Plate-shaped tungsten carbide-cobalt alloy and preparation method thereof

A tungsten carbide and cobalt alloy technology, applied in the field of materials, can solve problems such as difficult control of carbon content, uneven particle size distribution of plate-shaped tungsten carbide-cobalt alloy, and restrictions on the industrial application of plate-shaped tungsten carbide-cobalt alloy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

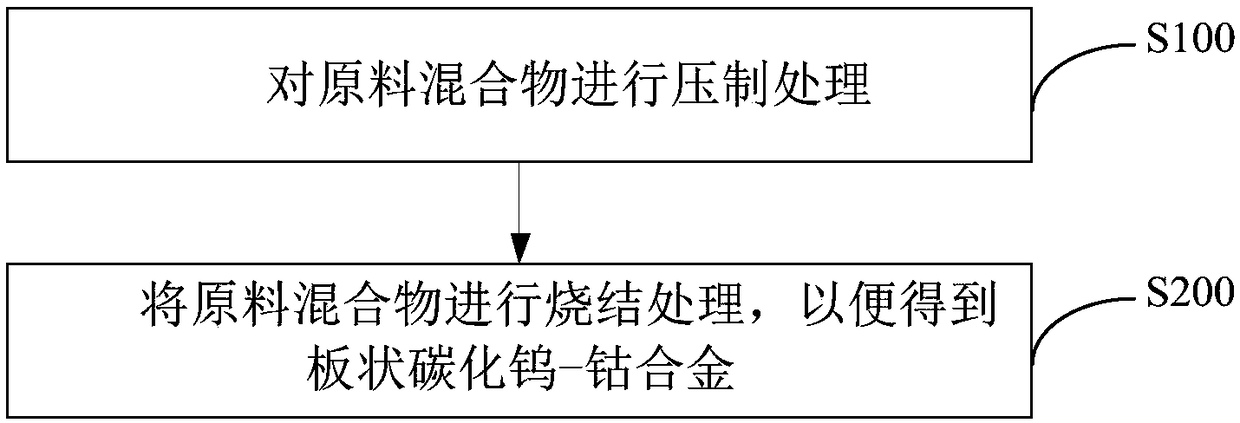

[0051] Method for preparing plate-shaped tungsten carbide-cobalt alloy

[0052] Add 100g of tungsten powder with a particle size of 5 μm into a ball milling tank for flattening treatment. Wet ball milling is used, with alcohol as the ball milling medium, the ball to particle ratio is 10:1, the ball milling speed is 250r / min, and the ball milling time is 36h. After ball milling, a vacuum drying oven was used for drying at a drying temperature of 60°C and a drying time of 8 hours.

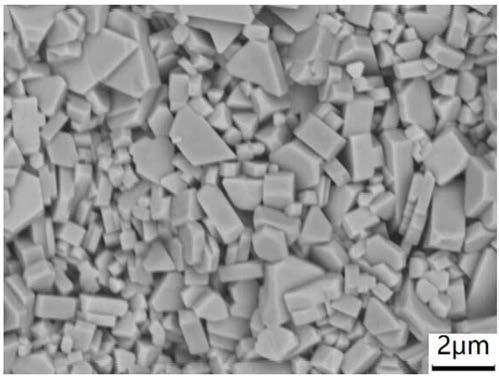

[0053] Add the flattened tungsten powder, superfine WC-Co powder, cobalt powder, carbon black and paraffin into the ball mill according to the stoichiometric ratio that the mass percentage of cobalt in the formed plate-shaped tungsten carbide-cobalt alloy is 10%. Mix in tank. Among them, the mass percentage of ultra-fine WC-Co powder is 5%, and the particle size is 0.4 μm; the particle size of cobalt powder is 0.85 μm, the particle size of carbon black is 0.3um, and the amount of carbon black added ...

Embodiment 2

[0057] Method for preparing plate-shaped tungsten carbide-cobalt alloy

[0058] Add 100g of tungsten powder with a particle size of 5 μm into a ball milling tank for flattening treatment. Wet ball milling is used, with alcohol as the ball milling medium, the ball to particle ratio is 10:1, the ball milling speed is 250r / min, and the ball milling time is 36h. After ball milling, a vacuum drying oven was used for drying at a drying temperature of 60°C and a drying time of 8 hours.

[0059] Add the flattened tungsten powder, superfine WC-Co powder, cobalt powder, carbon black and paraffin into the ball mill according to the stoichiometric ratio that the mass percentage of cobalt in the formed plate-shaped tungsten carbide-cobalt alloy is 10%. Mix in tank. Among them, the mass percentage of ultrafine WC-Co powder is 10%, and the particle size is 0.4 μm; the particle size of cobalt powder is 0.85 μm, and the particle size of carbon black is 0.3 μm, and the amount of carbon black a...

Embodiment 3

[0063] Method for preparing plate-shaped tungsten carbide-cobalt alloy

[0064] Add 100g of tungsten powder with a particle size of 5 μm into a ball milling tank for flattening treatment. Wet ball milling is used, with alcohol as the ball milling medium, the ball to particle ratio is 10:1, the ball milling speed is 250r / min, and the ball milling time is 36h. After ball milling, a vacuum drying oven was used for drying at a drying temperature of 60°C and a drying time of 8 hours.

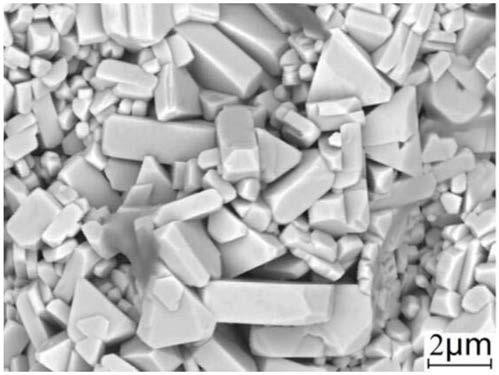

[0065] Add the flattened tungsten powder, ultrafine WC-Co powder, cobalt powder, carbon black and paraffin into the ball mill tank according to the stoichiometric ratio of 10% cobalt content in the formed plate-shaped tungsten carbide-cobalt alloy. mix. Among them, the mass percentage of ultra-fine WC-Co powder is 20%, and the particle size is 0.4 μm; the particle size of cobalt powder is 0.85 μm, and the particle size of carbon black is 0.3 μm, and the amount of carbon black added is the plate shap...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com