Repair technology for wind turbine cabin chassis crack repairing welding and strengthening

A wind turbine, chassis technology, applied in welding equipment, welding accessories, arc welding equipment and other directions, can solve the problems of no repair method, long replacement time, affecting production, etc., to save maintenance time and cost, and improve service life. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

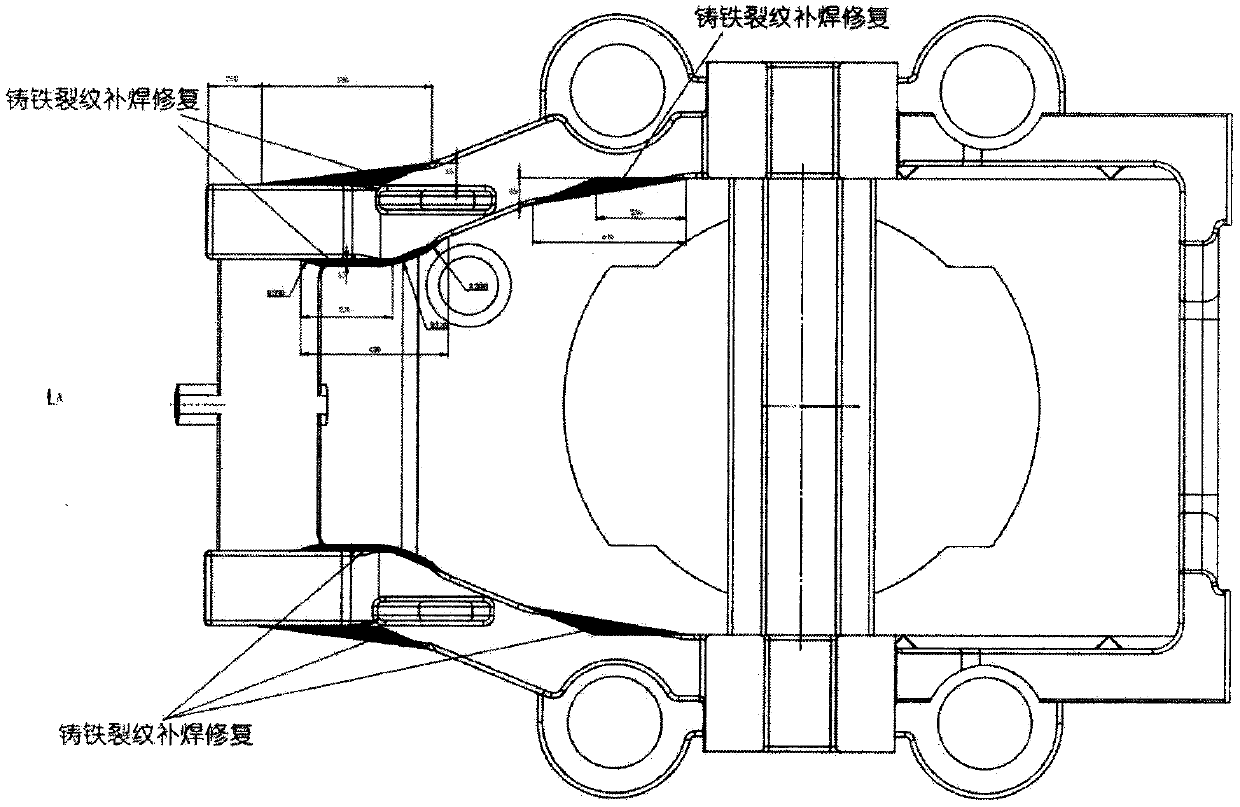

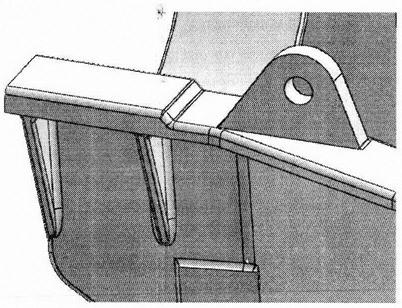

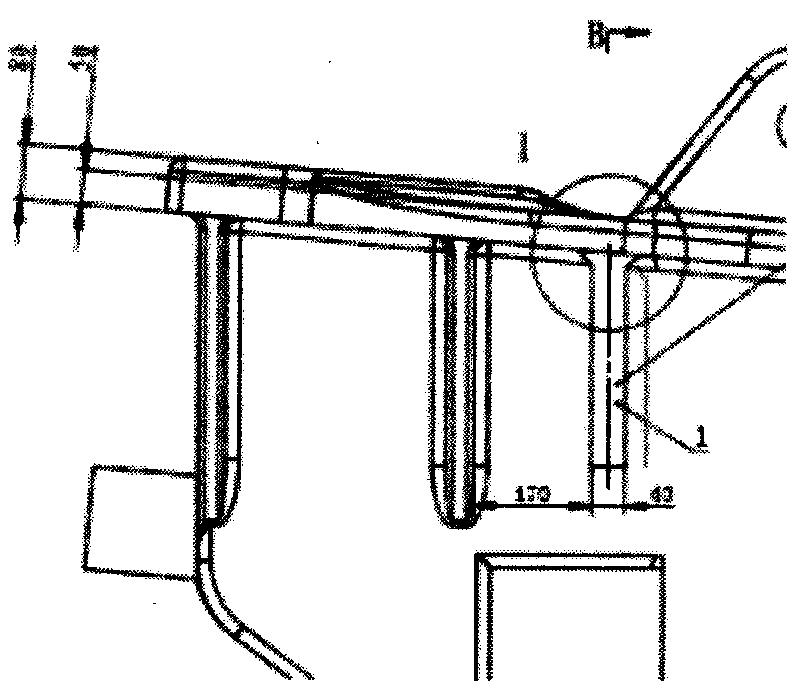

[0030] refer to Figure 1-6 , the specific implementation method adopts the following technical scheme: the repair process of repairing and welding reinforcement of the chassis cracks of the wind turbine generator set, including welding repairs at the cracks of the chassis and reinforcing ribs on the outside of the chassis; the welding repair at the cracks of the chassis is based on the characteristics of nodular cast iron And weldability, choose to use AMALLOY440 cast iron welding rod, its weld can meet the mechanical strength and ductility required by ductile iron welding; it includes the following steps:

[0031] 1 Before welding, the cracks of the chassis of the engine room should be dyed and inspected to clarify the direction and location of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com