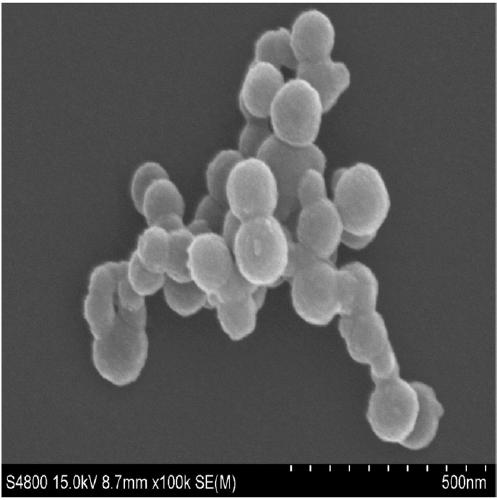

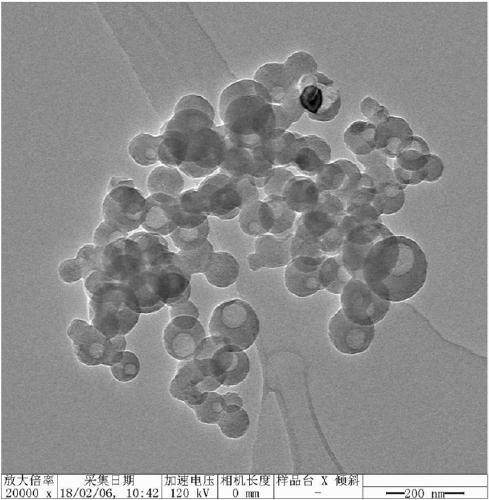

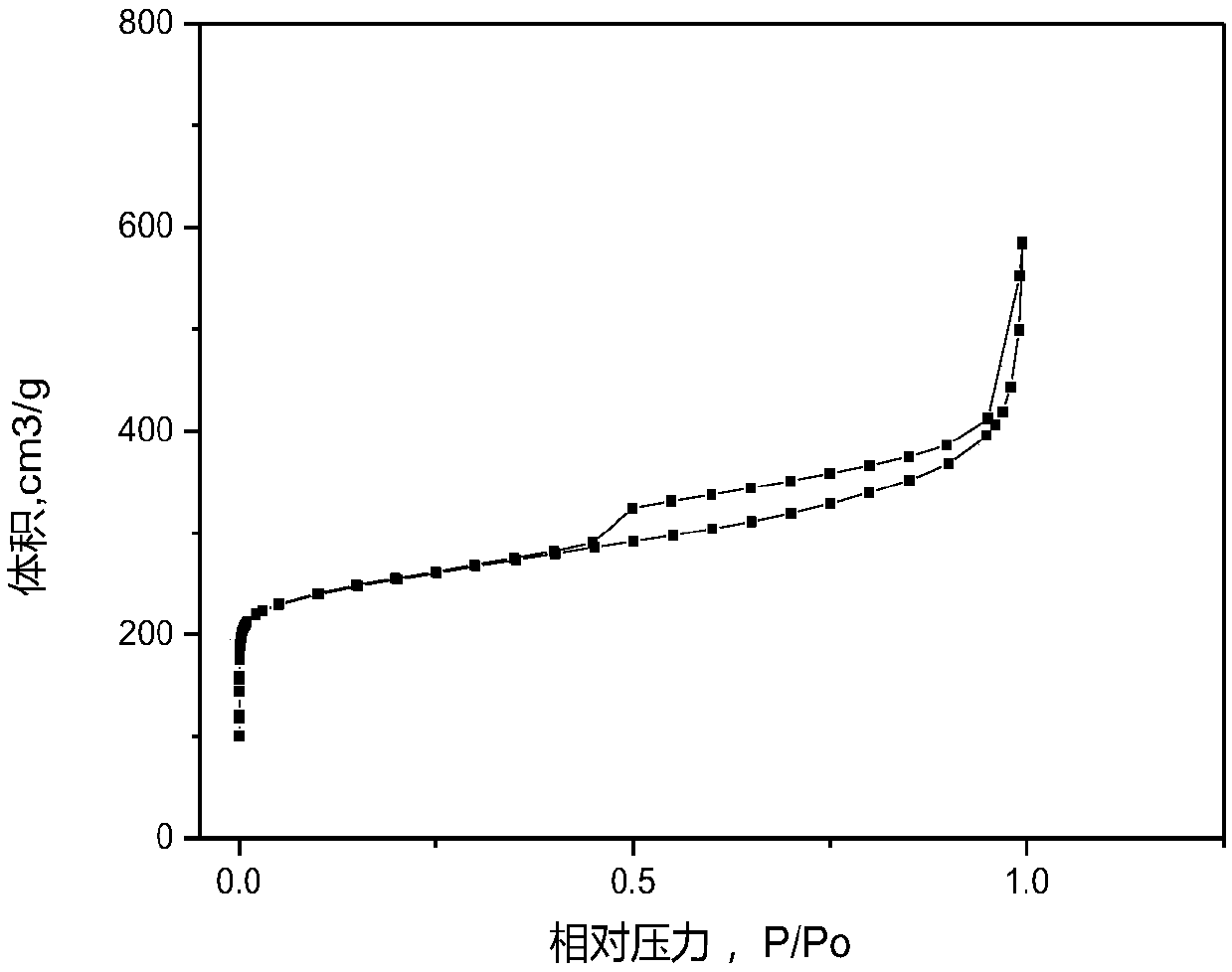

Nanoporous carbon sphere, and preparation method and application thereof

A nanoporous carbon and nanotechnology, applied in the field of porous carbon materials, can solve the problem that porous carbon spheres cannot adapt to different requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0069] Dissolve 1g of chlorinated polypropylene (mass content of chlorine element is 70wt%, Cl / C molar ratio is 0.92:1) in 100ml of tetrahydrofuran, stir well and heat to 60°C, use nitrogen as protective gas to condense and reflux, fully dissolve 2 Hour; 1000ml of acetone is placed in the beaker and stirred rapidly, and the tetrahydrofuran solution that has dissolved the chlorinated polypropylene is injected rapidly into the rapidly stirred acetone with a disposable injection needle; when all the solutions are fully injected, chlorinated polypropylene nanospheres are obtained; Take 100ml of the above-mentioned solution containing chlorinated polypropylene nanospheres, add 100ml of distilled water, pour it into a rotary evaporator for distillation under reduced pressure, and completely spin off tetrahydrofuran and acetone; pour the remaining solution into a 50ml high-pressure reaction kettle, 10°C per minute to 350°C, react for 8 hours to obtain a liquid containing black precipi...

Embodiment 2

[0073] Dissolve 1g of chlorinated polypropylene (mass content of chlorine element is 70wt%, Cl / C molar ratio is 0.92:1) in 100ml of dimethyl sulfoxide, stir well and heat to 120°C, use nitrogen as protective gas to condense and reflux , fully dissolved for 2 hours; 1000ml of acetone was placed in a beaker and stirred quickly, and the dimethyl sulfoxide solution dissolved in chlorinated polypropylene was quickly injected into the rapidly stirred acetone with a disposable injection needle; after all the solutions were injected, the preparation Obtain chlorinated polypropylene nanospheres; get the above-mentioned solution 100ml containing chlorinated polypropylene nanospheres, pour it into a rotary evaporator for distillation under reduced pressure, pour the remaining solution into a 50ml high-pressure reactor, and heat up to 10°C per minute. React at 350°C for 8 hours to obtain a liquid containing black precipitate, then remove the supernatant, wash with ethanol solution, and dry...

Embodiment 3

[0076] Dissolve 1g of chlorinated polyethylene (the mass content of chlorine element is 60wt%, and the Cl / C molar ratio is 0.68:1) in 100ml of xylene, stir well and heat to 120°C, use nitrogen as protective gas to condense and reflux, fully dissolve 2 hours; put 1000ml of methanol in a beaker and stir quickly, and quickly inject the xylene solution dissolved in chlorinated polyethylene into the rapidly stirred distilled water with a disposable injection needle; after all the solutions are injected, the chlorinated polyethylene nano balls; take 100ml of the above solution containing chlorinated polyethylene nanospheres, pour it into a rotary evaporator for distillation under reduced pressure, pour the remaining solution into a 50ml high-pressure reactor, heat up to 350°C at 20°C per minute, and react for 6 hours , to obtain a liquid containing black precipitate, then remove the supernatant, wash with ethanol solution, and dry to obtain a black powder; put the black powder into t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Pore volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com