Suaeda glauca ultrafine powder briquetting active carbon and preparation method thereof

A technology of powdered activated carbon and Suaeda-based, which is applied in the preparation and application of bio-based activated carbon, which can solve the problems of low output and long preparation time, and achieve the effects of large specific surface area, improved performance and yield, and high activation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

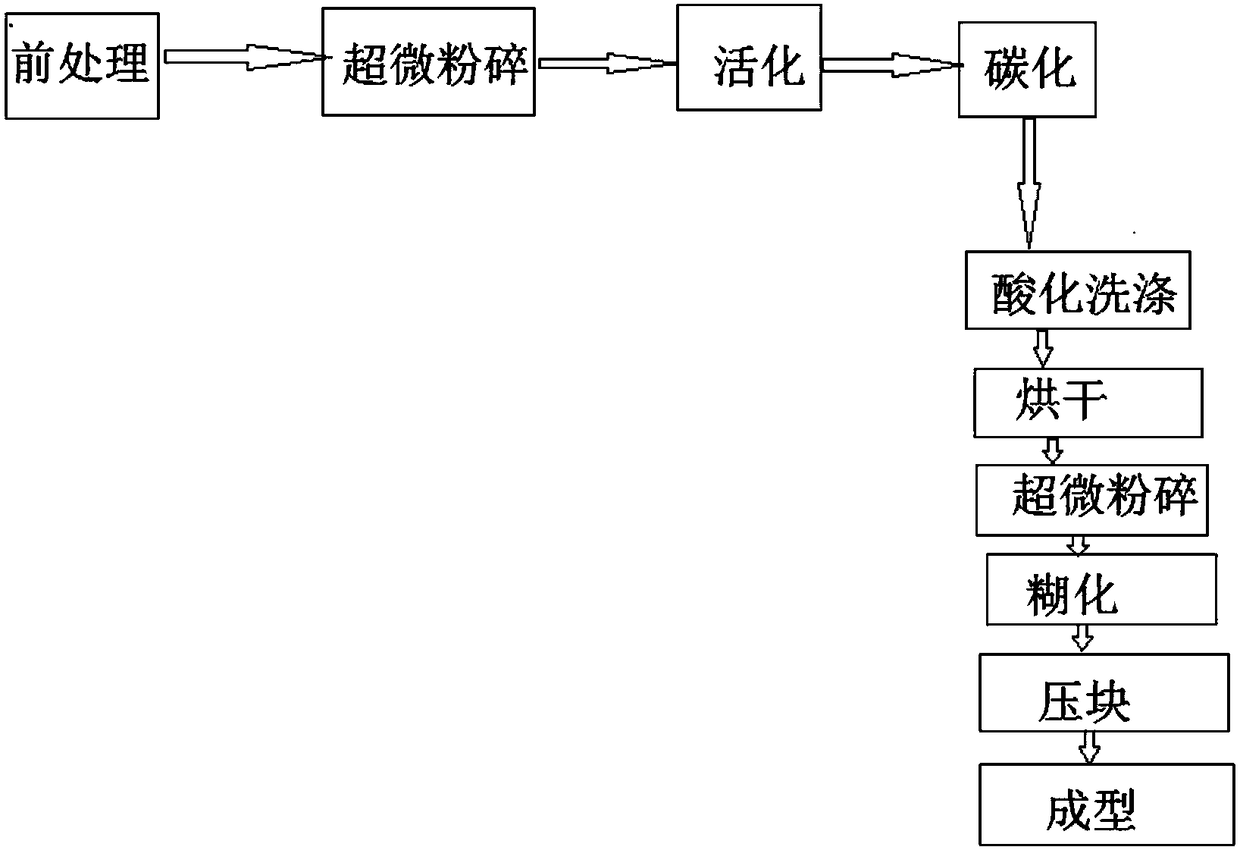

Method used

Image

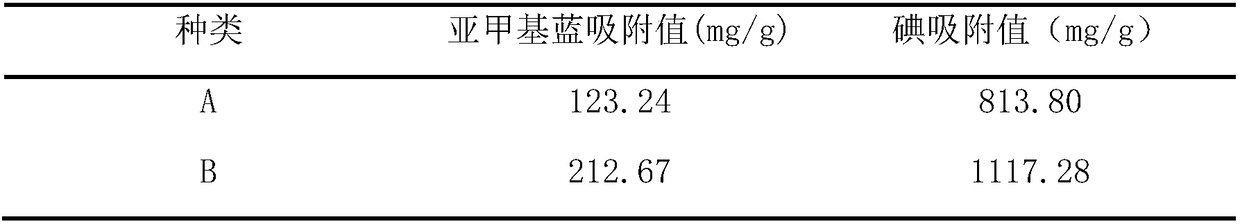

Examples

Embodiment 1

[0031] A preparation method of suaeda-based superfine powder briquetted activated carbon, comprising steps as follows:

[0032] (1) Pretreatment

[0033] Clean the extracted Suaeda salsa in an ultrasonic cleaner for 20 minutes under 400W power ultrasonic conditions, remove the cleaned Suaeda salsa, drain the epidermal water droplets, rinse repeatedly with distilled water for 5 times, wring out the water with clean gauze, and place on the Under the condition of 105°C, carry out blast drying for 3 hours to constant weight. The purpose of ultrasonic cleaning: to clean the soil carried by the roots and stems and leaves of Suaeda salsa, so that the microorganisms and secretions adhering to Suaeda salsa will fall off, which is more conducive to ultrafine pulverization;

[0034] (2) Superfine grinding

[0035] Take a certain amount of Suaeda salsa dried to a constant weight, put it into an air-flow ultrafine pulverizer for 30 minutes, pass it through a 200-mesh sieve by brush sievi...

Embodiment 2

[0047] A preparation method of suaeda-based superfine powder briquetted activated carbon, comprising steps as follows:

[0048] (1) Pretreatment

[0049] Clean the extracted Suaeda salsa in an ultrasonic cleaner for 20 minutes under 500W power ultrasonic conditions, remove the cleaned Suaeda salsa, drain the epidermal water droplets, rinse repeatedly with distilled water for 3 times, wring out the water with clean gauze, and place Under the condition of 120°C, carry out blast drying for 5 hours to constant weight. The purpose of ultrasonic cleaning: to clean the soil carried by the roots and stems and leaves of Suaeda salsa, so that the microorganisms and secretions adhering to Suaeda salsa will fall off, which is more conducive to ultrafine pulverization;

[0050] (2) Superfine grinding

[0051] Take a certain amount of Suaeda salsa dried to constant weight, put it into an air-flow ultrafine pulverizer for pulverization for 40 minutes, pass through a 200-mesh sieve by brush...

Embodiment 3

[0061] A preparation method of suaeda-based superfine powder briquetted activated carbon, comprising steps as follows:

[0062] (1) Pretreatment

[0063] Clean the extracted Suaeda salsa in an ultrasonic cleaner for 15 minutes under 450W power ultrasonic conditions, remove the cleaned Suaeda salsa, drain the epidermal water droplets, rinse repeatedly with distilled water for 4 times, wring out the water with clean gauze, and place Under the condition of 110°C, carry out blast drying for 4 hours to constant weight. The purpose of ultrasonic cleaning: to clean the soil carried by the roots and stems and leaves of Suaeda salsa, so that the microorganisms and secretions adhering to Suaeda salsa will fall off, which is more conducive to ultrafine pulverization;

[0064] (2) Superfine grinding

[0065] Take a certain amount of Suaeda salsa dried to a constant weight, put it into an air-flow ultrafine pulverizer for 35 minutes, pass it through a 200-mesh sieve by brush sieving, and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| iodine adsorption value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com