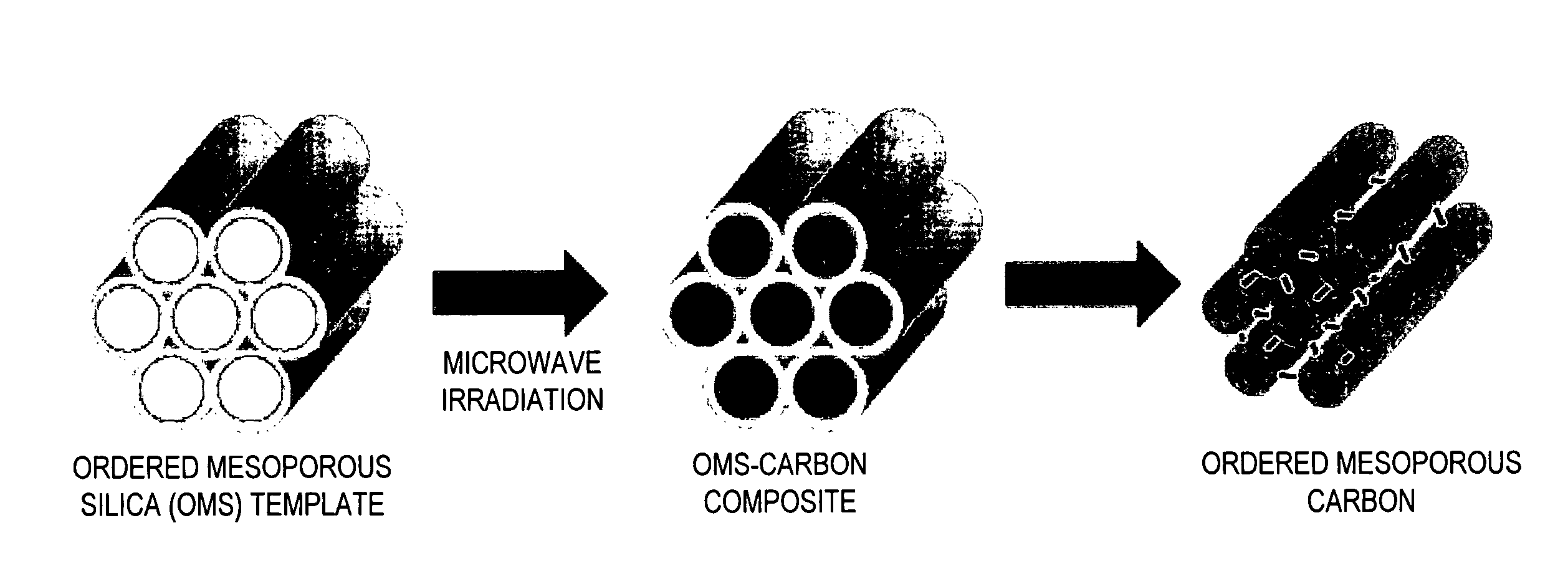

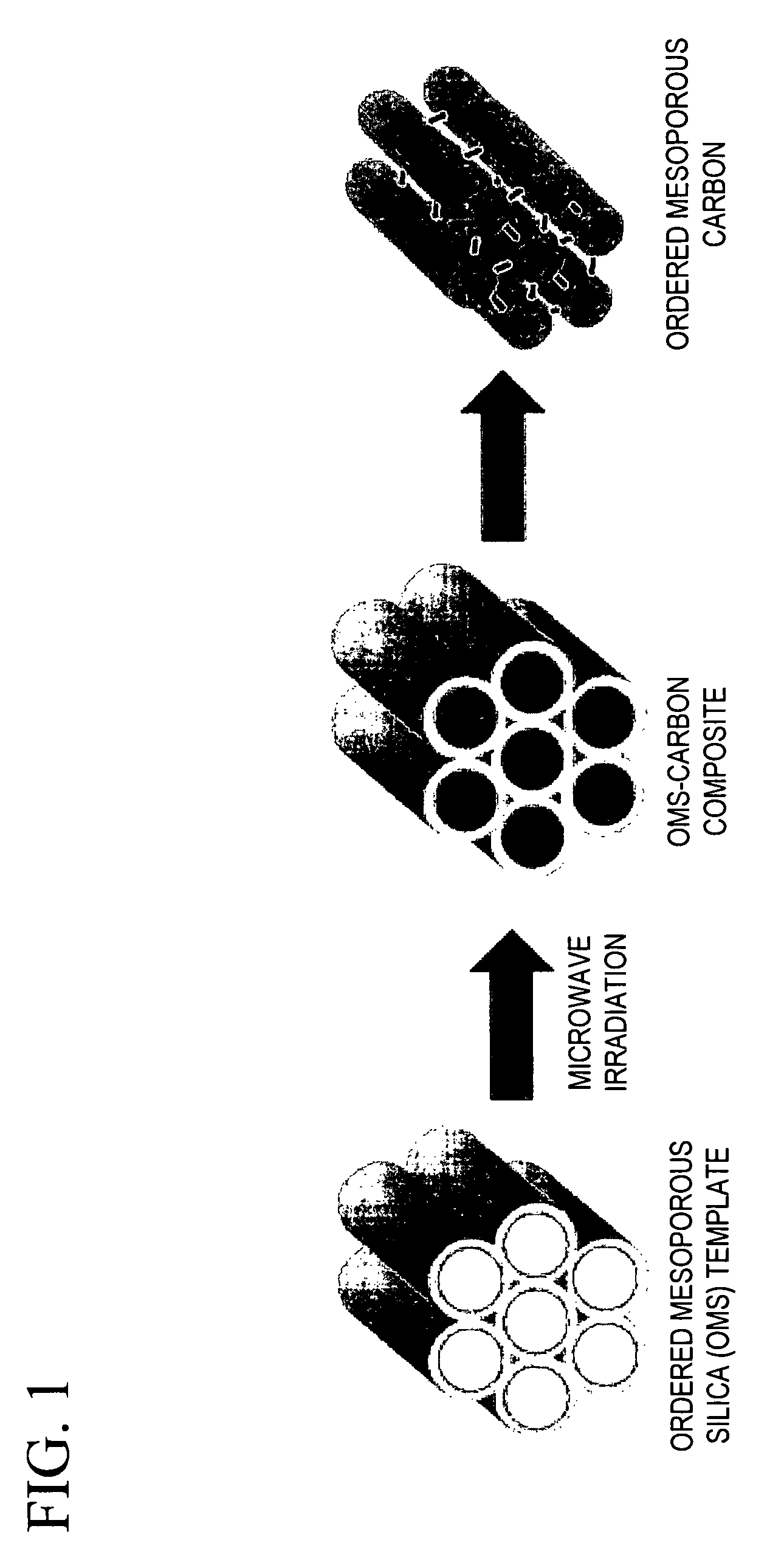

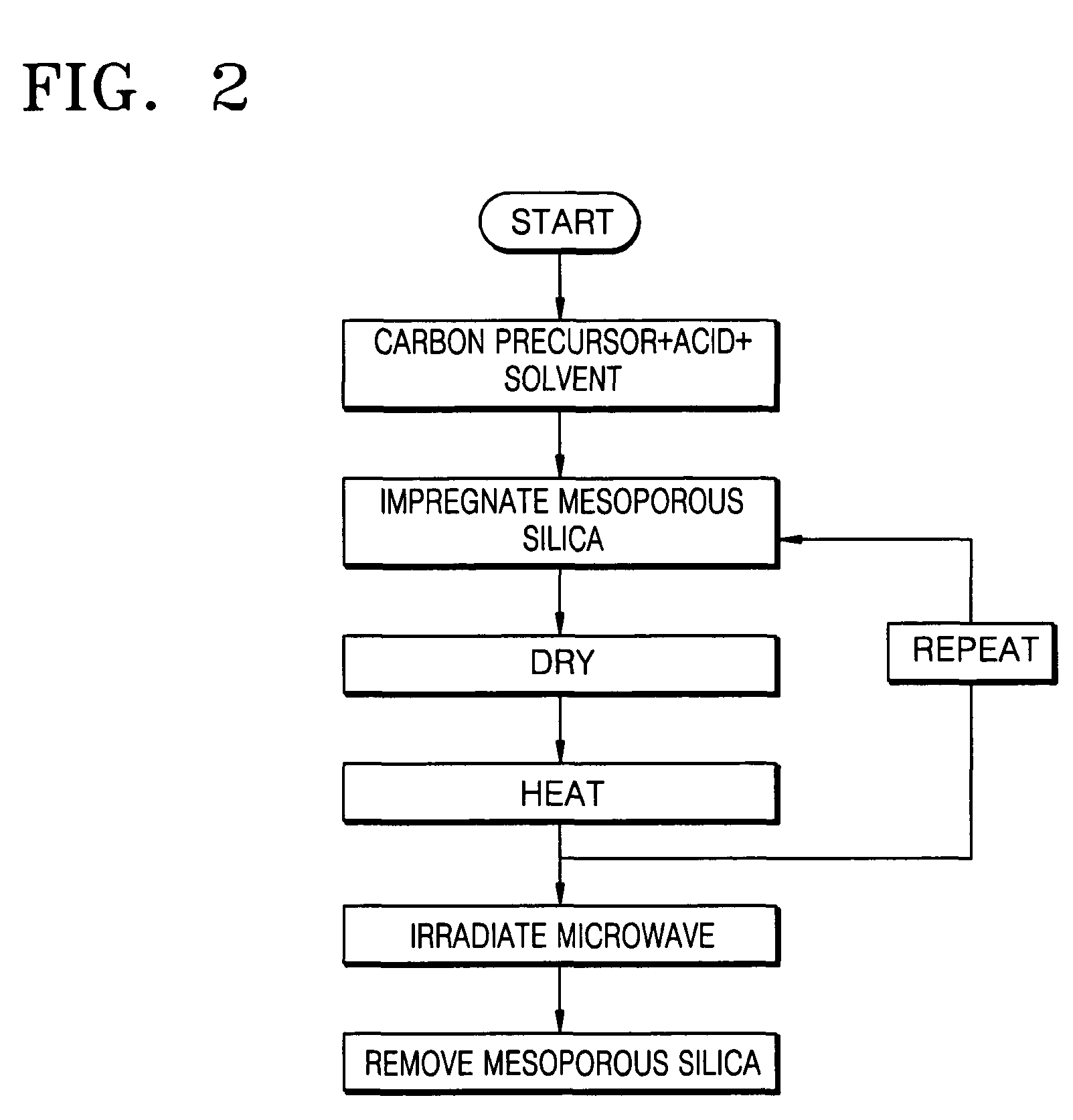

Mesoporous carbon, method of preparing the same, and fuel cell using the carbon

InactiveUS7854913B2Increase resistanceShorten carbonization timeMaterial nanotechnologyCarbon compoundsCarbon compositesMicrowave

A mesoporous carbon is prepared by mixing a carbon precursor, an acid, and a solvent to obtain a carbon precursor mixture; impregnating an ordered mesoporous silica (OMS) with the carbon precursor mixture; carbonizing the impregnated OMS at 800 to 1300° C. by irradiating microwave energy with a power of 100 to 2000 W thereon to form an OMS-carbon composite; and removing the mesoporous silica from the OMS-carbon composite. The method of preparing a mesoporous carbon can significantly reduce a carbonization time by carbonizing a carbon precursor using microwave energy in a silica template compared to a conventional method using a heat treatment. A supported catalyst and a fuel cell include the mesoporous carbon.

Owner:SAMSUNG SDI CO LTD

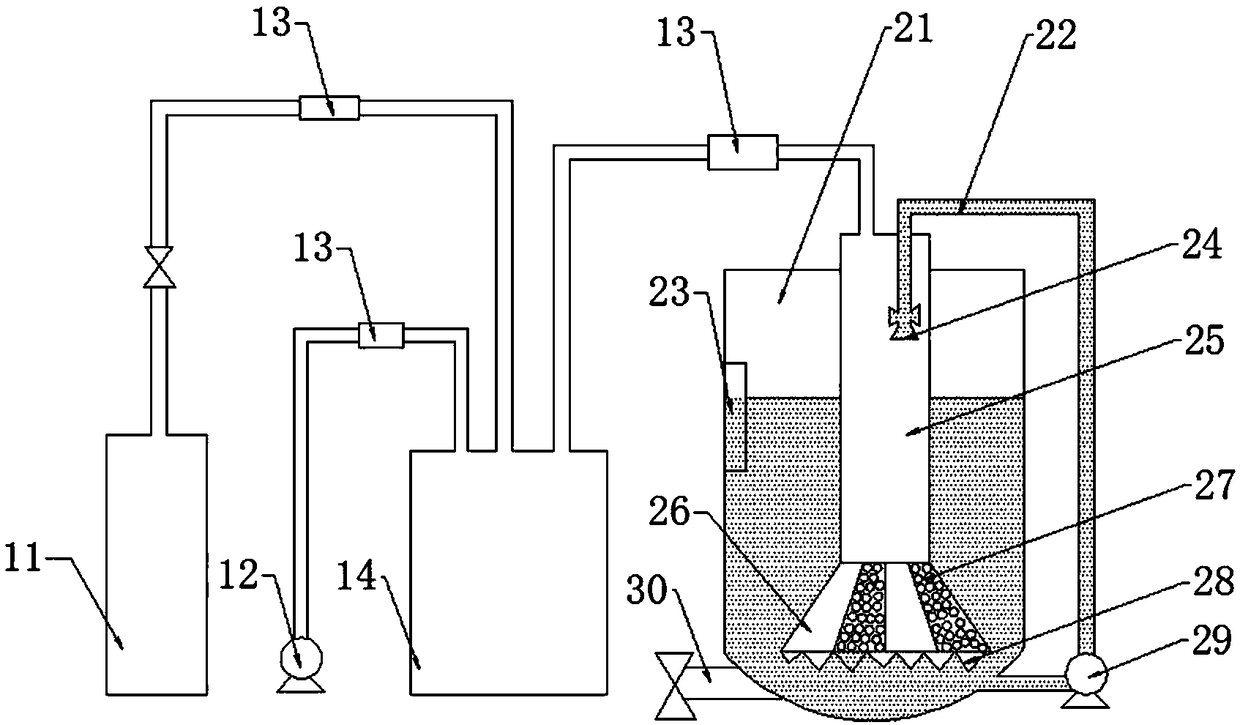

Device and method for strengthening recycled aggregate by means of CO2

ActiveCN106277885AEnhance basic propertiesLow water absorptionSolid waste managementPorosityCarbon dioxide cylinder

The invention relates to a device and method for strengthening recycled aggregate by means of CO2. The device comprises a reaction kettle with a kettle cover, a plurality of layers of stacked material frames are arranged in the reaction kettle, a gas inlet connected with a carbon dioxide steel cylinder is formed in the side of the reaction kettle, a pressurizing opening is formed in the kettle cover and connected with the carbon dioxide steel cylinder through a booster pump, and the kettle cover is further provided with an exhaust port and a vacuum opening connected with a vacuum pump. The device is simple in structure, convenient to install and maintain, convenient to clean and high in universality. By means of reaction of CO2 and recycled aggregate, the recycled aggregate is strengthened, basic properties of the recycled aggregate are improved, the water absorption rate and porosity of the recycled aggregate are reduced, the aperture is reduced, carbonization time is shortened, carbonization depth is increased, the treatment effect is improved, the yield is increased, and the equipment utilization rate is increased.

Owner:FUZHOU UNIV

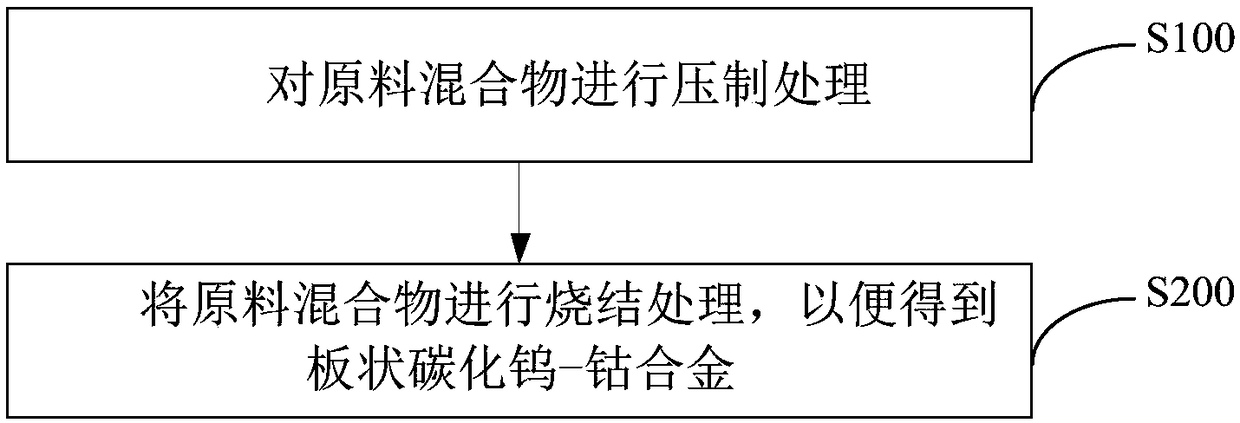

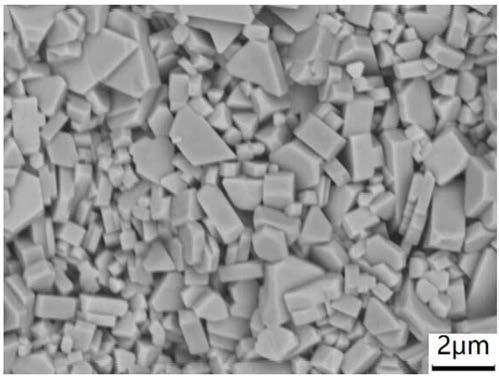

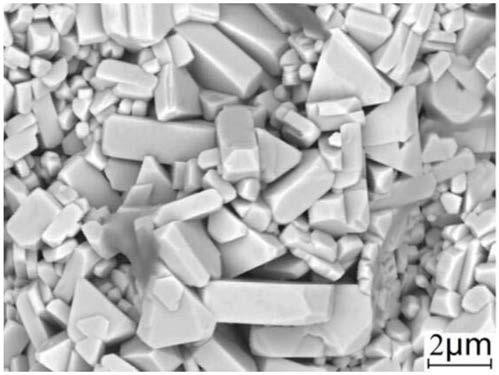

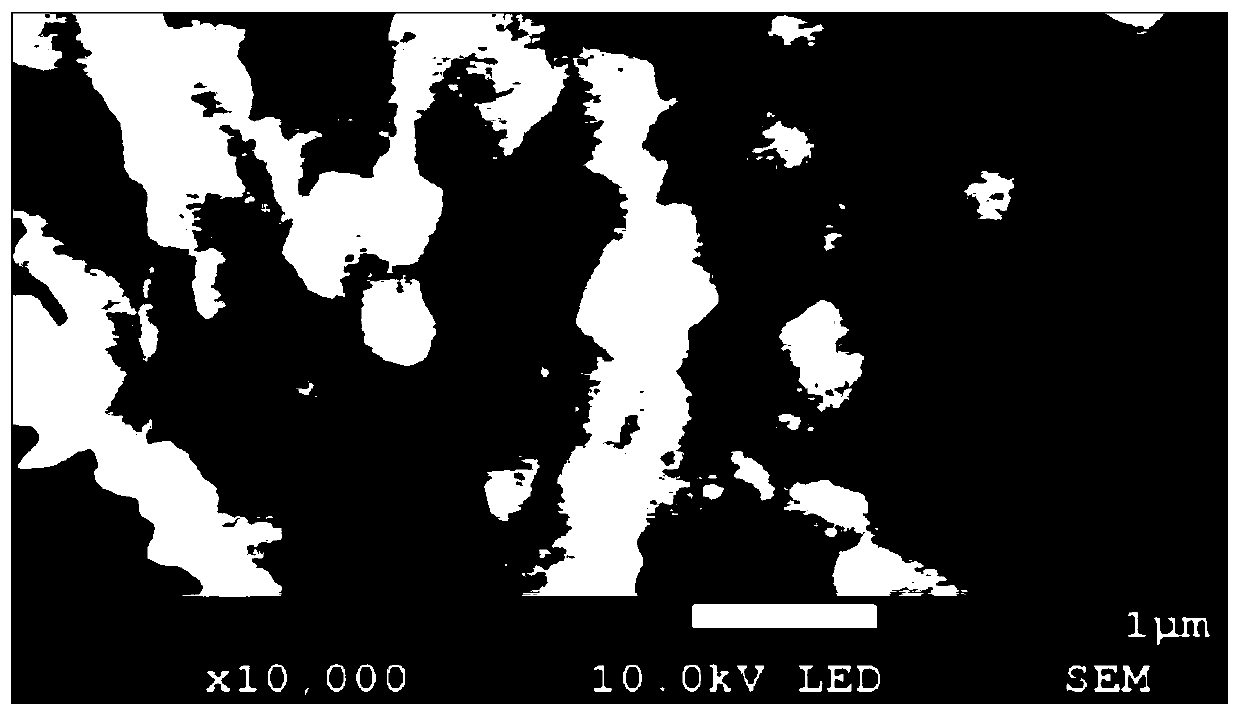

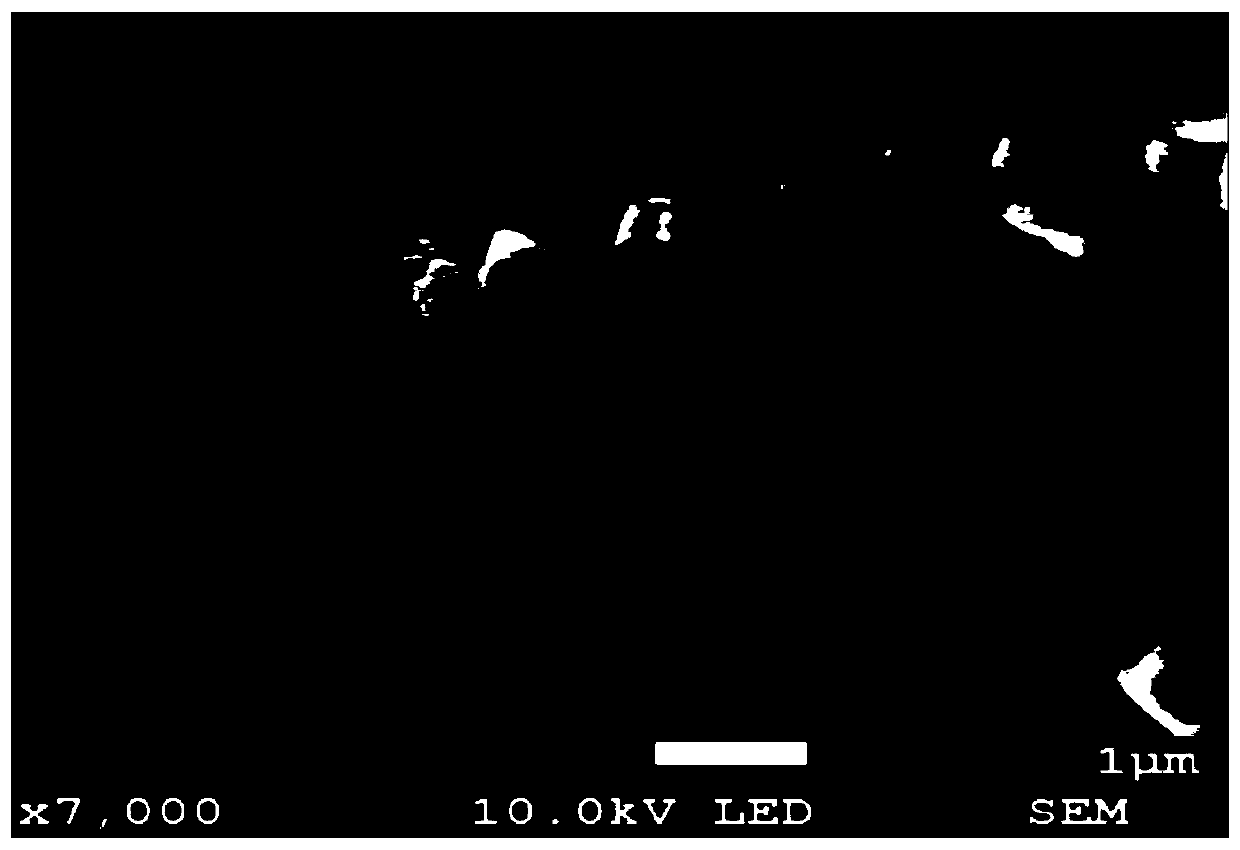

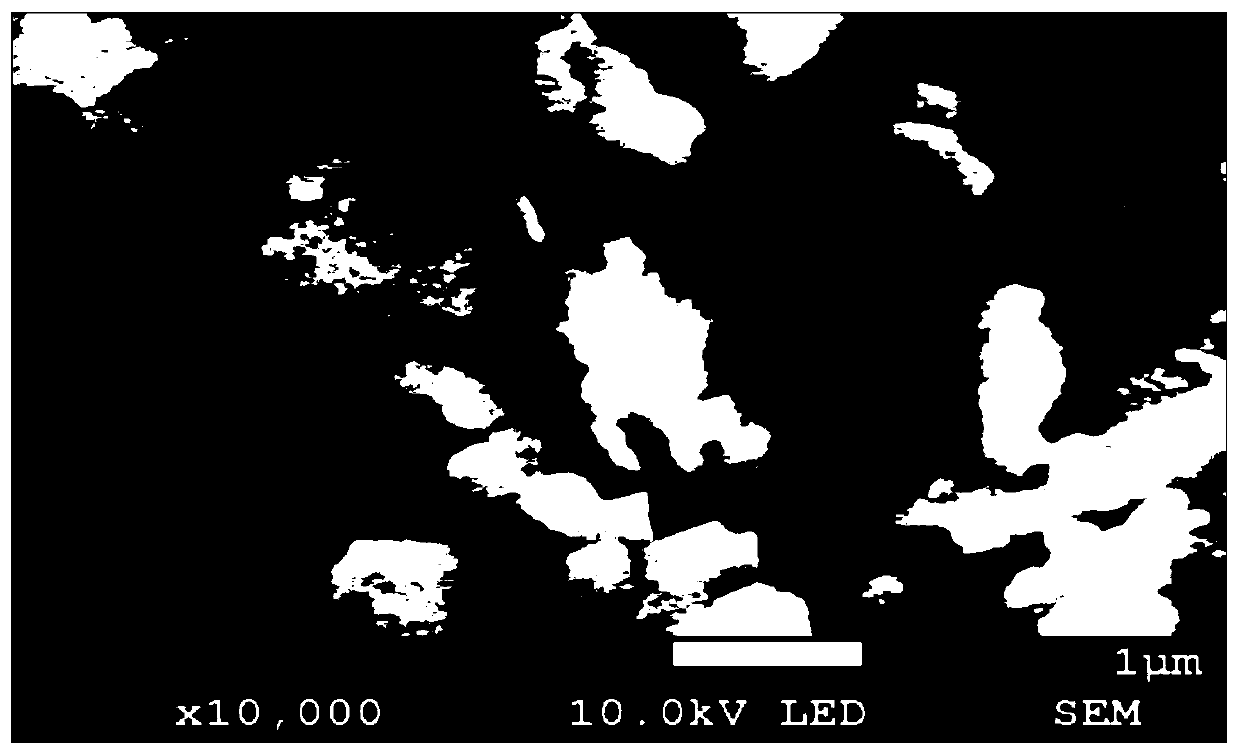

Plate-shaped tungsten carbide-cobalt alloy and preparation method thereof

The invention provides plate-shaped tungsten carbide-cobalt alloy and a preparation method thereof. The method comprises the following steps: enabling a raw material mixture to be subjected to sintering treatment so as to obtain the plate-shaped tungsten carbide-cobalt alloy, wherein the raw material mixture contains superfine WC-Co powder, and in the raw material mixture, the grain sizes of at least 90% or more of the superfine WC-Co powder are not greater than 800 nm. The method is simple and convenient to operate, easy to realize, relatively low in cost and easy to industrialize, and the prepared plate-shaped tungsten carbide-cobalt alloy has relatively uniform particle sizes and excellent mechanical properties.

Owner:CHONGYI ZHANGYUAN TUNGSTEN

Technology method for co-producing nano calcium carbonate from melamine tail gas

InactiveCN110627101AGood physical and chemical propertiesHas size effectCalcium/strontium/barium carbonatesAmmonium nitratesSlurryBiological activation

The invention discloses a technology method for co-producing nano calcium carbonate from melamine tail gas. The technology method for co-producing the nano calcium carbonate from the melamine tail gascontains the following steps: (1) introducing melamine tail gas into an inorganic acid for neutralization after the melamine tail gas is subjected to filtering and washing, and compressing collectedgas to obtain carbon dioxide; (2) adding a crystal form control agent into calcium hydroxide suspension liquid, and then introducing the carbon dioxide for a carbonation reaction to generate nano calcium carbonate slurry; (3) at 60-90 DEG C, adding modifying liquid into the nano calcium carbonate slurry in the step (2), and conducting stirring and mixing to obtain modified nano calcium carbonate slurry, wherein the adding amount of a dry basis of the modifying liquid is 2-10% of the mass of the nano calcium carbonate; and (4) conducting filtering, drying and crushing on the modified nano calcium carbonate slurry to obtain the nano calcium carbonate. According to the technology method for co-producing the nano calcium carbonate from the melamine tail gas, the generated nano calcium carbonate is in a shape of a chain, the average primary particle diameter is 40-80 nm, the nano calcium carbonate shows hydrophobicity, an activation grade reaches 99% or above, and the dispersion performancewhen the generated nano calcium carbonate is compatible with a polymer organic matrix is good, so that the application performance of the mechanical performance, the optical performance, the thixotropic performance and the like are significantly improved.

Owner:HENAN JUNHUA DEV

Extraction solution for preparing active light calcium carbonate, application and preparation method of active light calcium carbonate

ActiveCN110755882AIncrease added valueReduce manufacturing costCalcium/strontium/barium carbonatesLiquid solutions solvent extractionCalcium hydroxideCarboxylate

The invention relates to an extraction solution for preparing active light calcium carbonate, application and a preparation method of the active light calcium carbonate. The extraction solution is selected from any one of a first extraction solution and a second extraction solution; the first extraction solution comprises an organic extraction solvent, organic amine and carboxylic acid, the organic extraction solvent is difficult to dissolve in water and can dissolve the organic amine, the organic amine is difficult to dissolve in water and easy to dissolve in the organic extraction solvent, and organic amine carboxylate formed by organic amine and carboxylic acid is easy to dissolve in the organic extraction solvent, calcium carboxylate obtained by reacting carboxylic acid with calcium hydroxide is easy to dissolve in water and difficult to dissolve in the organic extraction solvent; the second extraction solution comprises an organic extraction solvent, organic amine and carboxylic acid, the organic amine is difficult to dissolve in water and easy to dissolve in the organic extraction solvent, and calcium carboxylate obtained by reacting carboxylic acid with calcium hydroxide iseasy to dissolve in the organic extraction solvent and difficult to dissolve in water. According to the extraction solution disclosed by the invention, CaCO3 synthesis and surface treatment are combined into one, so that superfine CaCO3, particularly nano CaCO3, can be easily obtained.

Owner:厦门市汇创源科技有限公司

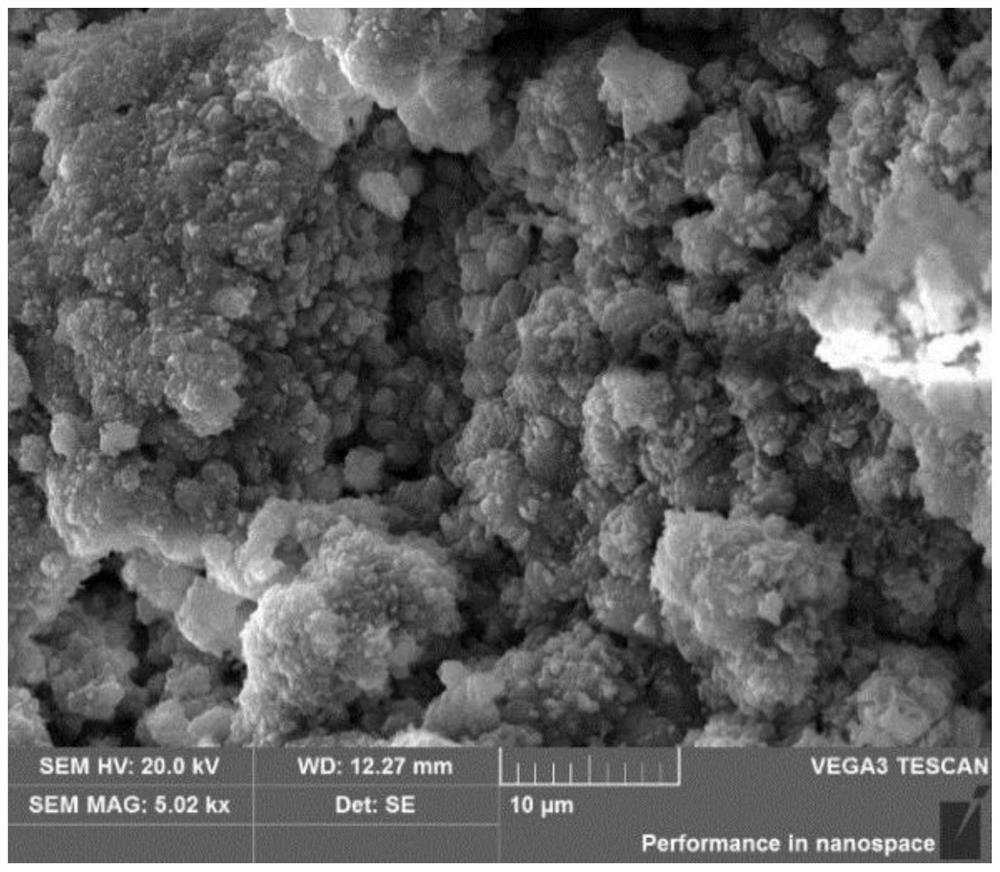

A method of wet carbonization to activate waste concrete regenerated micropowder and the application of regenerated micropowder

ActiveCN112125541BHigh activityEasy to achieve continuous productionCement productionCarbonizationPhysical chemistry

The present invention proposes a method for activating recycled micropowder of waste concrete by wet carbonization. The powder produced in the process of crushing waste concrete to produce recycled aggregate is used as regenerated micropowder, and the regenerated micropowder is dispersed in water to form a mixed slurry, which is mixed in the The industrial waste gas containing carbon dioxide is continuously fed into the slurry, and during this process, the carbon dioxide contained in the industrial waste gas and the regenerated micropowder undergo a carbonization reaction. In the present invention, the regenerated micropowder is subjected to carbonization reaction in an aqueous solution, and the calcium carbonate and silicon dioxide produced by carbonization have higher activity, and the pozzolanic ash activity is better than auxiliary gelling materials such as commonly used fly ash and silica fume, and can be used as auxiliary gelling materials material used.

Owner:HENAN POLYTECHNIC UNIV

A method and equipment for continuously preparing vanadium nitrogen alloy

The invention discloses a method for continuously preparing vanadium-nitrogen alloy. The method includes the first step of preparation, the second step of blending and blank manufacturing, the third step of adding, the fourth step of preheating and prereduction, the fifth step of carbonization and nitridation sintering, and the sixth step of discharging. A device for preparing vanadium-nitrogen alloy according to the method comprises a vertical boiler, a top feeding bin (1) and a continuous automatic discharging device (2), wherein the vertical boiler is composed of a preheating section (4), a calcination section (4) and a cooling section (5); the lower end of the vertical boiler is connected with the continuous automatic discharging device (2) through a pipeline; the tail end of the continuous automatic discharging device is connected with a finished product trolley (20) through a discharge pipe (18); the bottom of the vertical boiler is provided with a nitrogen inlet (21). The method has the advantages that the process and the device are compact, the production process is short, electric energy is saved, little investment is required, yield is high, continuous production is really achieved, and the industrialized and scale production requirement is met.

Owner:SICHUAN ZHANXIANG SPECIAL ALLOY TECH

Device for microwave-assisted double bed layer catalysis of fast pyrolysis of biomass

InactiveCN107674698AShorten carbonization timeImprove yield and qualityLiquid hydrocarbon mixture productionHydrocarbon oils treatmentPyrolysisCarbonization

A device for microwave-assisted double bed catalysis of fast pyrolysis of biomass includes a feeder, a microwave absorbent bed, a double-port quartz reaction flask, a catalyst bed, a condensing systemand a suction pump. After the temperature of the microwave absorbent bed reaches target temperature, a material is fed into the dual-port quartz reaction flask from a feed inlet through the feeder. Generated pyrolysis vapor passes through the catalyst bed under the action of the suction pump for catalytic reforming, and then enters the condensing system to condense into bio-oil, and the bio-oil is collected at a collection port. The device can realize microwave assisted catalysis of the rapid pyrolysis of the biomass, and reduces the carbonization process of the biomass in a low temperature stage, the defects that a catalyst is easy to passivate and inactivate caused by mixing of the catalyst and a material can be completely avoided, and the utilization efficiency of the catalyst is effectively improved. The suction pump is used, and is beneficial to increase the yield and quality of the bio-oil.

Owner:NANCHANG UNIV

Method for preparing biomass-based aircraft fuel by utilizing stalks and waste plastic food bags

InactiveCN107828439AHigh yieldReduced inactivation rateLiquid hydrocarbon mixture productionHydrocarbon oils treatmentMicrowave pyrolysisMass ratio

A method for preparing biomass-based aircraft fuel by utilizing stalks and waste plastic food bags comprises the following steps: (1) respectively smashing the stalks and the waste plastic food bags,and uniformly mixing according to a mass ratio that the stalks to the waste plastic food bags is (1 to 1) to (1 to 10); (2) weighing a catalyst according to a mass ratio that the catalyst to the mixture of the stalks and the waste plastic food bags is (1 to 1) to (1 to 10), putting the catalyst into a U-shaped quartz tube which is connected with a pyrolysis steam outlet of a quartz double-openingbottle, and adding a microwave absorption agent into a quartz cup; (3) embedding the quartz double-opening bottle and the U-shaped quartz tube connected with the quartz double-opening bottle into thequartz cup filled with the microwave absorption agent, putting the quartz cup in a microwave pyrolysis instrument, heating to 450 to 650 DEG C, quickly adding the mixture of the stalks and the waste plastic food bags into the quartz double-opening bottle, catalyzing and reforming pyrolysis steam through the catalyst in the U-shaped quartz tube under the action of an air pump, and forming the biomass-based aircraft fuel through condensation of a condensation tube. According to the method disclosed by the invention, the carbonizing time is greatly shortened, and the productivity and the qualityof biomass oil and the content of hydrocarbons in the biomass oil are increased.

Owner:NANCHANG UNIV

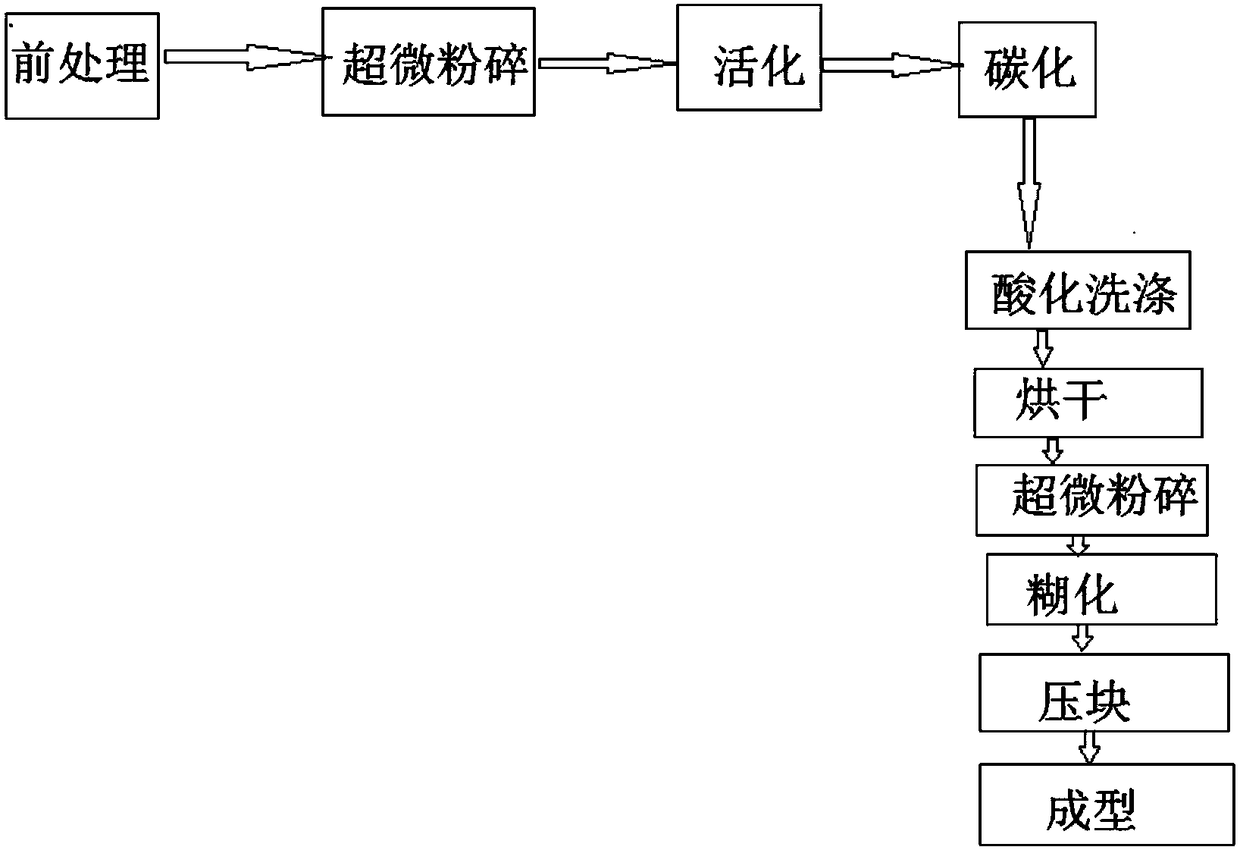

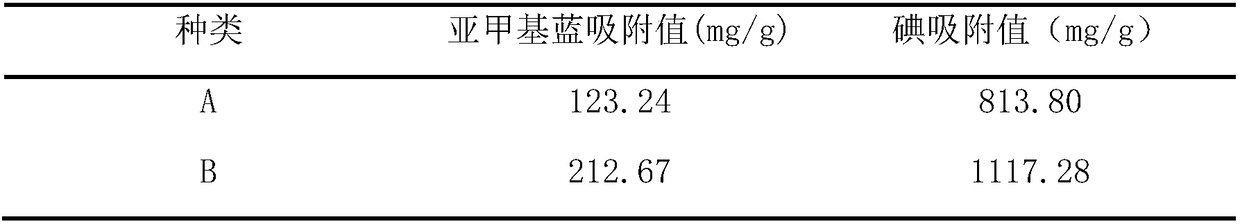

Suaeda glauca ultrafine powder briquetting active carbon and preparation method thereof

ActiveCN108264044AReduce energy consumptionAvoid timeCarbon compoundsCarbonizationBiological activation

The invention relates to suaeda glauca ultrafine powder briquetting active carbon and a preparation method thereof. According to the method, suaeda glauca ultrafine powder is firstly crushed into drypowder; then, ZnCl2 and FeCl3 composite activation solution is used for activation; next, heating carbonization is performed; after the carbonization, acidification washing, drying and ultrafine crushing are performed to obtain the suaeda glauca ultrafine powder active carbon; shaping agents, auxiliary materials and additives are added into the suaeda glauca ultrafine powder active carbon; mixingand water adding pasting are performed; briquetting and shaping are performed to obtain the suaeda glauca ultrafine powder briquetting active carbon. The suaeda glauca ultrafine powder briquetting active carbon and the preparation method thereof have the advantages that the cost is low; the preparation efficiency is high; the product adsorption performance is good.

Owner:DONGYING GUANGYUAN BIOTECH CO LTD

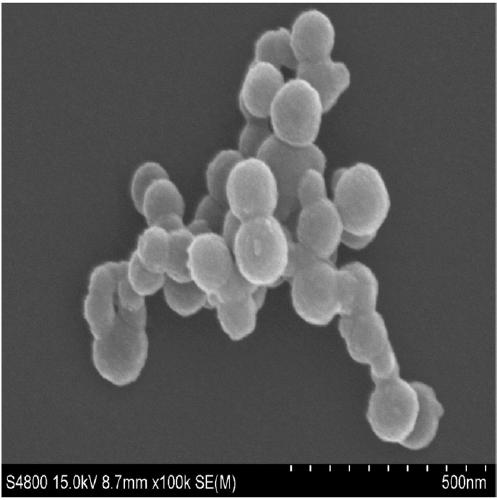

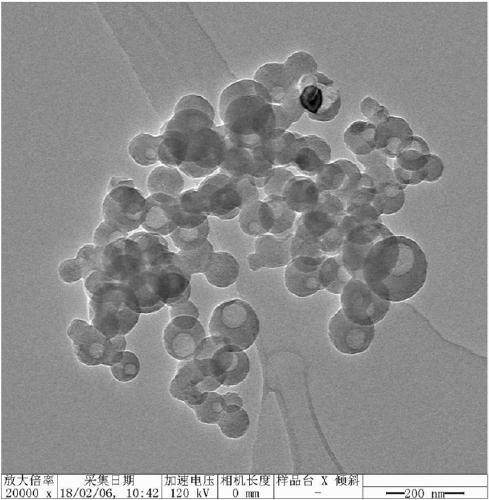

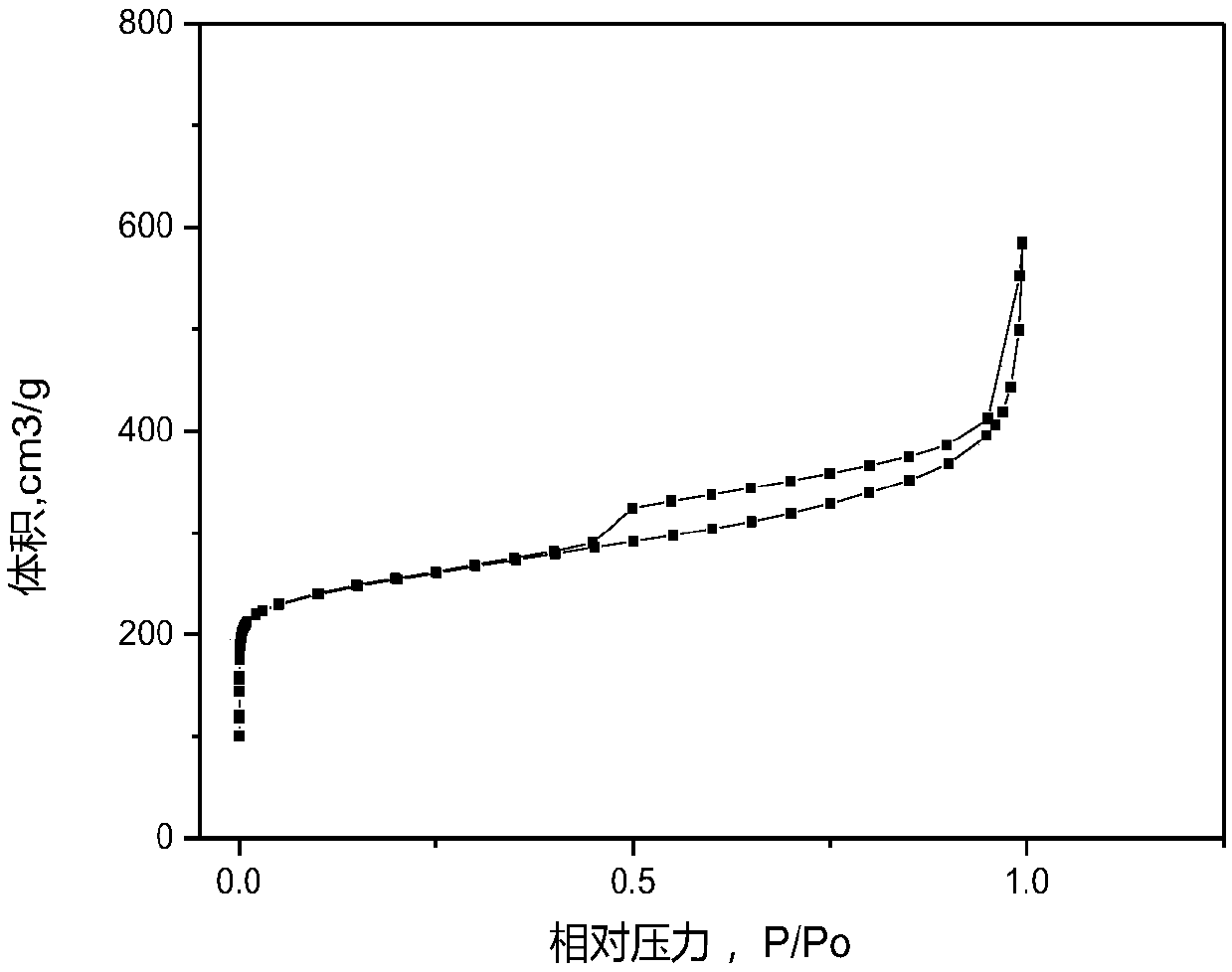

Nanoporous carbon sphere, and preparation method and application thereof

PendingCN110386596AShorten carbonization timeReduce use costMaterial nanotechnologyCarbon preparation/purificationPolymer sciencePolyolefin

The invention belongs to the technical field of porous carbon materials, and discloses a nanoporous carbon sphere, and a preparation method and an application thereof. The nanoporous carbon sphere hasan average particle diameter of 20 to 800 nm, a specific surface area of 50 to 5000 m<2> / g, a pore volume of 0.2 to 2.0 cm<3> / g and a graphitization degree ID / IG of 0.5 to 1. 8. With the method provided by the invention, a polymer nanosphere is prepared by using a halogenated polyolefin polymer as a raw material through a precipitation method; the polymer nanoparticle is hydrothermally carbonizedat a low temperature; and a hydrothermally carbonized polymer nanoparticle is then placed into an inert gas atmosphere for further carbonization. The nanoporous carbon sphere prepared by using the method provided by the invention has good sphericity and microporous-mesoporous structure; and the method provided by the invention has the advantages of simple process, convenient operation, low requirements on equipment, capability of realizing large-scale preparation, and application prospect in industrial production.

Owner:INST OF CHEM CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com