Chilling ring of gasification furnace

A chilling ring and gasifier technology, which is applied in the gasification of granular/powdered fuels, the manufacture of combustible gas, and the petroleum industry. It can solve problems that affect the stable operation of the gasifier and increase operating costs, and save maintenance time. and maintenance costs, reduction in repair costs, easy replacement and maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

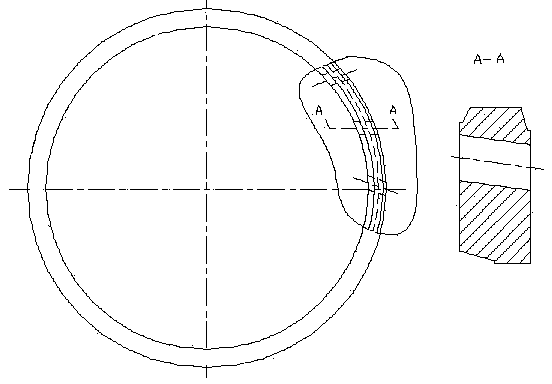

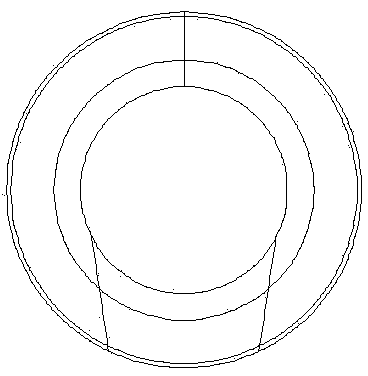

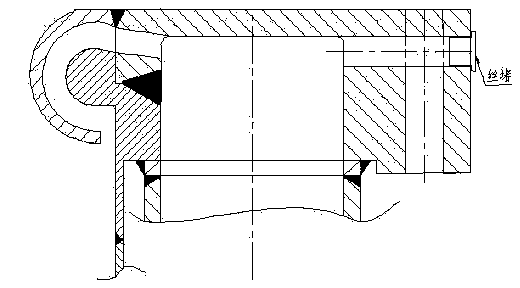

[0025] In the prior art, the structure of a typical gasifier quenching ring is as follows figure 1 As shown, the inner lip ring and the inner ring of the water chamber, the nozzle ring and the outer ring of the water chamber are all integral parts, and the thickness of the outer lip ring is uniform. According to the quenching ring of the gasifier of the present invention, its structure is as follows: figure 2 , 3 , 4 shown.

[0026] An improved gasifier quenching ring, including outer lip ring 1, inner lip ring 2, nozzle ring 4, water chamber inner ring 5, water chamber outer ring 6, water chamber bottom plate 7, downcomer 10 and excitation ring The cold water delivery pipe 9, the inner lip ring 2 and the outer lip ring 1 form the chilled water distribution chamber 3, the water chamber inner ring 5, the nozzle ring 4, the water chamber outer ring 6 and the water chamber bottom plate 7 form the water chamber 8, the chilled water delivery pipe 9 communicates with the water c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com