Anti-rut pavement paving method capable of continuously paving base layer and surface layer

An anti-rutting and base-layer technology, applied to roads, roads, on-site coagulation pavements, etc., can solve the problems of increasing construction costs, prolonging the construction period, and low strength, so as to ensure no cracking, improve crack resistance, and save The effect of maintenance time and maintenance cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

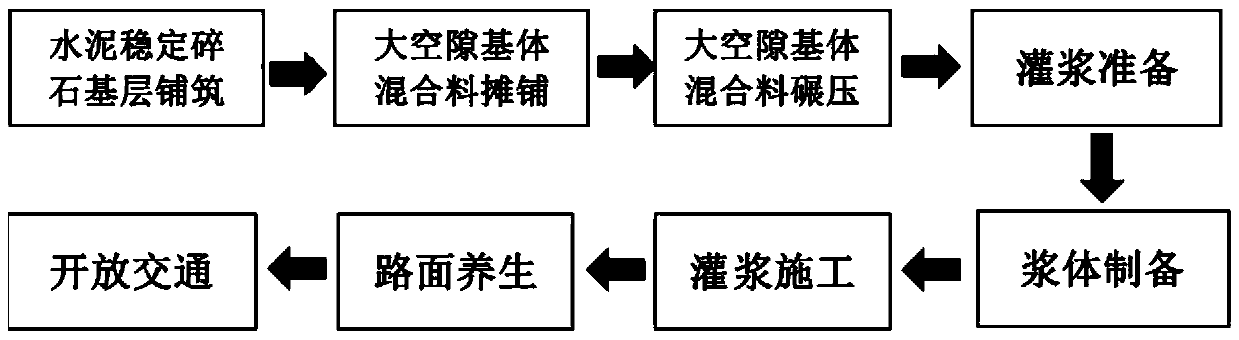

Method used

Image

Examples

Embodiment 1

[0033] The anti-rutting pavement pavement structure of the base layer and the surface layer of this embodiment that can be continuously paved is composed of a 18cm super early strength anti-cracking cement stabilized macadam lower base paved from bottom to top, a 18cm super early strength anti-cracking cement stabilized macadam The base layer on the stone and the 10cm cold-mixed and cold-laid rigid-flexible composite surface layer.

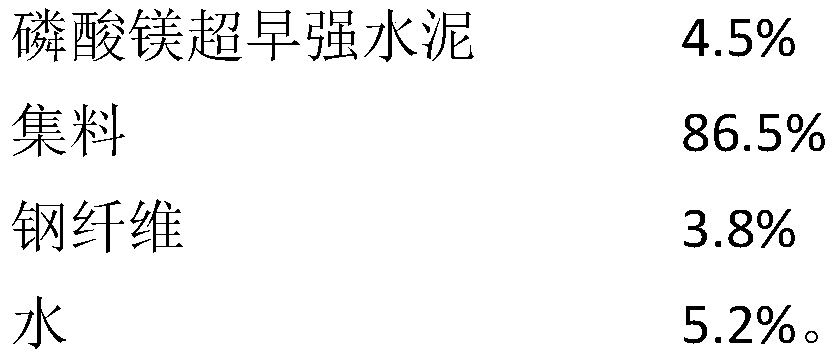

[0034] The super-early-strength anti-cracking cement-stabilized macadam lower base and the super-early-strength anti-cracking cement-stabilized macadam upper-base are mixed with the following materials by mass percentage:

[0035]

[0036] The specific gradation of super early strength anti-cracking cement stabilized crushed stone mixture is:

[0037] Standard sieve hole 26.5mm pass rate range is 100%; standard sieve hole 19mm pass rate range is 83.9%; standard sieve hole 16mm pass rate range is 75.1%; standard sieve hole 9.5mm pass rate range ...

Embodiment 2

[0068] The anti-rutting pavement pavement structure of the base layer and the surface layer that can be paved continuously in this embodiment consists of a 20cm super early strength anti-cracking cement stabilized macadam lower base paved from bottom to top, a 20cm super early strength anti-cracking cement stabilized macadam The base layer on the stone and the 12cm cold-mixed and cold-laid rigid-flexible composite surface layer.

[0069] The super-early-strength anti-cracking cement-stabilized macadam lower base and the super-early-strength anti-cracking cement-stabilized macadam upper-base are mixed with the following materials by mass percentage:

[0070]

[0071] The specific gradation of super early strength anti-cracking cement stabilized crushed stone mixture is:

[0072] Standard sieve hole 26.5mm pass rate range is 100%; standard sieve hole 19mm pass rate range is 82.1%; standard sieve hole 16mm pass rate range is 73.2%; standard sieve hole 9.5mm pass rate range is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com