Whole forging process method of super-high pressure valve body

A technology of integral forging and process method, which is applied in the processing field of mechanical parts, can solve the problems that the concentricity of the disc body and the guide body is difficult to guarantee, the concentricity is difficult to guarantee, and the quality of the product is affected, so as to save equipment maintenance costs and time, The effect of good product quality and high concentricity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

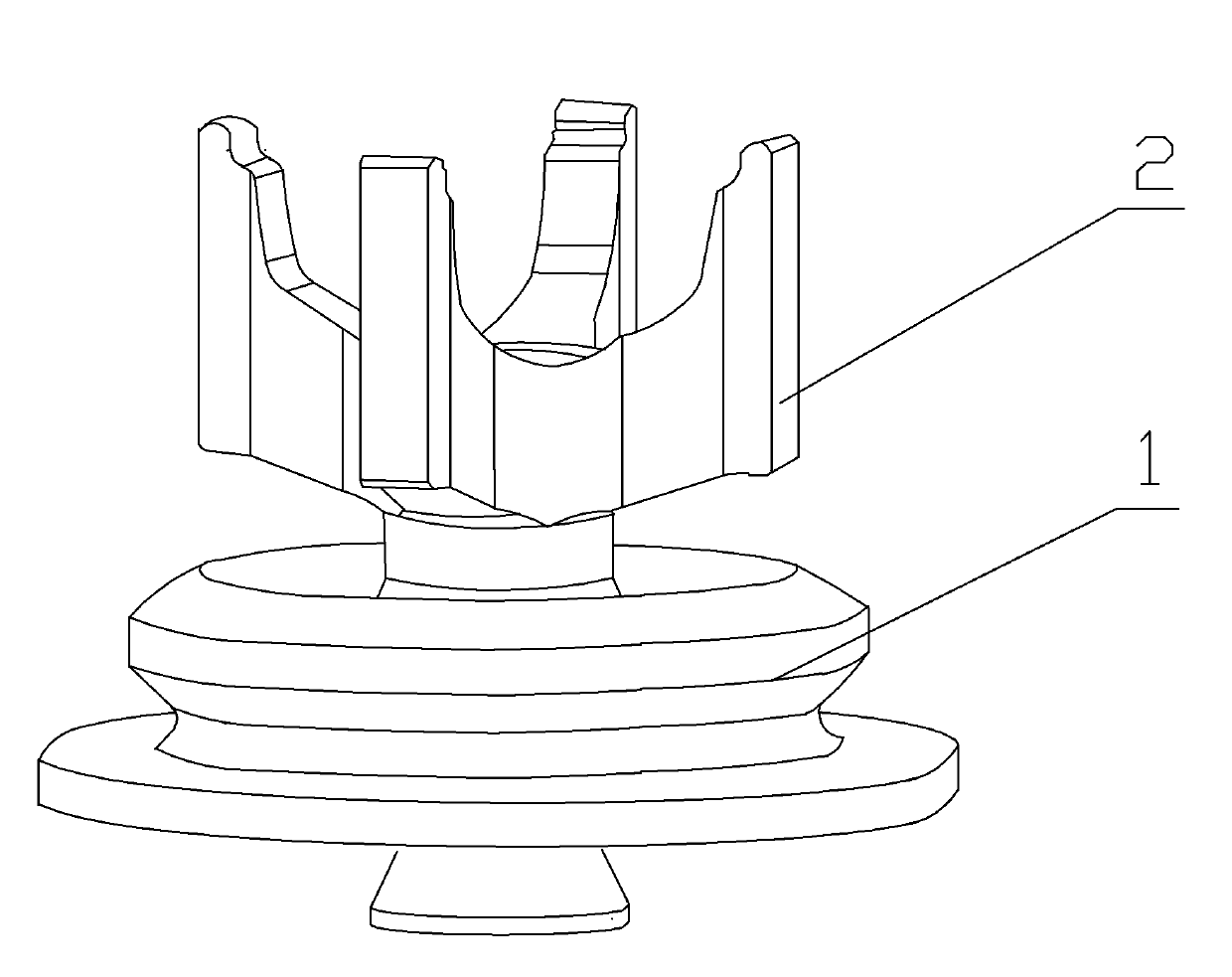

[0010] Example 1: see figure 1 , using the present invention to produce such as figure 1 The method shown for the Valerian body includes the following process: select 42CrMo round steel blanking → use intermediate frequency furnace to heat the round steel material to 1250 ° C → hot forging (forging in a forging die) → forming → inspection → storage.

example 2

[0011] Example 2: adopt the present invention to produce such as figure 1 The method shown for the Valerian body includes the following process: select 40CrNiMo round steel blanking → use intermediate frequency furnace to heat the round steel material to 1240 ° C → hot forging (forging in a forging die) → forming → inspection → storage.

example 3

[0012] Example 3: adopt the present invention to produce such as figure 1 The method shown for the Valerian body includes the following process: select 20CrNiMo round steel blanking → use intermediate frequency furnace to heat the round steel material to 1230 ° C → hot forging (forging in a forging die) → forming → inspection → storage.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com