Method and device for producing calcium carbonate through dynamical carbonation method

A technology of calcium carbonate and carbonization method, which is applied in the fields of calcium carbonate/strontium/barium, chemical instruments and methods, inorganic chemistry, etc. It can solve the problems of large consumption of dynamic method and low utilization rate of carbon dioxide, etc., so as to save carbonization time and increase gas -The effect of liquid contacting the surface and prolonging the gas-liquid contact time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

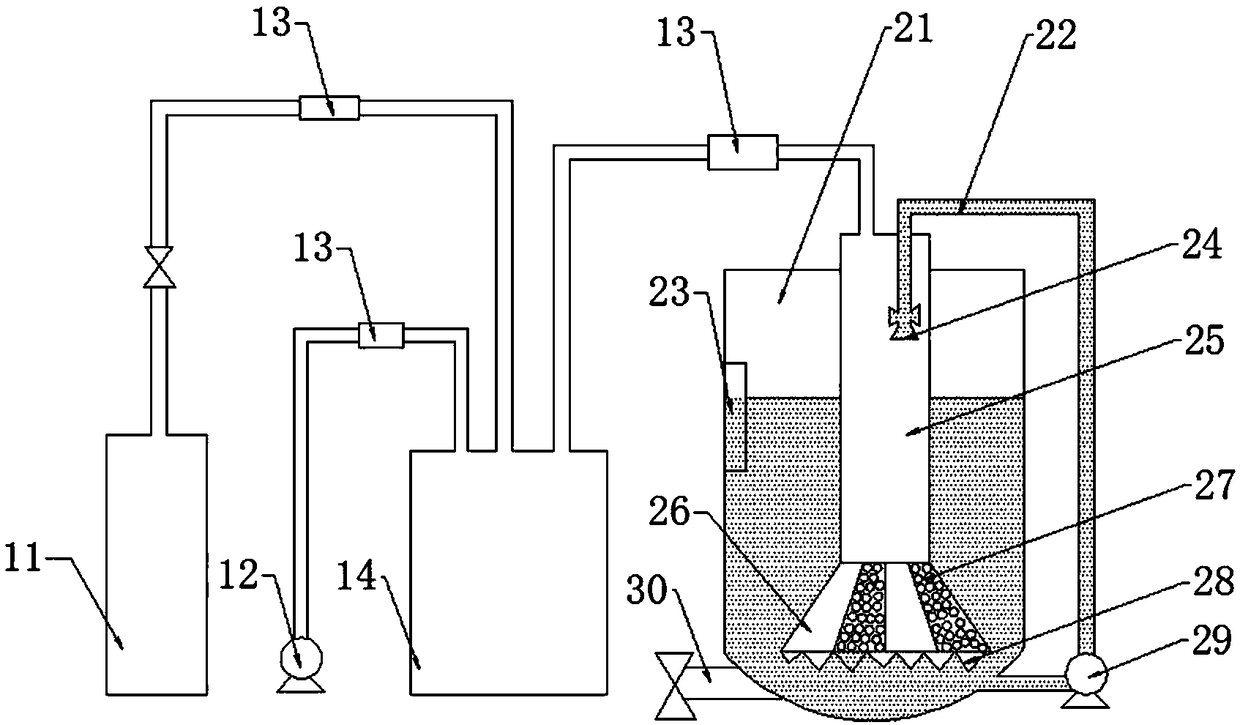

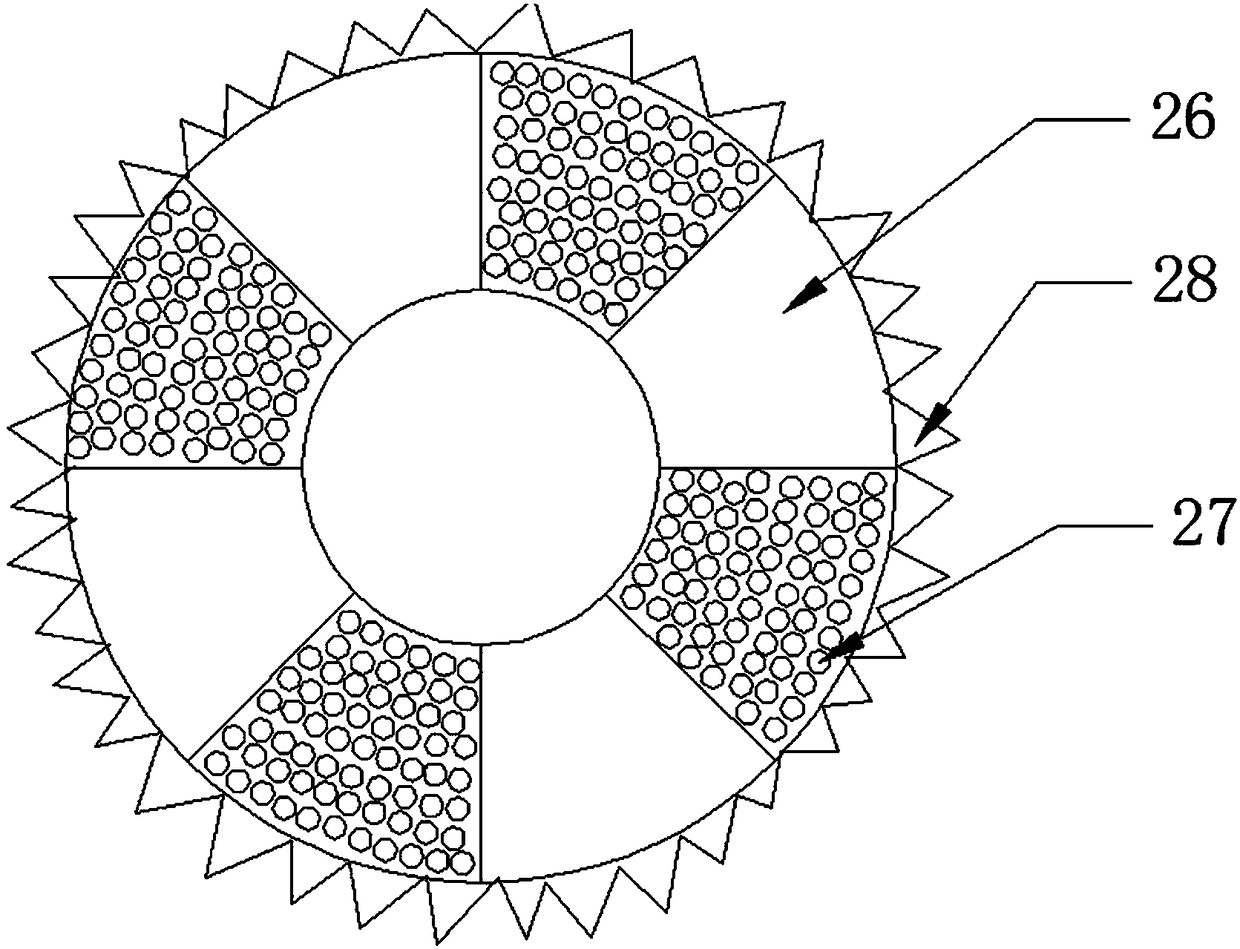

[0058] The embodiment of the present invention provides a kind of dynamic carbonization method to produce the device of calcium carbonate, refer to the attached figure 1 and 2 , including a reaction tank 21, and also includes: a dynamic reactor 25, suspended and confined in the reaction tank 21, the bottom end of the dynamic reactor 25 is open, and an umbrella-shaped gas distributor 26 is provided;

[0059] CO 2 Proportioner 14 for blending CO 2 The volume content of the gas is communicated with the upper end of the dynamic reactor 26 through a pipeline;

[0060] The slurry return pipe 22, the liquid inlet port communicates with the return port at the bottom of the reaction tank 21, and the liquid outlet port communicates with the upper end of the dynamic reactor 25 through a return pump 29;

[0061] The pH measuring device 23 is arranged on the side wall of the reaction tank 21 .

[0062] A spray device 24 is provided at the outlet end of the slurry return pipe 22 . The ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| whiteness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com