Patents

Literature

138results about How to "Save maintenance time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

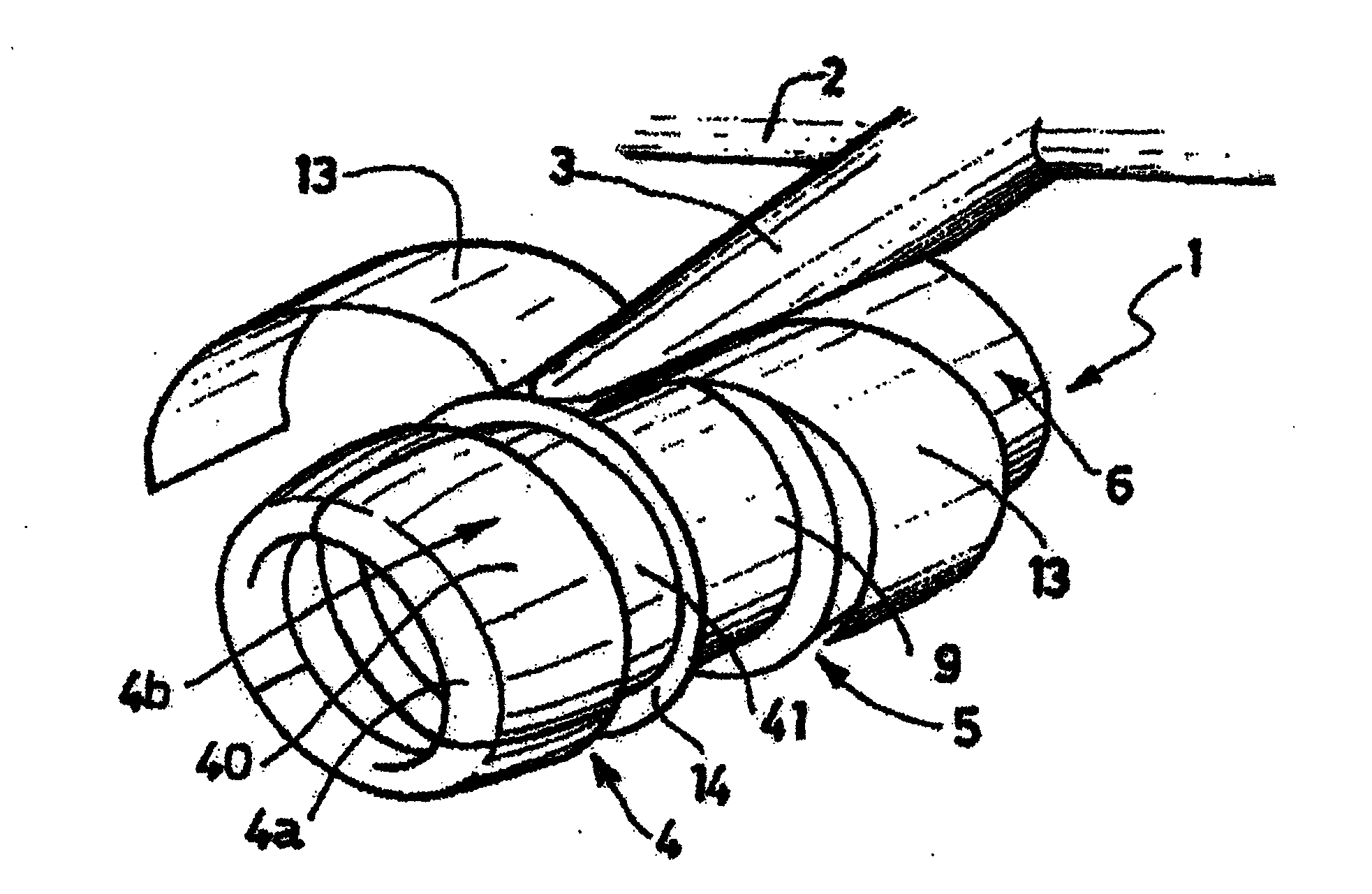

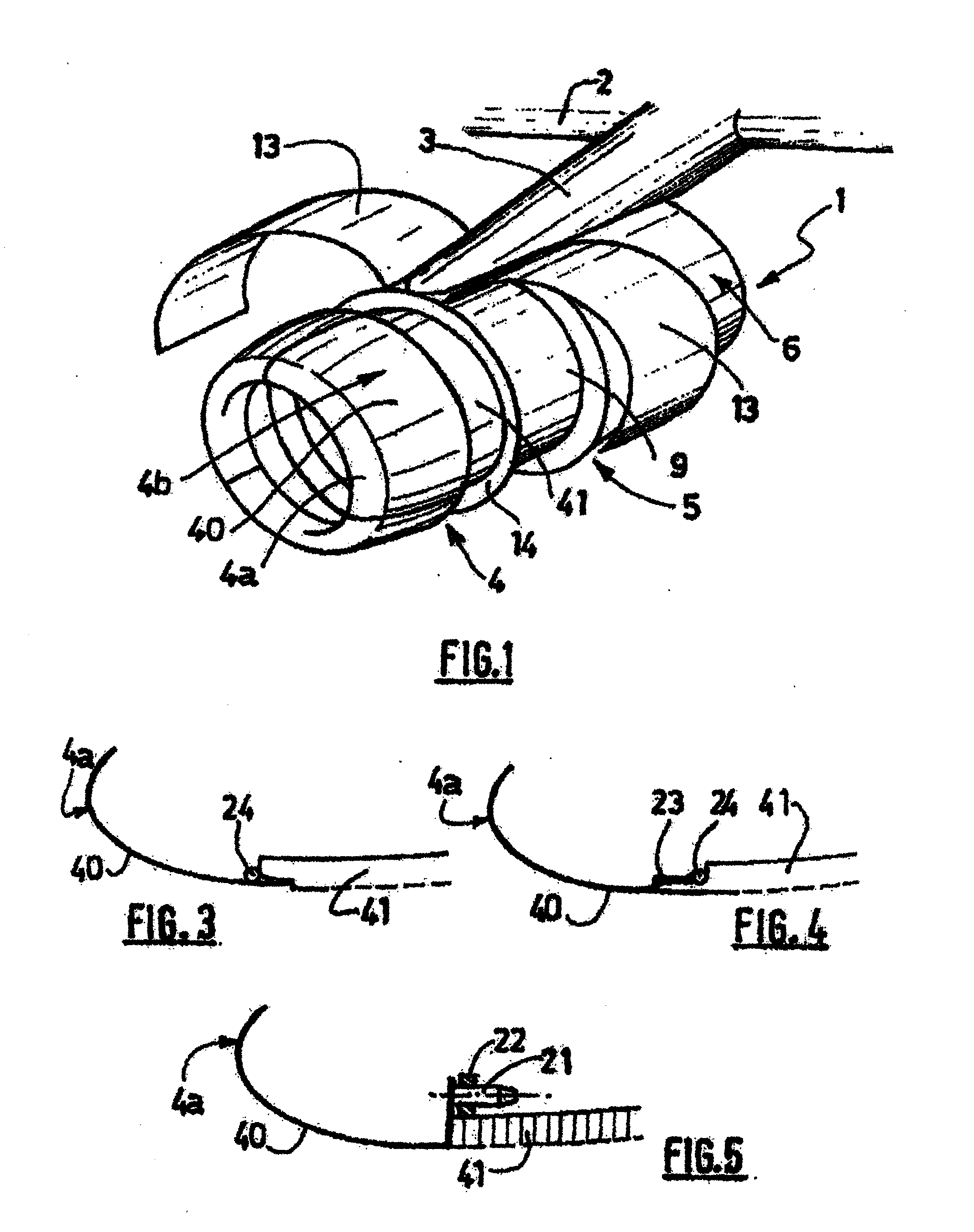

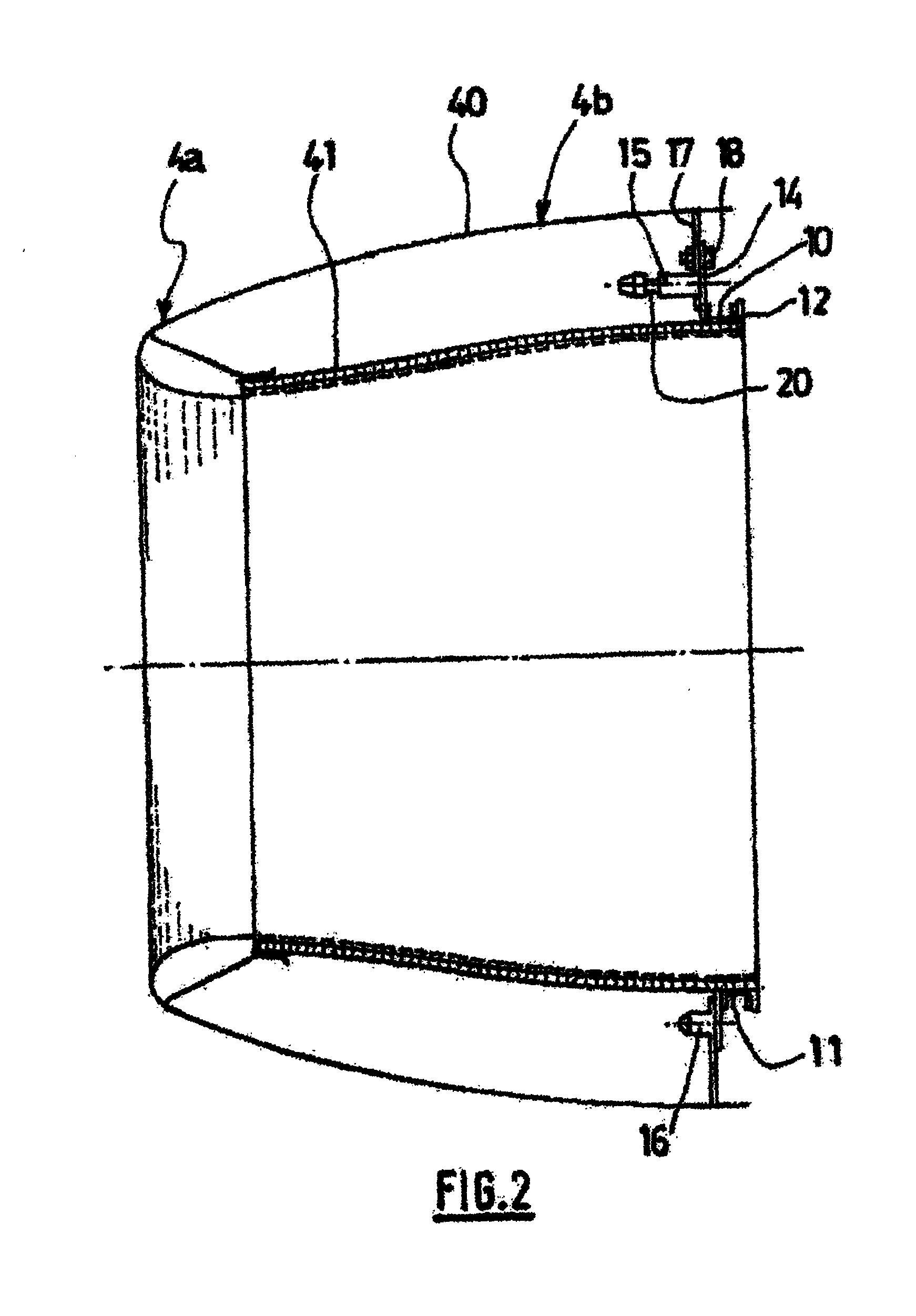

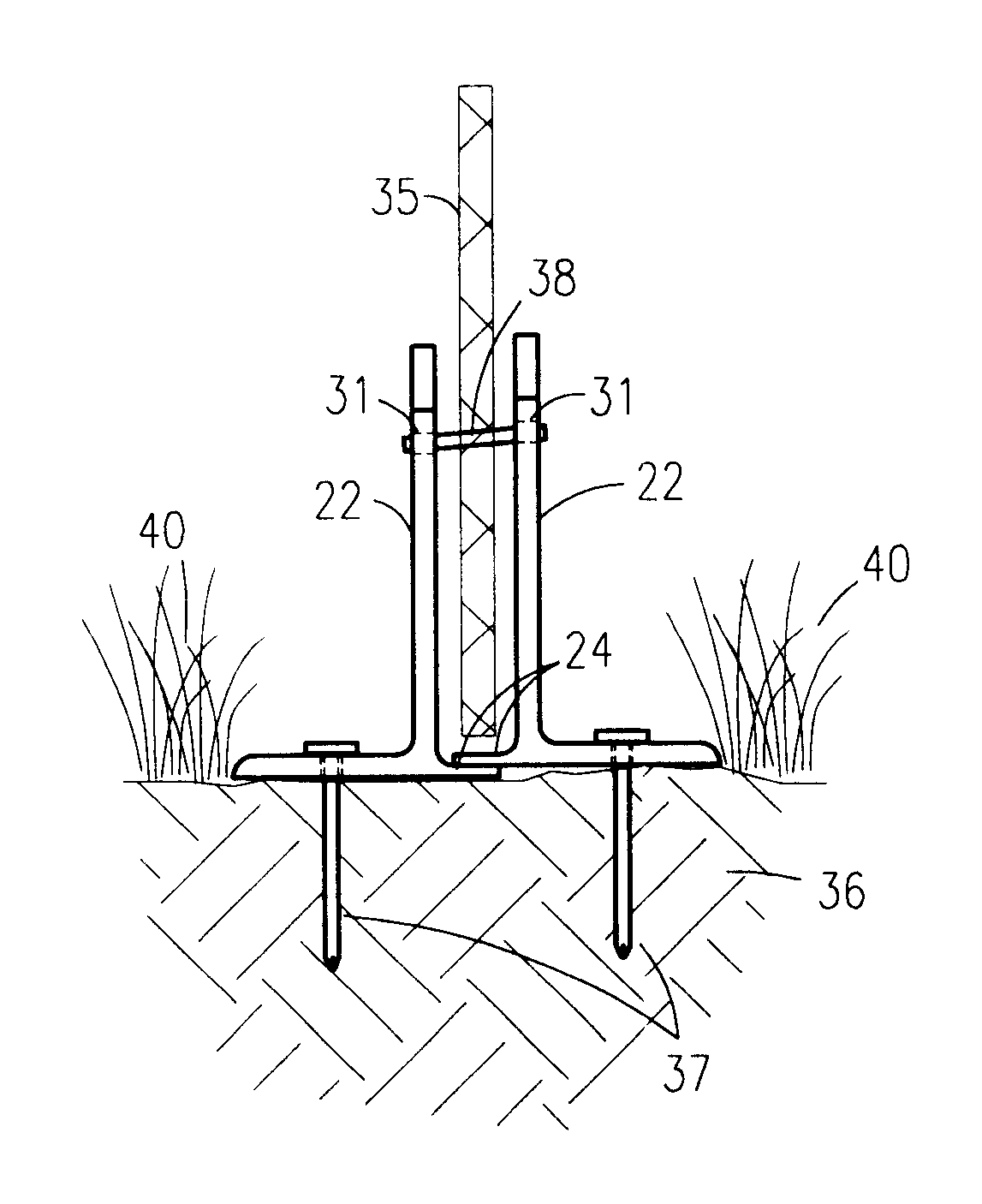

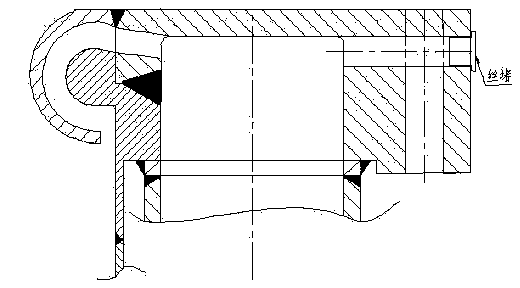

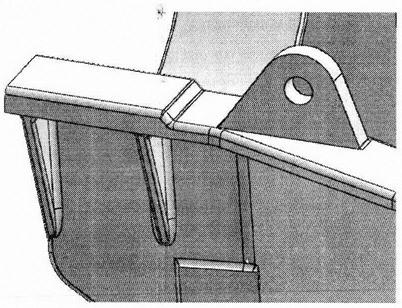

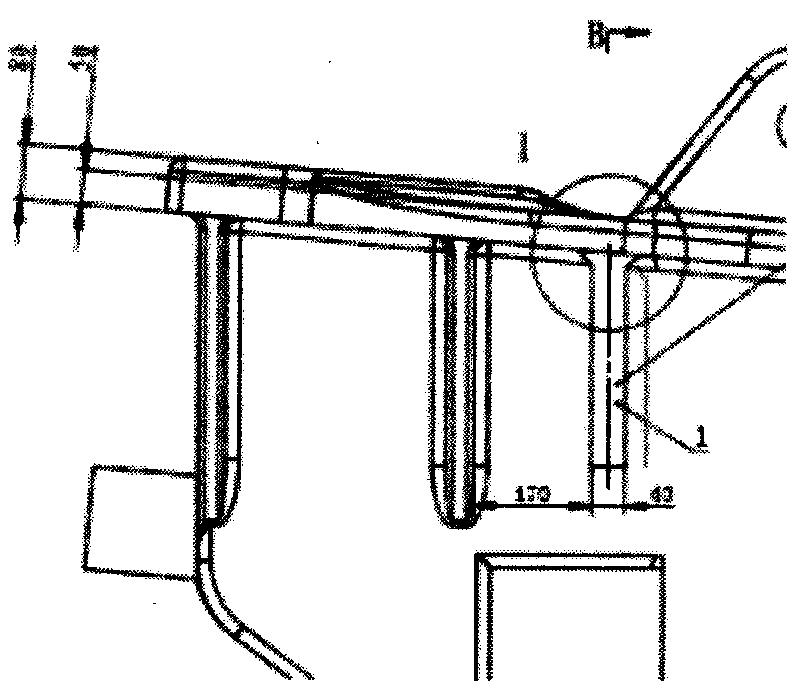

Removable air intake structure for turbojet engine nacelle

ActiveUS20100084507A1Improve outer aerodynamic lineEasy to disassemblePower plant inspection panelsEfficient propulsion technologiesNacelleTurbojet engine

The present invention relates to a nacelle (1) for a turbojet engine comprising an air intake structure (4) capable of ducting a flow of air towards a fan and a central structure (5) intended to surround the said fan and to which the air intake structure is attached, the central structure comprising a casing (9) intended to surround the fan and an external structure (13), characterized in that the air intake structure comprises, on the one hand, at least one internal panel (41) attached to the central structure via the casing and therewith forming a fixed structure and, on the other hand, at least one longitudinal external panel (40) attached removably to the fixed structure and incorporating an air intake lip (4a), the said external panel being removable between an operating position in which the external panel is aerodynamically continuous with the external structure of the central section and the air intake lip provides aerodynamic continuity with the internal panel of the air intake structure, and a maintenance position in which the external panel is separated from the external structure of the central section and the air intake lip is separated from the internal panel of the air intake structure.

Owner:SAFRAN NACELLES

Mineral separation process of magnetic iron ore

ActiveCN101480632AReduce energy consumptionFine Concentrate SizeSievingScreeningMagnetiteMaterials science

The invention discloses a beneficiation method for a pure magnetic iron ore. A crude ore is sequentially treated according to the steps such as first crushing, first-stage dry-type magnetic dressing, medium crushing, second-stage dry-type magnetic dressing, fine crushing and third-stage dry-type magnetic dressing, fine ore is obtained after a great amount of gangues are thrown by the third-stage dry-type magnetic dressing and sent to a grinding head sieve to be griddled and separated, granules griddled by the grinding head sieve are treated in a first-section magnetic dressing process, rough ore griddled by the grinding head sieve is treated in a first-section ball grinding and then enters the first-section magnetic dressing process; ore aggregates obtained from the first-section magnetic dressing process are treated in a second-section ball grinding after discharging gangue sands till the granularity of ore powder is -200meshes being more than or equal to 60 percent, ore powder generated from the second-section ball grinder are treated in second-section magnetic dressing, ore aggregates generated from the second-section magnetic dressing are treated in a high-frequency sieve after discharging gangue sands, products positioned on the high-frequency sieve are filtered to obtain ore concentrate, and products positioned below the high-frequency sieve are treated with desliming and then treated with floatation. The invention adopts two sections of grinding ore open-way processes and distinguishes the ore aggregates during the ore dressing process, thereby greatly reducing the energy consumption of a system, lowering the production cost and enhancing the utility ratio of equipment.

Owner:安徽大昌矿业集团有限公司

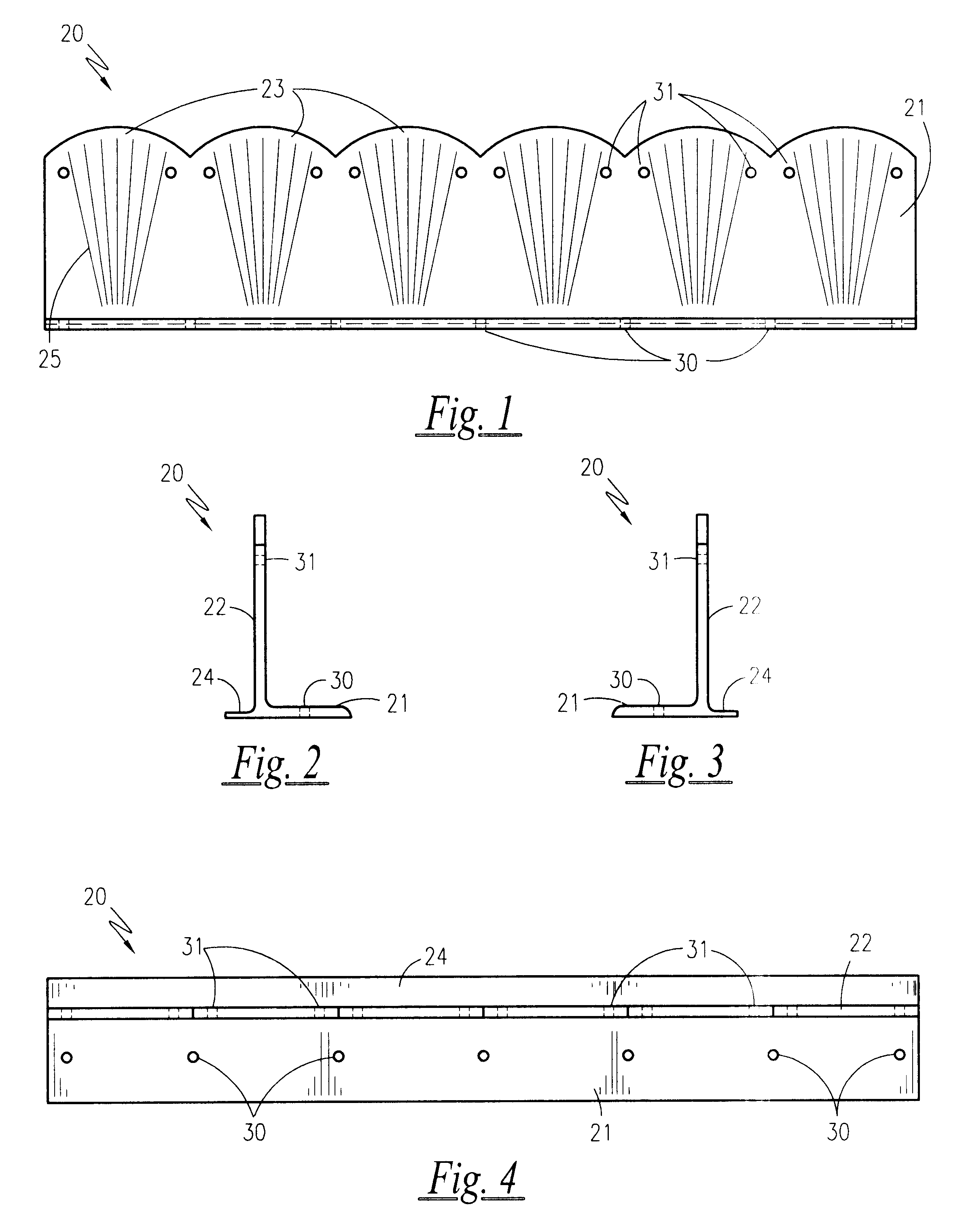

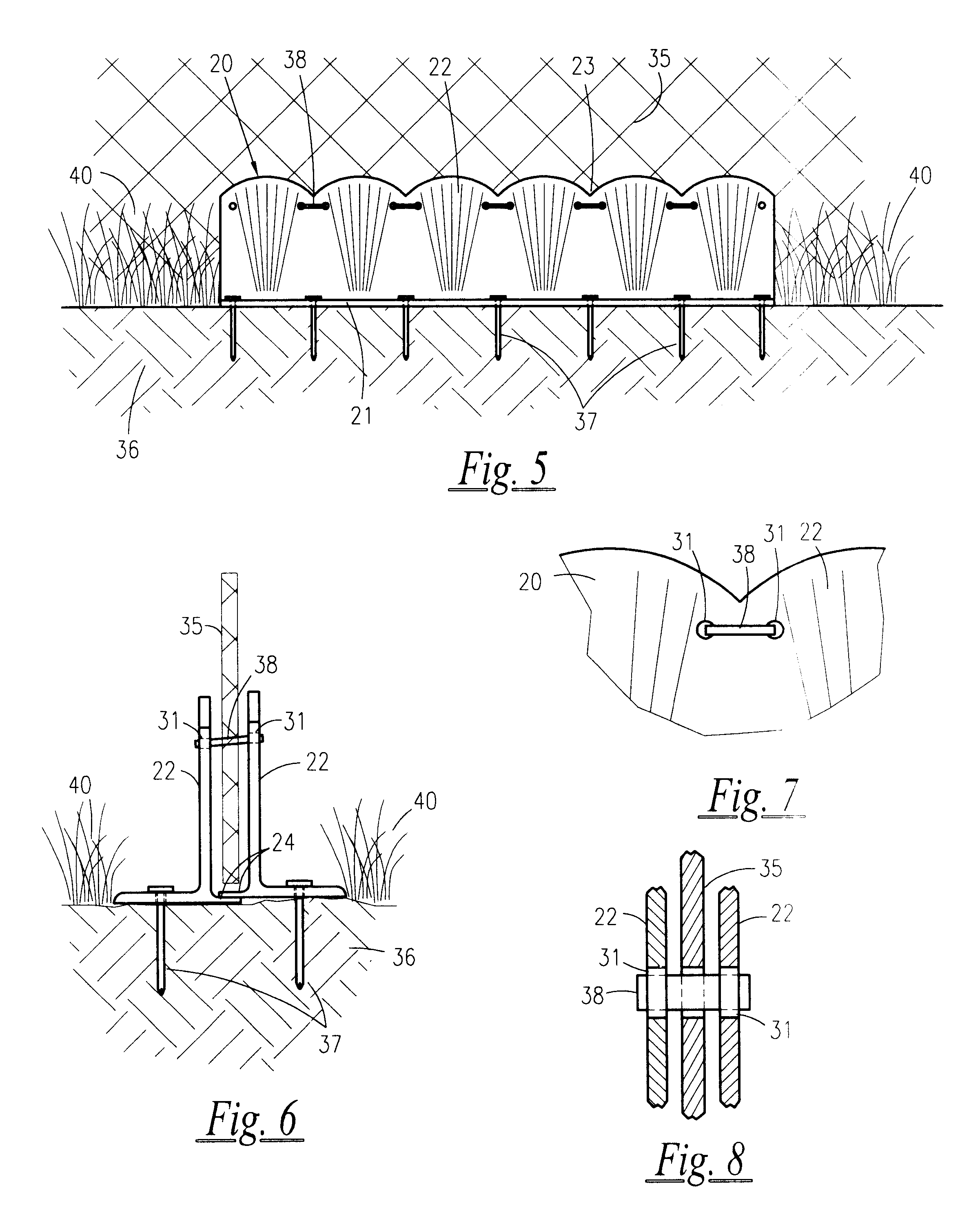

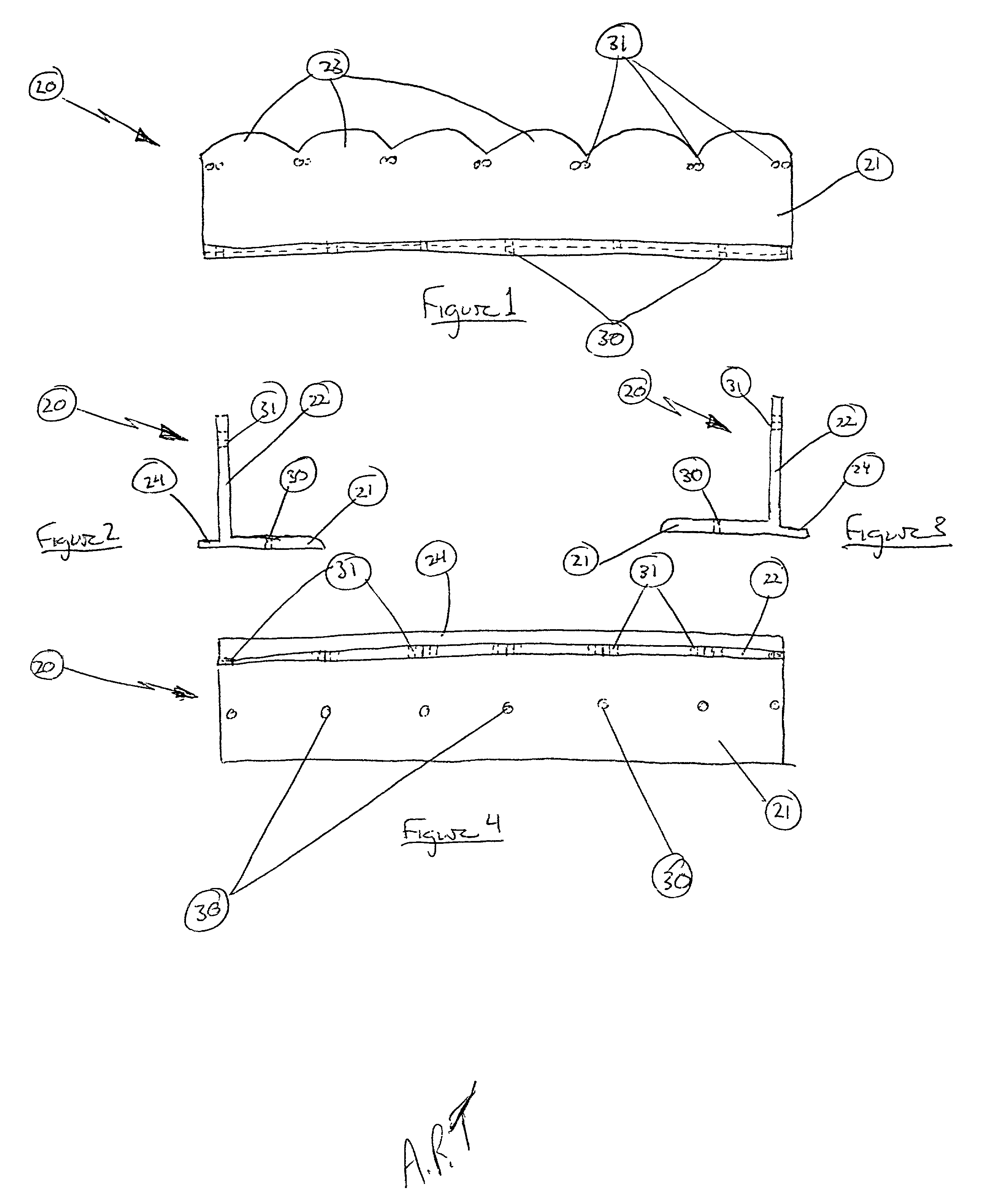

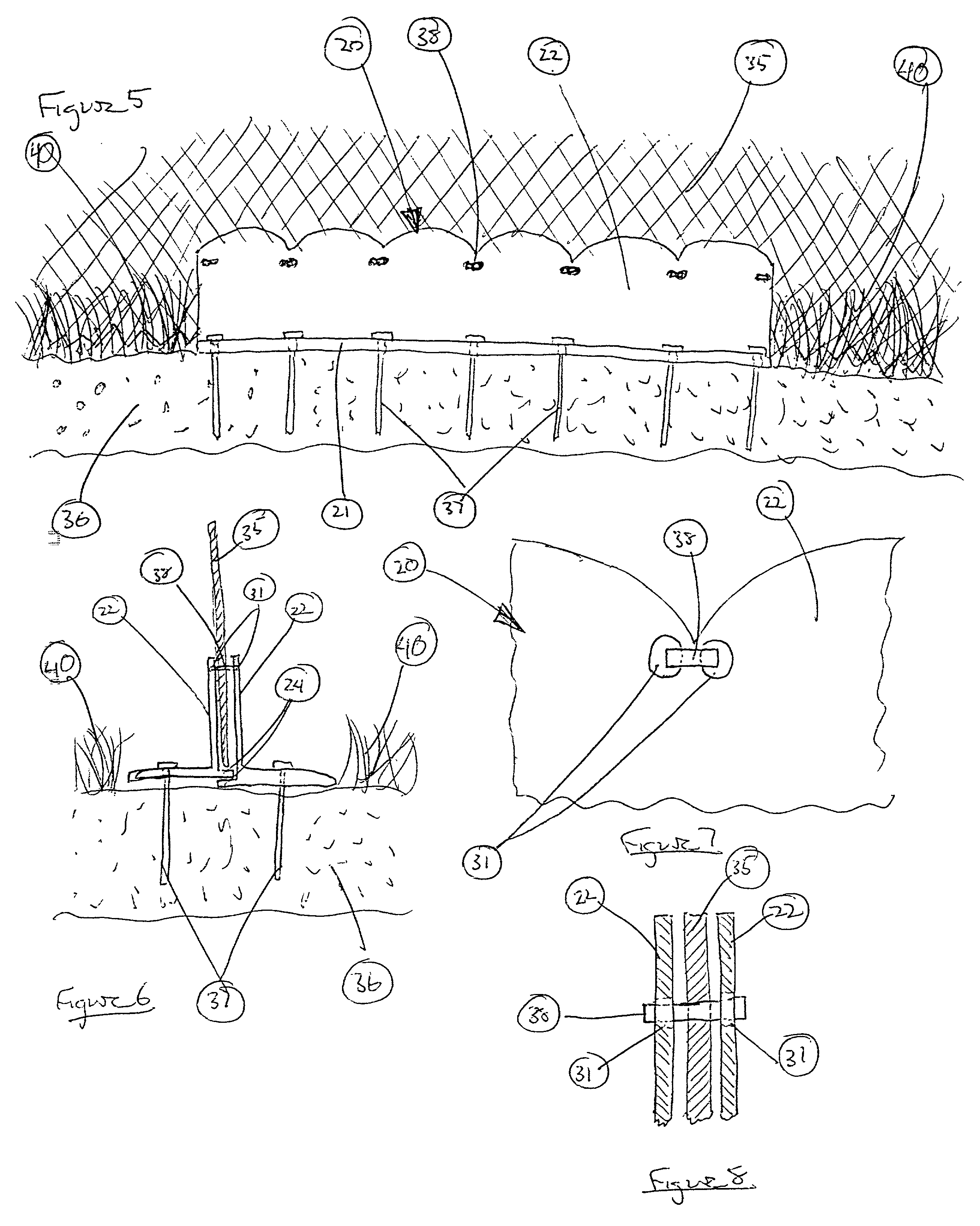

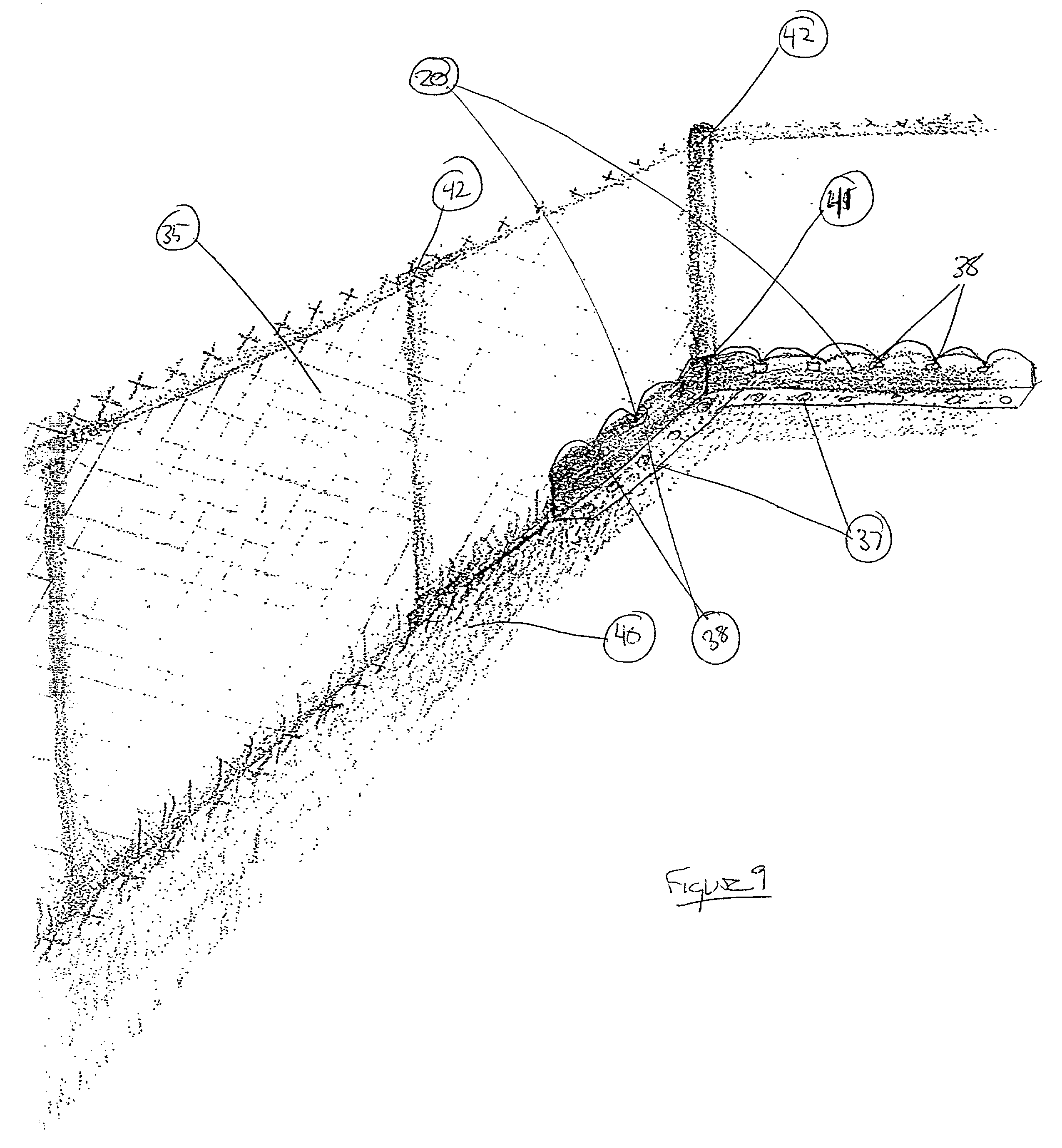

Fence guard

Disclosed is a covering designed to be attached to and along the bottom portion of chain-linked and other similar types of fencing in order to prevent grass and weeds from growing between the links. Produced in varying lengths from a rubber or plastic type material, the covering has an L-shaped profile that allows it to be placed along the bottom edge of the fencing resting on the ground and against the fence. The mowing strip portion of the L-shape guard that rests upon the ground extends out horizontally from the bottom of the fence serves a shield that will prevent plant growth along the fence line.

Owner:THOMPSON ALLEN R +1

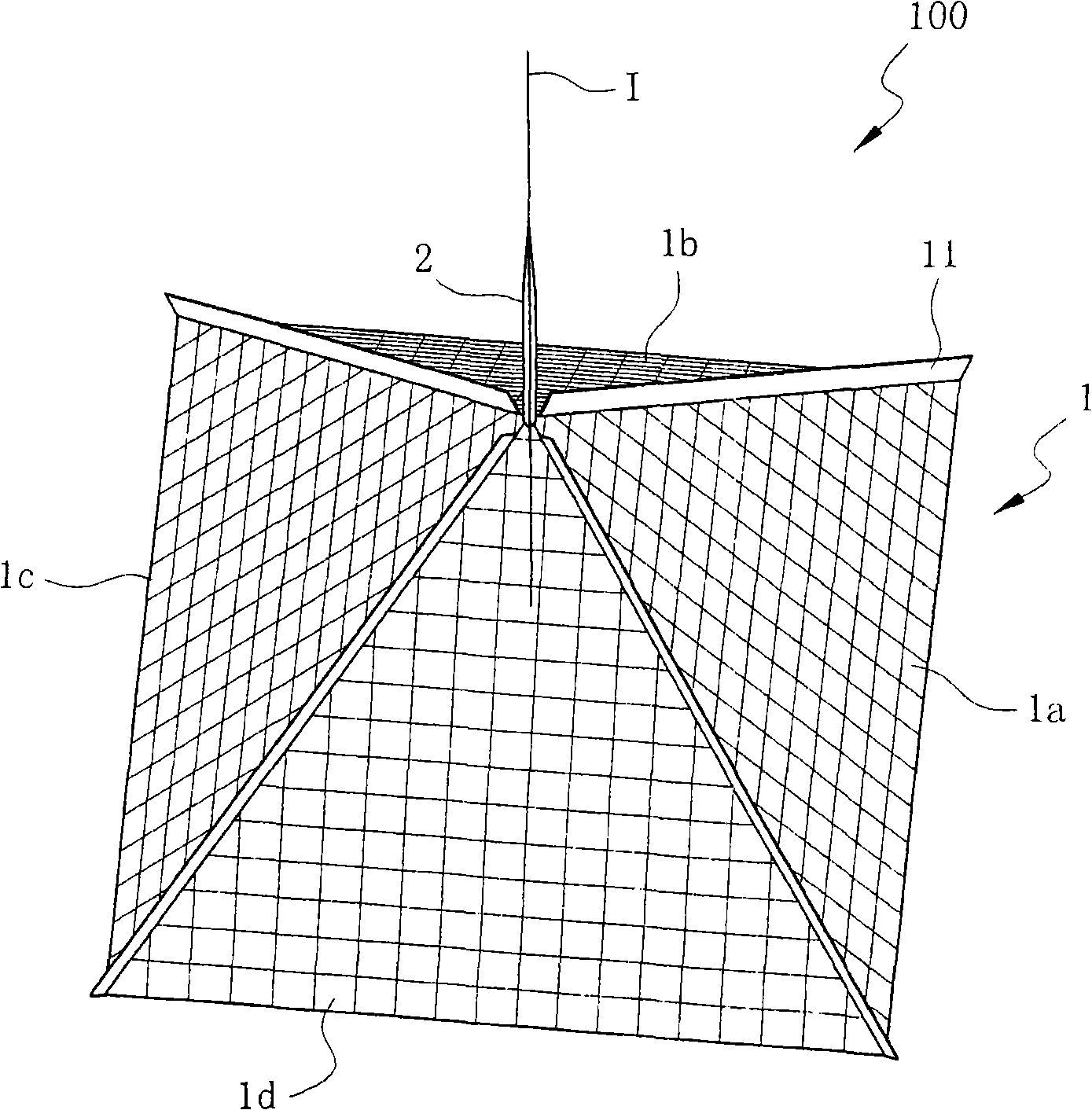

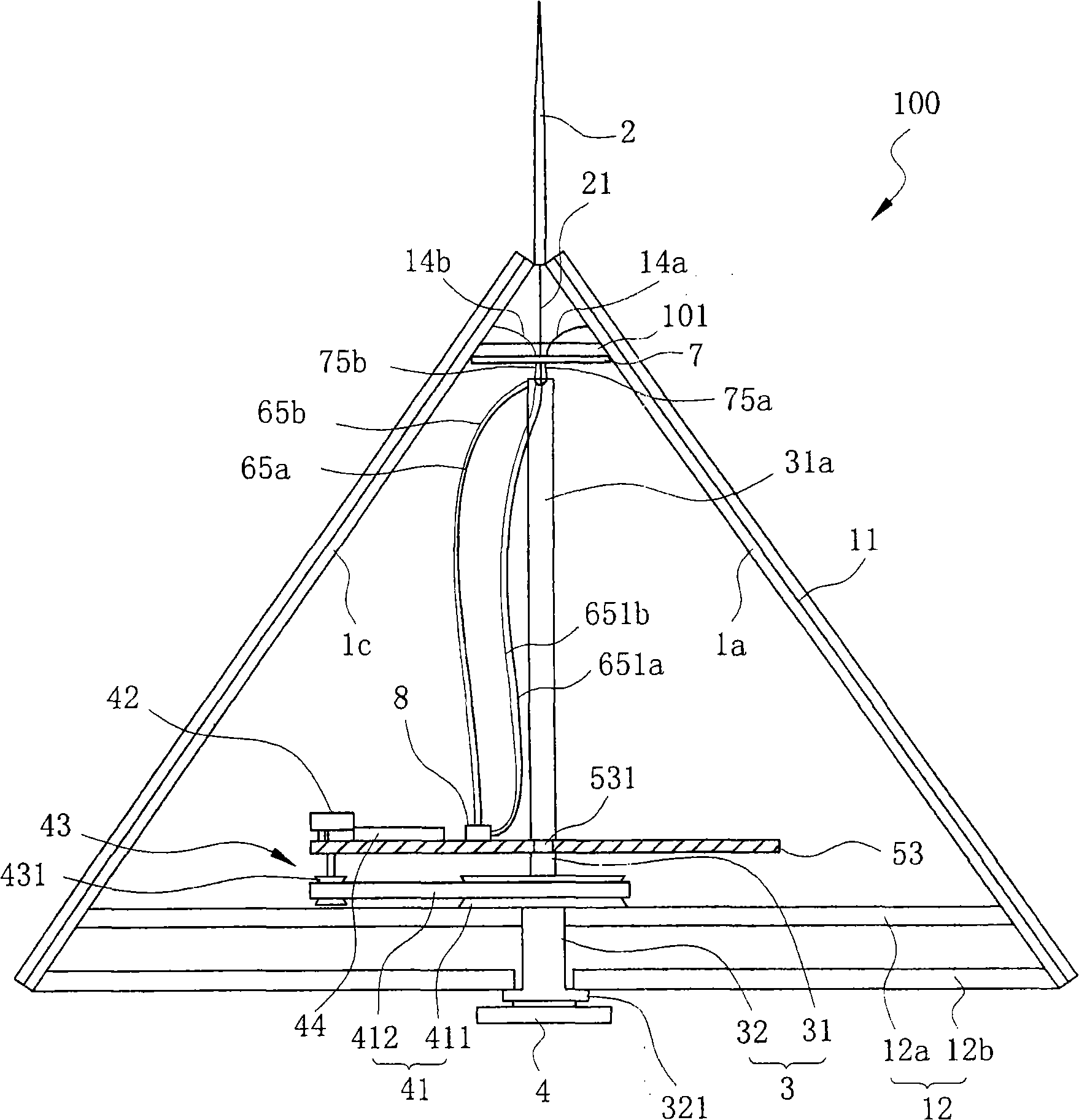

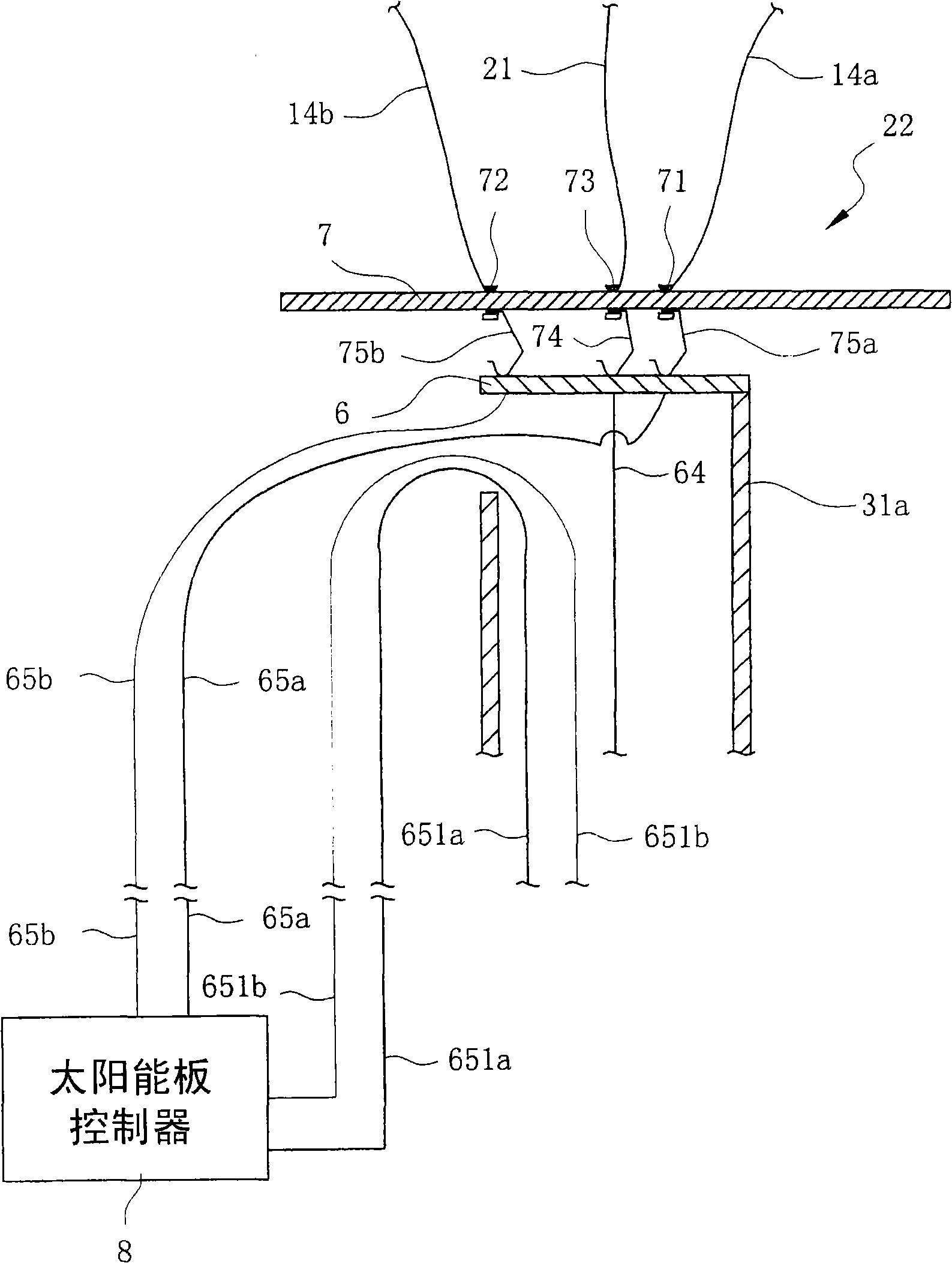

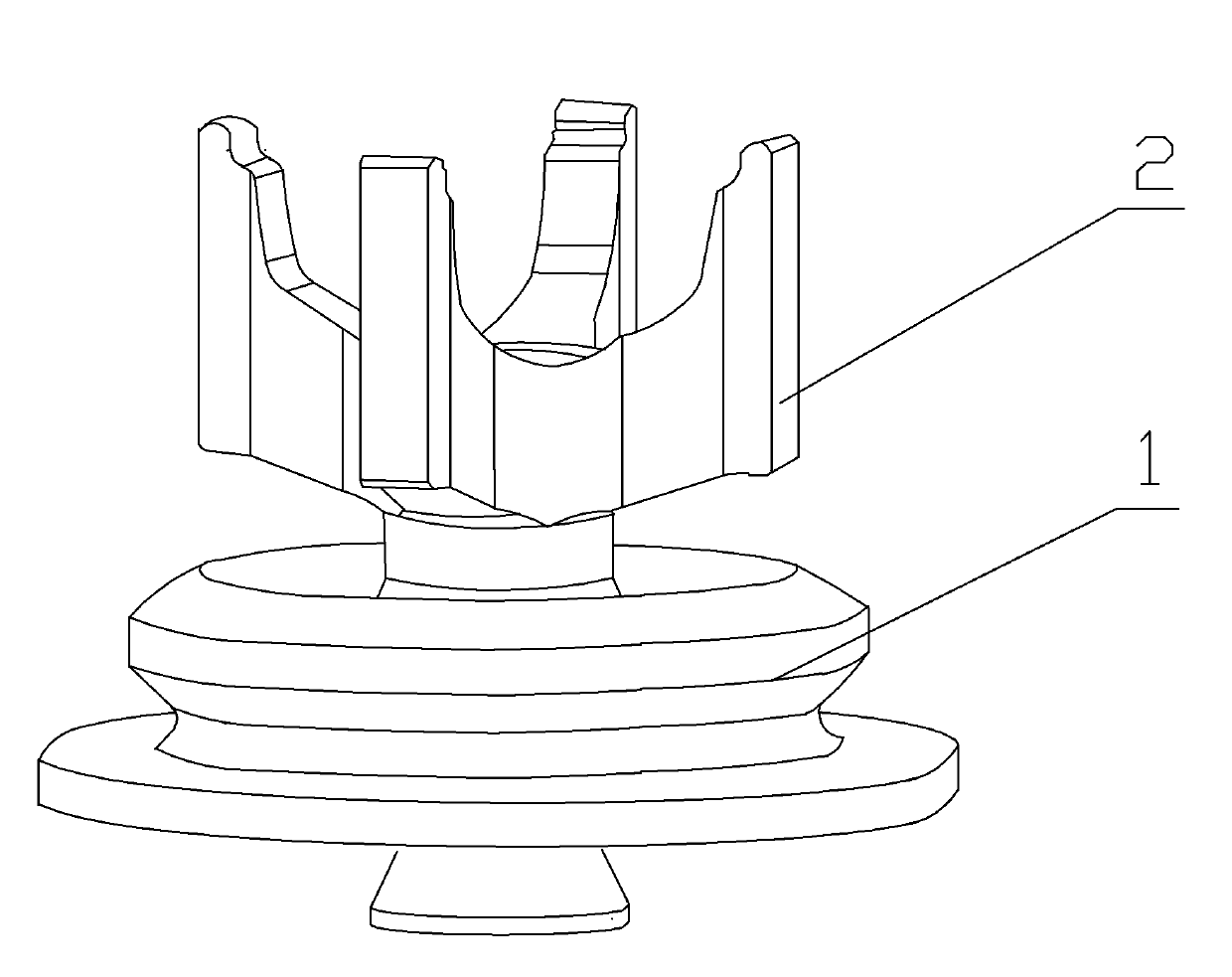

Cone-shaped solar energy power supply device

InactiveCN101515605ASave cost and maintenance timeSave maintenance timePhotovoltaic supportsPhotovoltaic energy generationAerospace engineeringDevice form

The invention discloses a cone-shaped solar energy power supply device, which comprises a solar energy power supply device formed by at least three solar panels. Each two solar panels are arranged adjacently at a certain inclination angle by taking a central axis as a center and all solar panels thus arranged form a cone-shaped solar panel group. Wings with a preset length extend outward between adjacent side edges of each solar panel to allow the cone-shaped solar panel group to rotate under the action of wind.

Owner:杨良智 +1

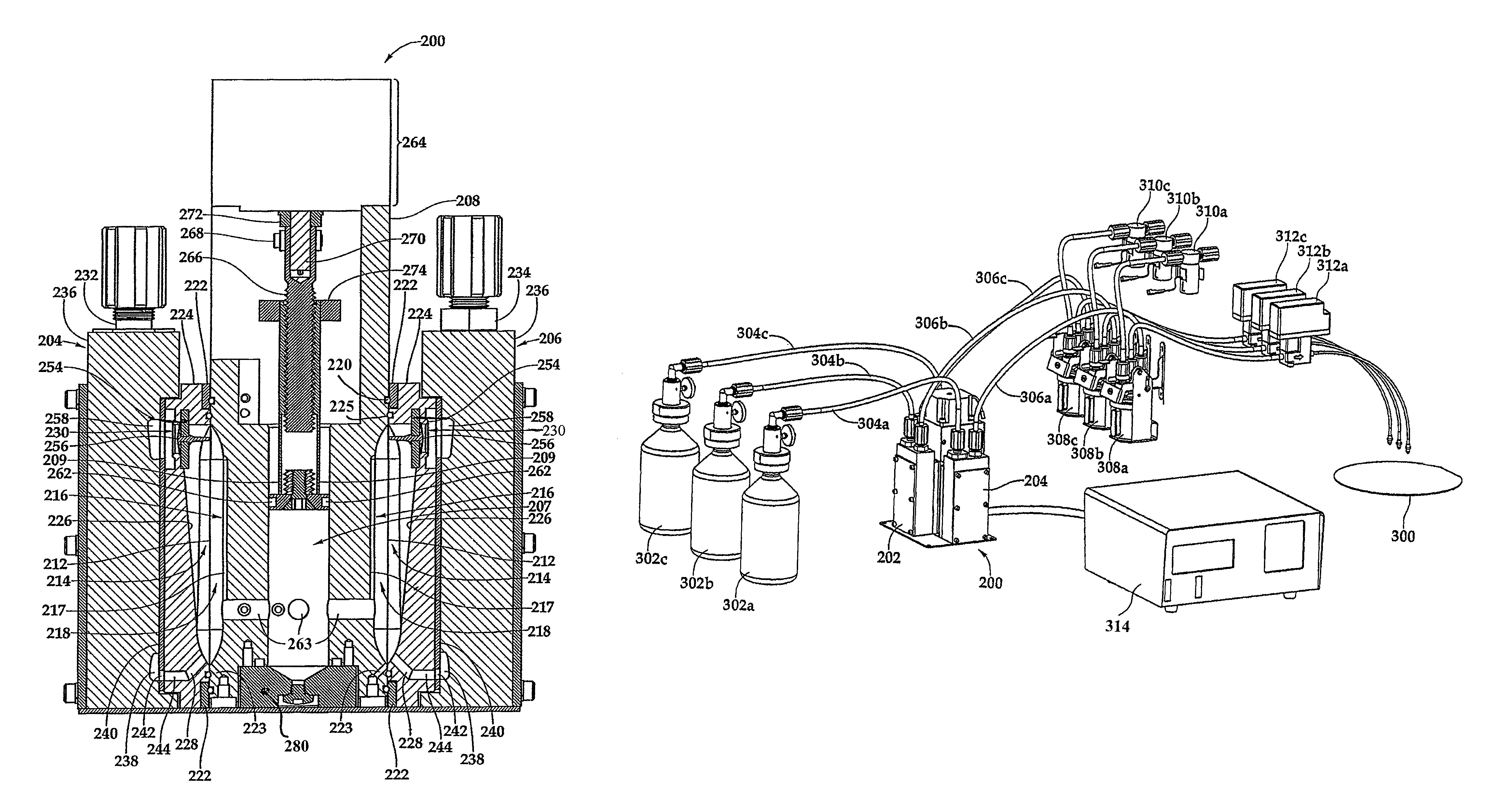

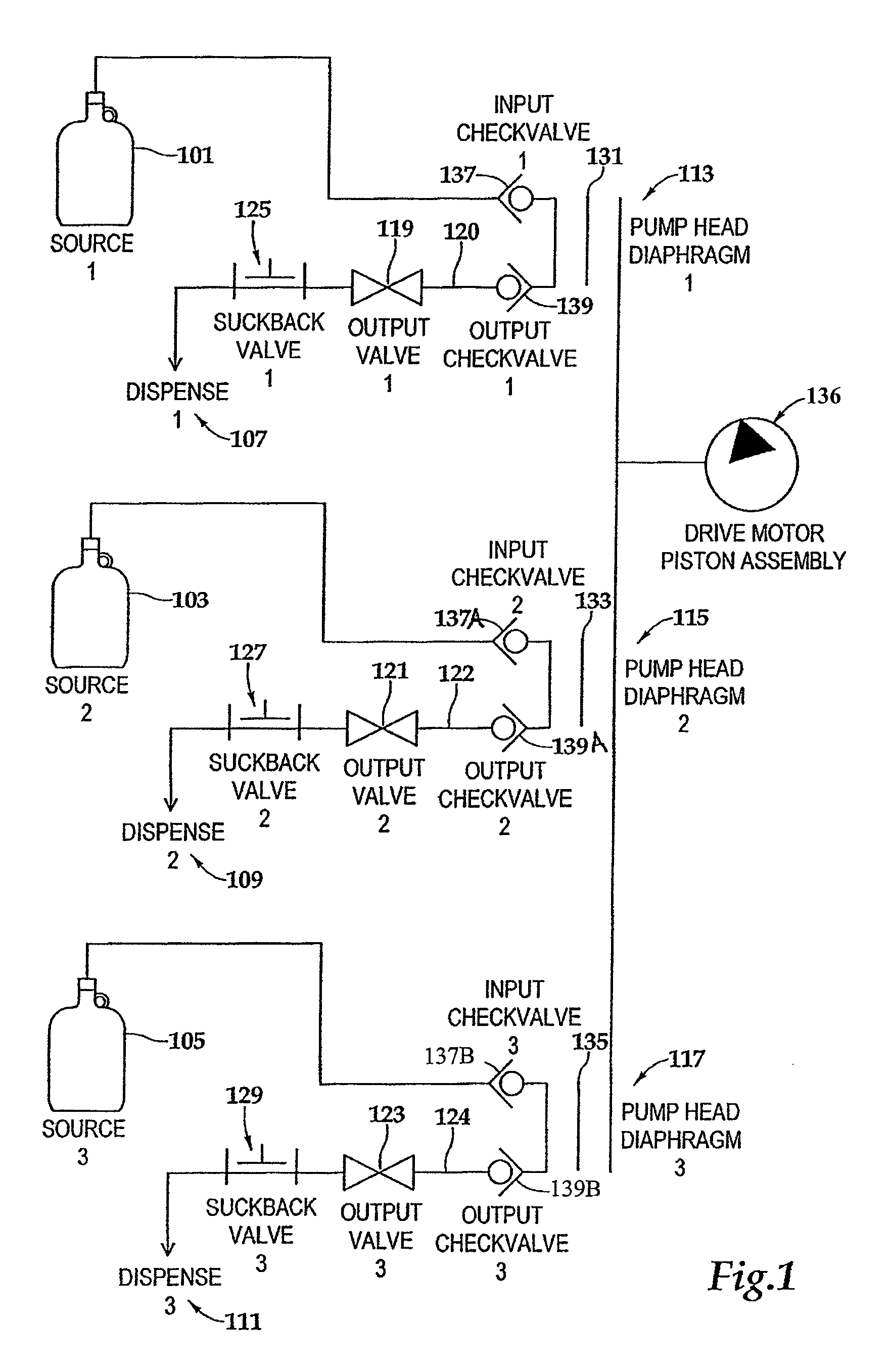

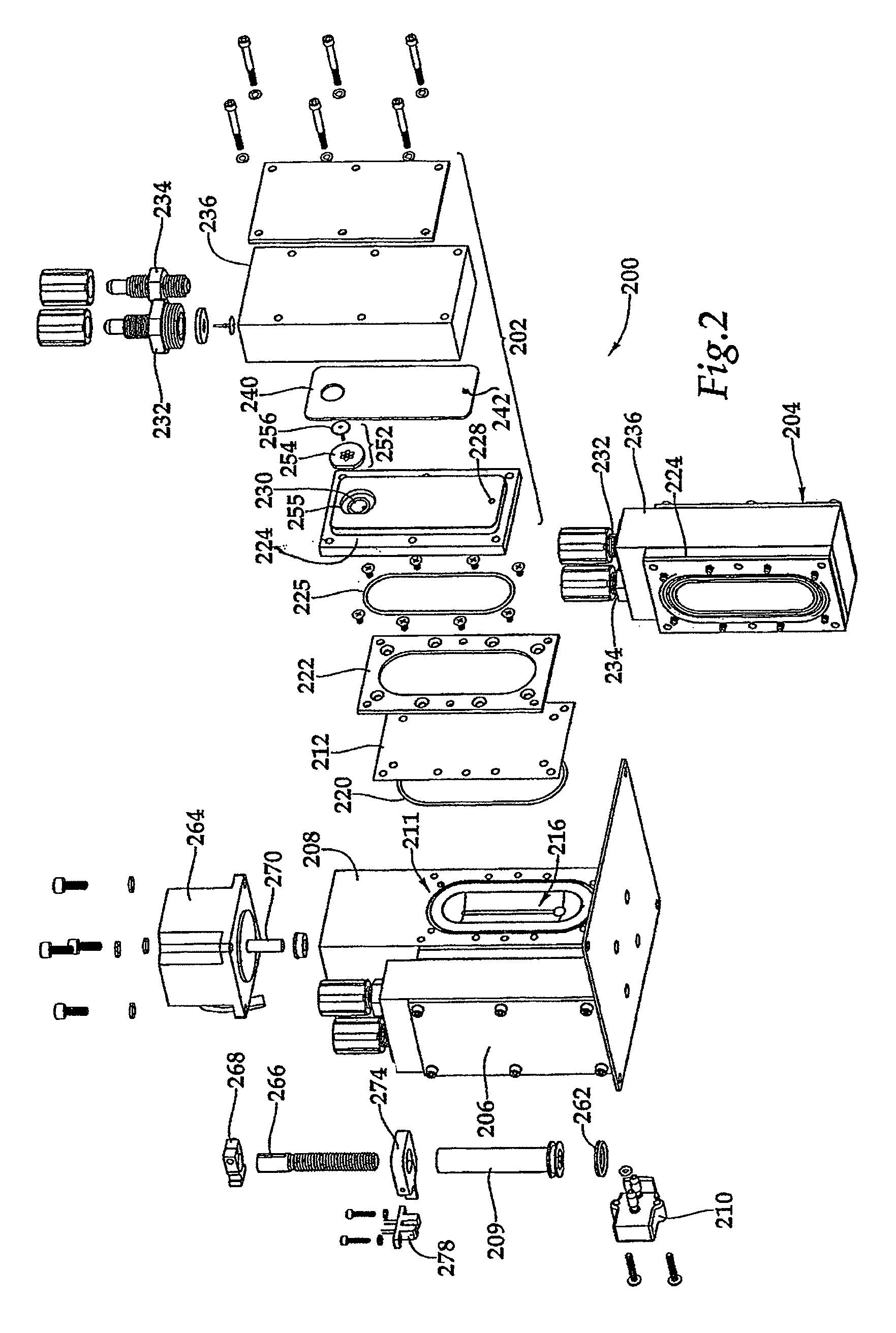

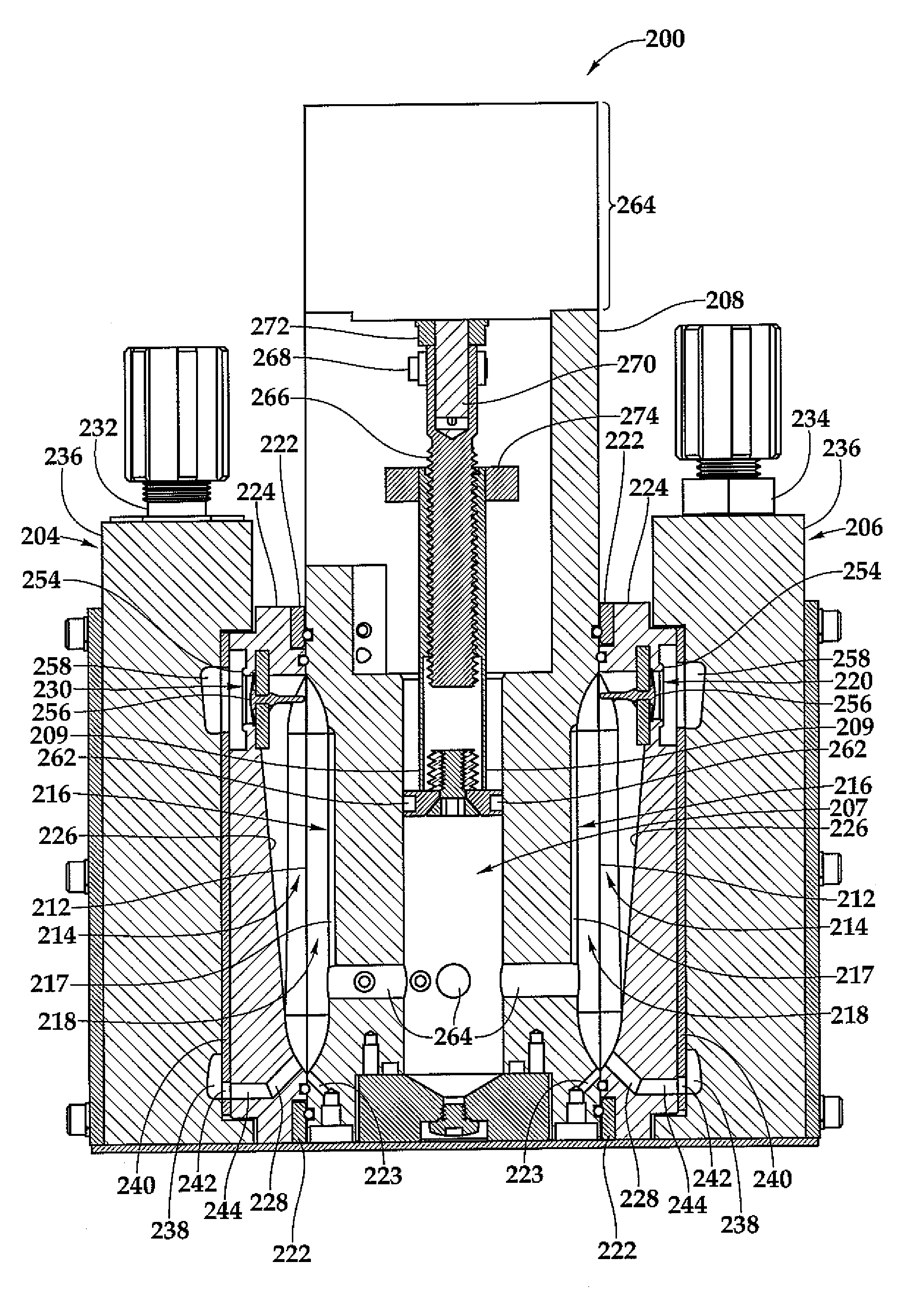

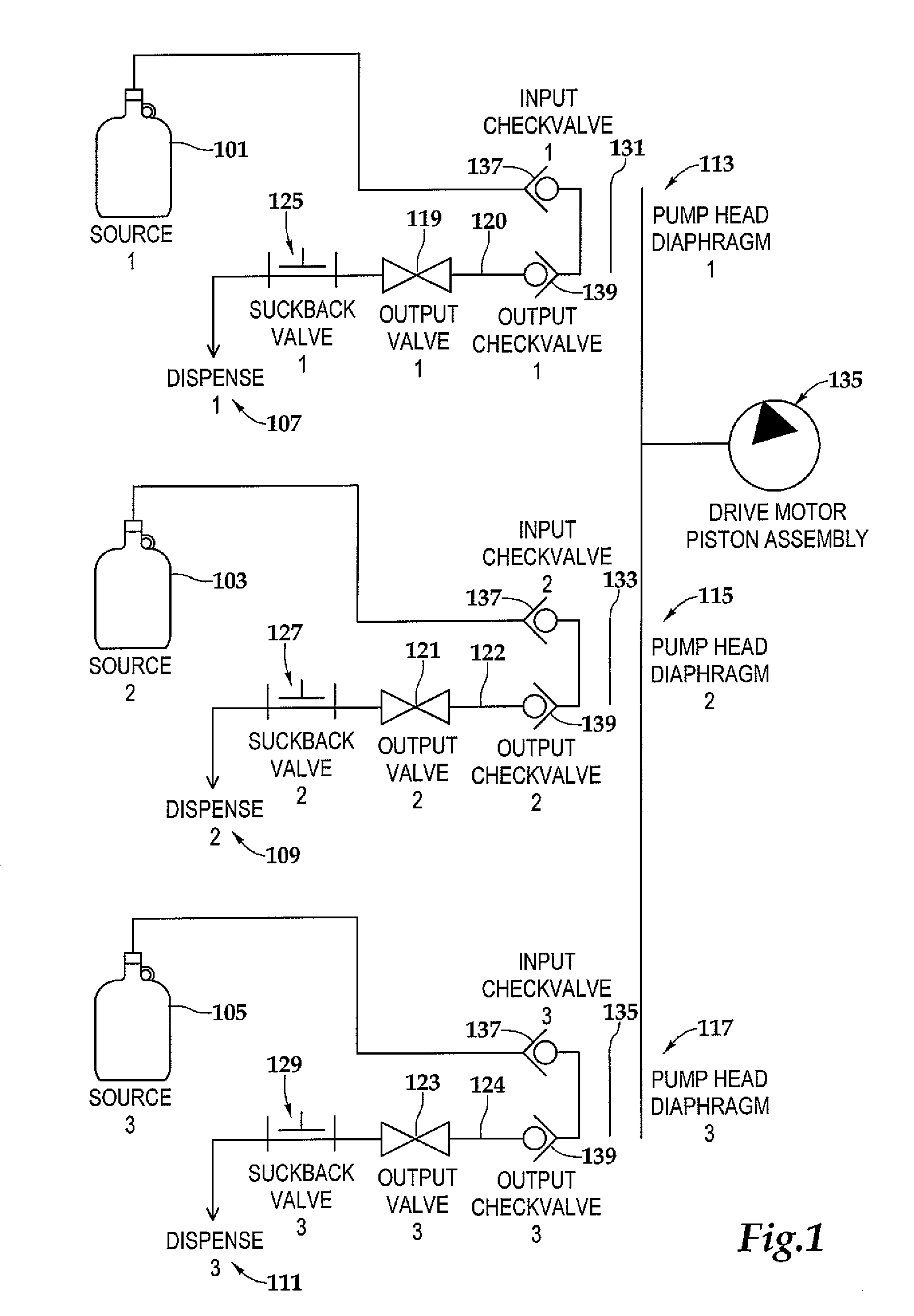

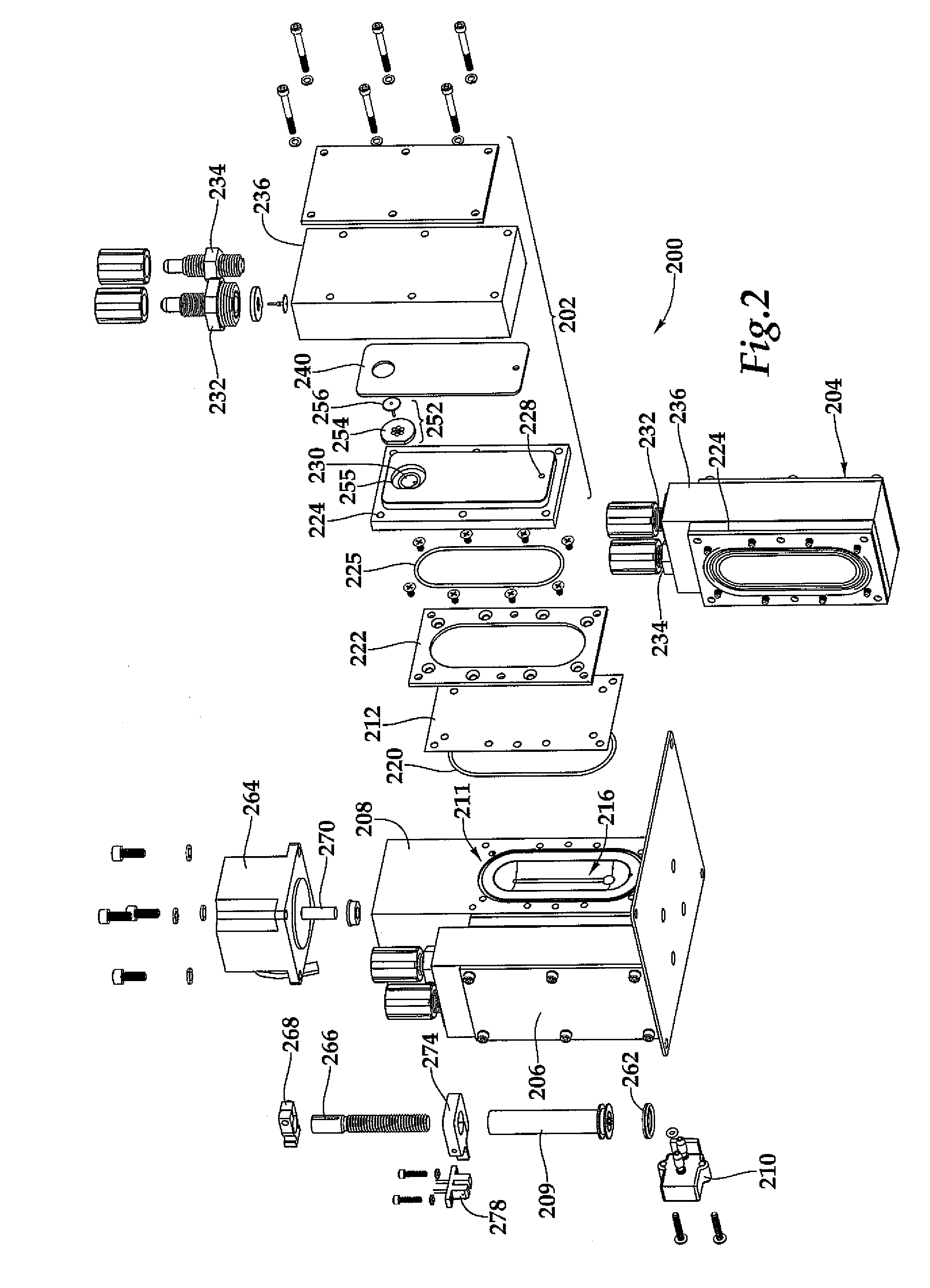

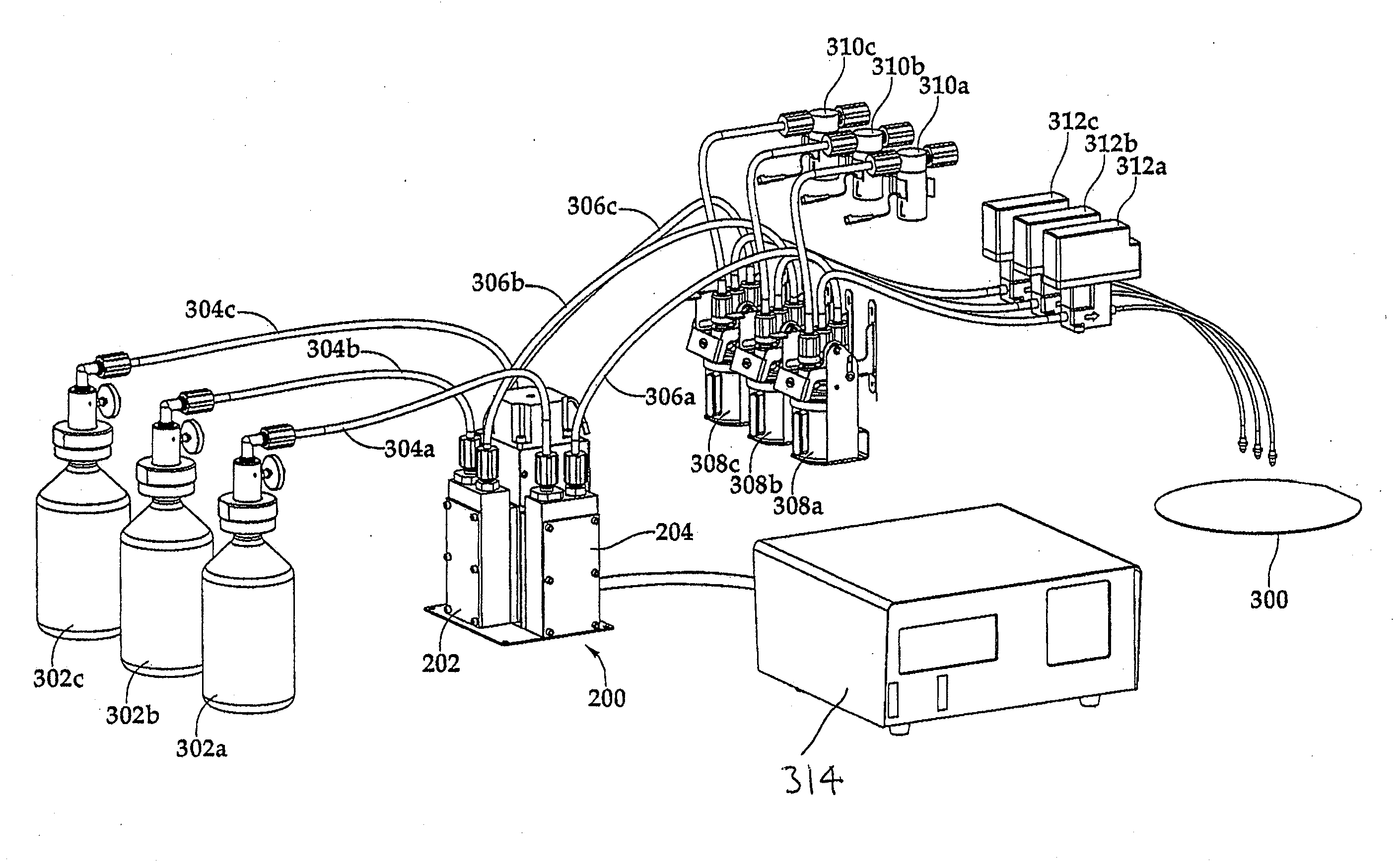

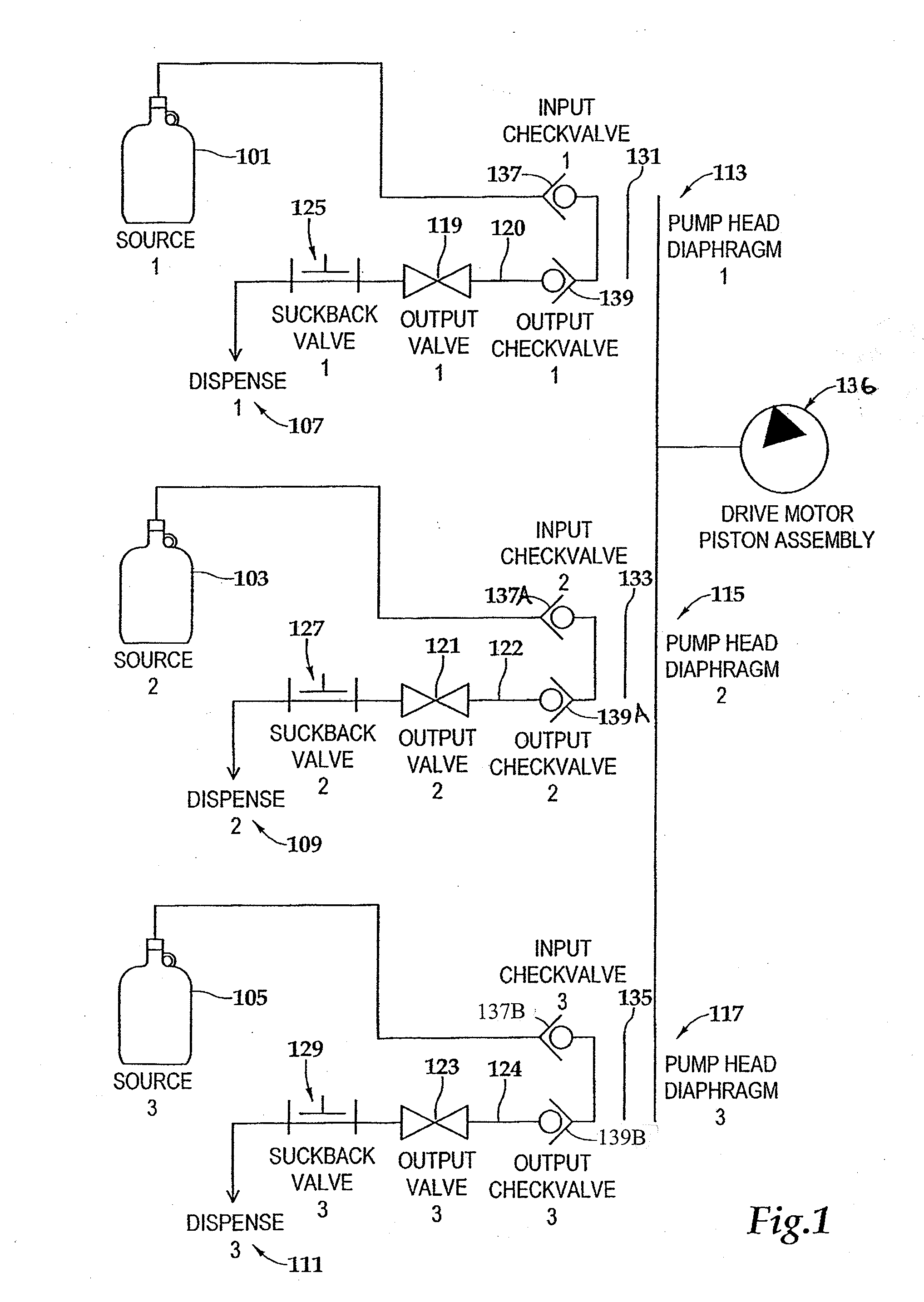

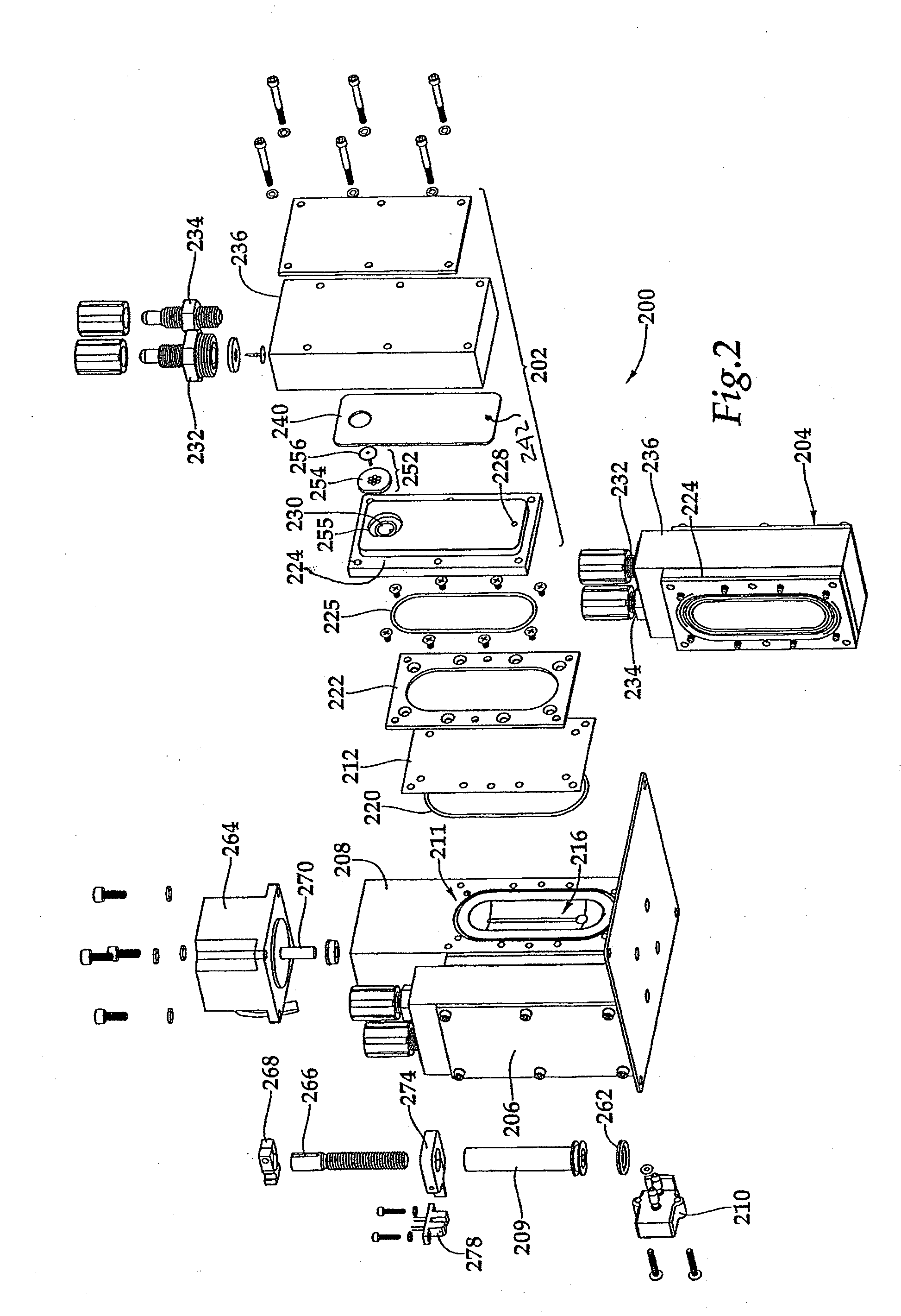

Precision pump having multiple heads and using an actuation fluid to pump one or more different process fluids

ActiveUS8317493B2Save maintenance timeSave valuable spacePositive displacement pump componentsFlexible member pumpsPump chamberEngineering

Owner:TELEDYNE DIGITAL IMAGING US INC

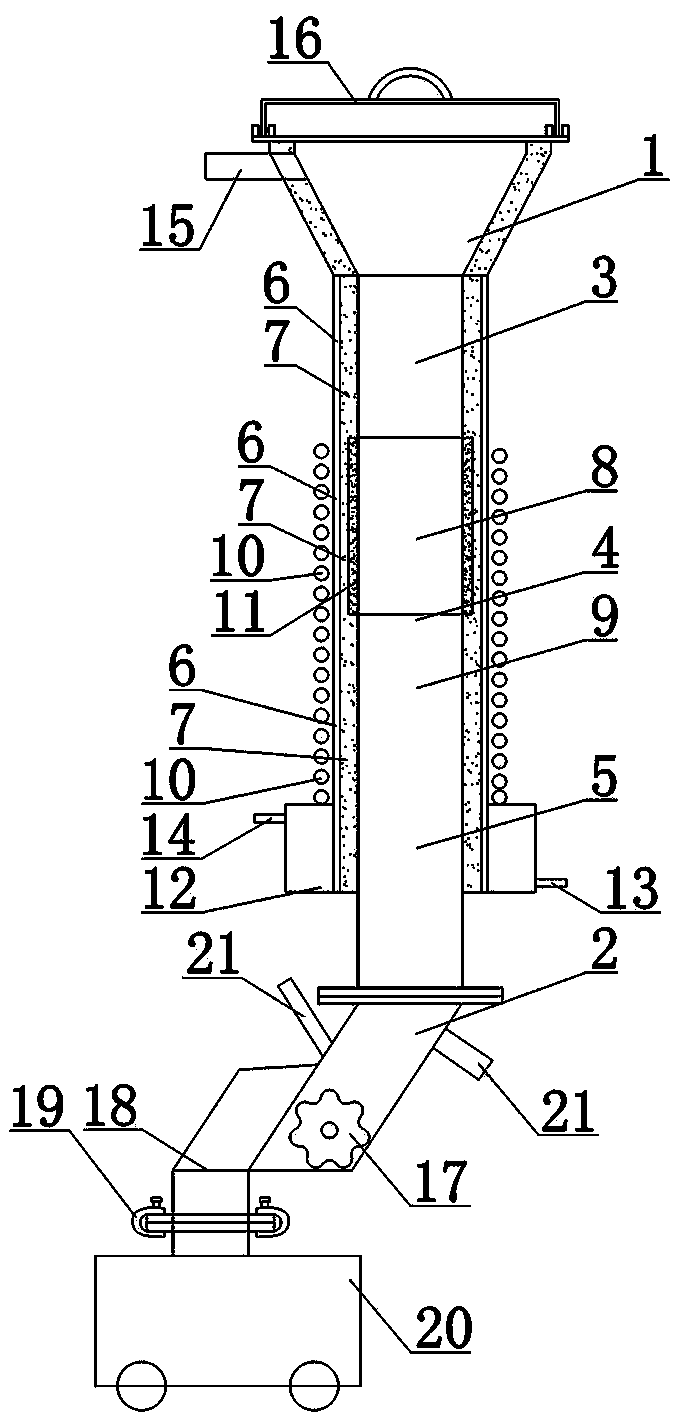

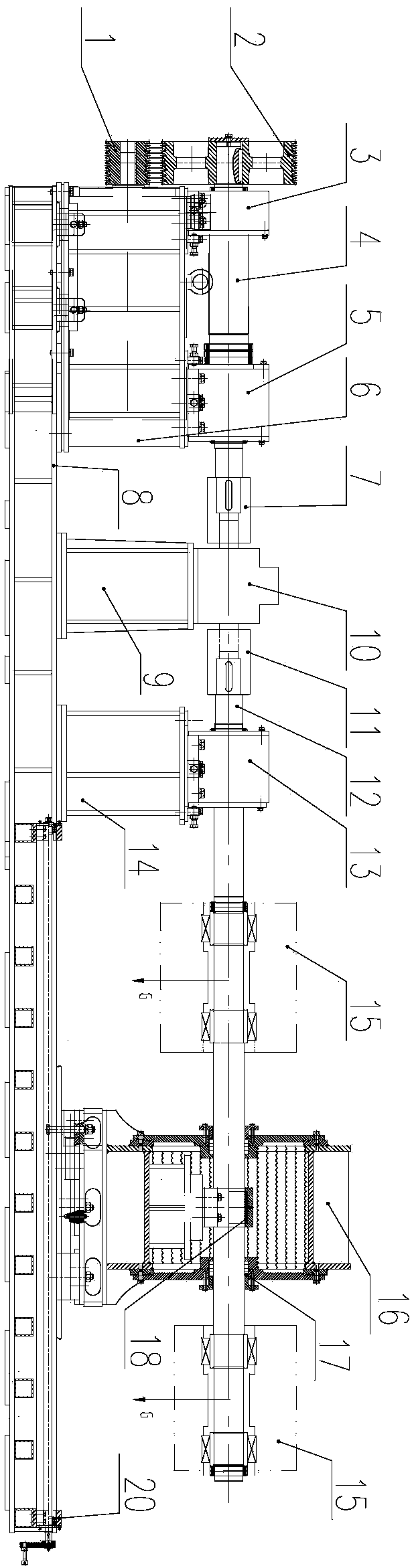

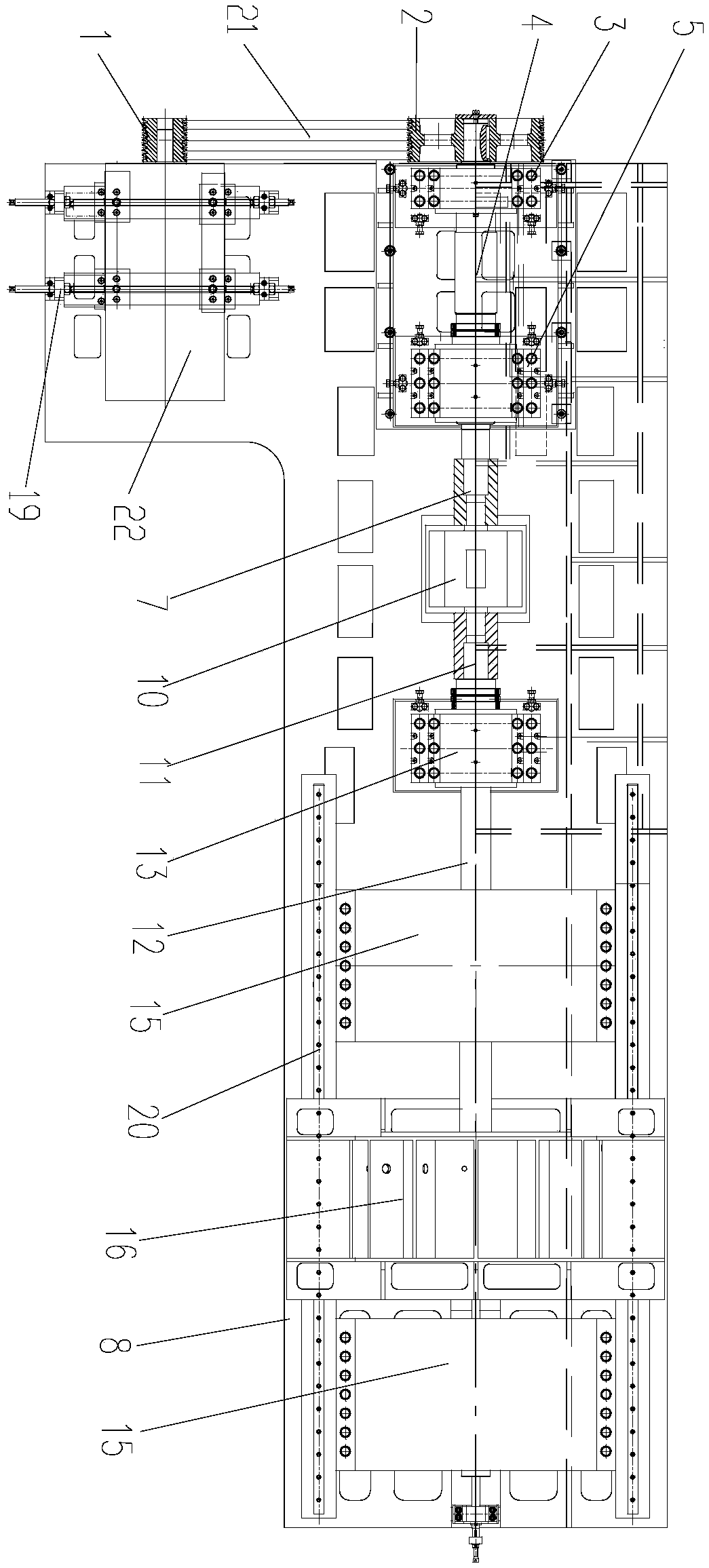

Method and device for continuously preparing vanadium-nitrogen alloy

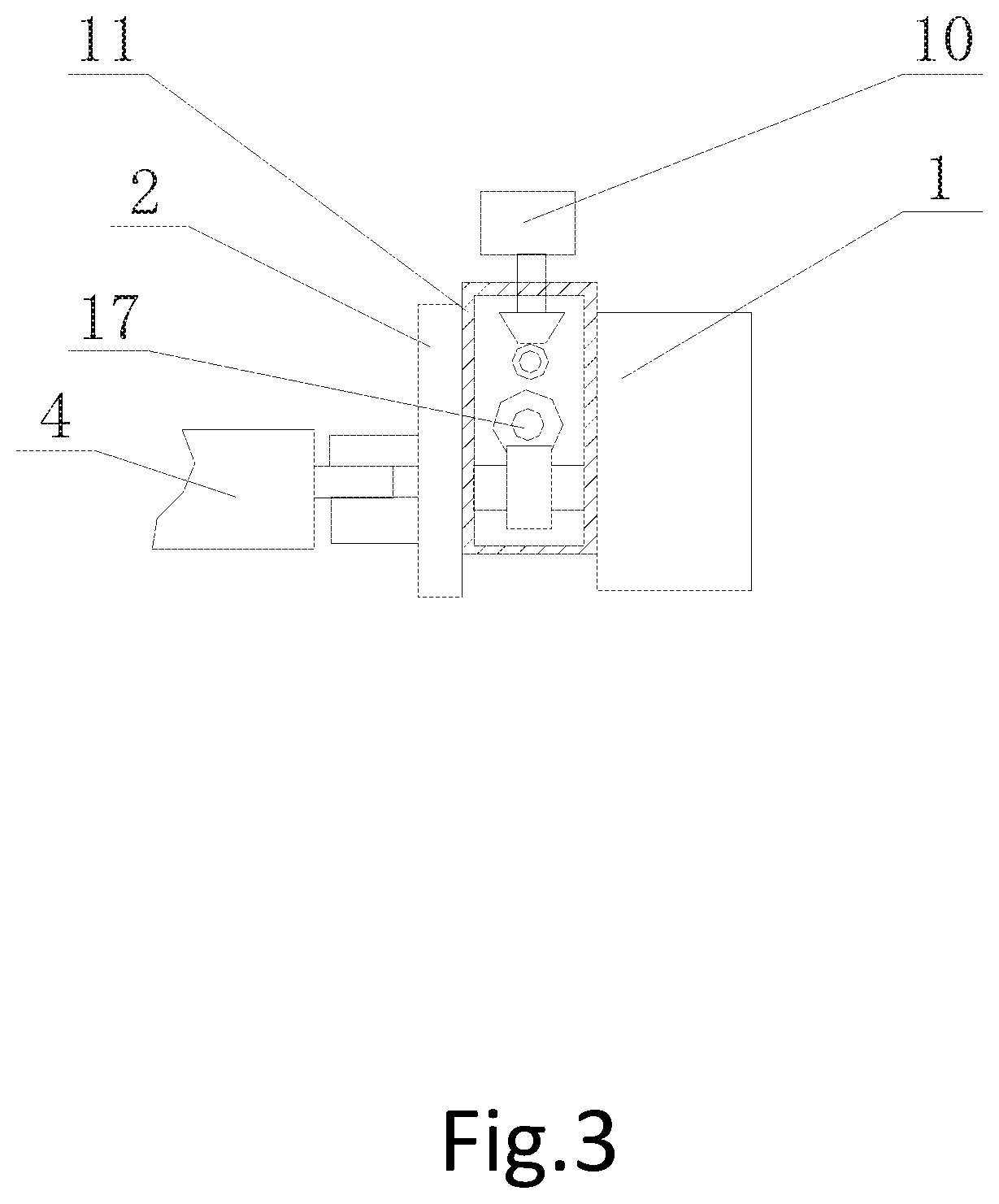

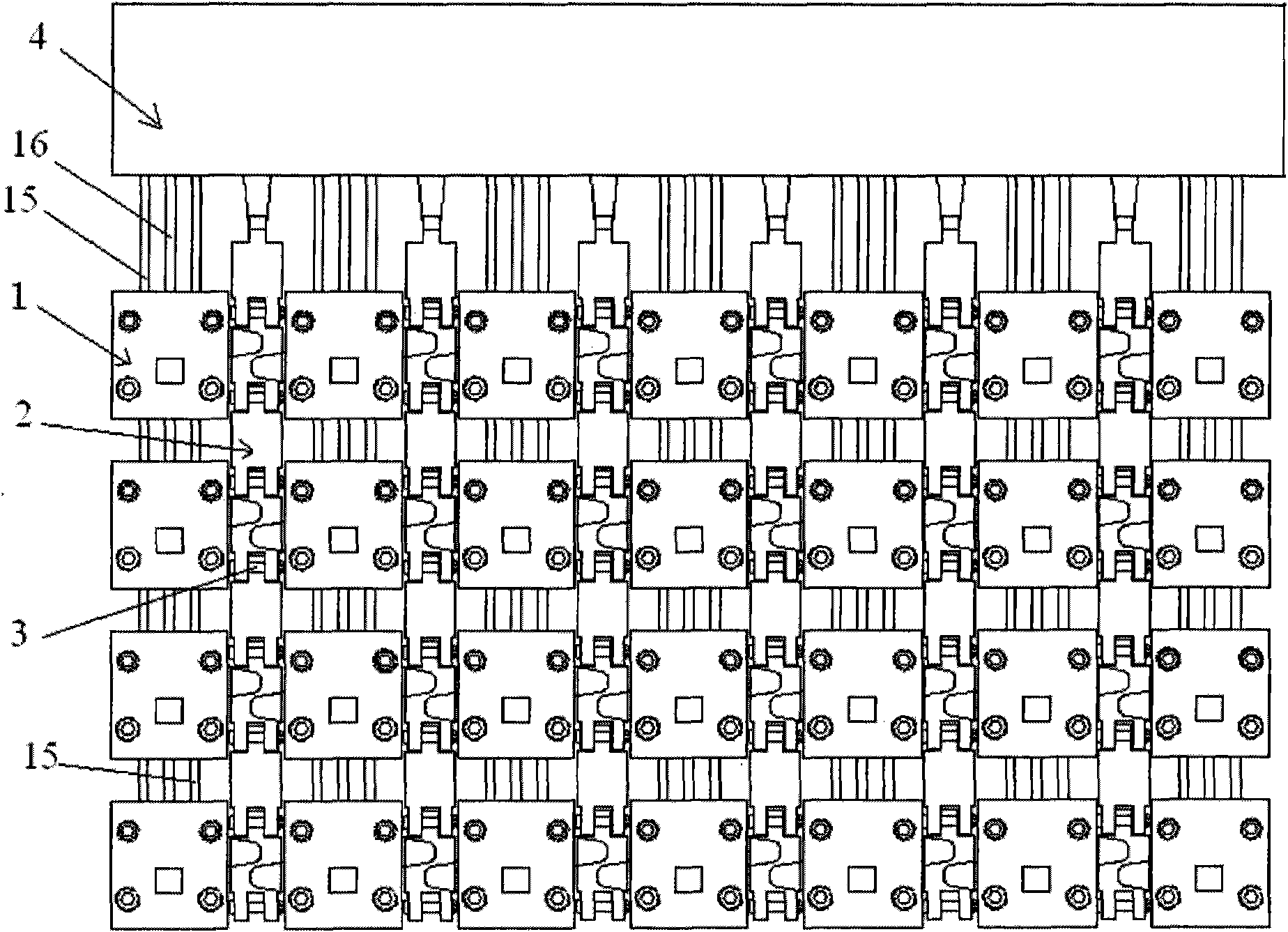

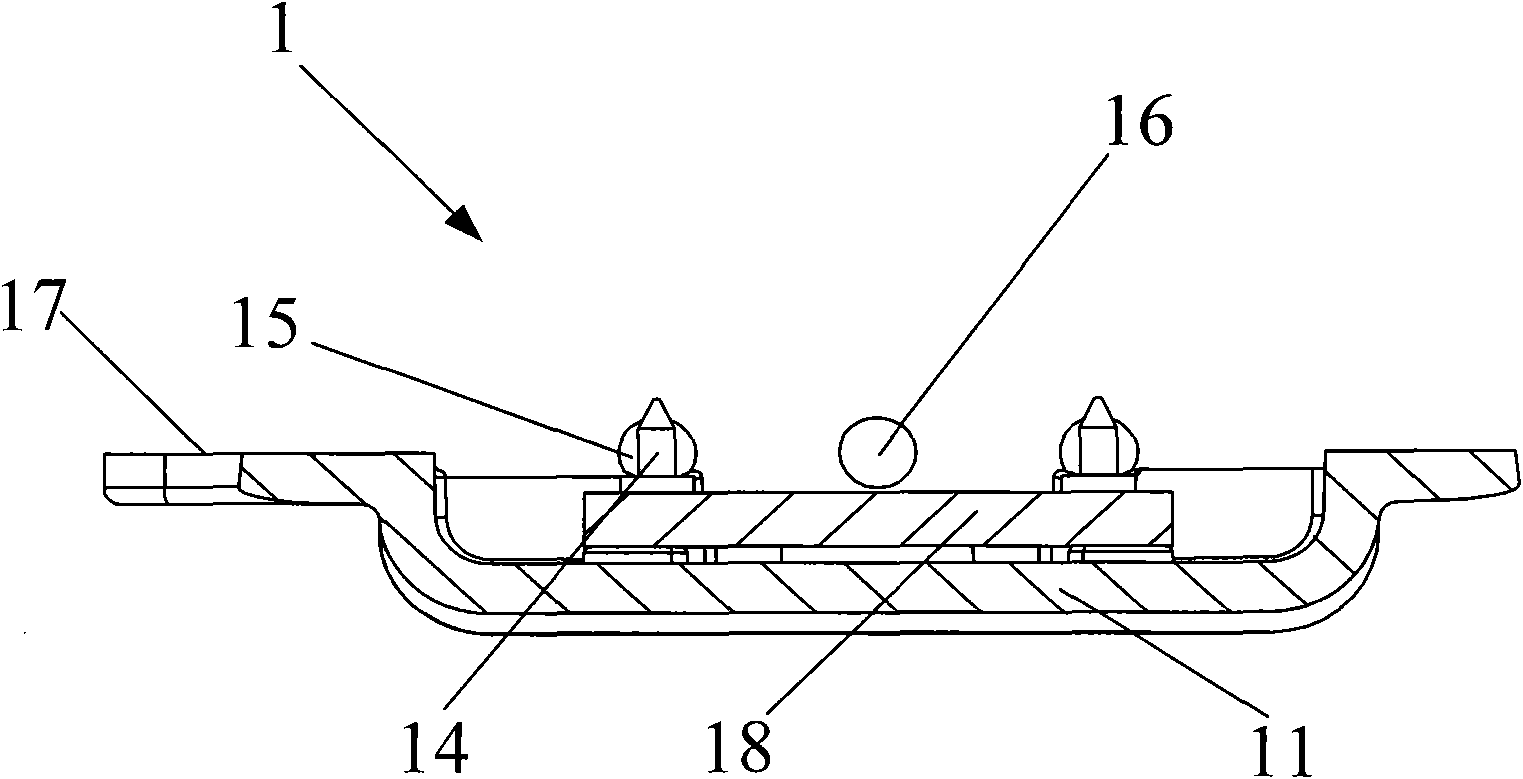

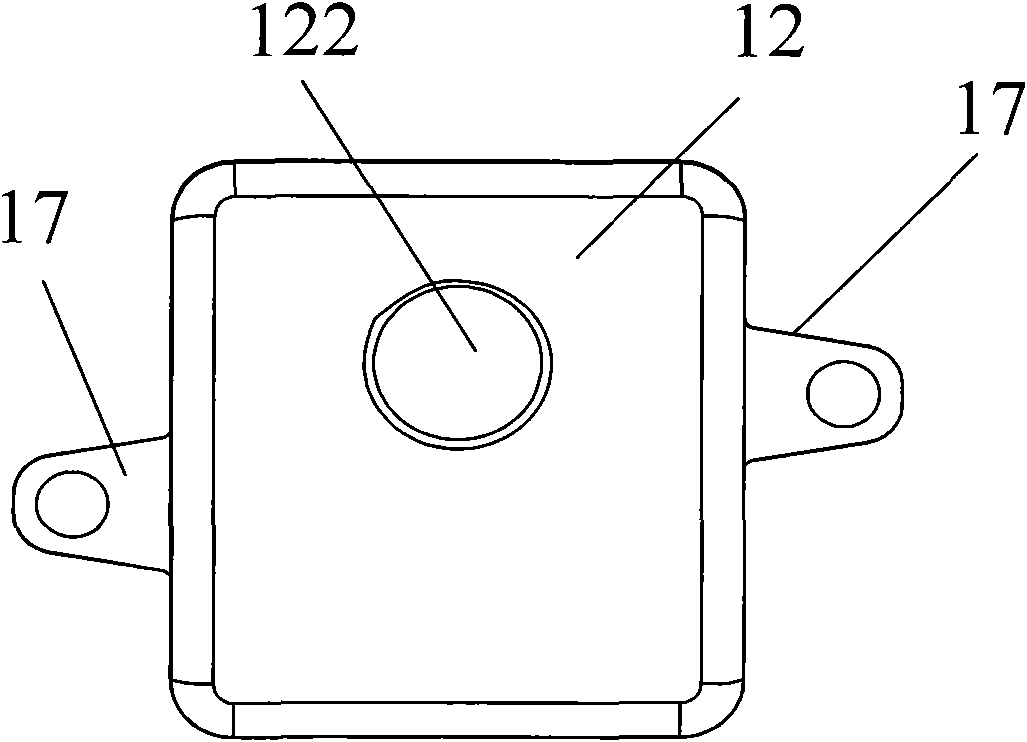

The invention discloses a method for continuously preparing vanadium-nitrogen alloy. The method includes the first step of preparation, the second step of blending and blank manufacturing, the third step of adding, the fourth step of preheating and prereduction, the fifth step of carbonization and nitridation sintering, and the sixth step of discharging. A device for preparing vanadium-nitrogen alloy according to the method comprises a vertical boiler, a top feeding bin (1) and a continuous automatic discharging device (2), wherein the vertical boiler is composed of a preheating section (4), a calcination section (4) and a cooling section (5); the lower end of the vertical boiler is connected with the continuous automatic discharging device (2) through a pipeline; the tail end of the continuous automatic discharging device is connected with a finished product trolley (20) through a discharge pipe (18); the bottom of the vertical boiler is provided with a nitrogen inlet (21). The method has the advantages that the process and the device are compact, the production process is short, electric energy is saved, little investment is required, yield is high, continuous production is really achieved, and the industrialized and scale production requirement is met.

Owner:SICHUAN ZHANXIANG SPECIAL ALLOY TECH

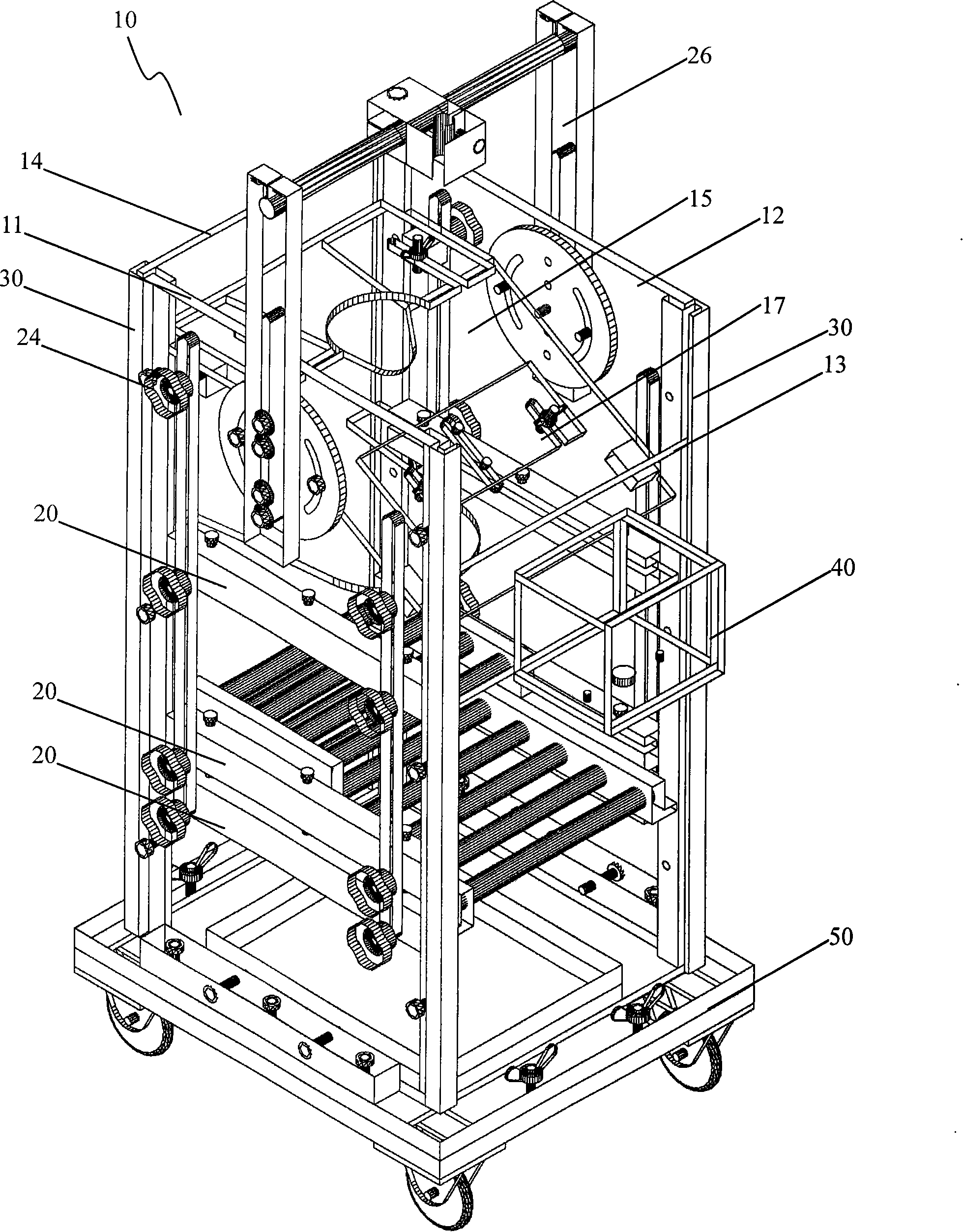

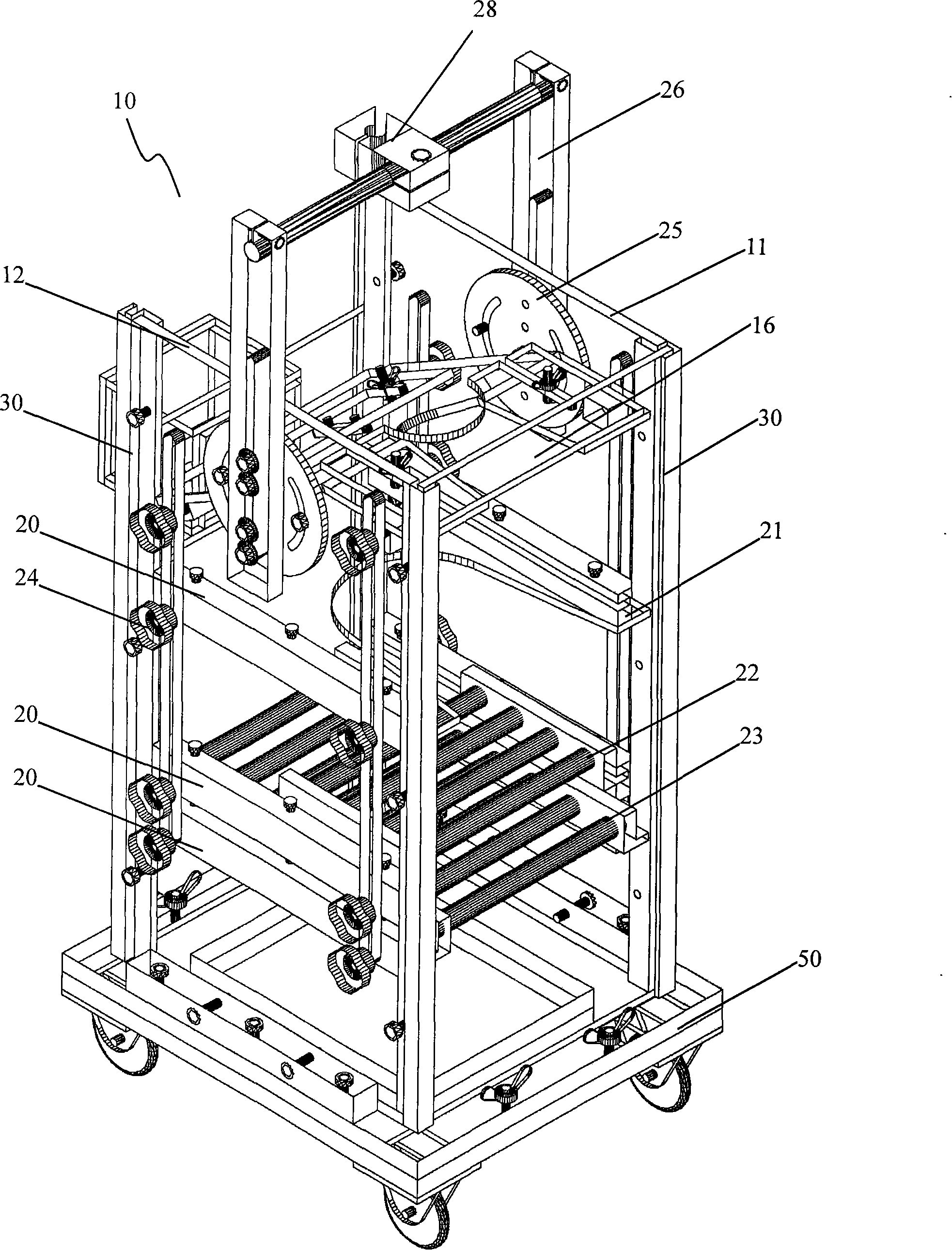

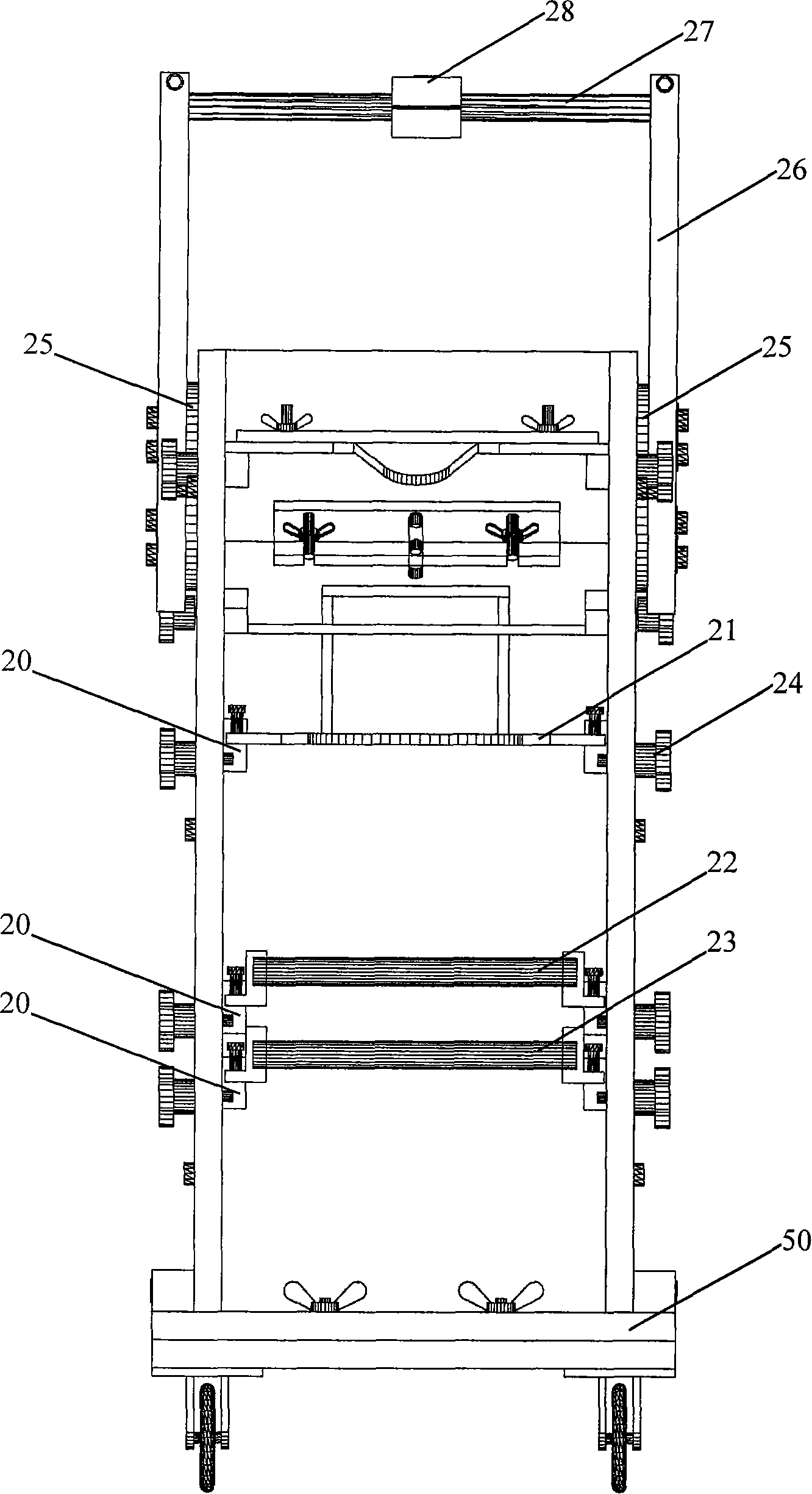

Multifunctional adjustable monkey chair

InactiveCN101249026AFacilitate surgeryEasy to operateAnimal fetteringEngineeringScientific experiment

The invention discloses a multifunctional adjustable monkey chair, comprising a chair space surrounded by a lateral plate, a front plate and a back plate and allowing an experimental animal entering inside, and an upper plate and a head fixing plate installed above the chair space, wherein a plurality of fixing grooves are installed on the inner side of the lateral plate, and a groove is opened on the inner side of the fixing groove for installing matched plug-in units; and a rotary fixed element is installed on the outer side of the lateral plate and connected with a positioning rack for adjusting the position of the positioning rack. The monkey chair can be adjusted according to experimental conditions; and is suitable for scientific experiments on primates with different ages and shapes. The inventive monkey chair has the advantages of good commonality and convenient installation.

Owner:INSITUTE OF BIOPHYSICS CHINESE ACADEMY OF SCIENCES +1

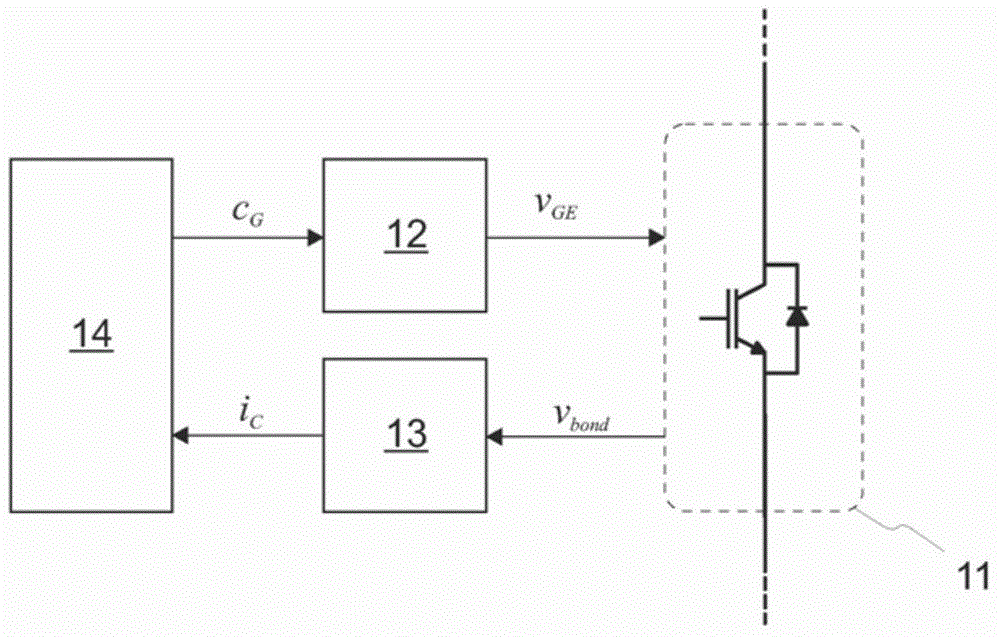

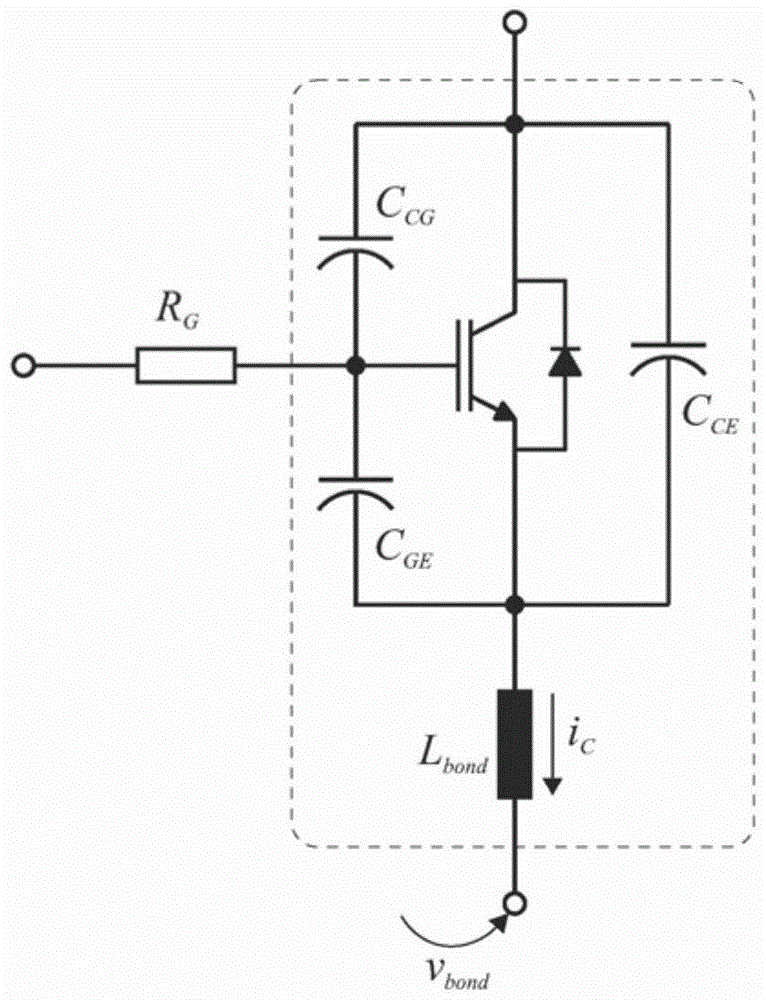

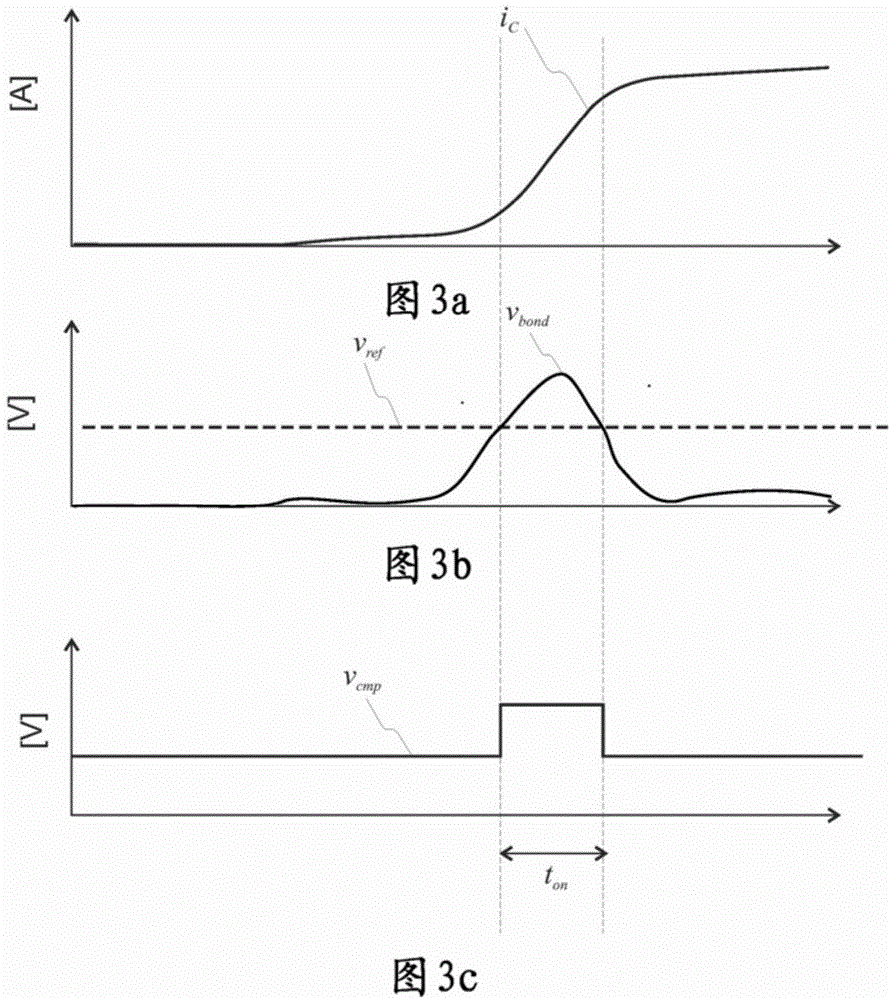

Method and apparatus for short circuit protection of power semiconductor switch

InactiveCN104702253ADisconnect limit and fastLow risk of mechanical damageTransistorElectronic switchingPower semiconductor deviceTerminal voltage

The present disclosure presents a method, and an apparatus implementing the method, for a power semiconductor switch, wherein a current through the switch is responsive to a control terminal voltage at a control terminal of the switch, and the control terminal voltage is driven by a driver unit, The method comprises estimating the current on the basis of a bond voltage of the switch, detecting a short circuit by comparing the estimated current to a short circuit current limit, controlling an on-state voltage level of the control terminal voltage on the basis of the comparison in order to limit the current through the switch during the short circuit, and controlling the control terminal voltage to an off-state voltage level in order to turn the switch off. The on-state voltage level voltage is controlled by pulse-width modulating the output of the driver unit. A switching frequency of the modulation is at least the cut-off frequency of low-pass characteristics of the control terminal.

Owner:ABB (SCHWEIZ) AG

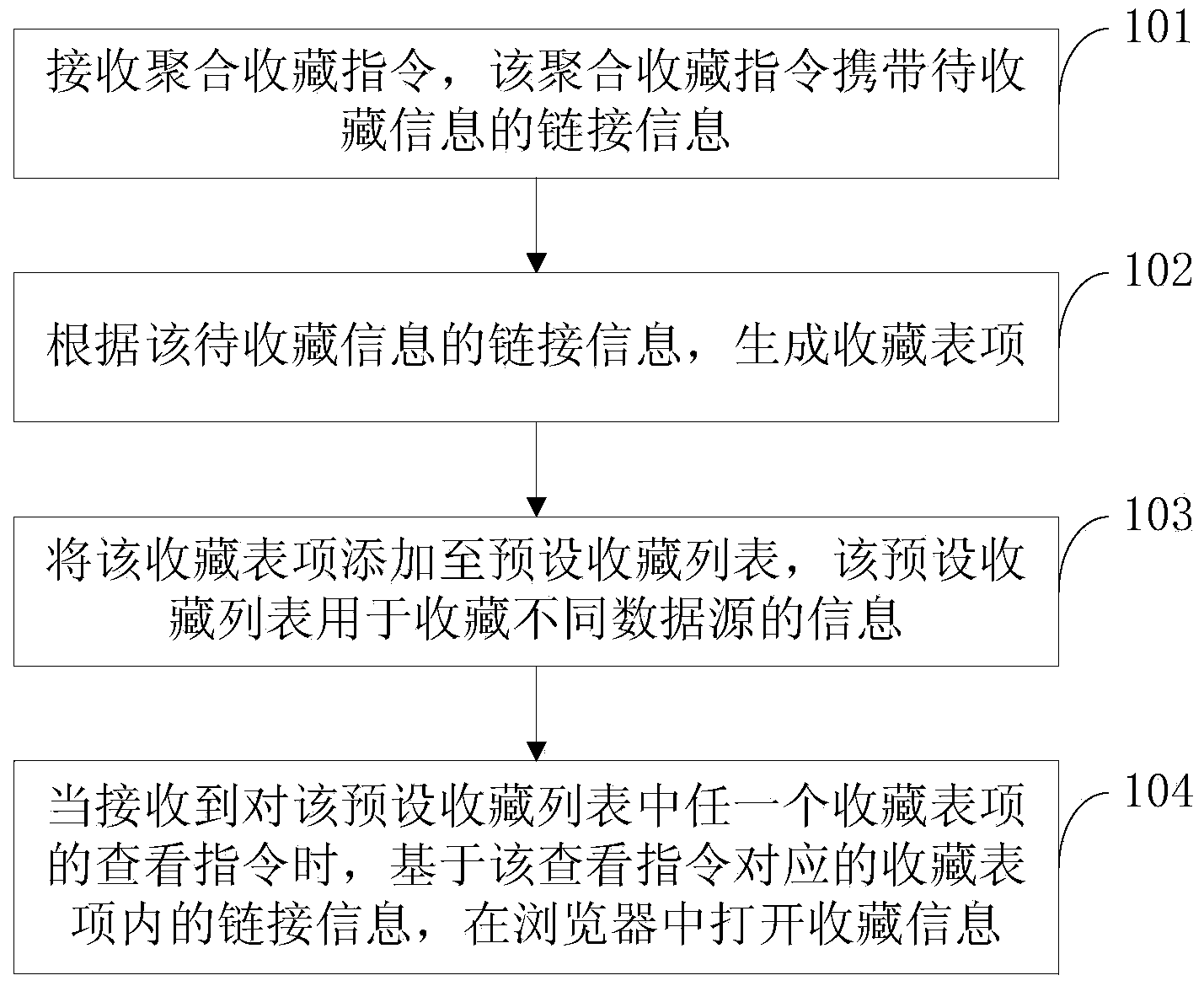

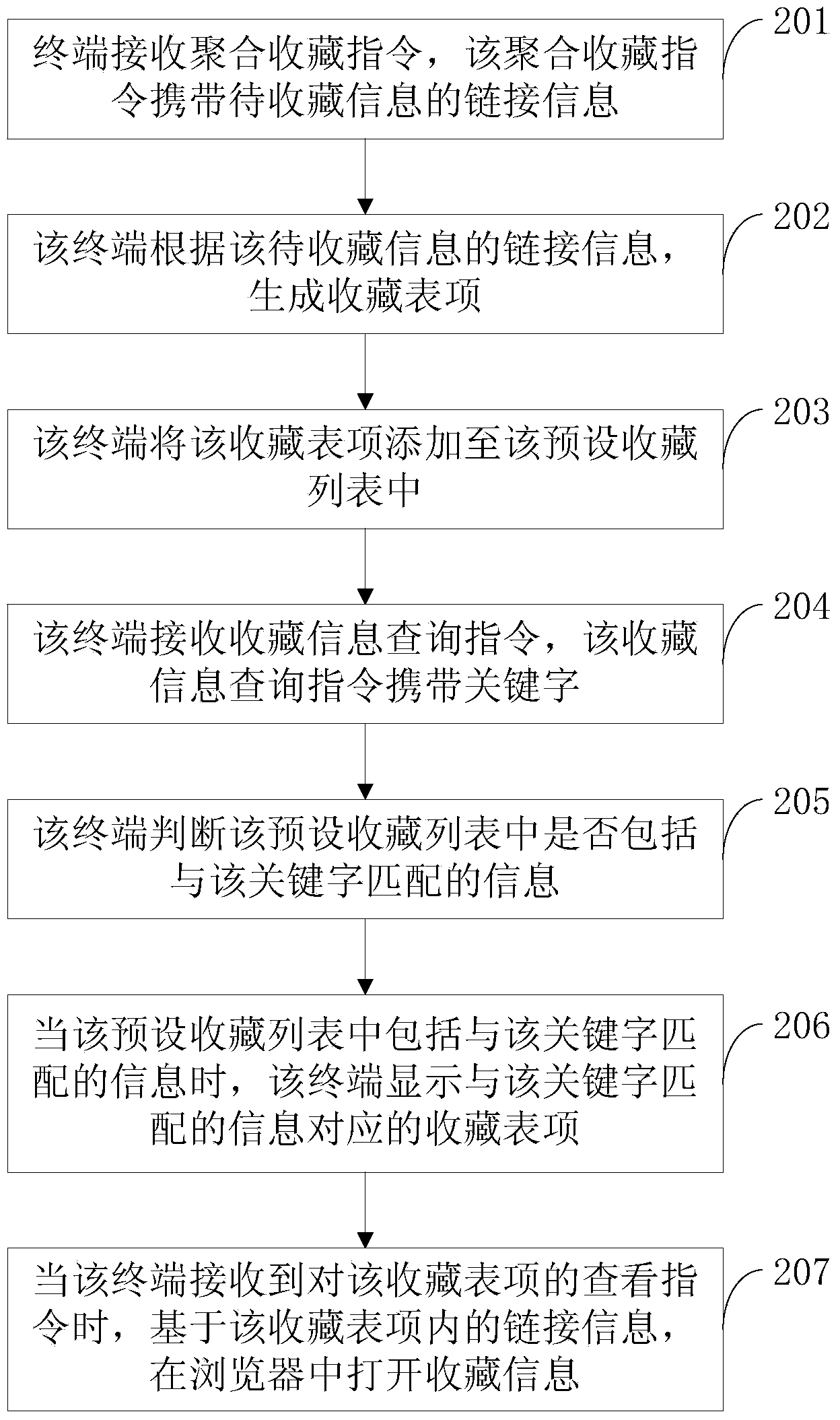

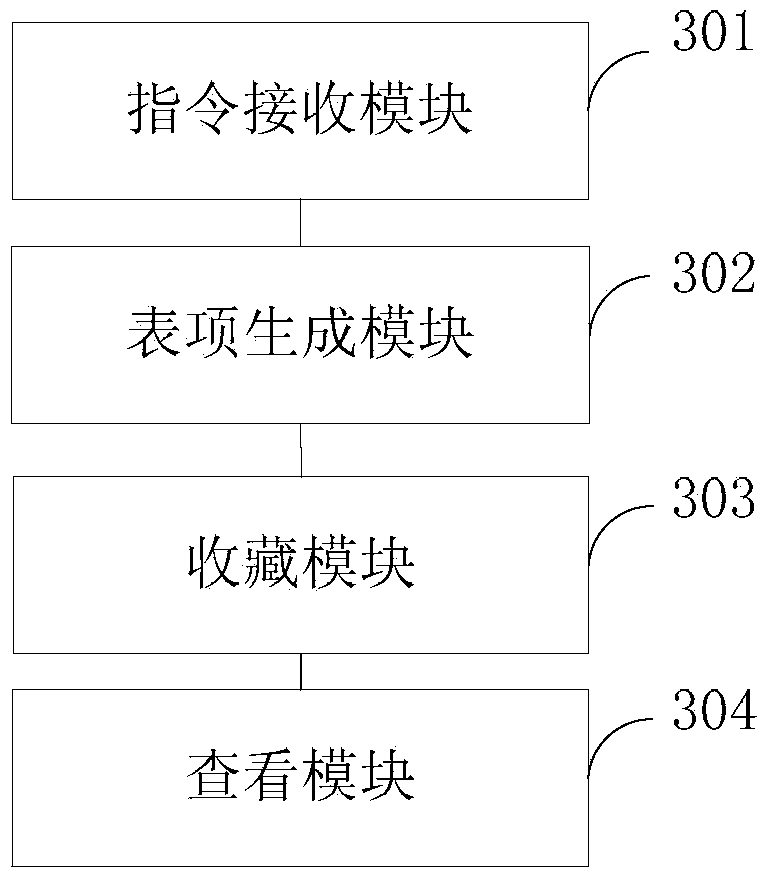

Information collection method and device

ActiveCN103678502AEasy to manageEasy to readWebsite content managementSpecial data processing applicationsThe InternetData source

The invention discloses an information collection method and device and belongs to the Internet field. The method includes the steps that an aggregation collection instruction is received, and the aggregation collection instruction carries link information of information to be collected; according to the link information of the information to be collected, a collection list item is generated; the collection table item is added to a preset collection list, and the preset collection list is used for collecting information of different data sources; when an instruction for viewing any collection list item in the preset collection list is received, the collected information is opened in a browser on the basis of the link information, corresponding to the view instruction, in the collection list item. With the information collection method and device, information of different data sources is collected into the same preset collection list in an aggregating mode, when the view instruction is received, the collected information is opened directly in the browser, the collection list does not need to be maintained for different data sources respectively, and thus maintenance time and maintenance cost are saved, and a user can carry out management and read conveniently.

Owner:XIAOMI INC

Bituminous pavement top-crack or settlement treating method

The invention discloses processing technique dealing with asphalt pavement sink and crack, which includes following steps: drill pouring holes at cracking area piercing face and ground; pouring material into the holes and fix the ground, sealing the holes; make slots along surface gaps, fill the slots till the sinking area is flush with the ground, block the section till pulp material coagulates till the normal service will not damage the pouring pulp again. By pouring pulp material into pouring holes at sinking area, the rigidity of ground base and surface is enhanced effectively so to keep the ground from further damage, lengthening the road service life greatly.

Owner:邓敬森

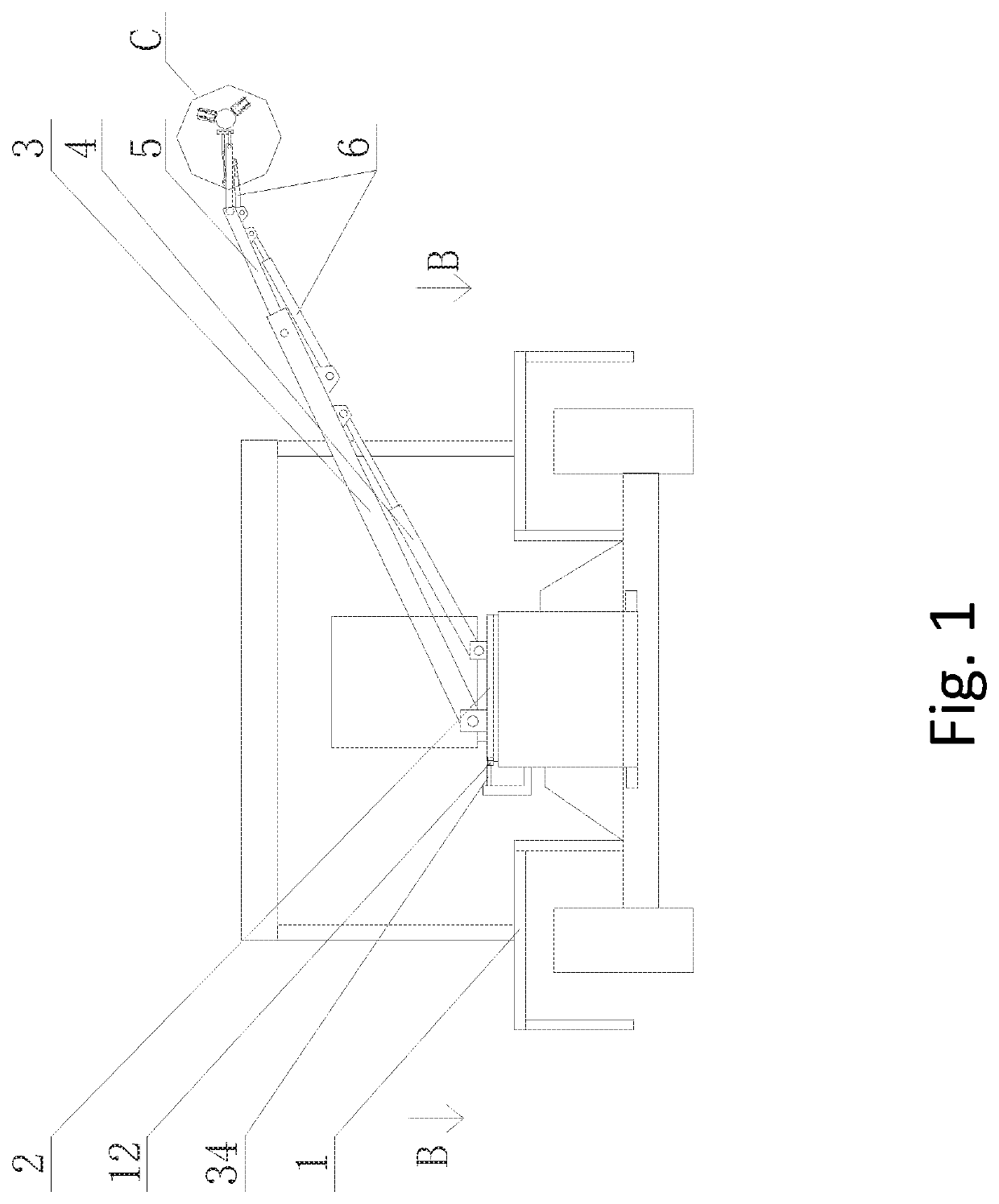

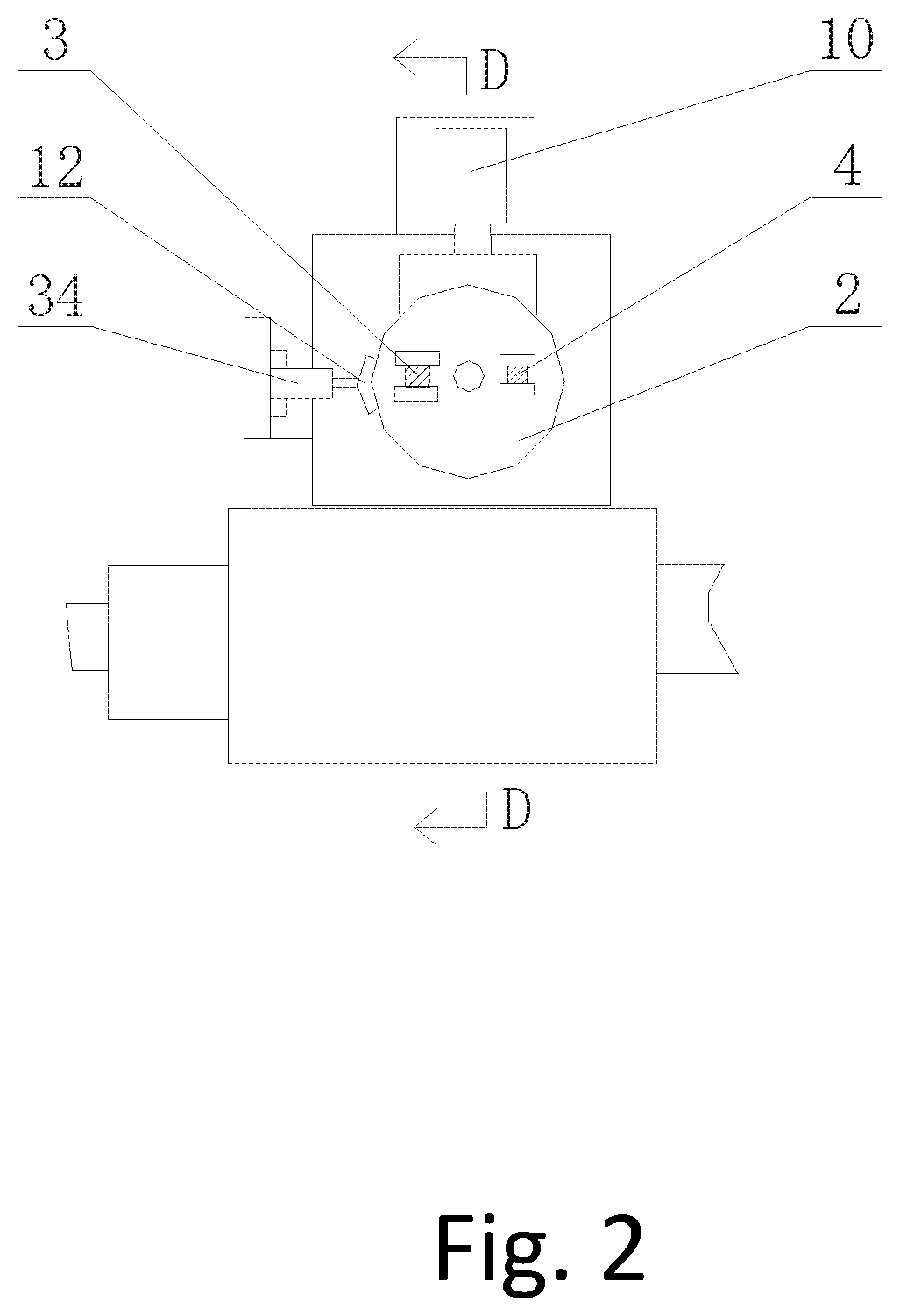

Automatic Walking Garden Trimmer

InactiveUS20200260650A1Low efficiencyImprove efficiencyMetal sawing devicesHedge trimming apparatusAgricultural engineeringStructural engineering

The invention relates to an automatic walking garden trimmer which includes a power locomotive and a trimming device. The power locomotive is rotatably connected with a turntable support whose horizontal rotation is driven by a power device. The turntable support is hinged with a lower support arm and a base cylinder which drives the lower support arm to swing. The end of the lower support arm is hinged with at least two outstretched arms and an extension cylinder used to drive the outstretched arms to swing and adjust outstretching distance. The connecting seat is connected to a sphere. Two sets of trimming devices are arranged on the side of the sphere. The trimming device includes a spiral device and a trimming ring. The spiral device includes a spiral bracket and a sleeve arranged on the spiral bracket. The rotating blade of the trimming device of the present invention can be replaced. The operator can select a suitable blade according to the shape and size of the trimmed shoots, and operate the device to make the device have a wider use range with practicality. In the case of a damaged blade, a new blade can be replaced, saving maintenance time and enhancing work efficiency.

Owner:NG KI LAI

Rolling curtain screen

ActiveCN102385814ASimple structureEasy to assembleIdentification meansLight-emitting diodeMatrix form

The invention discloses a rolling curtain screen, which comprises a screen formed by a plurality of LED (Light Emitting Diode) modules distributed in a matrix form, wherein adjacent LED modules in the same row are connected by a connecting member; and the LED modules in the same column are connected through at least one power cord and at least one signal wire. According to the rolling curtain screen disclosed by the invention, the power cord and the signal wire are woven in the screen of a product to form a whole, so that the power cord is prevented from being hoarded and wound at the lateral surface of the screen, potential safety hazards are reduced and the attractiveness of the screen is promoted. Furthermore, each LED module is a pixel point, so that the LED module is pointedly detached and maintained when the screen is maintained, the workload is reduced and the maintenance time and labor force are saved.

Owner:驻马店进化伙伴机器人有限公司

Precision Pump With Multiple Heads

InactiveUS20090016903A1Save valuable spaceSave maintenance timeSemiconductor/solid-state device manufacturingPiston pumpsSingle stageMechanical engineering

A high purity, high precision pump capable of pumping more than one type of chemistry or process fluid without requiring cleaning or changing of surfaces contacting the processing fluid. The pump employs a single drive mechanism coupled in parallel with multiple pumping chambers, each capable of handling a different type of manufacturing fluid. The pump can be utilized as part of a single stage or multi-stage pump system.

Owner:INTERGRATED DESIGNS LP

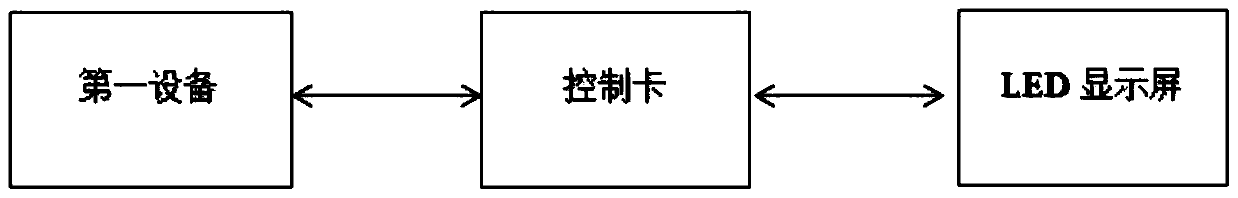

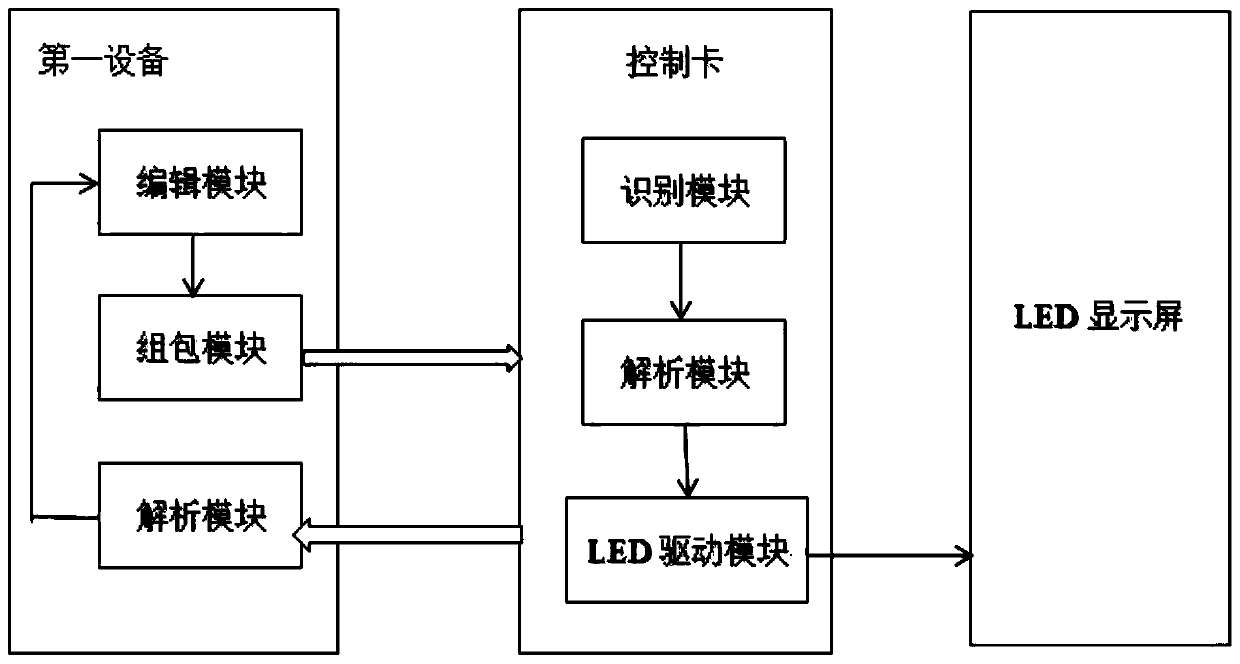

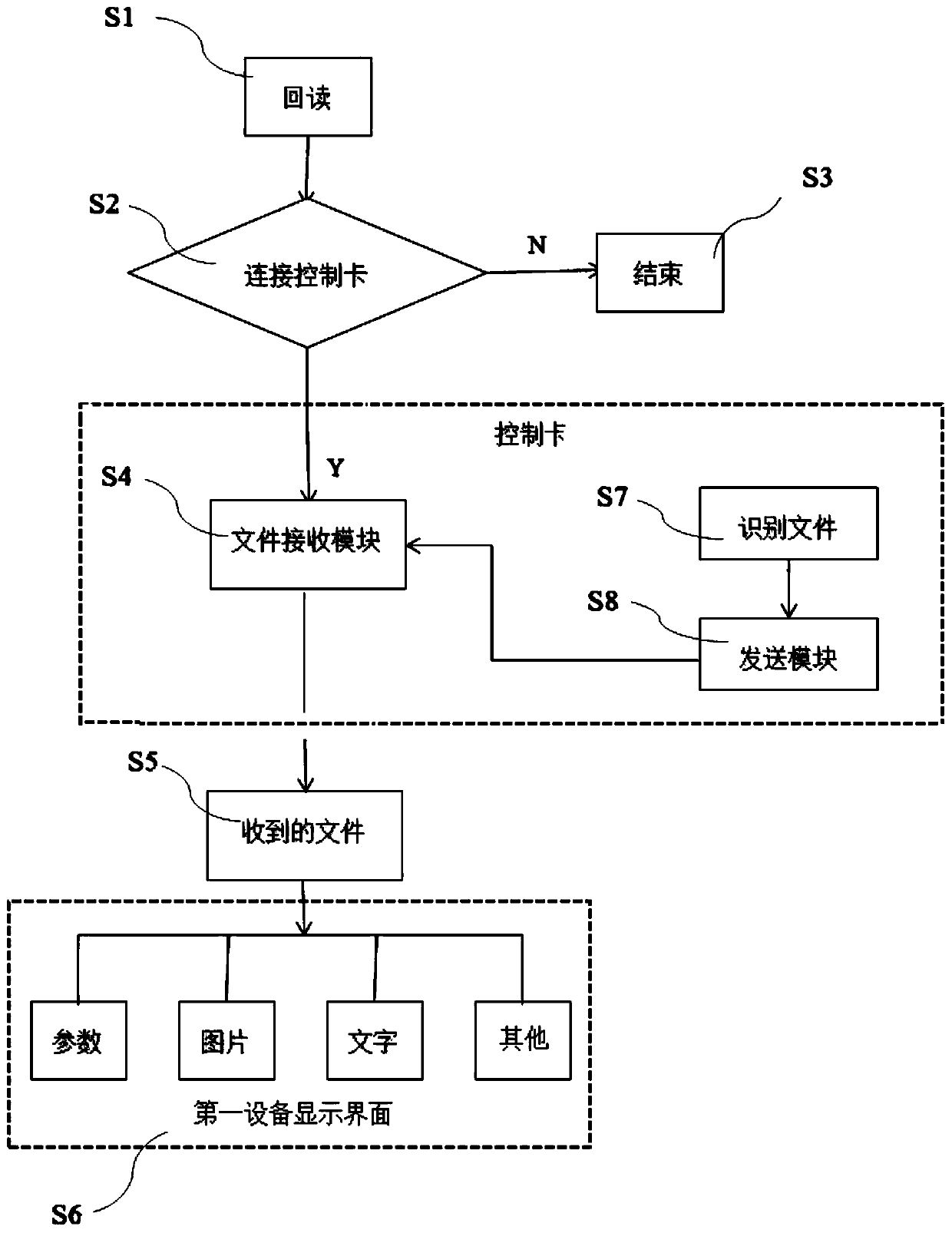

LED display screen data read-back control system

InactiveCN110827749ARealize multiplexingSave maintenance timeStatic indicating devicesLED displayControl system

The invention provides an LED display screen data read-back control system. The LED display screen data read-back control system comprises a first device, a control card and an LED display screen. Thefirst device receives the screen display setting parameters and the display content and sends the parameters and the content to the control card, the control card drives the LED display screen to display according to the display information, and a file receiving module is arranged in the control card. The control card recognizes the display content and the screen parameters of the LED display screen to form the read-back data and sends the read-back data to the file receiving module, the first device sets an independent storage area in a memory of the first device in response to entering a read-back mode and is used for storing the read-back data obtained from the file receiving module of the control card, and the read-back data at least comprises the display content and the screen parameters of the corresponding LED display screen, so that through the bidirectional communication between the control card and the display control device, and by compiling and reversely analyzing the dotmatrix data of the LED display screen, the multiplexing of the display content data and the screen parameters is achieved, and the simple and efficient use of the display screen control card is achieved.

Owner:苏州飞控软件科技有限公司

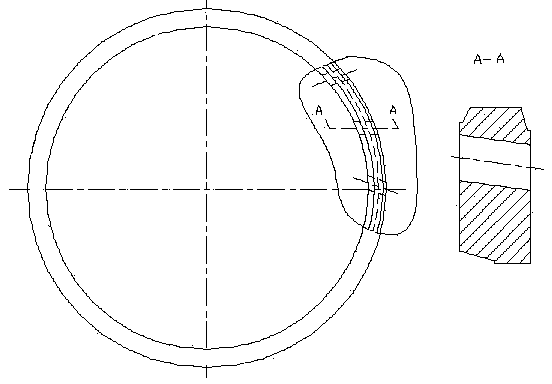

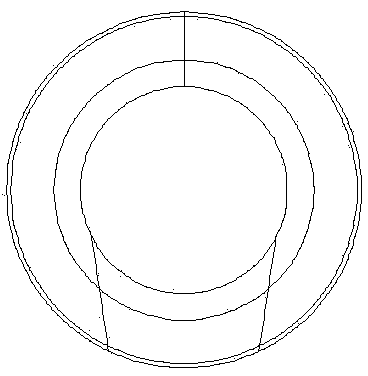

Chilling ring of gasification furnace

ActiveCN103525469AExtended service lifeIncrease profitGranular/pulverulent flues gasificationChilled waterEngineering

The invention discloses a chilling ring of a gasification furnace. The chilling ring comprises an outer lip ring, an inner lip ring, a nozzle ring, an inner ring of a water cavity, an outer ring of the water cavity, a bottom plate of the water cavity, a chilling water conveying pipe and a descending pipe, wherein the parts are connected by welding; the outer lip ring and the inner lip ring form a chilling water distribution chamber, the nozzle ring, the inner ring of the water cavity, the outer ring of the water cavity and the bottom plate of the water cavity form the water cavity, and the chilling water conveying pipe is communicated with the water cavity and the chilling water distribution chamber; a chilling water circular gap is formed between the outer lip ring and the descending pipe; preferably, the circular outer lip ring is a three-piece type, and is thickened in a jet direction of the nozzle ring. According to the chilling ring of the gasification furnace provided by the invention, the outer lip ring is in the three-piece type which replaces an integral circular structure, and the inner lip ring, the nozzle ring, the outer ring of the water cavity and the inner ring of the water cavity are changed to independent pieces; parts of assemblies can be directly changed in the furnace in the using process, vulnerable assemblies can be independently changed, and assemblies which are not easy to wear can be repeatedly used, so that the chilling ring is long in service life and convenient and economical to maintain.

Owner:NANJING CHENGZHI CLEAN ENERGY CO LTD

Remote monitoring and fault diagnosis system for touch screen

ActiveCN103543413AEasy to troubleshootConvenient work arrangementsLamps testingMonitoring systemComputer terminal

The invention discloses a remote monitoring and fault diagnosis system for a touch screen, and particularly relates to a touch screen monitoring system which comprises a touch screen body. The touch screen body comprises a touch screen control module connected with a central processing unit, the central processing unit is provided with a display terminal used with the touch screen body and is connected with a communication module, the touch screen body is connected with a server for remote monitoring through the communication module, and the central processing unit actively pushes state information of the touch screen body to the server. The touch screen is remotely monitored, a user is helped to timely know the abnormal working state of the touch screen, early warning of a fault is given in advance, a solution is given, the fault of the touch screen is judged at low cost, and after-sales service efficiency is improved.

Owner:程抒一

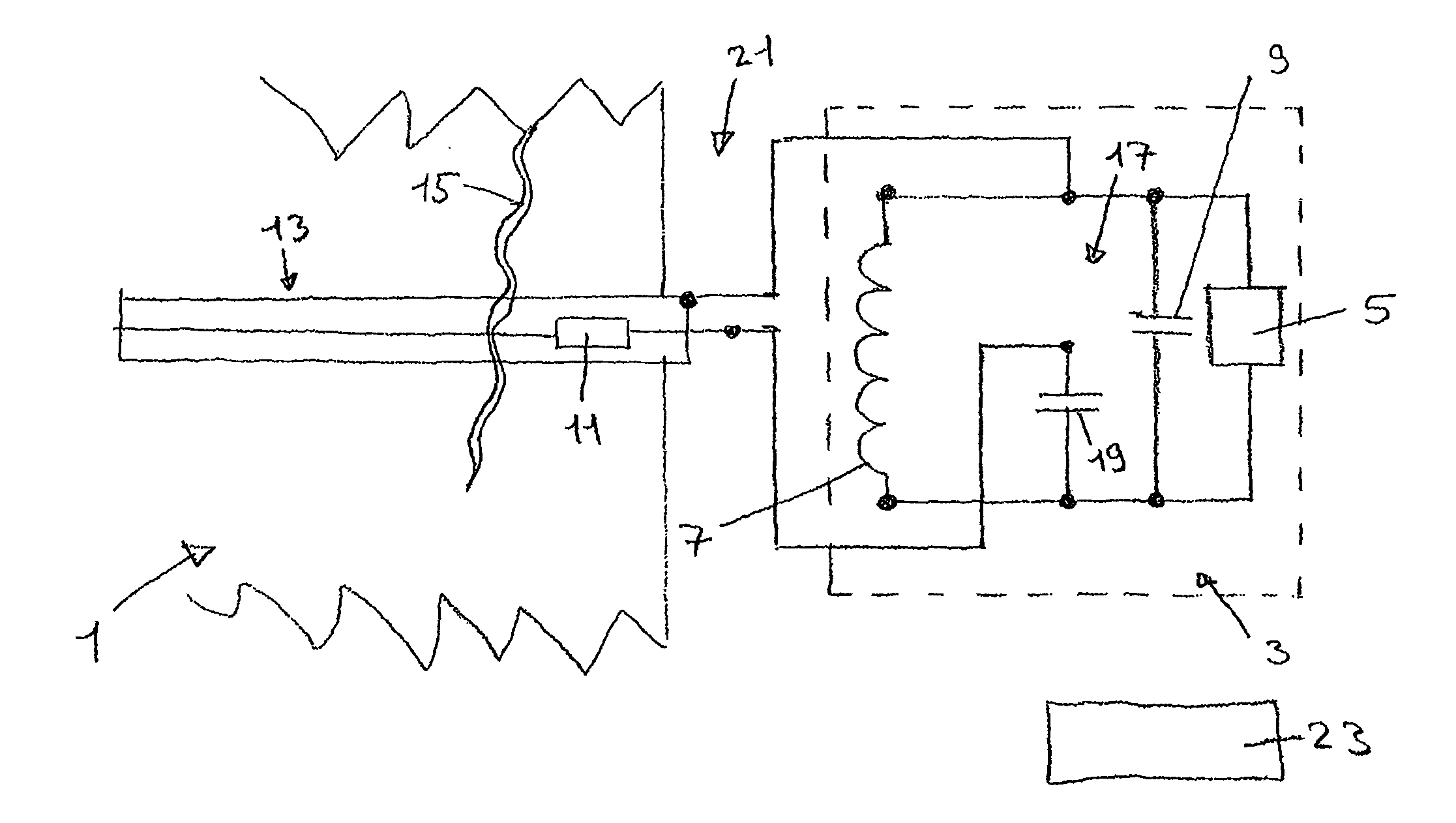

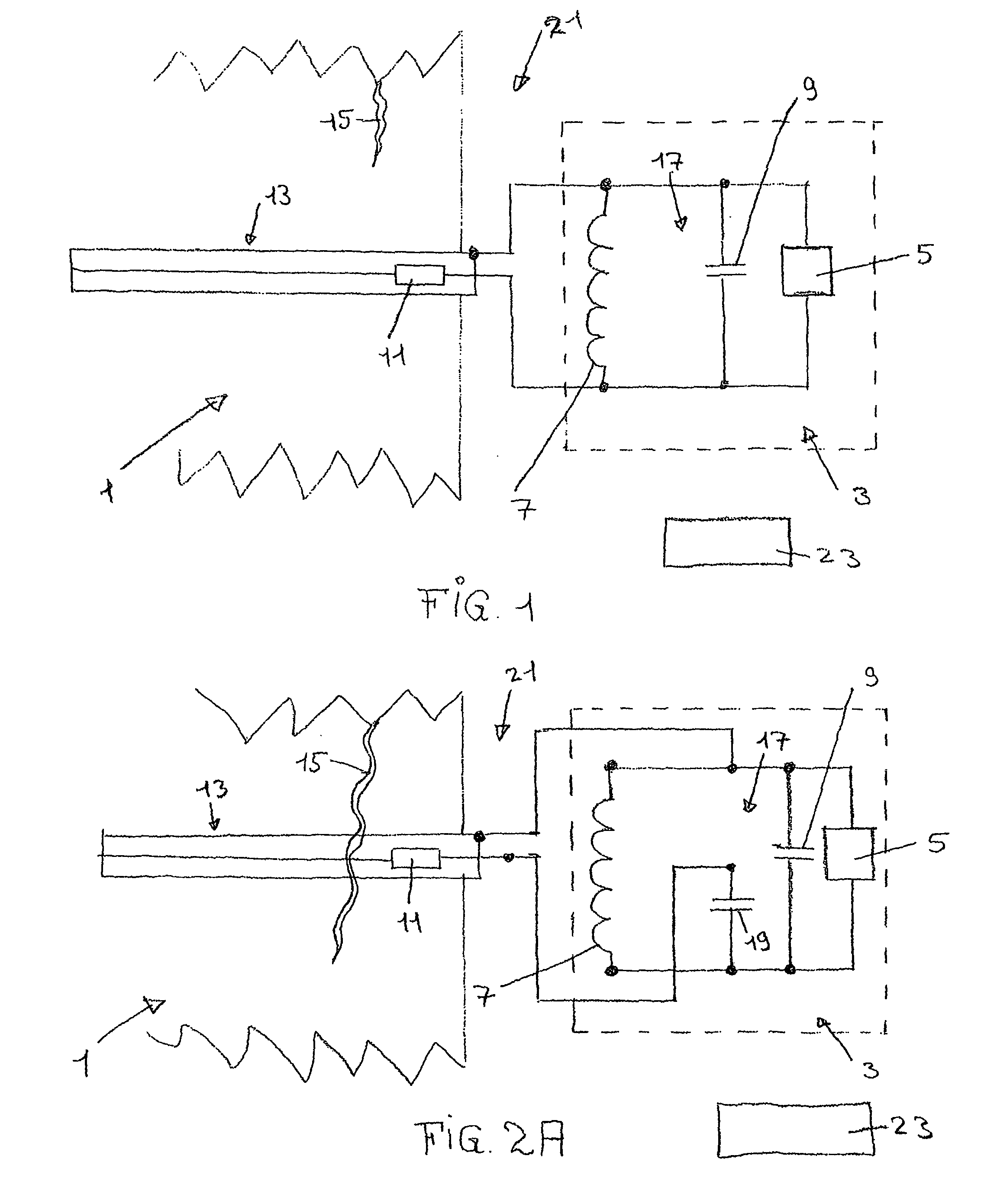

Irregularity detection in a structure of an aircraft

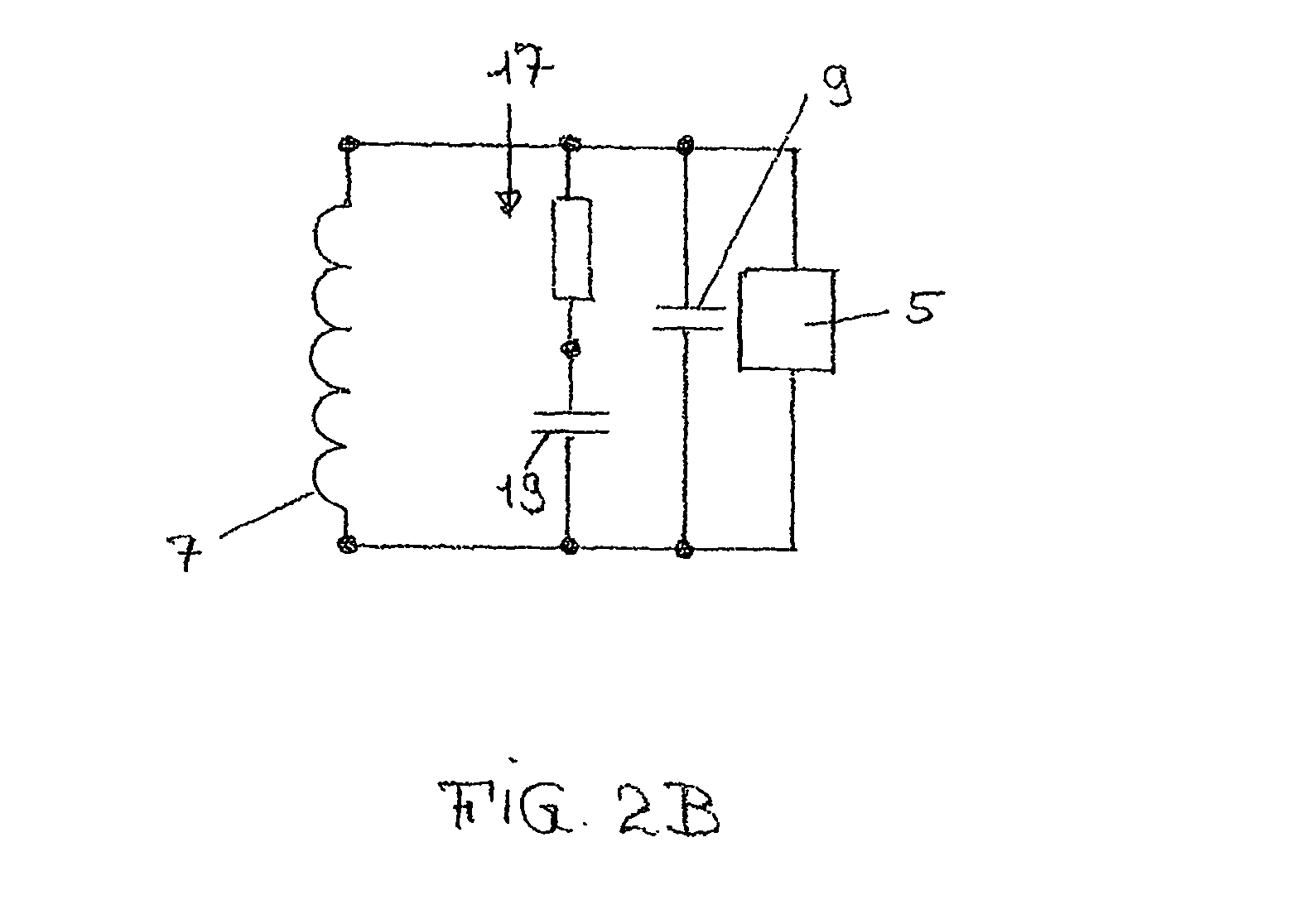

InactiveUS20110248732A1Low costSaving weightResistance/reactance/impedenceMaterial resistanceResonanceAirplane

A device, a system and a method for detecting an irregularity in a structure of an aircraft are proposed. The device includes a resonant circuit with a resonance frequency and a probe for tuning the resonance frequency of the resonant circuit. The resonant circuit and the probe are operatively connected in such a way that the probe changes the resonance frequency of the resonant circuit if the structure changes due to a formation of an irregularity.

Owner:EADS DEUT GMBH +1

Anticorrosion anti-sulfur wear-resistant oil pipe laser cladding coating preparation process

InactiveCN105586588AIntensity has no effectGuaranteed StrengthMetallic material coating processesMelting tankHeat-affected zone

The present invention discloses an anticorrosion anti-sulfur wear-resistant oil pipe laser cladding coating preparation process. According to the preparation process, a 5000 W cross-flow CO2 laser is used, and the work platform is a digital control laser processing machine; nickel-based alloy powder is automatically conveyed into a laser cladding pool by using a coaxial or paraxial powder conveying device, and a uniform and compact anticorrosion anti-sulfur wear-resistant laser cladding coating with a thickness of 3-6 mm is formed on the processed surface; and a laser surface cladding process is used, the heat-affected zone is small and the strength of the oil pipe is not affected during the cladding process, and the nickel-based alloy with characteristics of good corrosion resistance and high strength is used, such that the oil pipe achieves excellent corrosion resistance and excellent wear resistance while the strength of the oil pipe is ensured. According to the present invention, corrosion resistance, sulfur resistance and wear resistance of the oil pipe are reinforced, the service life of the oil pipe is prolonged, and the long-term problem in the application fields of the oil pipes and the oil pipe corrosion in the petroleum exploration, the oil, gas and water well production operation and construction, and maintenance is solved.

Owner:HUBEI XINCHEN AUTOMATION EQUIP

Laser-cladding coating preparation process of corrosion-resistant, sulfur-resistant and wear-resistant tubing coupling

ActiveCN104032301AIntensity has no effectGuaranteed StrengthMetallic material coating processesMelting tankNumerical control

The invention discloses a laser-cladding coating preparation process of a corrosion-resistant, sulfur-resistant and wear-resistant tubing coupling. A 5000 W cross-flow CO2 laser is used; a working platform is a numerical control laser machine; a coaxial or paraxial powder feeding device is used for automatically feeding nickel-based alloy powder into a laser molten pool; and a corrosion-resistant, sulfur-resistant and wear-resistant laser-cladding coating with uniformity and compactness is formed on a processing surface, and is 3-6 mm thick. A laser surface cladding process is adopted; in the cladding process, a heat-affected zone is small, and no influence is generated on the strength of the coupling; and nickel-based alloy with good corrosion resistance and high strength is adopted, so that the coupling obtains excellent corrosion resistance and wear resistance while the strength of the coupling is guaranteed. The preparation process intensifies the corrosion resistance, sulfur resistance and wear resistance of the tubing coupling, prolongs the service life of the tubing coupling, and solves a difficulty unsolved for a long time in the corrosion-resistant application field of an oil tube and the tubing coupling in the oil exploitation and the production operation and maintenance of oil, gas and water wells in our country.

Owner:江苏点金激光科技有限公司

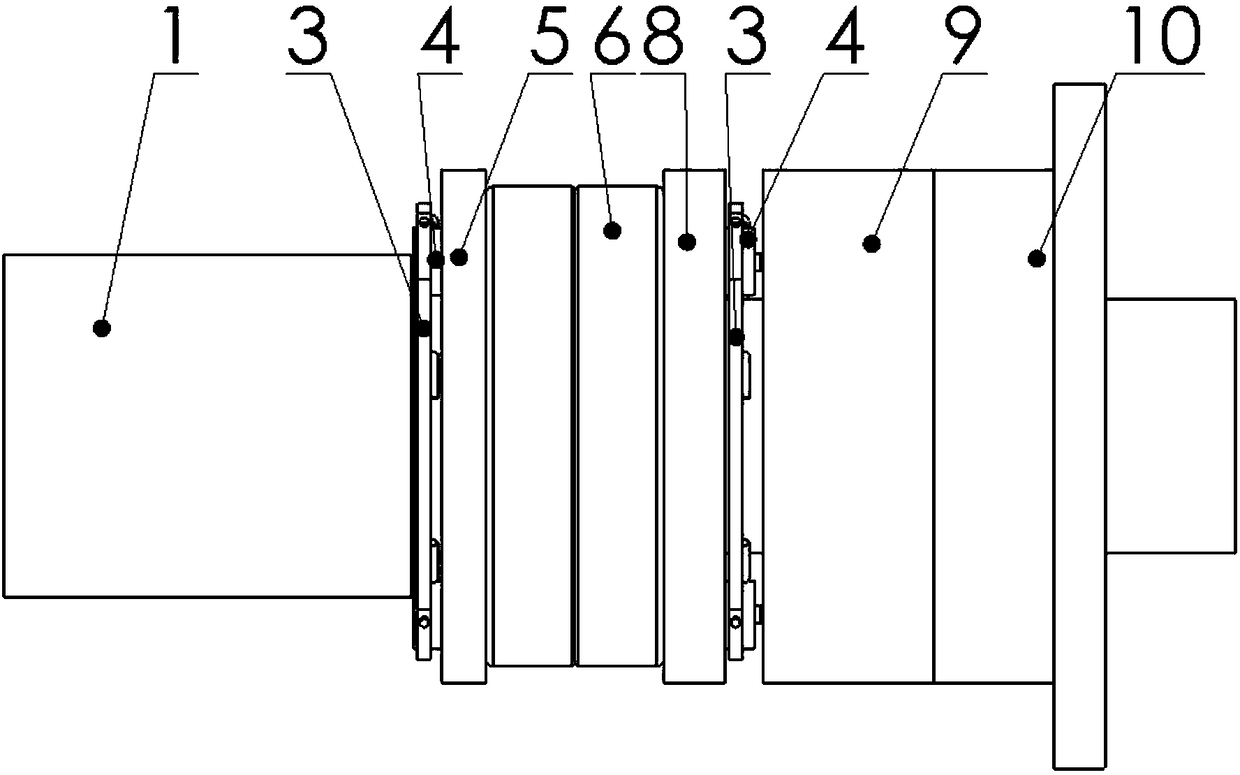

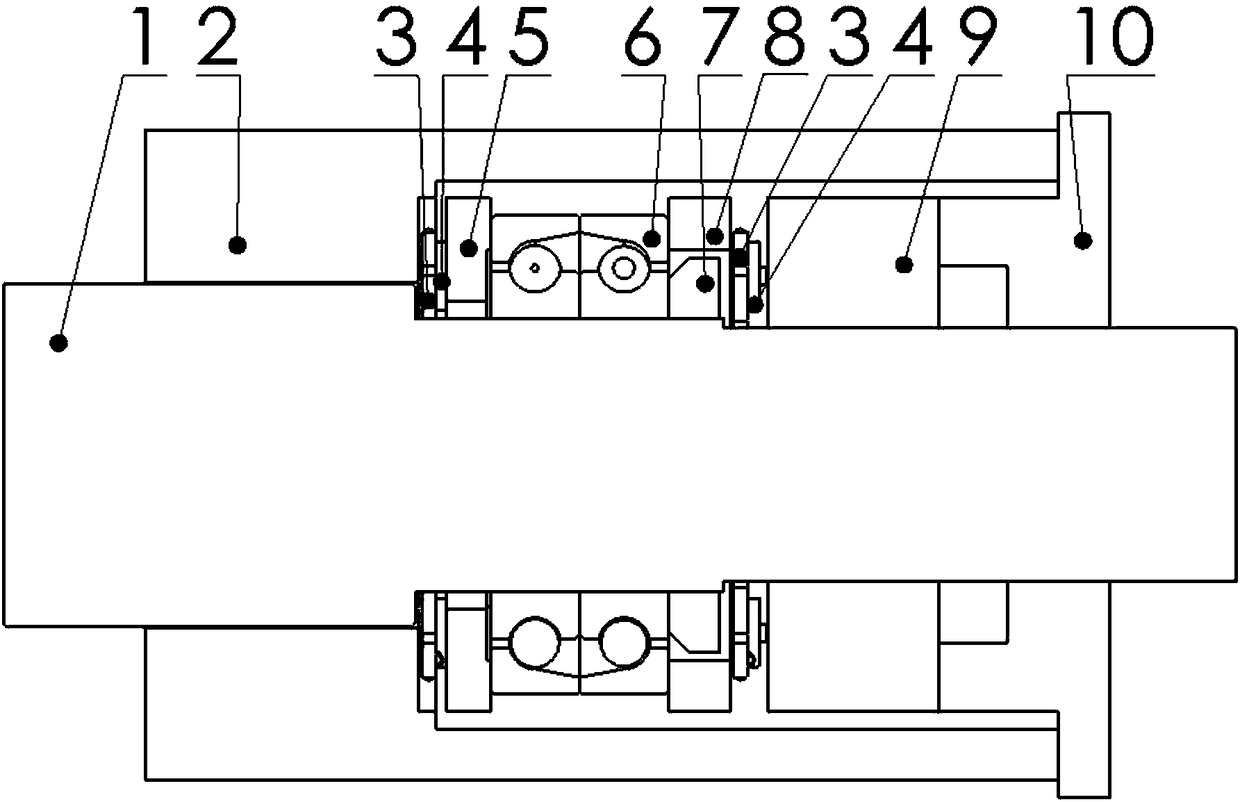

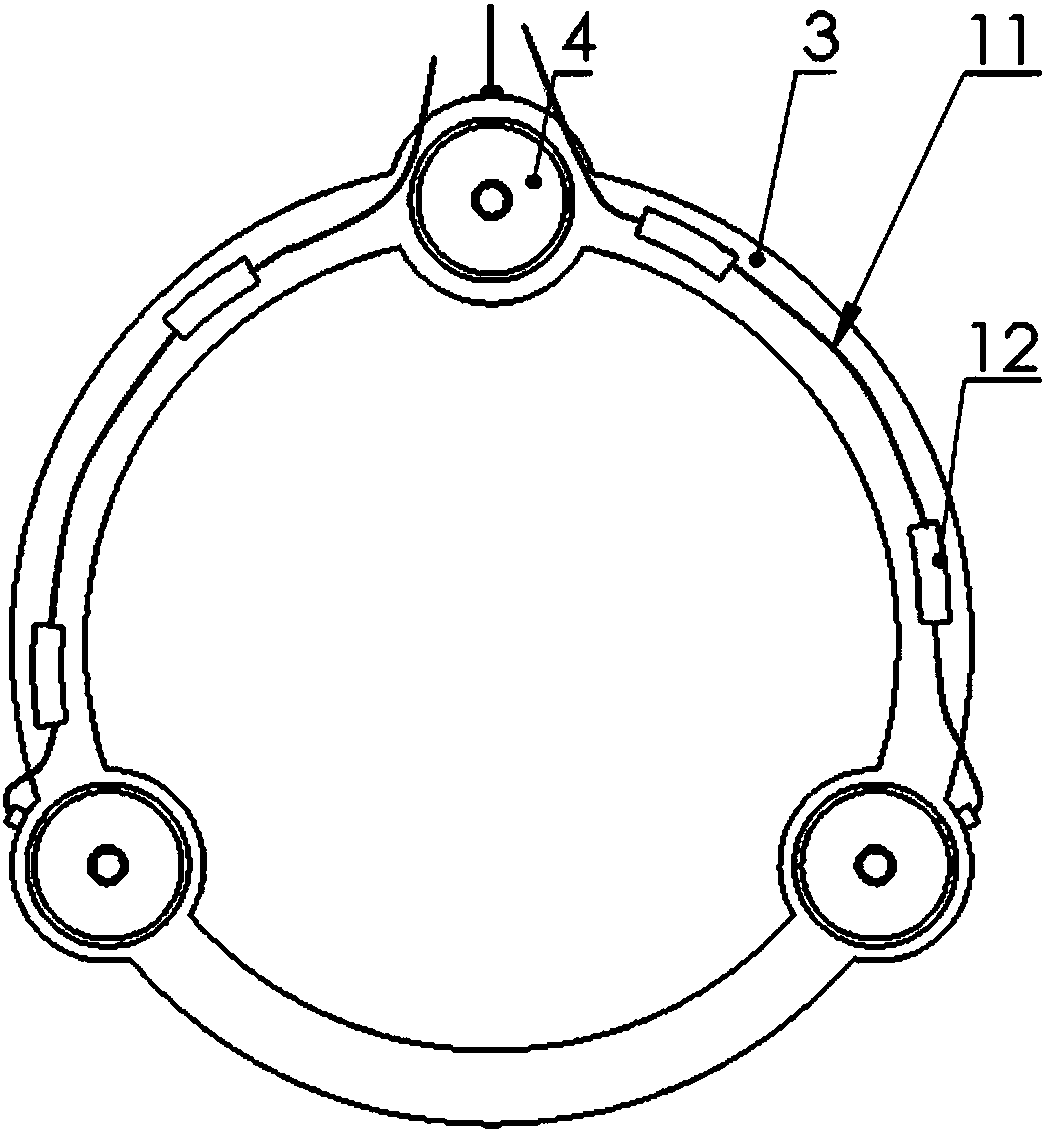

Measuring device and method for rotor axial force of double-screw compressor

ActiveCN108534940AStable and real-time measurementStable and real-time monitoringApparatus for force/torque/work measurementGas compressorThrust bearing

The invention discloses a measuring device and method for rotor axial force of a double-screw compressor. The measuring device mainly comprises two groups of stress sensors arranged on two sides of athrust bearing at an exhaust end of the double-screw compressor, each group of stress sensor assembly comprises three standard stress sensors, stress is uniform, stable measurement and real-time monitoring can be realized, and the three standard stress sensors are fixed on a corresponding bracket and are mounted and positioned by through holes. The measuring device adopts two-way force measurementdesign, can accurately measure the direction and magnitude of axial force without interference to operation of a rotor.

Owner:XI AN JIAOTONG UNIV

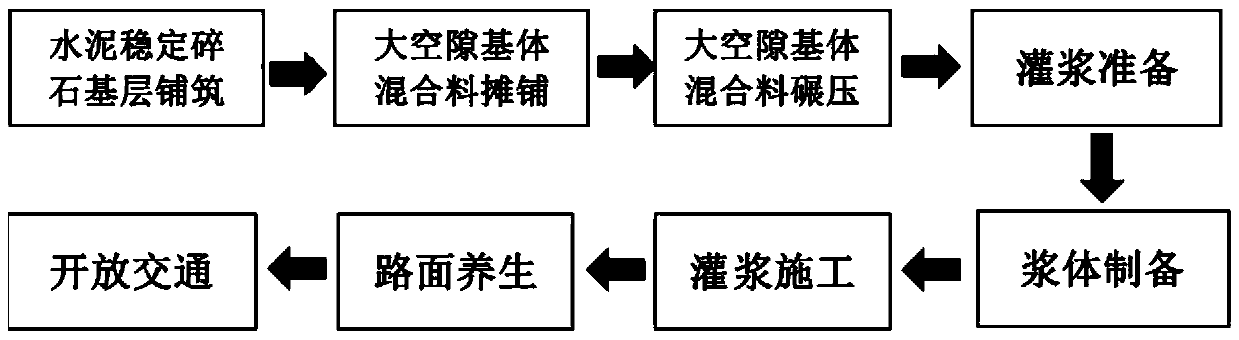

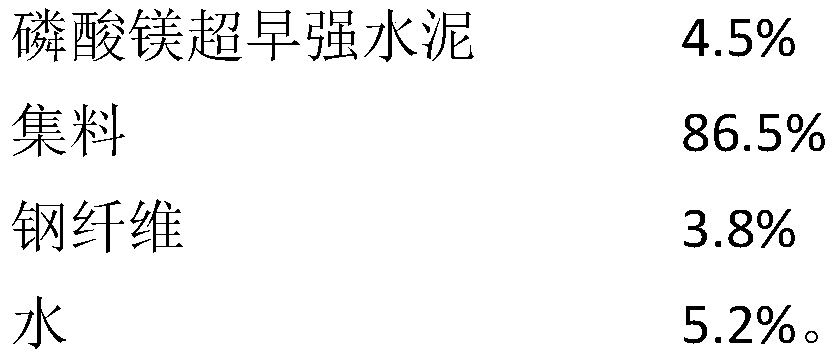

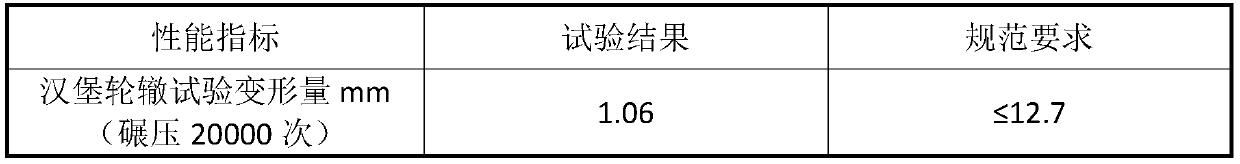

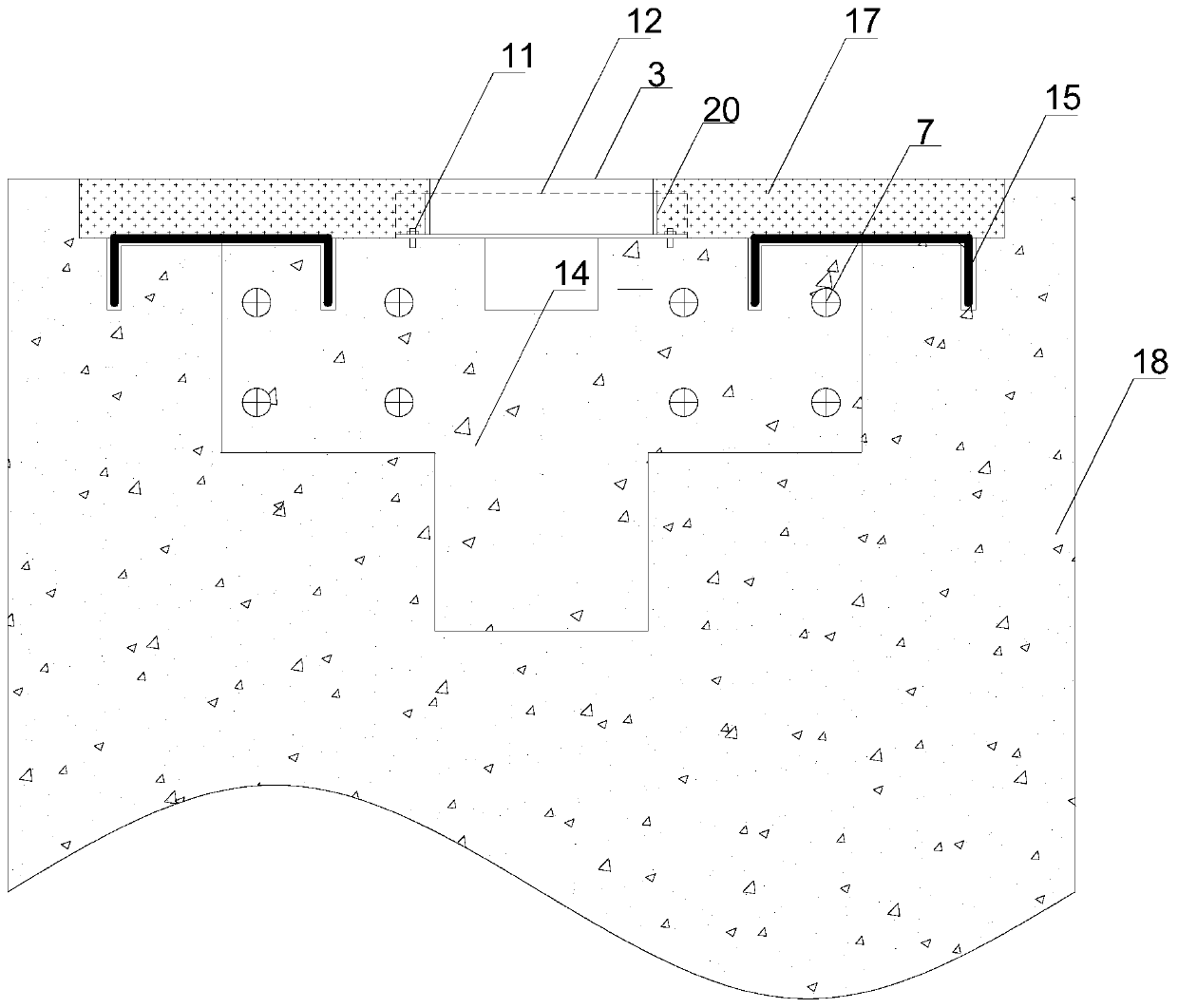

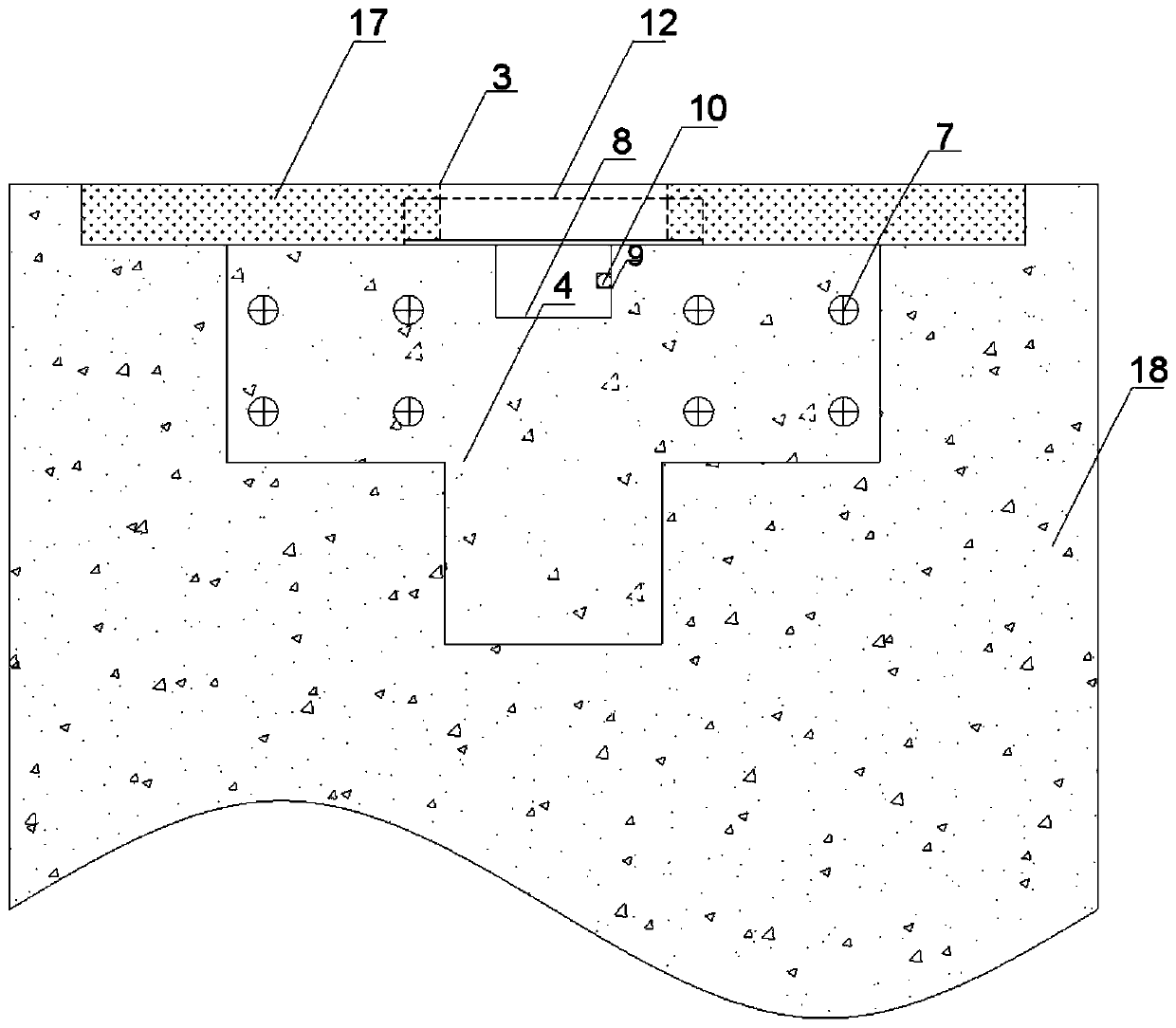

Anti-rut pavement paving method capable of continuously paving base layer and surface layer

PendingCN111549608ASolve temperature problemsSolving Difficult to Compact ProblemsIn situ pavingsRoad engineeringStructural engineering

The invention discloses an anti-rut pavement paving method capable of continuously paving a base layer and a surface layer, and belongs to the field of road engineering. The method is characterized inthat a super-early-strength anti-cracking cement stabilized macadam base layer is paved firstly, and after the base layer is rolled, a cold-mixed cold-paved rigid-flexible composite surface layer ispaved under the condition that the surface is still in a wet state. Compared with the prior art, according to the anti-rut pavement paving method capable of continuously paving the base layer and thesurface layer, continuous paving of the cement stabilized macadam base layer and the surface layer can be realized; maintenance time for 7 days of the cement stabilized macadam base layer can be omitted, meanwhile, the continuity of the base layer and the surface layer is improved, the overall cooperative stress of the pavement structure is guaranteed, a permeable layer and a macadam sealing layerdo not need to be sprayed on the surface of the cement stabilized macadam base layer, and the construction cost is reduced. Meanwhile, the cold-mixed and cold-paved rigid-flexible composite surface layer does not need centralized hot mixing, so that construction is convenient, resources are saved, and the environment is protected. The anti-rutt pavement structure with the base layer and the surface layer capable of being continuously paved has high high-temperature anti-rutting performance, anti-cracking performance, water stability and durability, and has high popularization and applicationvalues.

Owner:SHANDONG TRANSPORTATION INST +2

Precision pump with multiple heads

ActiveUS20100158716A1Save money and maintenance timeLittle delayPositive displacement pump componentsFlexible member pumpsEngineeringBiological activation

Owner:TELEDYNE DIGITAL IMAGING US INC

Embedding structure and method for preventing cracking of concrete pavement luminous marks

ActiveCN111254778AImproved anti-reflective crack performanceReduce widthSingle unit pavingsPaving gutters/kerbsArchitectural engineeringRoad surface

The invention discloses an embedding structure and method for preventing cracking of concrete pavement luminous marks. A step-shaped groove is embedded in a pavement, luminous marks are uniformly arranged on the upper surface of a precast concrete member, PVC casing pipes are arranged in holes on one side of a shaping plate type component, reinforcing steel bars are arranged in holes on the otherside, a drainage groove is formed in the middle of the upper surface of the precast concrete member, strip-shaped grooves are formed above a joint at equal intervals, drilling holes are formed at bothends of the strip-shaped grooves, the middle parts of horseshoe ribs are matched with the strip-shaped grooves, both ends of the horseshoe ribs are arranged in the drilling holes, second equilateralangle steels are arranged on the upper surface of the precast concrete member and are symmetrically distributed along the drainage groove, first equilateral angle steels are perpendicularly arranged on both sides of the second equilateral angle steels, the luminous marks are arranged between the first equilateral angle steels and the second equilateral angle steels, and an asphalt layer is arranged above the pavement. The anti-reflection crack performance of the concrete surface layer where the luminous marks are buried can be improved, and the width and expansion of concrete pavement cracks are reduced.

Owner:NANTONG TIANCHENG OPTOELECTRONICS TECH CO LTD

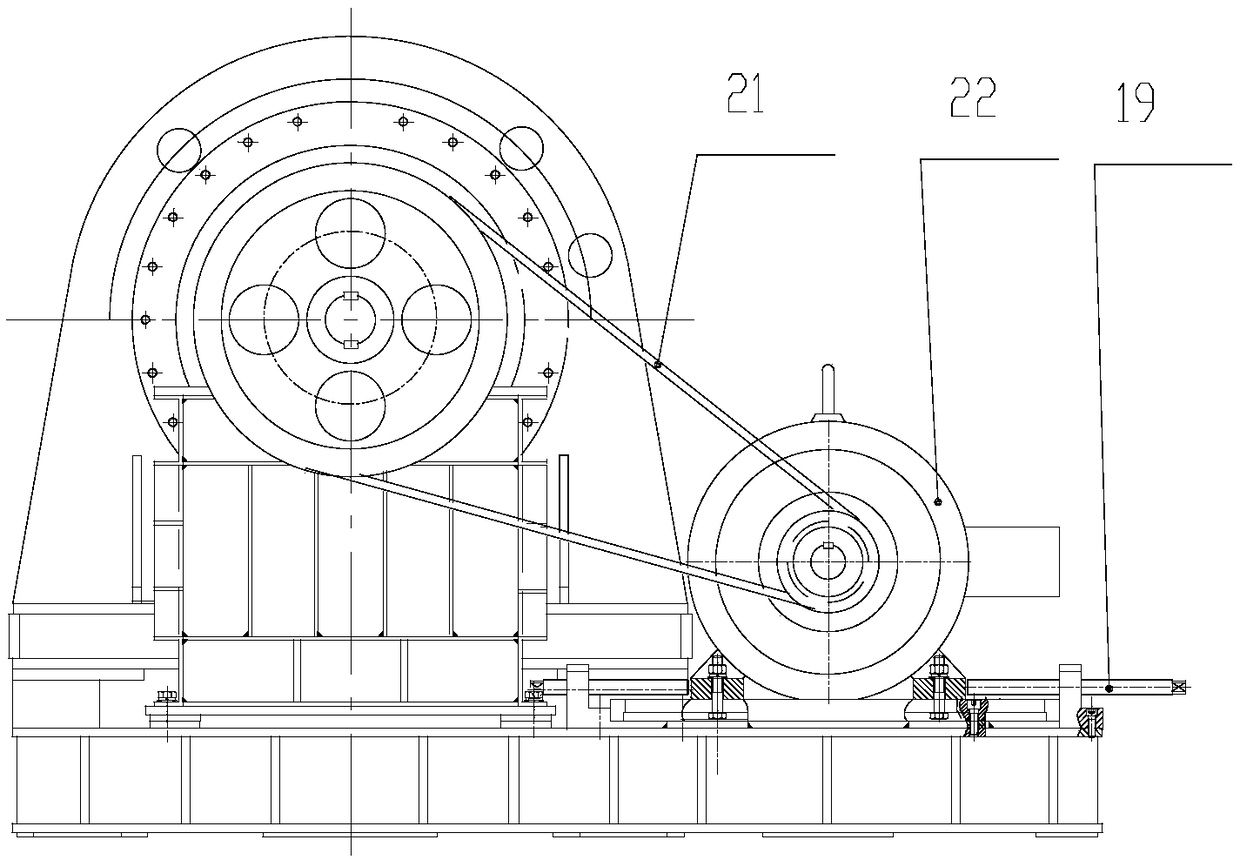

Water lubricated bearing performance test device

InactiveCN109238704AEasy maintenanceSufficient maintenance space, convenient maintenanceMachine bearings testingTransmission beltDrive shaft

The invention relates to an inspection device, in particular to a water lubricated bearing performance test device. The water lubricated bearing performance test device comprises a base; a servo motor, a transmission device, a slave and a water tank are mounted on the base; a driving pulley is mounted on a shaft of the servo motor; the driving pulley is connected with a driven pulley on the transmission device by utilizing a transmission belt; the rear end of a driven shaft in the slave runs through the water tank; and a water lubricated bearing device set is mounted at a part of the driven shaft , which passes through the water tank. The water lubricated bearing performance test device is compact and reasonable in structure and good in integrity; the water lubricated bearing performance test device is simple in manufacturability, good in interchangeability, sufficient in assembling and repairing space and convenient to maintain and repair, can be used for various construction operations, and saves maintenance, clamping and disassembling time of testing personnel; the difficult problem of performance test of a water lubricated bearing of a domestic ship shafting is solved; and meanwhile, the water lubricated bearing performance test device can also give consideration to a torque and implements safety and high efficiency in the testing process, labor is saved, and cost is reduced.

Owner:WUXI HONGYUAN DEVFLEX

Display panel thin grinder

InactiveCN101143424AEven flow distributionConsistent grinding efficiencyOptical surface grinding machinesEngineeringGuide tube

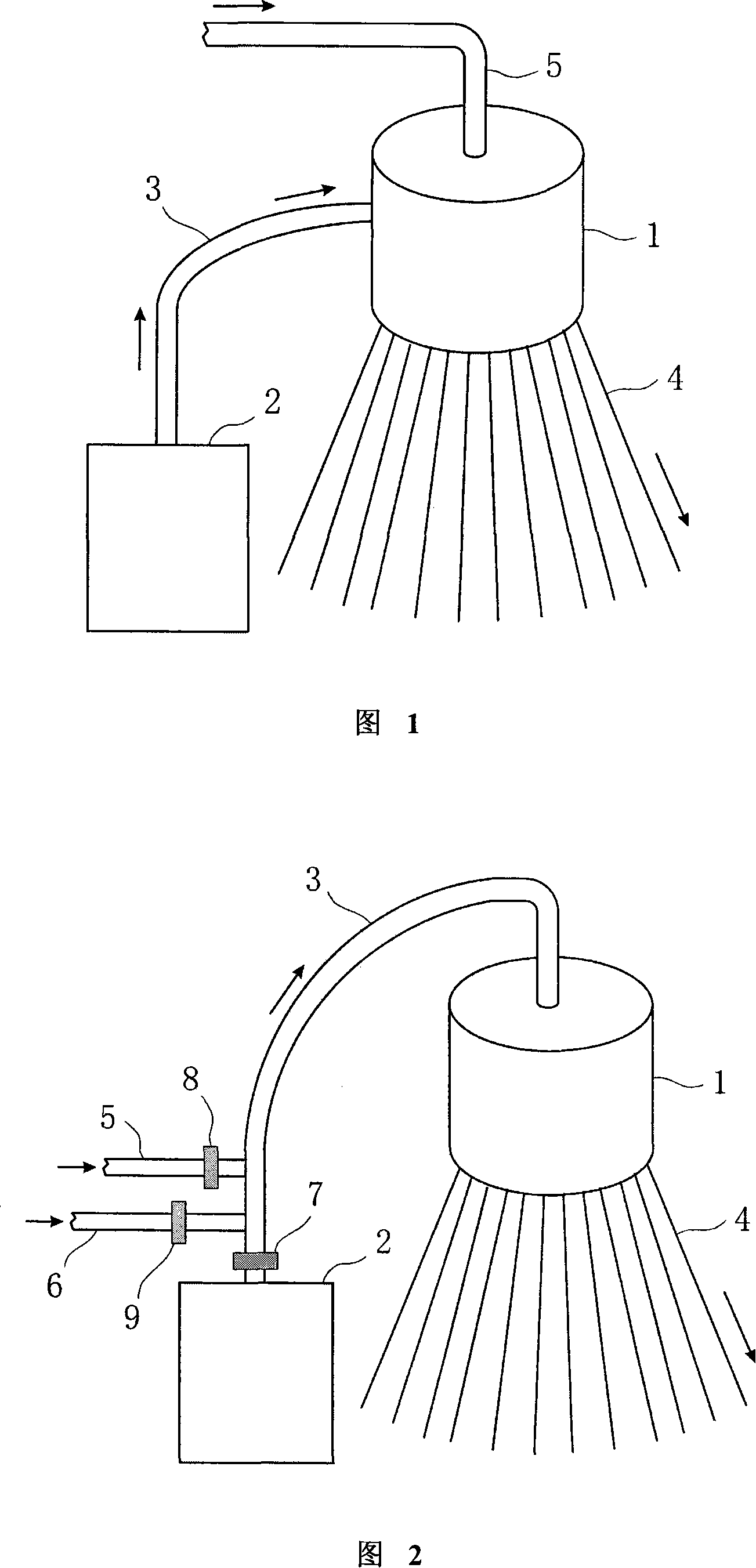

The invention discloses a display-panel thinning grinding machine, consisting of an overhead supply tank (1), a storage tank for grinding fluid (2), a grinding platform, a grinding fluid pipe (3) connecting with the storage tank for grinding fluid (2) and the overhead supply tank (1) and a plurality of catheters (4) connecting with the overhead supply tank (1) and the grinding platform, wherein the connecting ports between the catheters (4) and the overhead supply tank (1) are located at the bottom of the overhead supply tank (1), and the grinding fluid pipe (3) is connected from the top central location of the overhead supply tank (1). Besides, a water pipe (5) and a compressed air pipe (6) are respectively connected to the grinding fluid pipe (3). The invention enables the flow of grinding fluid provided to a system is uniform and the grinding efficiency of different regions of a glass substrate keeps the same; at the same time, the invention can clean the grinding fluid left in the pipe in a better way, thereby avoiding the impact of grinding fluid on a attached polishing pad, lowering cost, facilitating cleaning, saving maintenance time and improving yields.

Owner:AU OPTRONICS (SUZHOU) CORP LTD

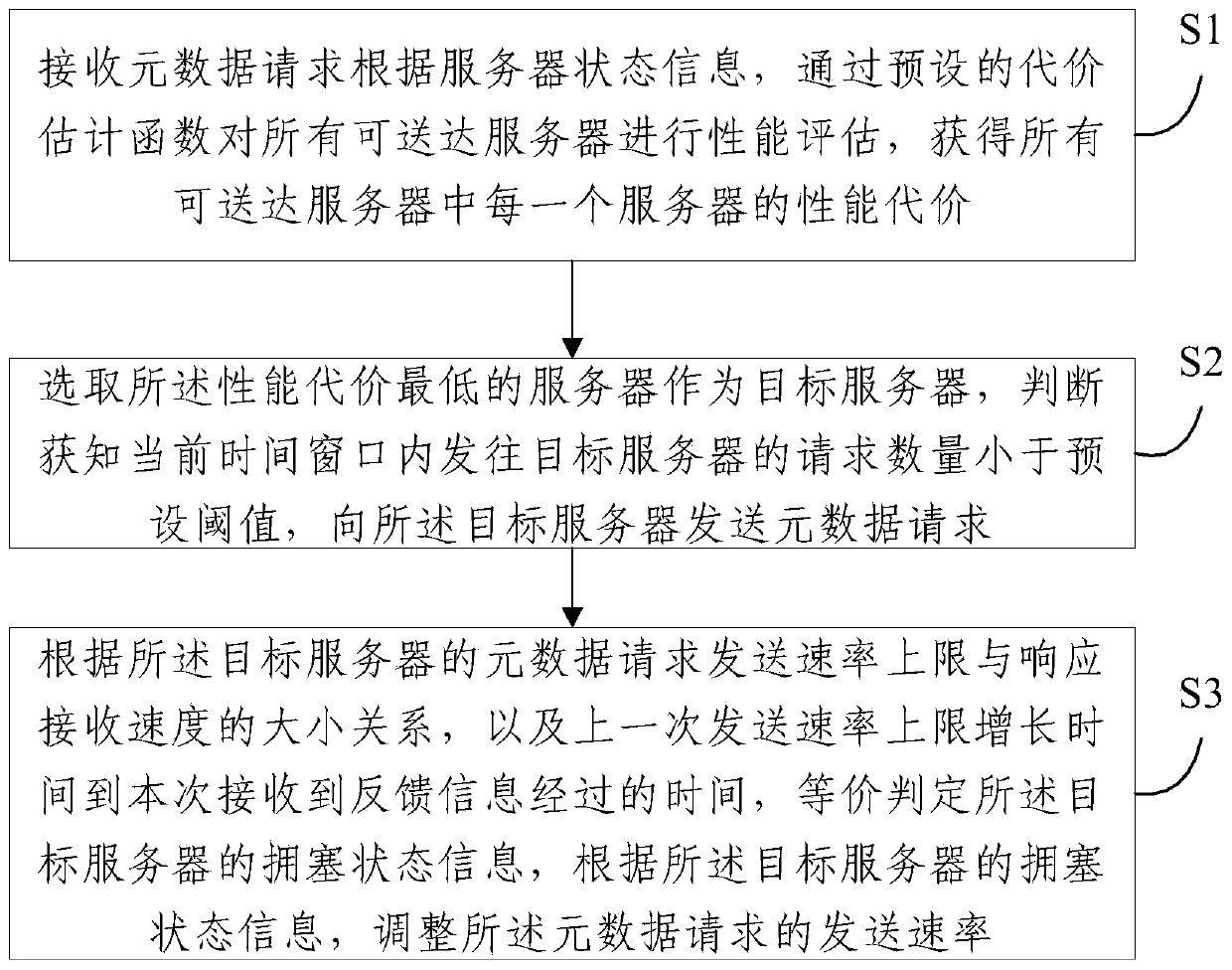

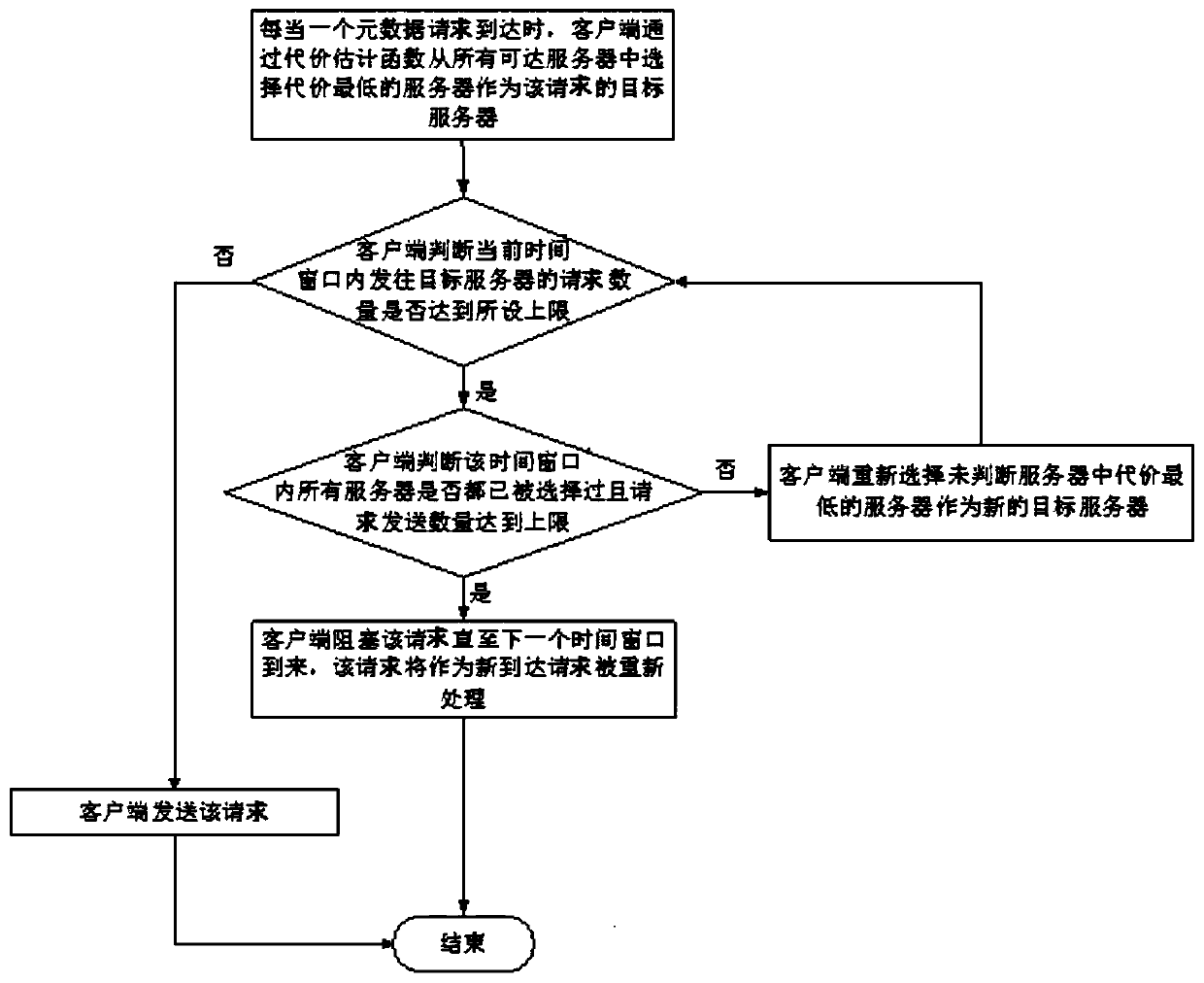

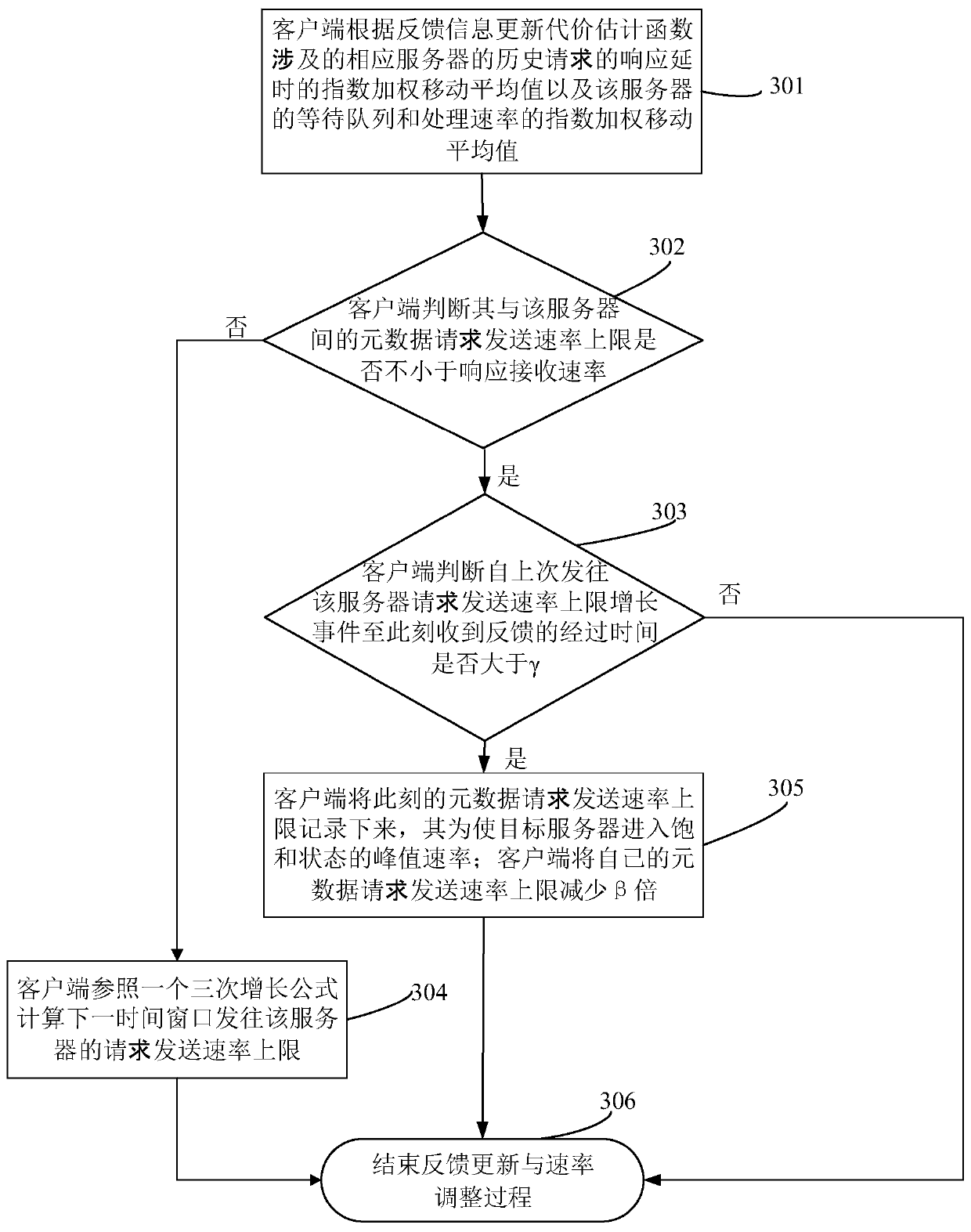

A metadata request distribution method and device based on congestion perception

ActiveCN109815204AProcessing speedImprove throughputDigital data information retrievalTransmissionPattern perceptionClient-side

The embodiment of the invention provides a metadata request distribution method and device based on congestion perception. The method comprises the steps of receiving a metadata request and server state information of all reachable servers, performing performance evaluation on all the reachable servers through a preset cost estimation function according to the server state information, and obtaining the performance cost of each server in all the reachable servers; selecting a server with the lowest performance cost as a target server, judging and knowing that the number of requests sent to thetarget server in the current time window is smaller than a preset threshold value, and sending a metadata request to the target server; And the client equivalently judges the congestion state of thetarget server, and adjusts the sending rate of the metadata request according to the congestion state of the target server. According to the method provided by the invention, the processing speed of the metadata request and the throughput rate of the whole system are improved, the request sending rate is adjusted by sensing the congestion condition of the server, and the maintenance cost and the time cost of the system are saved.

Owner:TSINGHUA UNIV

Fence guard

Disclosed is a covering designed to be attached to and along the bottom portion of chain-linked and other similar types of fencing in order to prevent grass and weeds from growing between the links. Produced in varying lengths from a rubber or plastic type material, the covering has an L-shaped profile that allows it to be placed along the bottom edge of the fencing resting on the ground and against the fence. The mowing strip portion of the L-shape guard that rests upon the ground extends out horizontally from the bottom of the fence serves a shield that will prevent plant growth along the fence line.

Owner:THOMPSON ALLEN R +1

Whole forging process method of super-high pressure valve body

InactiveCN103962486AGuarantee the quality of die forgingFast fullMetal-working apparatusOil drillingHigh pressure

The invention relates to a processing technology of a mechanical part, in particular to a whole forging process method of a super-high pressure valve body. The whole forging process method is characterized by comprising the following processes of: blanking round steel, heating to an initial forging standard temperature plus 50 DEG C, die-forging, forming, testing and warehousing. The whole forging process method has the benefits that the defects that an existing valve body is processed by welding or assembly, a disc body and a guide body have low concentricity, the service life is short, and the like are overcome; the valve body manufactured by the whole forging process method is mainly used in high-power fracturing equipment for oil drilling operation.

Owner:卢清华

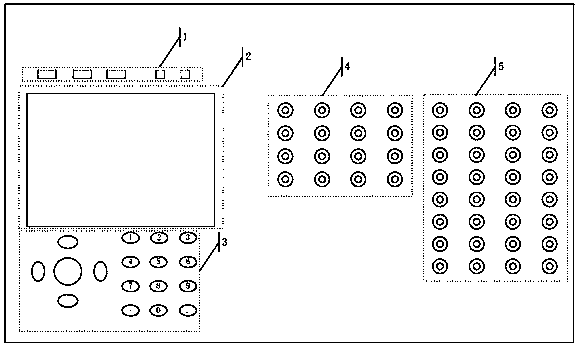

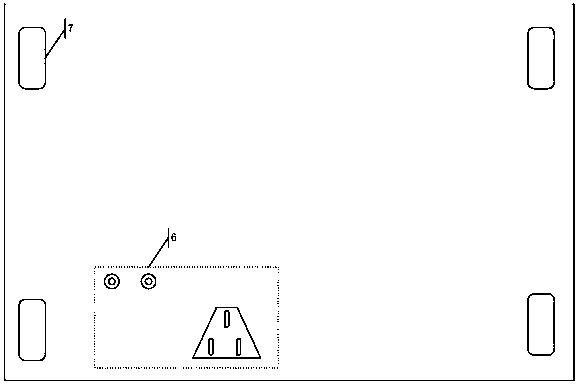

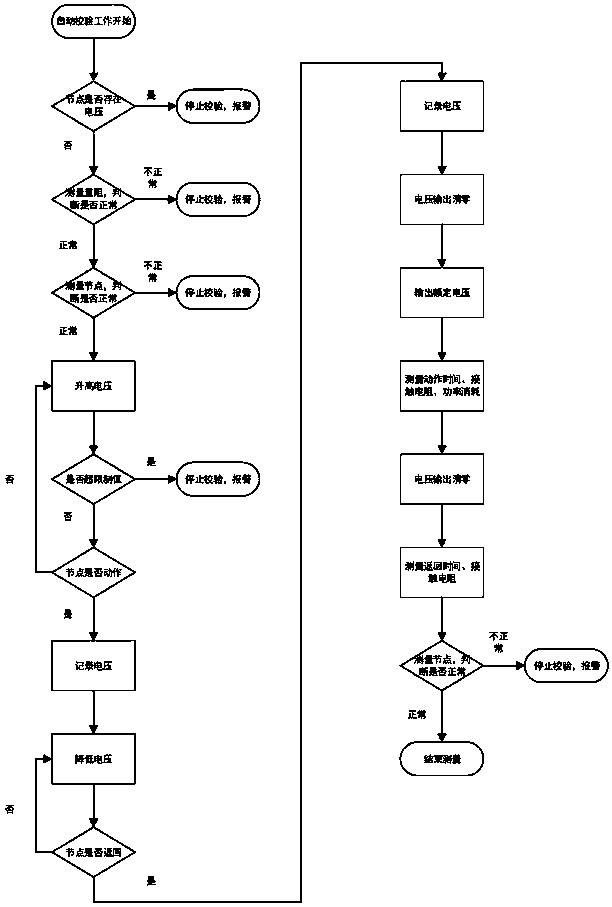

Moving type relay fully automatic verification device

ActiveCN109459689AImprove reliabilitySave human effortCircuit interrupters testingElectrical resistance and conductanceUltrasound attenuation

The invention belongs to the technical field of electrical research debugging maintaining, and particularly relates to a moving type relay fully automatic verification device. The device comprises anexternal interface module, a touch control screen, a button control area, an output interface module, a node interface module and a power supply interface; the touch control screen comprises all controlling functions and receives all information feedback of other components, and an operator perform all operations of parameter setting, variable input, starting, stopping and switching on and off when the device is operated; the button control area transmits instructions to the touch control screen and can takes the place of the touch control screen to execute all operations; the output interfacemodule is responsible for outputting direct current voltage or alternate current voltage and can measure the direct resistance of a coil and perform real-time power calculation; the node interface module is responsible for measuring the on and off of a node and measures the resistance and attenuation time of the node. The device has the advantages that problems of low relay verification and measuring operation efficiency, poor safety performance, the failure of evaluating the operating state of the relay and the like.

Owner:HAINAN NUCLEAR POWER

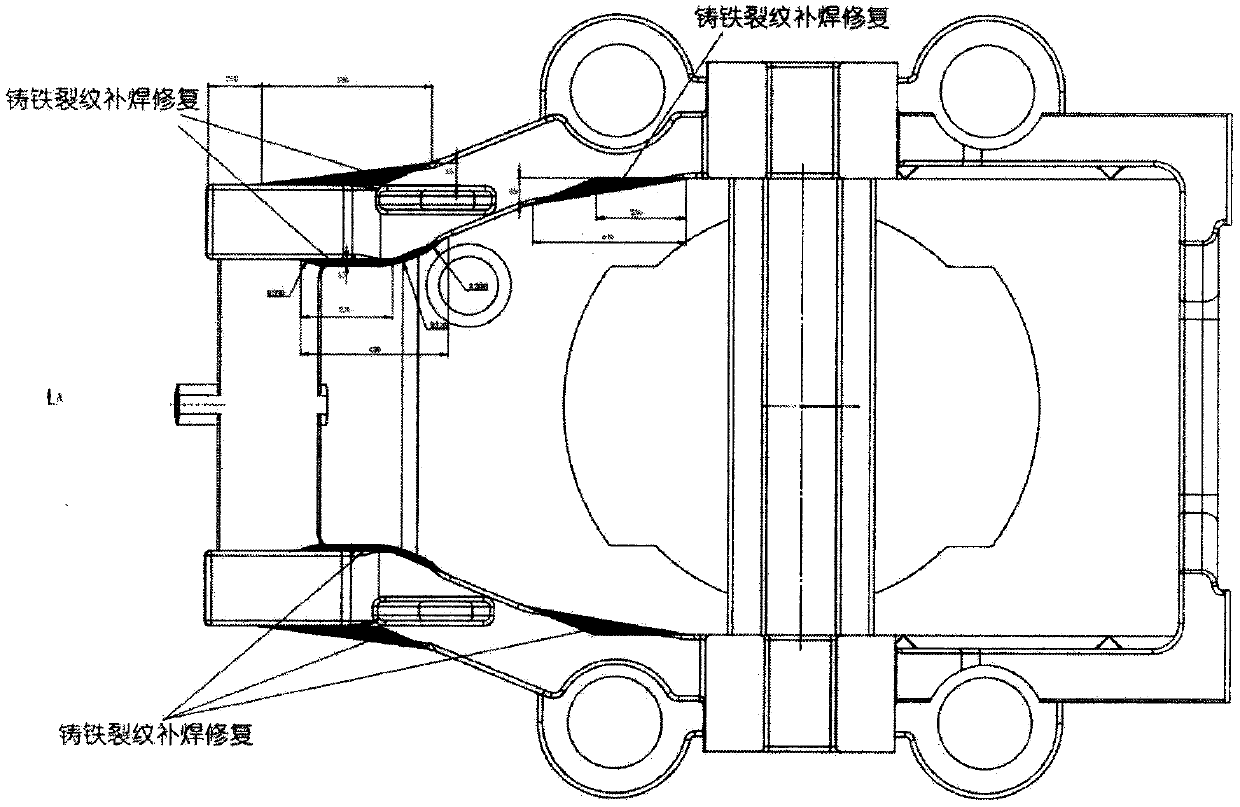

Repair technology for wind turbine cabin chassis crack repairing welding and strengthening

InactiveCN111318781AExtended service lifeSave maintenance timeWelding accessoriesDuctile ironCold welding

The invention discloses a repair technology for wind turbine cabin chassis crack repairing welding and strengthening, and relates to the technical field of on-line cold welding repair technology for large spheroidal graphite cast iron. The repair technology for wind turbine cabin chassis crack repairing welding and strengthening comprises a welding repair at a chassis crack and a reinforcing rib strengthening at the chassis outside; the welding repair at the chassis crack selects to use a AMALLOY440 cast iron welding rod according to the characteristics and weldability of spheroidal graphite cast iron, a weld of the AMALLOY440 cast iron welding rod can meet the mechanical strength and ductility required for the welding of the spheroidal graphite cast iron. The repair technology for wind turbine cabin chassis crack repairing welding and strengthening can realize a wide range of cold welding on a front cabin base in a fan field, the service life of the base is prolonged, and the maintenance time is greatly shortened and the cost is greatly saved.

Owner:TIANJIN YINGYUAN WELDING TECH +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com