Water lubricated bearing performance test device

A water-lubricated bearing and test device technology, applied in the direction of mechanical bearing testing, etc., can solve the problems of large wear amount and large temperature rise, and achieve the effects of simple manufacturing process, good interchangeability and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

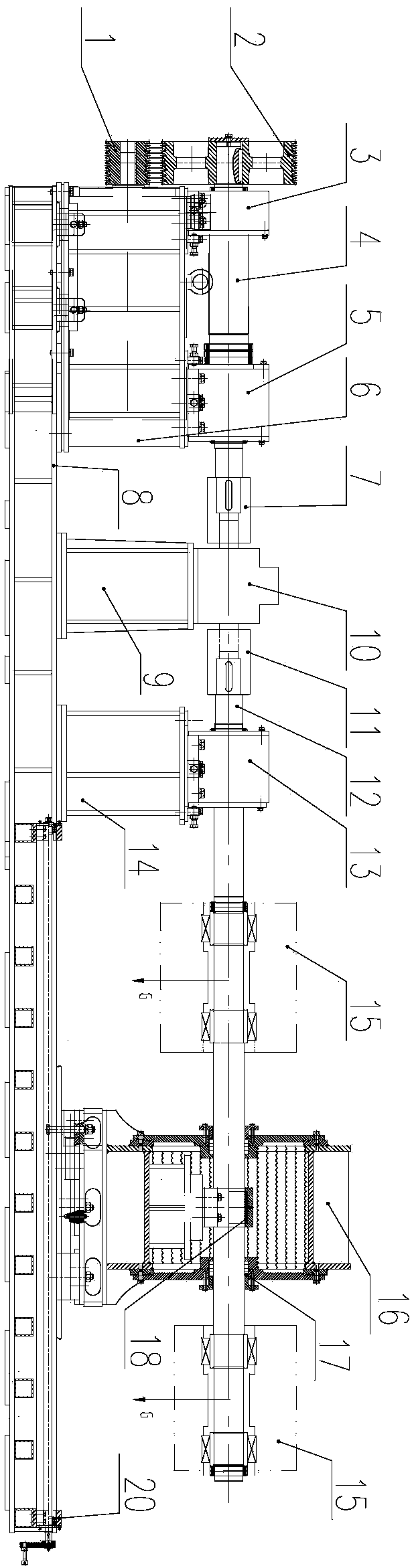

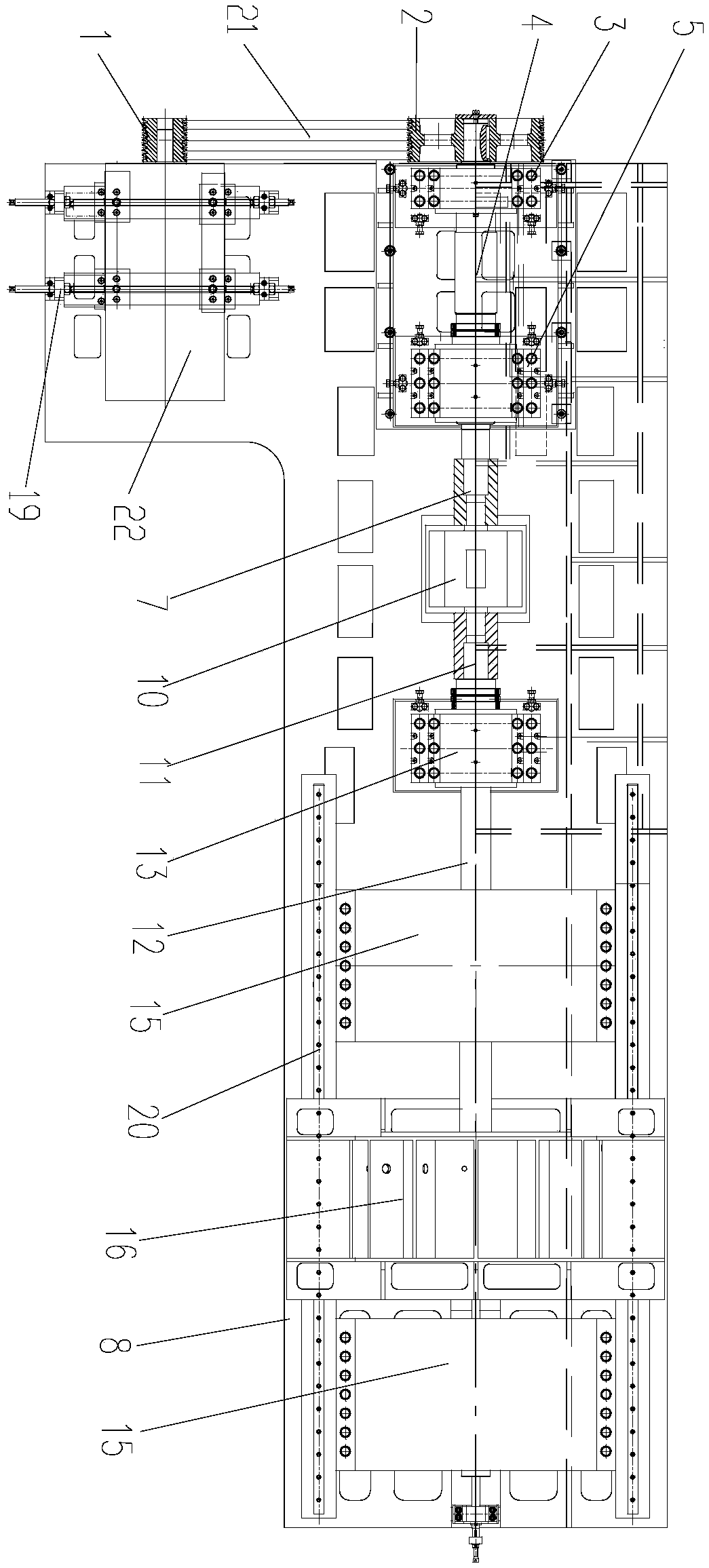

[0016] The present invention will be further described below in combination with specific embodiments and accompanying drawings.

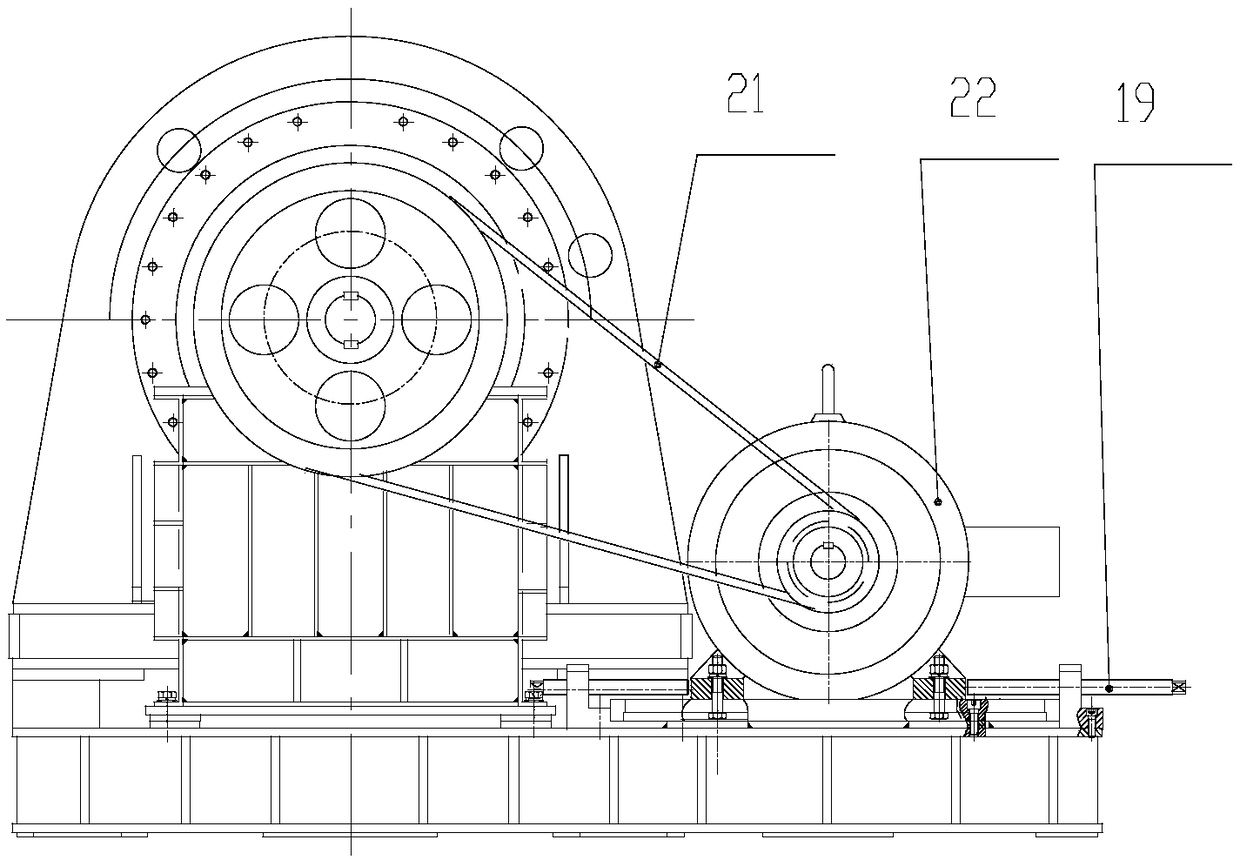

[0017] As shown in the figure: the water-lubricated bearing performance test device includes a base 8 on which a servo motor 22, a transmission device, a driven device and a water tank 16 are installed, and a drive pulley 1 is installed on the shaft of the servo motor 22. The pulley 1 is connected with the driven pulley 2 on the transmission device by a transmission belt 21 .

[0018] The transmission device includes a transmission shaft 4, and the two ends of the transmission shaft 4 are installed in the first bearing seat group 3 and the second bearing seat group 5 respectively. The front end of the transmission shaft 4 is fixedly connected to the driven pulley 2 , and the rear end of the transmission shaft 4 is connected to the output shaft at the front end of the torque testing device 10 by a first coupling 7 . The torque testing device 10 can...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com