Method for open type carbonization strengthening of waste concrete recycled aggregate

A technology of waste concrete and recycled aggregates, which is applied in the direction of solid waste management, sustainable waste treatment, climate sustainability, etc. It can solve the problems of uncontinuous production and difficult use of industrial waste gas, and achieve the effect of shortening the carbonization time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

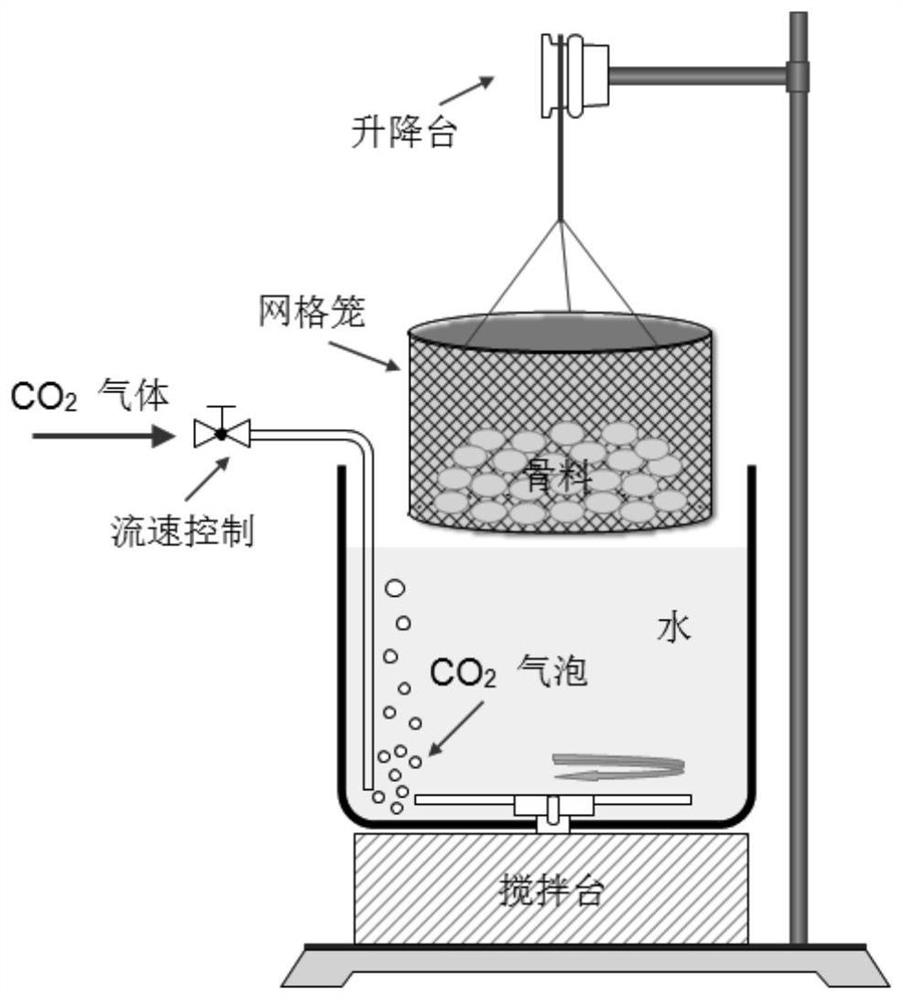

[0045] A method for open-type carbonization and strengthening recycled aggregates of waste concrete, comprising the following steps:

[0046] (1) crushing and sieving the waste concrete blocks to obtain granular waste concrete regenerated aggregates with a particle size range of 10-20 mm, and seal them for preservation;

[0047] (2) With the recycled aggregate of waste and old concrete obtained in step (1), take the recycled aggregate according to the concentration of the recycled aggregate in water of 100g / L, and put it into a mesh cage;

[0048] (3) Immerse the grid cage in step (2) in the aqueous solution, control the water temperature to 20°C, and the stirring speed to 150r / min;

[0049] (4) Pass into the industrial waste gas of chemical industry in the aqueous solution in step (3), the carbon dioxide gas concentration is 95% in this industrial waste gas, and the ventilation rate of industrial waste gas is 0.1L / min / g;

[0050] (5) Soak the recycled aggregate in step (2) i...

Embodiment 2

[0055] A method for open-type carbonization and strengthening recycled aggregates of waste concrete, comprising the following steps:

[0056] (1) crushing and sieving the waste concrete blocks to obtain granular waste concrete regenerated aggregates with a particle size range of 5-10 mm, and seal them for preservation;

[0057] (2) With the recycled aggregate of waste and old concrete obtained in step (1), take the recycled aggregate according to the concentration of the recycled aggregate in water of 50g / L, and put it into a mesh cage;

[0058] (3) Immerse the grid cage in step (2) in the aqueous solution, control the water temperature to 20°C, and the stirring speed to 100r / min;

[0059] (4) Pass into the lime kiln industrial flue gas in the aqueous solution in the step (3), the carbon dioxide gas concentration is 37%, and the ventilation rate of the industrial flue gas is 0.3L / min / g;

[0060] (5) Soak the recycled aggregate in step (2) in the aqueous solution in step (4) f...

Embodiment 3

[0063] A method for open-type carbonization and strengthening recycled aggregates of waste concrete, comprising the following steps:

[0064] (1) crushing and sieving the waste concrete blocks to obtain granular waste concrete regenerated aggregates with a particle size range of 5-10 mm, and seal them for preservation;

[0065] (2) With the recycled aggregate of waste and old concrete obtained in step (1), it is 25g / L to take the recycled aggregate according to the concentration of the recycled aggregate in water, and put it into a grid cage;

[0066] (3) Immerse the mesh cage in step (2) in the aqueous solution, control the water temperature to 20°C, and the stirring speed to 50r / min;

[0067] (4) passing cement industrial flue gas into the aqueous solution in step (3), the concentration of carbon dioxide gas is 15%, and the ventilation rate of industrial flue gas is 0.5L / min / g;

[0068] (5) Soak the recycled aggregate in step (2) in the aqueous solution in step (4) for 5 ho...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com