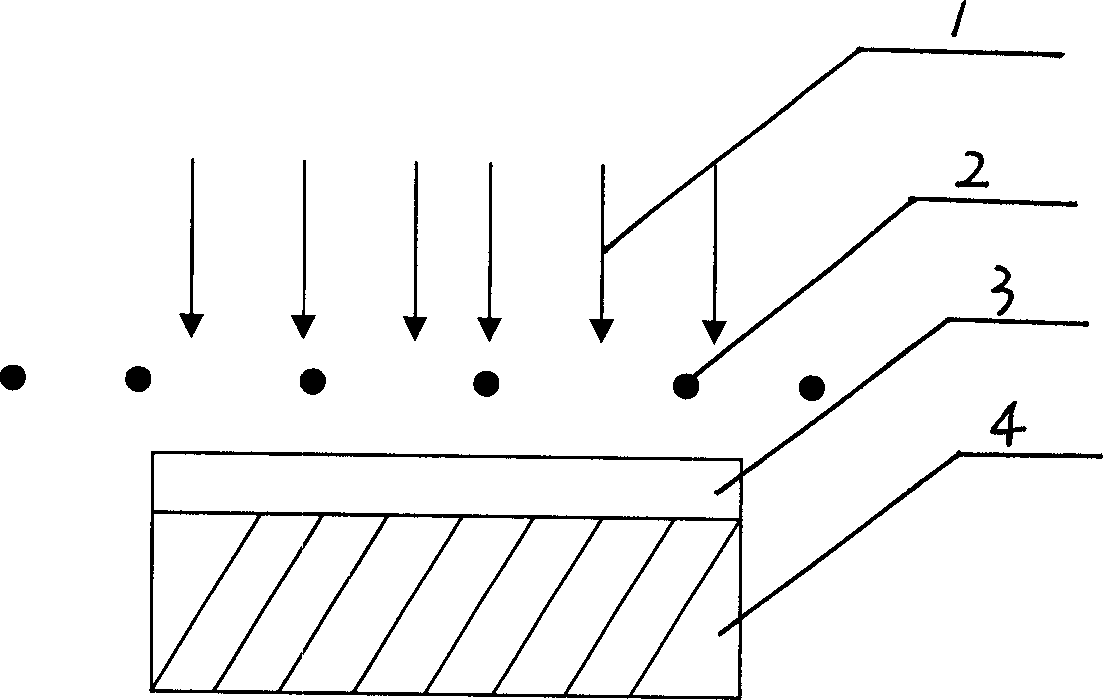

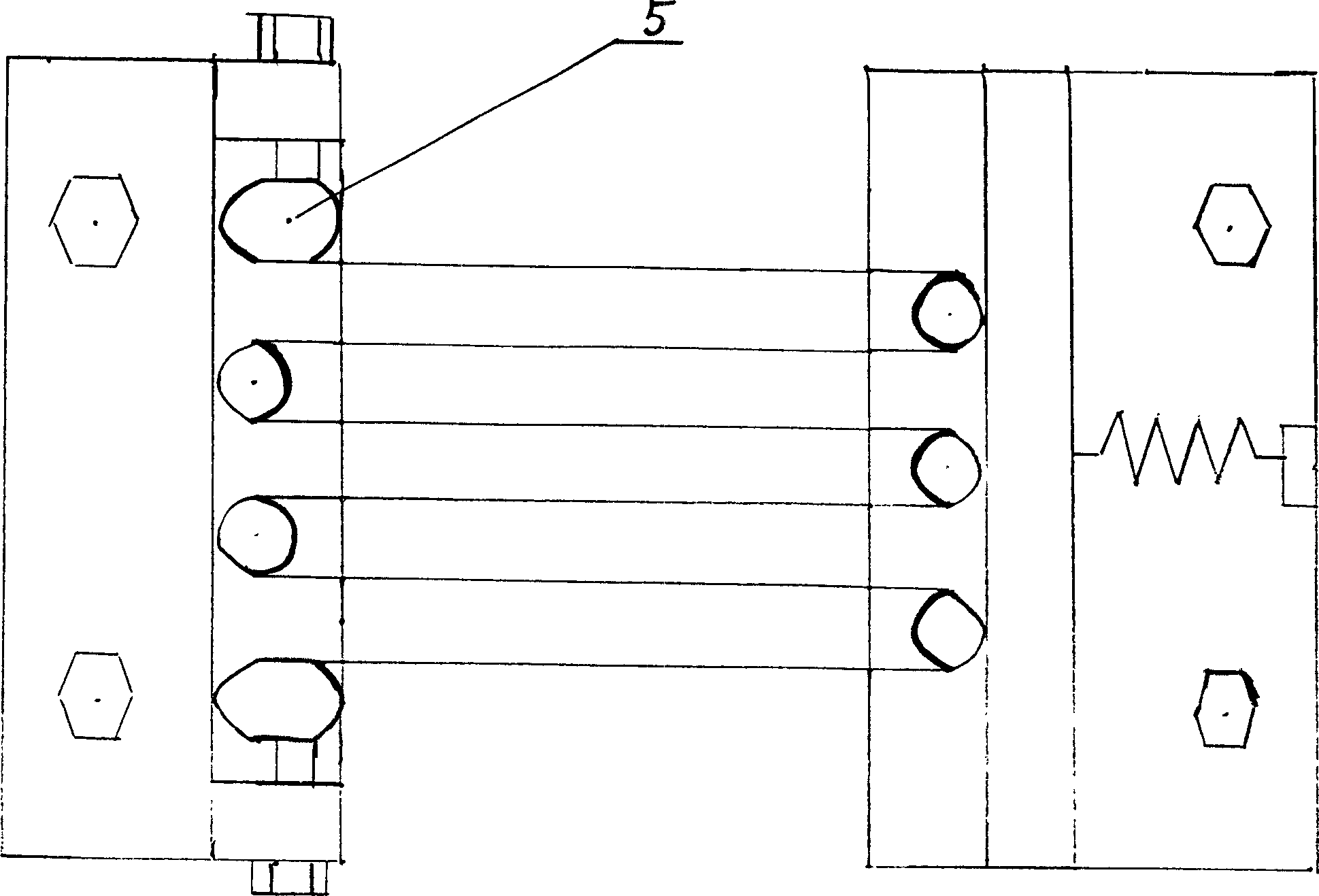

Hot wire for diamond film growth device and electrode structure thereof

A diamond film and electrode structure technology, applied in ohmic resistance electrodes, metal material coating process, ohmic resistance heating parts, etc., can solve the problem of waste of radiant energy, improve uniformity, reduce thermal blockage and thermal flow effect of phenomenon

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

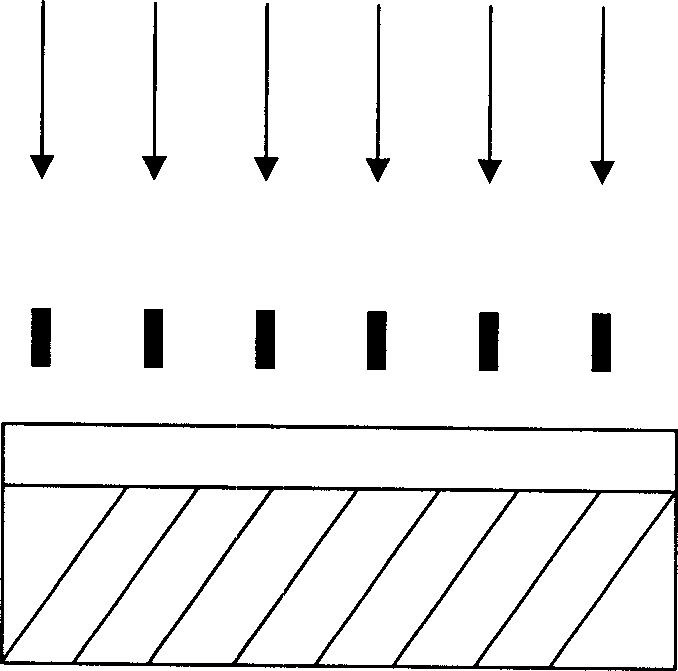

Method used

Image

Examples

Embodiment

[0020] The annealed soft Φ2mmTa wire is pressed into a section of 7×0.45mm 2 Compared with the φ2mm round wire, the flat wire has an outer surface area increased by 2.4 times. It is installed and fixed into a flat wire array. Compared with the Φ2mm round wire array, when other process parameters such as the temperature of the wire are 2400°C and the temperature of the substrate is 800 ℃, reaction pressure 35Torr, total gas flow rate 200SCCM, volume ratio CH4:H2=3:97 and other conditions are the same, the result observation shows that the nucleation density increases by three orders of magnitude up to 2×109 / cm2, the growth rate increases by 1.5 times, from 10um / hr→15um / hr, the power consumption per carat is reduced by 30%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com