Display panel thin grinder

A display panel and grinding machine technology, applied in the direction of optical surface grinders, grinding machines, grinding/polishing equipment, etc., can solve the problems of shortening the life of polishing pads, agglomeration, and not easy to find, so as to save maintenance time and flow distribution Uniformity, the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

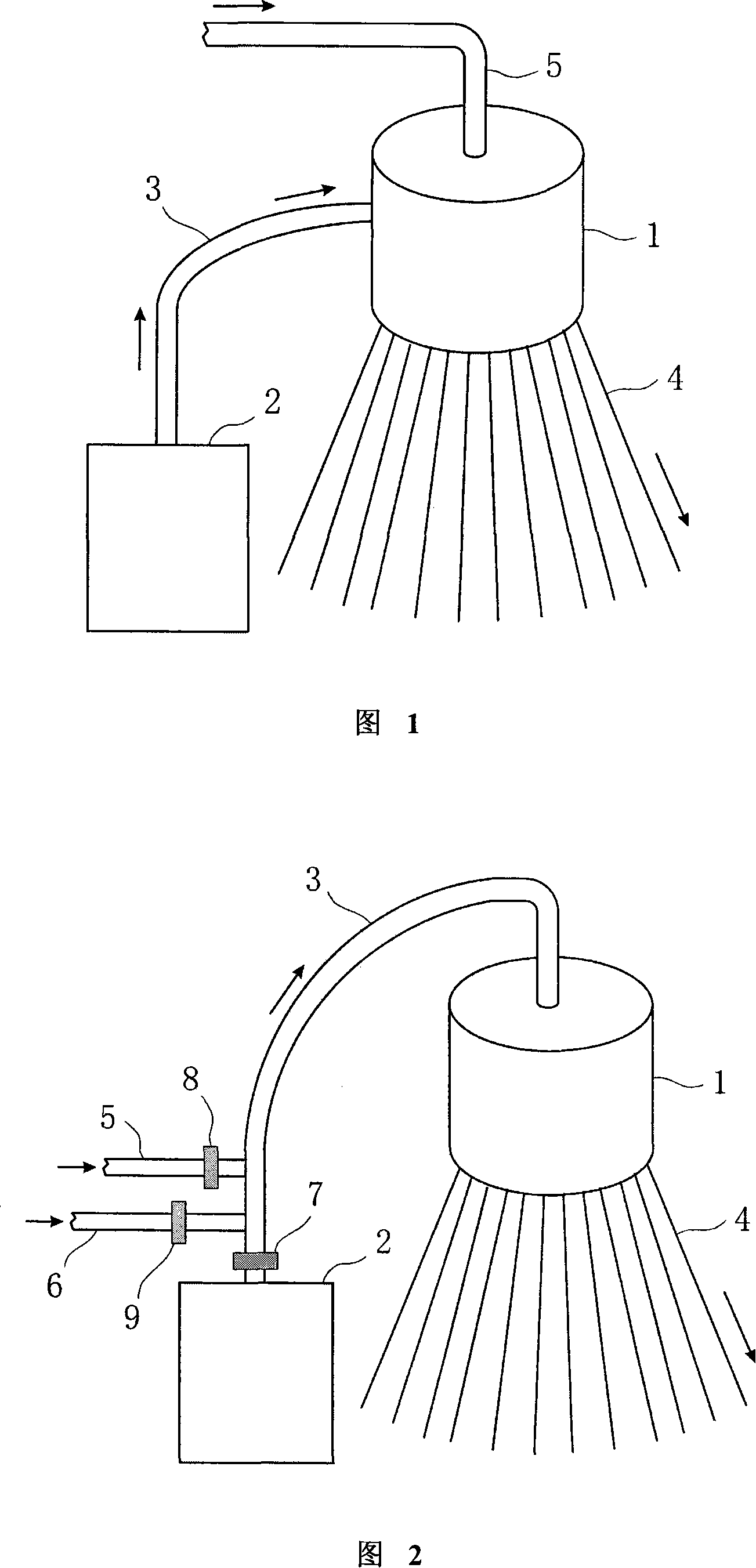

[0026] Embodiment: as shown in Fig. 2, a kind of display panel thinning grinder, it comprises overhead feeding tank 1, grinding fluid storage tank 2, grinding platform, connection grinding fluid storage tank 2 and overhead feeding tank 1 The grinding liquid pipeline 3 and 60 conduits 4 connecting the overhead feed tank and the grinding platform, the connection ports between the conduits 4 and the overhead feed tank 1 are distributed at the bottom of the overhead feed tank 1 .

[0027] The grinding liquid pipeline 3 is connected to the top center of the overhead feed tank 1 . At the same time, the water pipe 5 and the compressed air pipe 6 for conveying compressed air are respectively connected to the grinding liquid pipeline 3 .

[0028] The access position where the water pipe 5 and the compressed air pipe 6 are connected to the grinding liquid pipeline 3 is as close as possible to the grinding liquid pipe control valve 7 . Because the access position of the water pipe 5 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com