Method and device for continuously preparing vanadium-nitrogen alloy

A vanadium-nitrogen alloy and equipment technology, which is applied in the field of continuous preparation of vanadium-nitrogen alloy, can solve the problems of difficulty in improving production efficiency, high output and high cost, and achieve the effects of improved production efficiency, short production process and fast maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

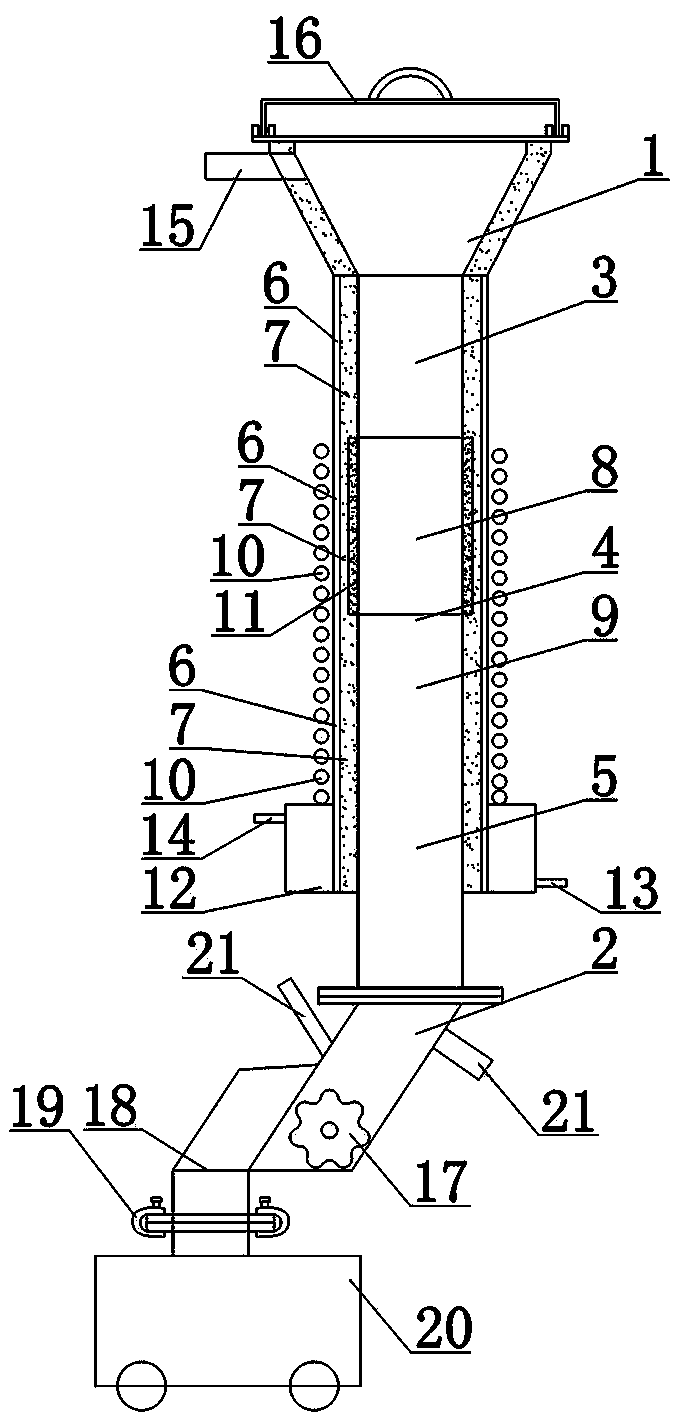

Image

Examples

Embodiment 1

[0031] A method for continuously preparing vanadium-nitrogen alloys, comprising the following steps:

[0032] S1, ingredients: take the following raw materials by weight, set aside:

[0033] Vanadium pentoxide powder 100;

[0035] Nitriding accelerator 5;

[0036] Sodium silicate aqueous solution 10;

[0037] Iron powder 1.5;

[0038] Described nitriding accelerator is urea, and the concentration of described sodium silicate aqueous solution is 15%;

[0039] S2. Mixing and billet making: Put the above raw materials into a blender and mix them evenly, then put them into a pair of roller compaction equipment, press the materials into a flat spherical shape, place them in a ventilated place to dry naturally for three days, and dry until the flat spherical materials contain The water content is less than 6%;

[0040] S3. Feeding: put the oblate material with a moisture content of less than 6% in the hopper, and use the lifting device to transport...

Embodiment 2

[0047] A method for continuously preparing vanadium-nitrogen alloys, comprising the following steps:

[0048] S1, ingredients: take the following raw materials by weight, set aside:

[0049] Vanadium pentoxide powder 100;

[0050] graphite powder 25;

[0051] Nitriding accelerator 4;

[0052] Sodium silicate aqueous solution 12;

[0053] iron powder 1;

[0054] Described nitriding accelerator is melamine, and the concentration of described sodium silicate aqueous solution is 18%;

[0055] S2. Mixing and billet making: Put the above raw materials into a blender and mix them evenly, then put them into a pair of roller compaction equipment, press the materials into a flat spherical shape, place them in a ventilated place to dry naturally for three days, and dry until the flat spherical materials contain The water content is less than 6%;

[0056] S3. Feeding: put the oblate material with a moisture content of less than 6% in the hopper, and use the lifting device to transpo...

Embodiment 3

[0063] A method for continuously preparing vanadium-nitrogen alloys, comprising the following steps:

[0064] S1, ingredients: take the following raw materials by weight, set aside:

[0065] Vanadium pentoxide powder 100;

[0066] graphite powder 35;

[0067] Nitriding accelerator 6;

[0068] Sodium silicate aqueous solution 8;

[0069] iron powder 2;

[0070] The nitriding accelerator is a mixture of urea and melamine, and the weight ratio between the two can be any value; the concentration of the sodium silicate aqueous solution is 20%;

[0071] S2. Mixing and billet making: Put the above raw materials into a blender and mix them evenly, then put them into a pair of roller compaction equipment, press the materials into a flat spherical shape, place them in a ventilated place to dry naturally for three days, and dry until the flat spherical materials contain The water content is less than 6%;

[0072] S3. Feeding: put the oblate material with a moisture content of less ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com