Patents

Literature

51results about How to "Fast maintenance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

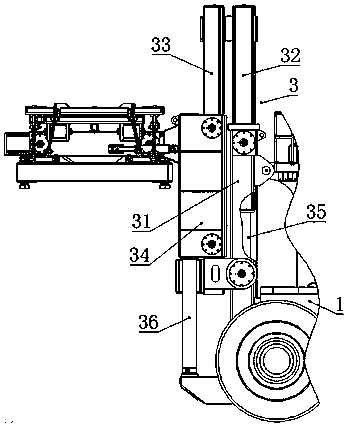

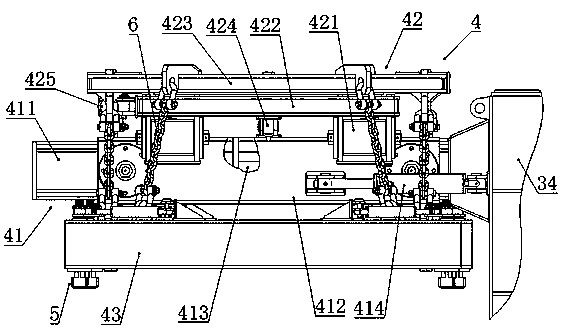

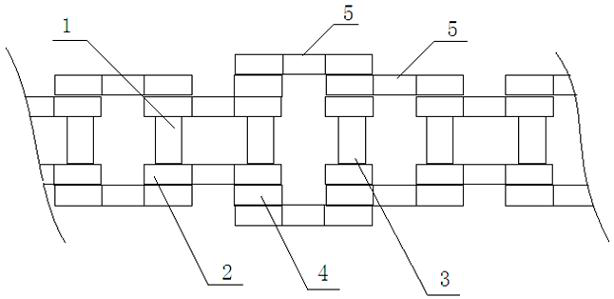

Vertical lifting container

ActiveCN101850884AGuaranteed smoothnessImprove shipping efficiencyStorage devicesSprocketEngineering

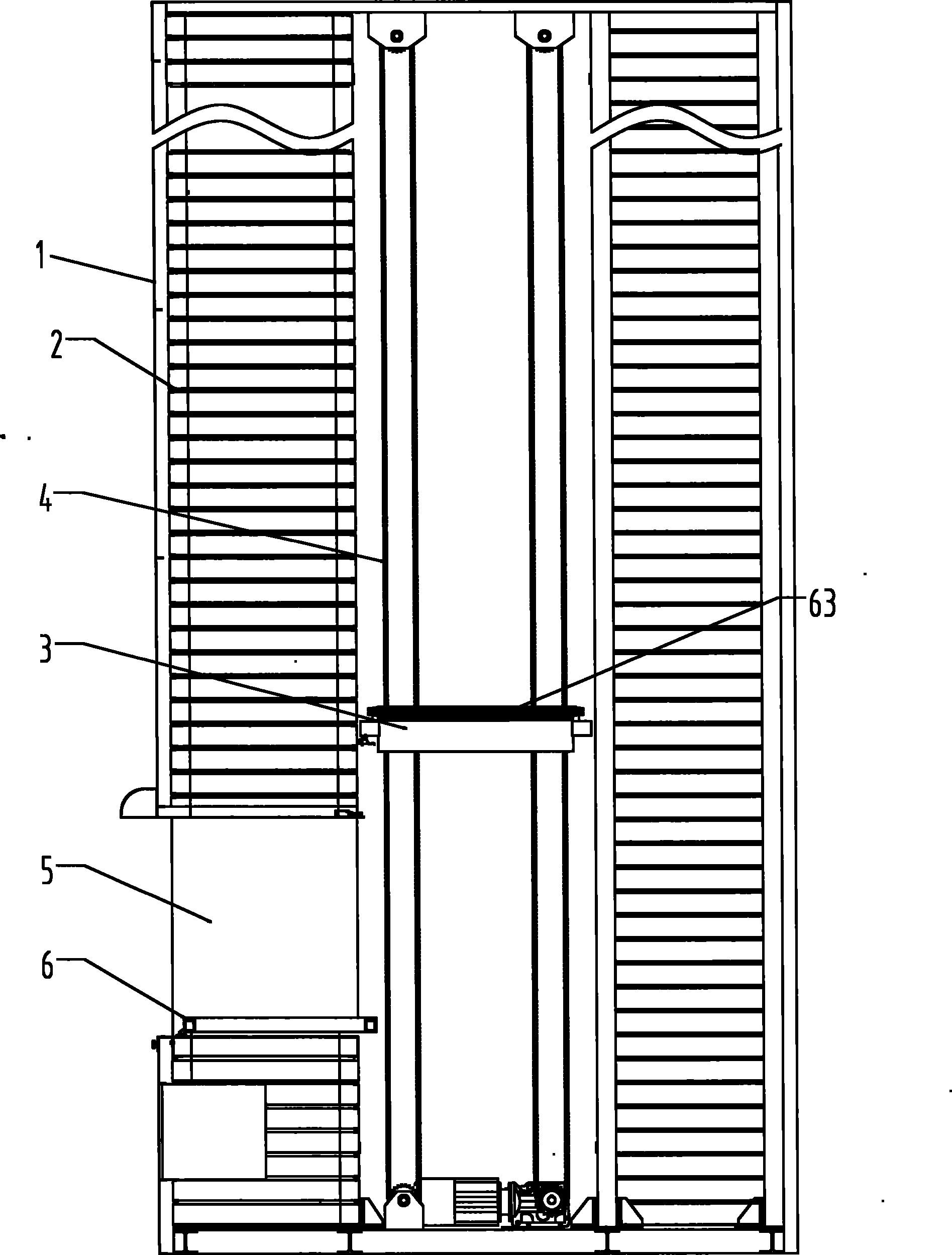

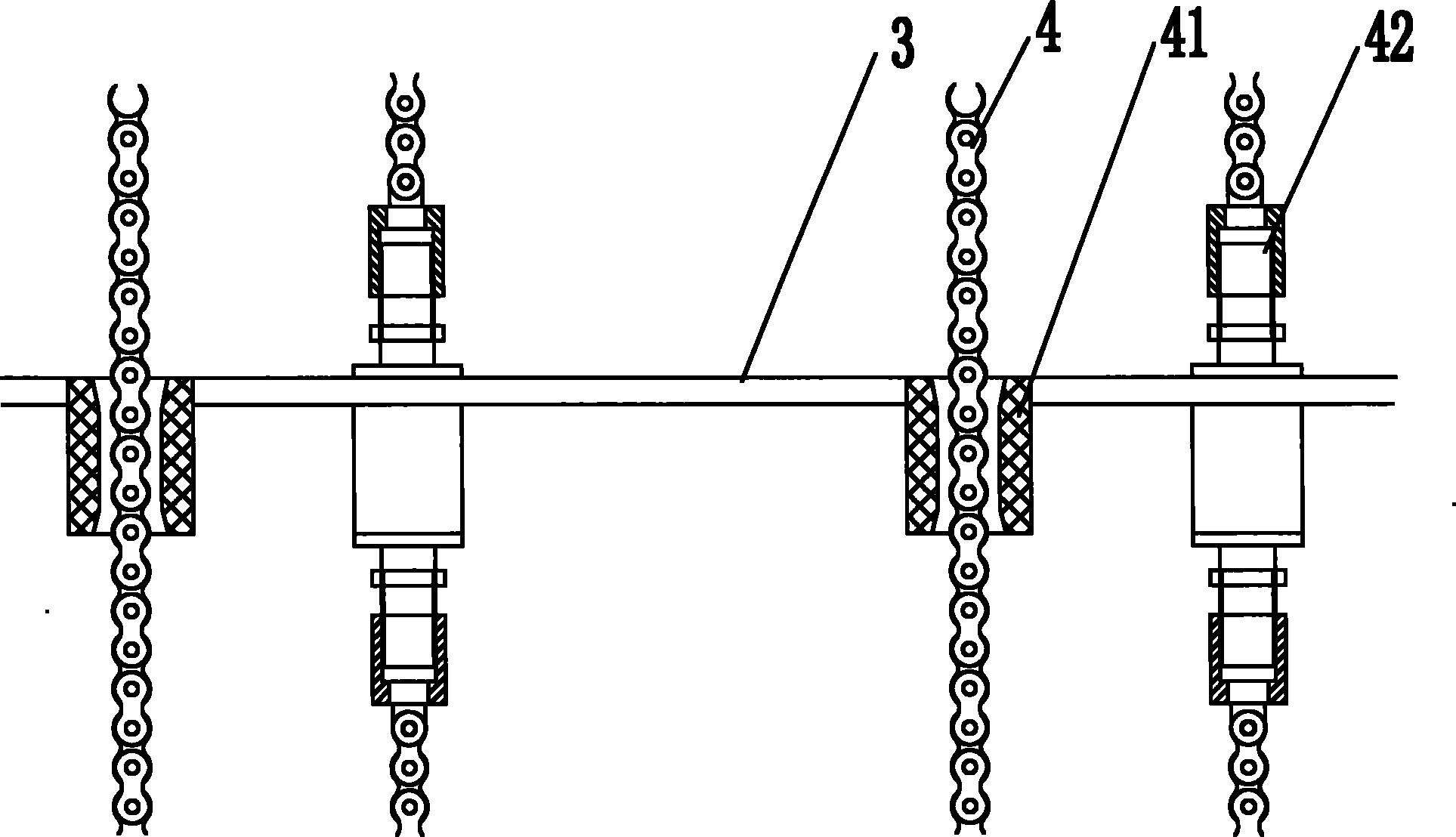

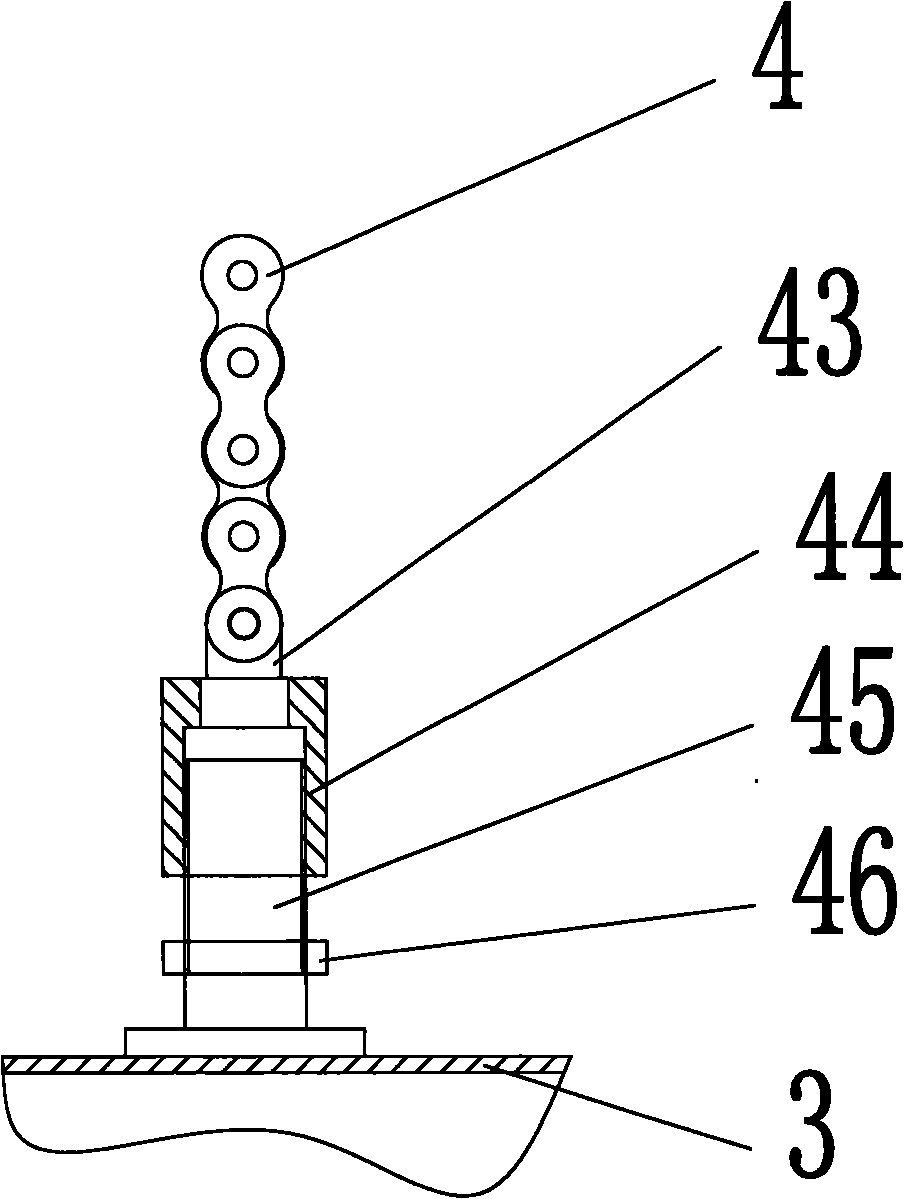

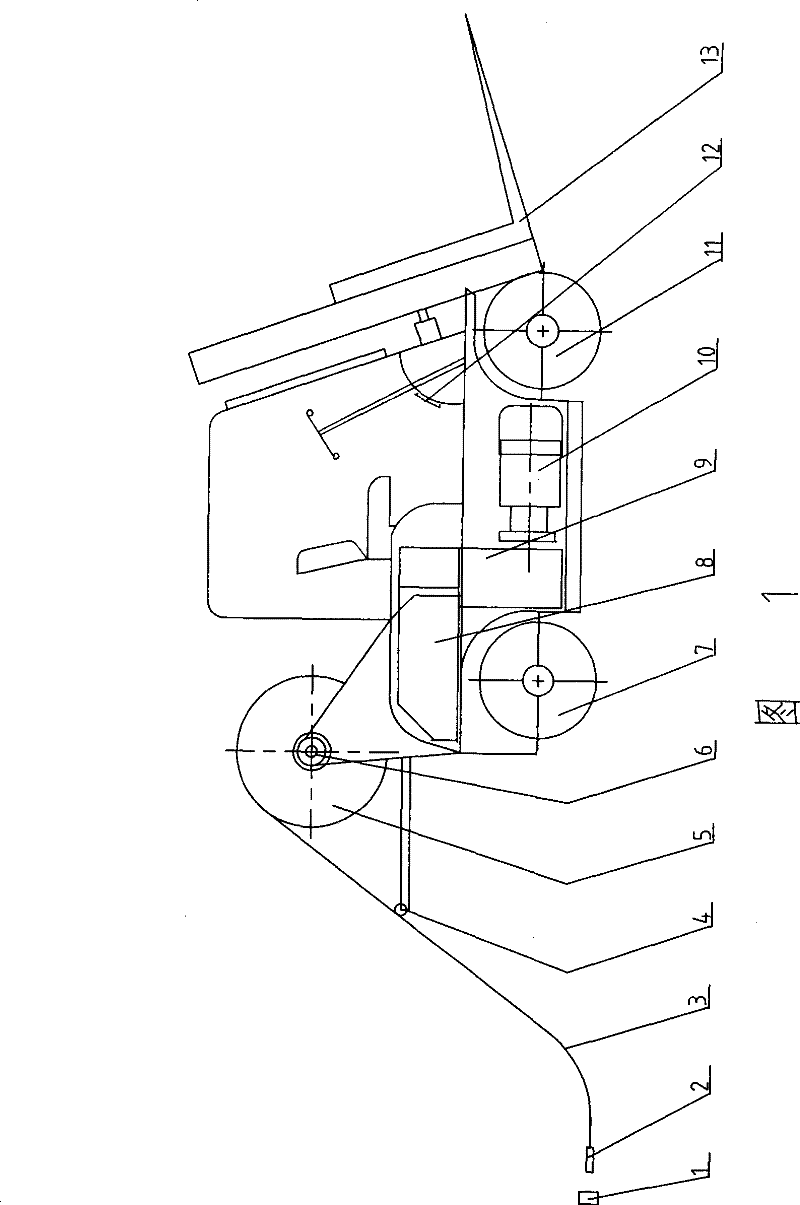

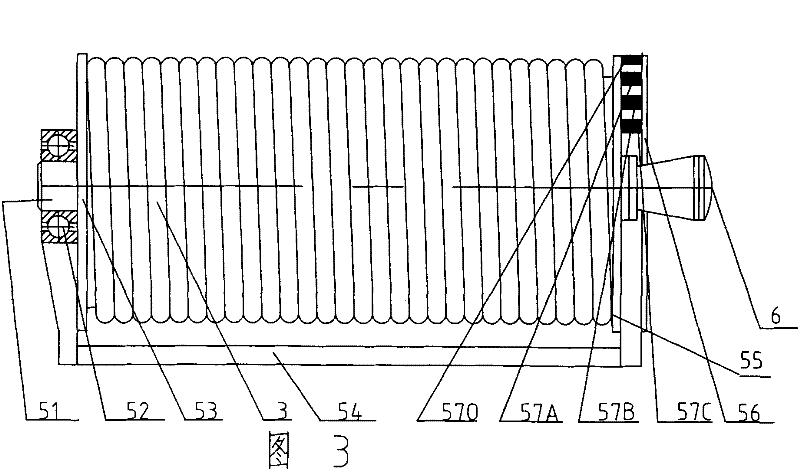

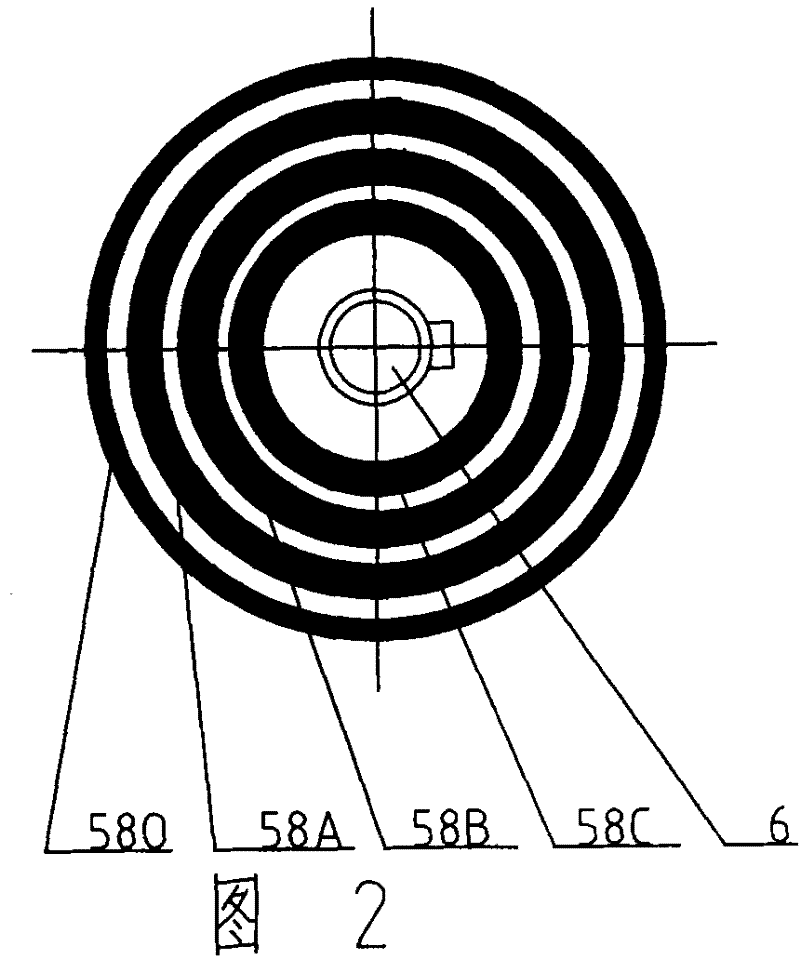

The invention discloses a vertical lifting container, which comprises a container body, a corbel for holding a pallet is respectively on the two sides of the container, a passage for the lifting platform to run from top to down is left between the cornels on the two sides of the container body, a lifting platform is hung in the passage through a lifting chain, one side of the container is provided with a goods outlet, the pallet for transporting into or out the goods is arranged in the goods outlet, and a drive device drives the pallet to translate. In the vertical lifting container of the invention, the pallet device is driven by a chain wheel device to smoothly and stably run, a guide device is arranged to further guarantee the smoothness of the pallet during the processes of drawing and withdrawing, so as to improve the operating efficiency of the goods and reduce running noise, and a chain tensioner can adjust the tension of the chain to avoid the swaying phenomenon and to enable the adjustment of the horizontal position of the lifting platform to be convenient. Since a guide upright similar to a guide rail is arranged, the vertical lifting platform can ensure the smoothness of the lifting platform and prevent the surface of the lifting platform from being oblique and shifted.

Owner:南京音飞储存设备(集团)股份有限公司

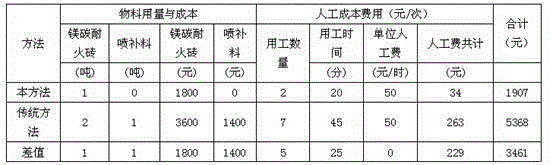

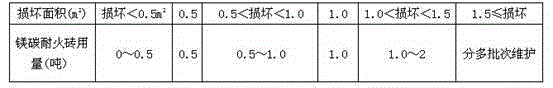

Method for rapidly maintaining converter lining

InactiveCN104673966AEasy to obtainEasy to burn throughManufacturing convertersProcess efficiency improvementBrickSlag

The invention discloses a method for rapidly maintaining a converter lining. The method comprises the following steps of: remaining slag after tapping of converter, pouring magnesia-carbon refractory brick blocks in the converter, shaking the converter till the magnesia-carbon refractory brick blocks and remained slag in the converter are flatly spread at a repaired part of the converter lining, and standing so that the mixture of the magnesia-carbon refractory brick blocks and the remained slag are stuck to the repaired part of the converter lining. According to the method disclosed by the invention, the converter repairing time is effectively shortened; the disadvantage that the time for pouring materials to repair the converter and sintering is long is changed; the operability of the converter is increased; high-temperature converter slag is easy to burn thoroughly; furthermore, a part of clearances can be filled by the molten part of converter repairing bricks; the erosion resistance and the scouring resistance are increased; the material collapse phenomenon due to non-thorough burning and half-baking of a part of positions in the event of traditionally repairing can be effectively avoided; the labour safety coefficient of workers is increased; a part of converter repairing materials and the labour cost are saved; the converter repairing cost is effectively reduced; compared with the original depletion speed, the depletion speed of the converter lining after the method is implemented is reduced; and therefore, the method has the characteristics of being rapid in maintenance speed, high in efficiency and safety and low in cost.

Owner:HEBEI IRON AND STEEL

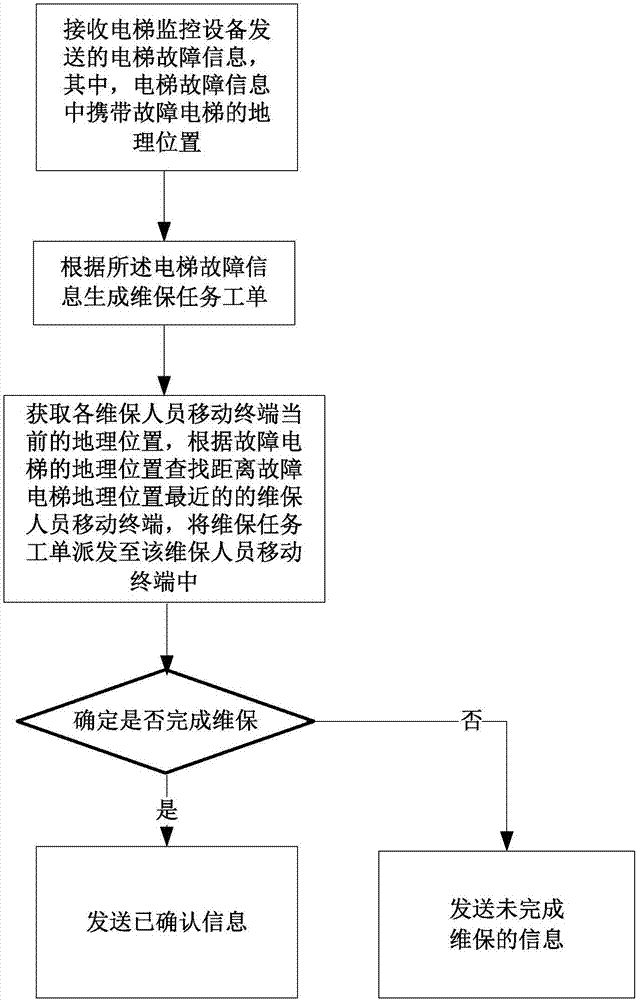

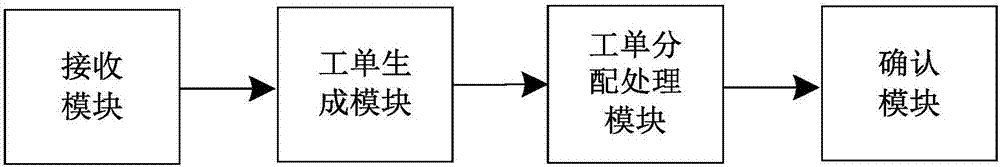

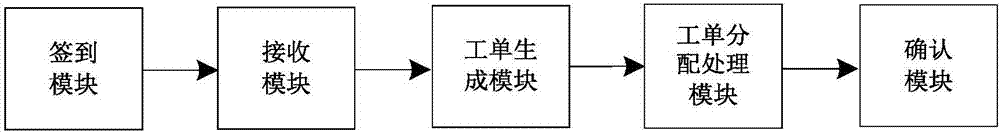

Elevator maintaining and supervising method and system

InactiveCN107187982AQuality improvementEffective supervisionElevatorsInstrumentsGeolocationComputer terminal

The invention relates to an elevator maintaining and supervising method and system. The elevator maintaining and supervising method comprises the steps that elevator fault information sent by elevator monitoring equipment is received and carries the geographic position of a fault elevator; a maintenance task work order is generated according to the elevator fault information; the current geographic positions of maintenance personnel mobile terminals are obtained, the maintenance personnel mobile terminal closest to the geographic position of the fault elevator is searched according to the geographic position of the fault elevator, and the maintenance task work order is distributed to the maintenance personnel mobile terminal; when elevator maintenance completing information fed back by the maintenance personnel mobile terminal is received, maintenance data are obtained from elevator monitoring equipment, and whether the maintenance personnel finishes the set elevator maintenance procedure or not is determined according to the maintenance data. According to the elevator maintaining and supervising method and system, through overhauling maintenance data, the whole elevator maintenance process can be supervised and managed, the maintenance work quality is effectively improved, and the whole maintenance process is effectively supervised.

Owner:成都烽火源信息技术有限公司

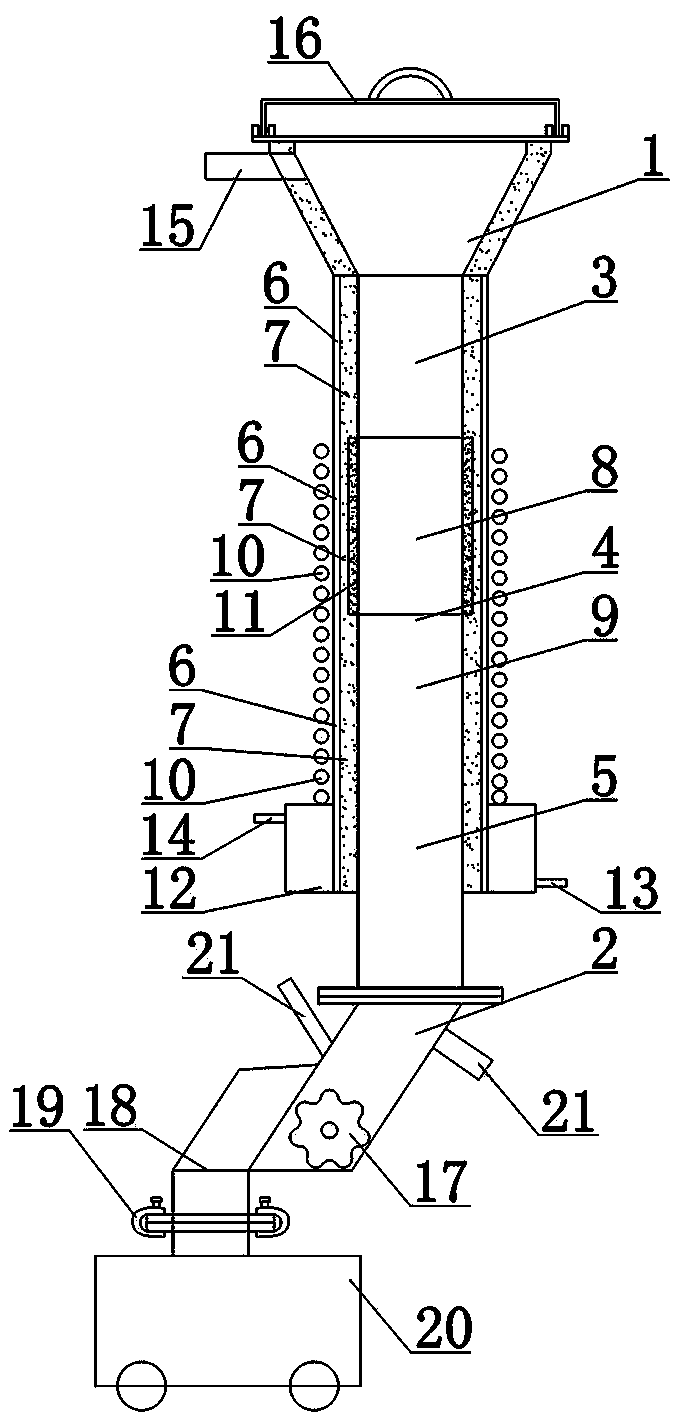

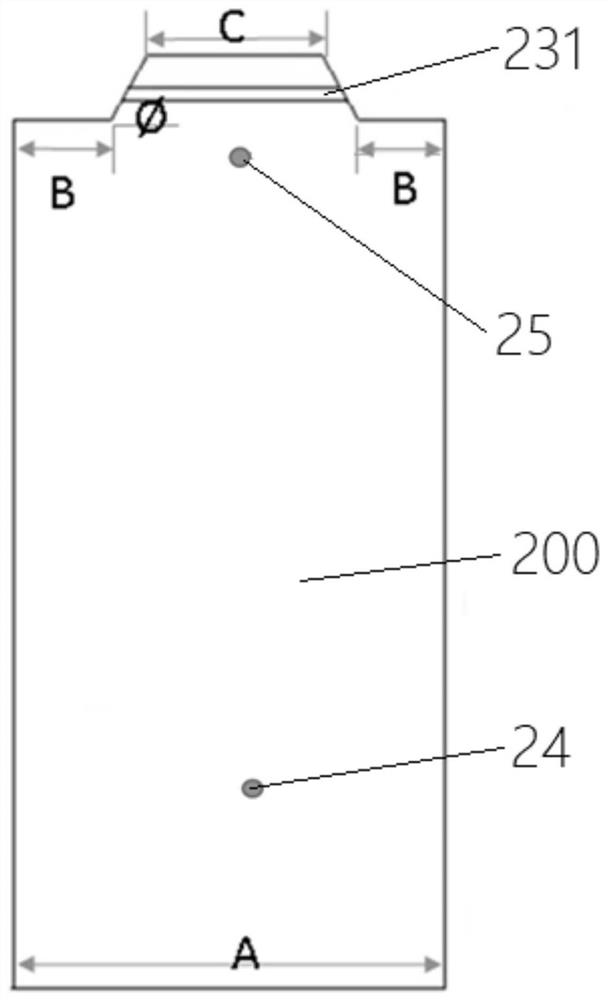

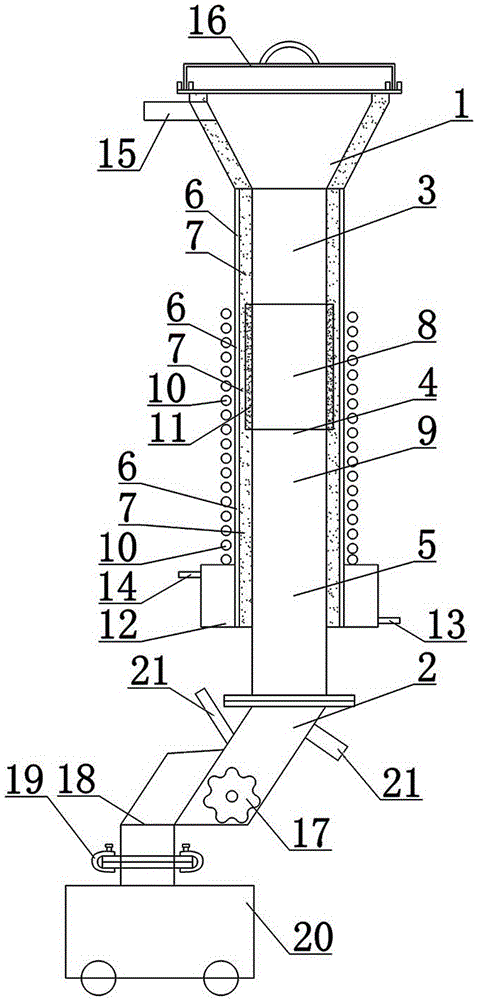

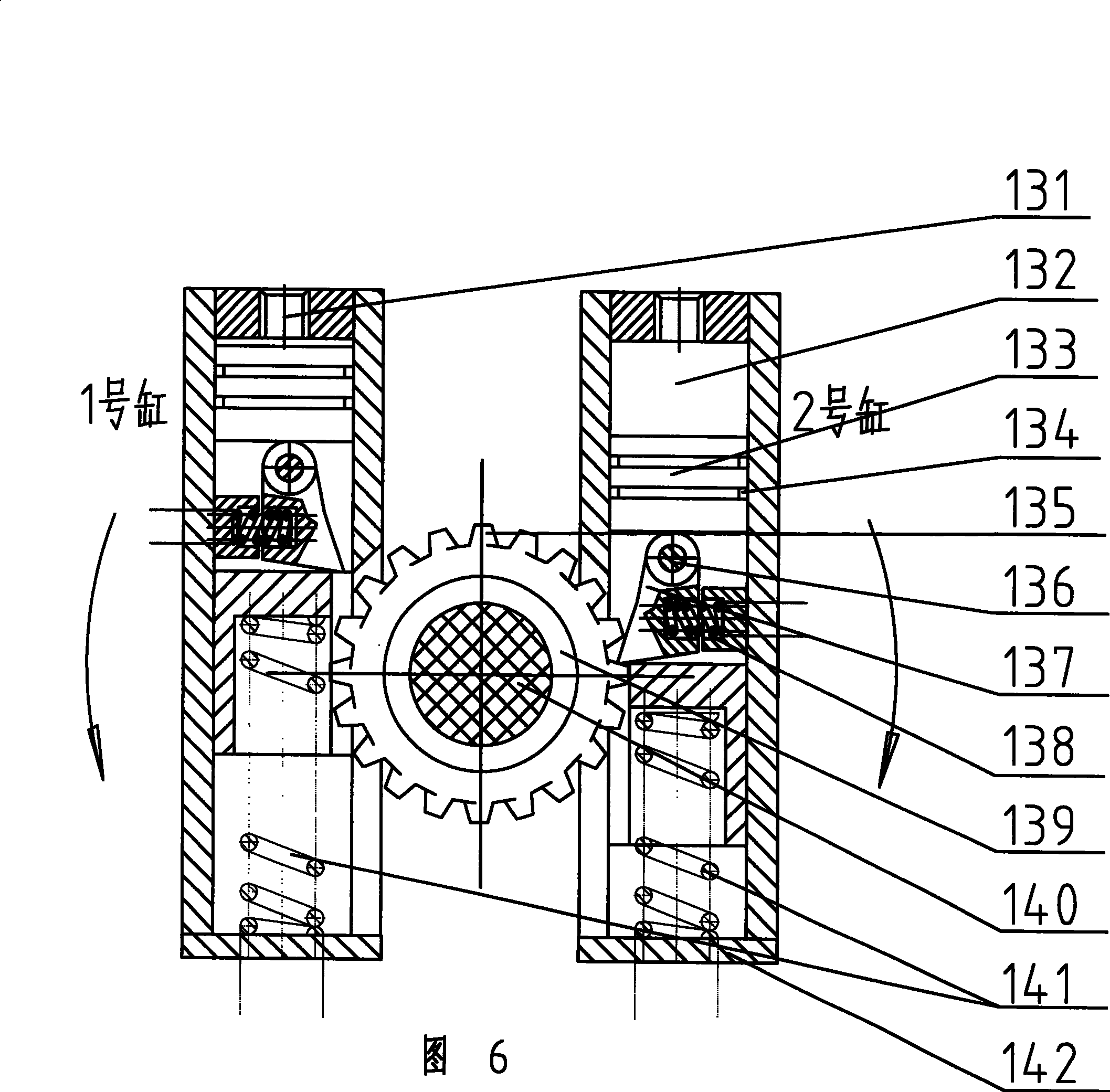

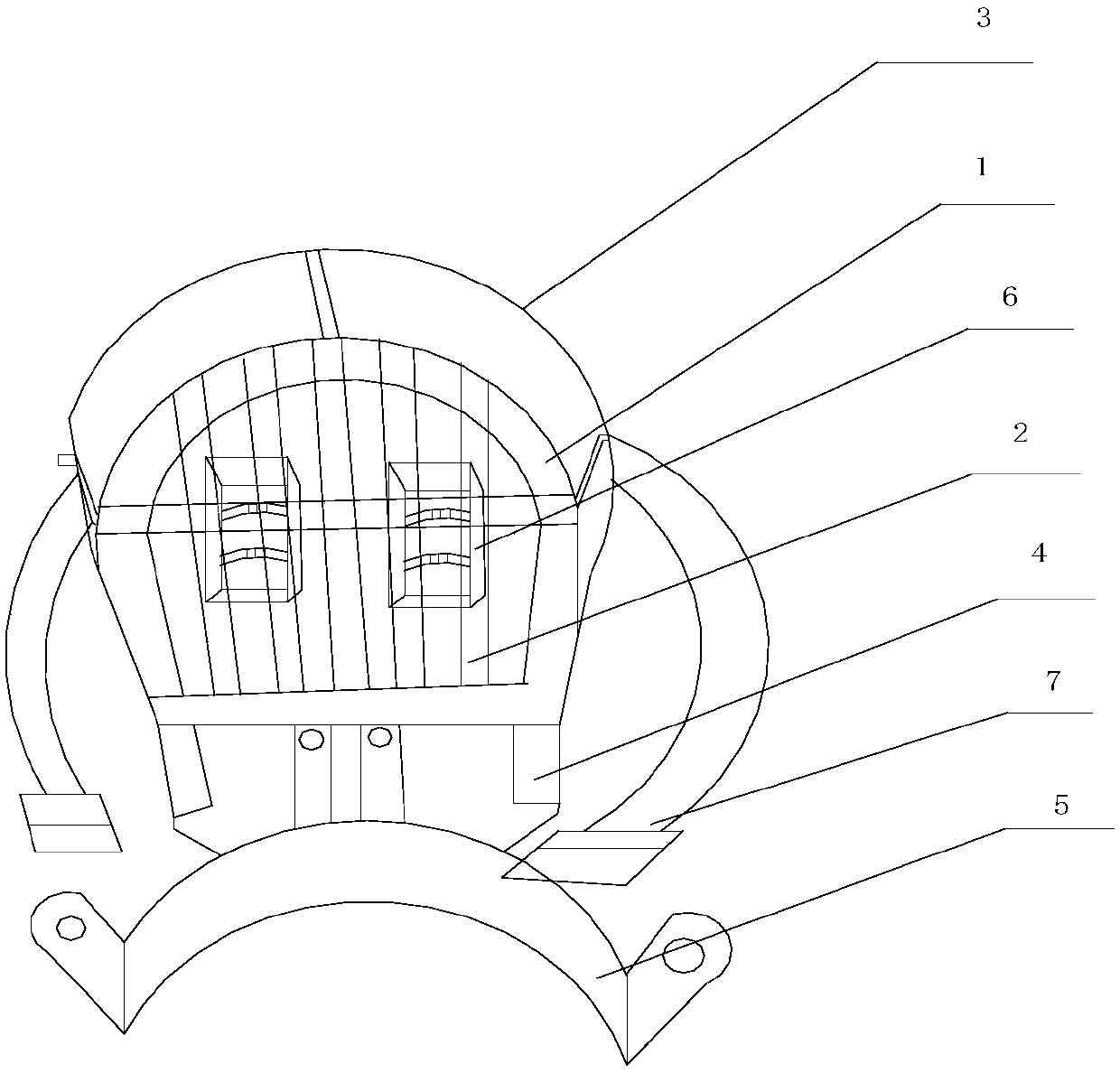

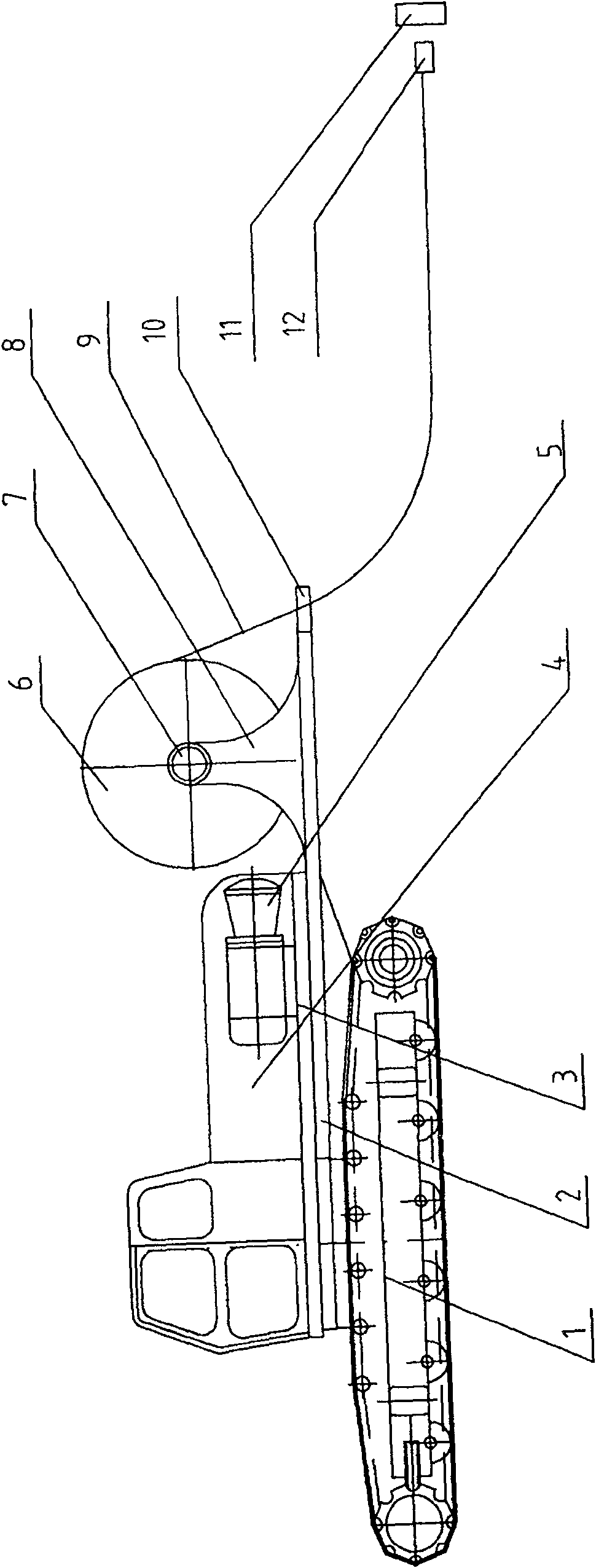

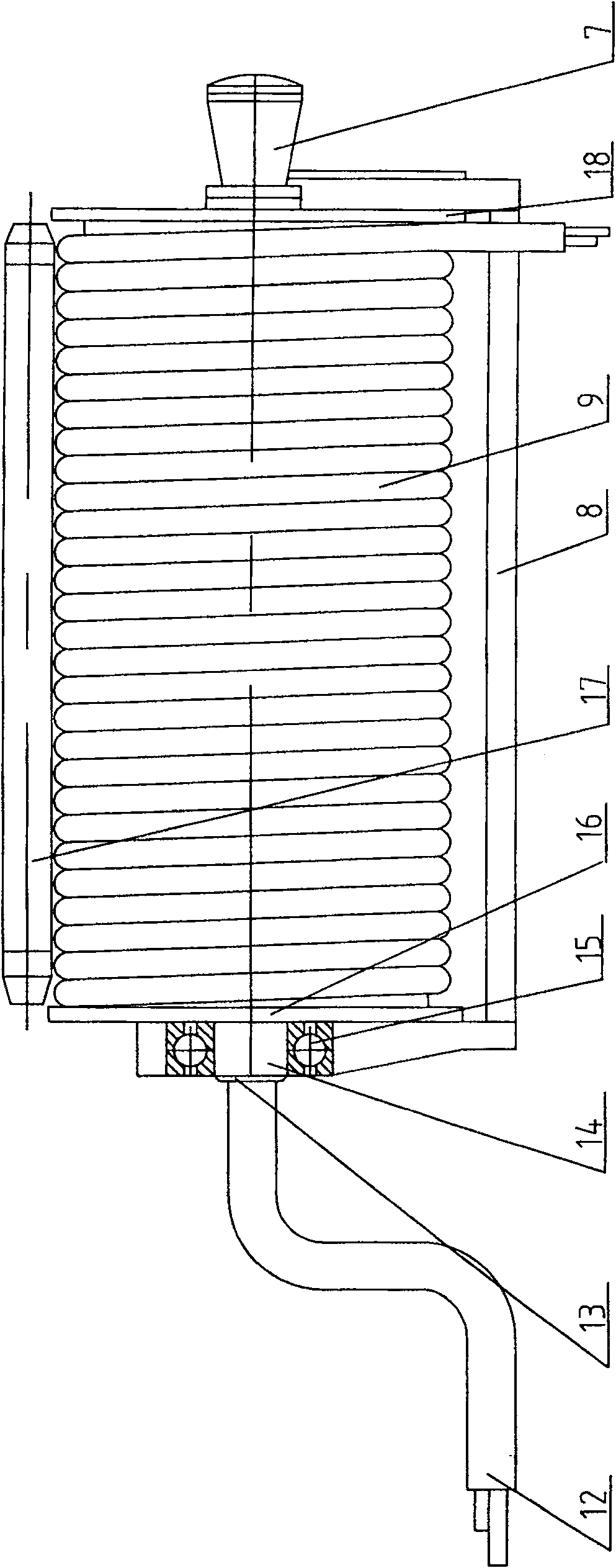

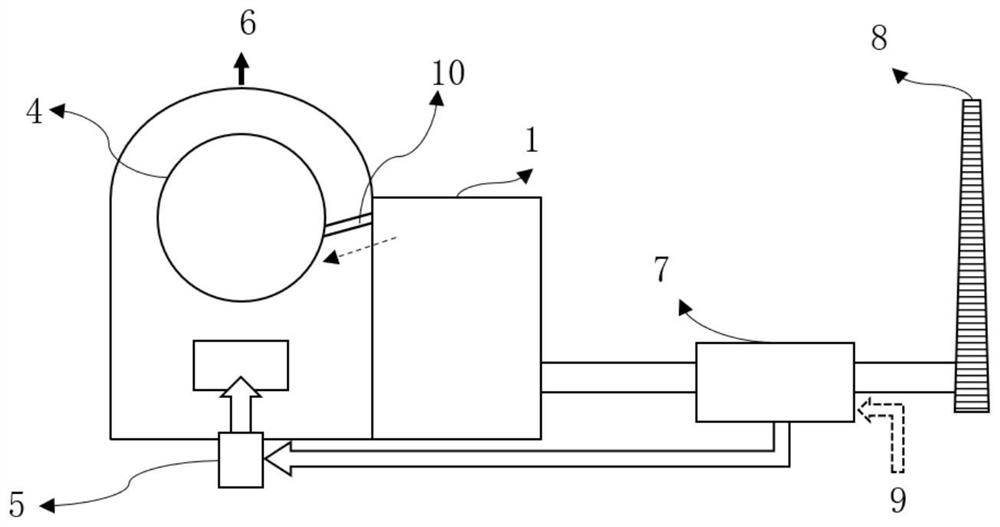

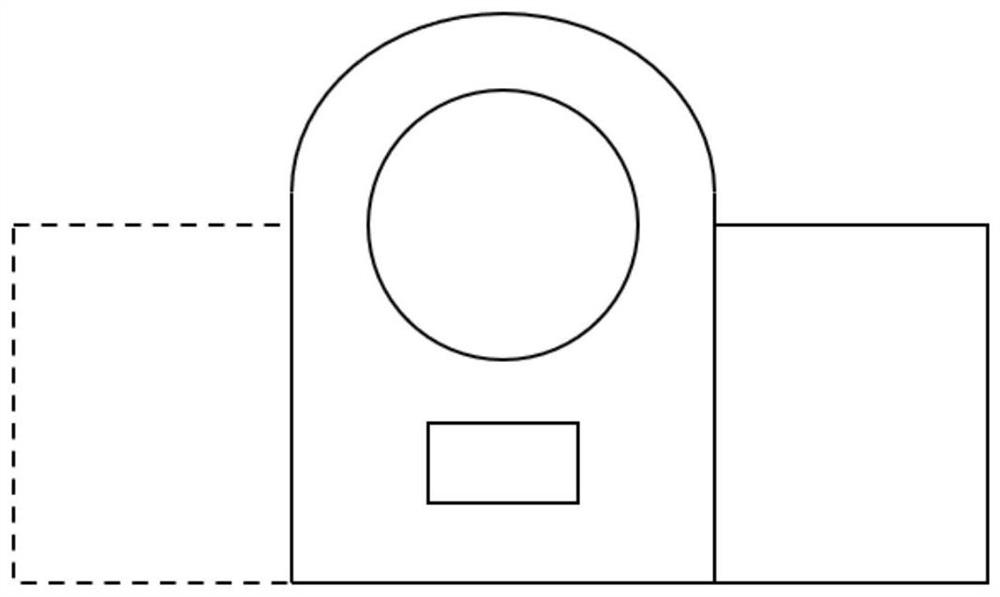

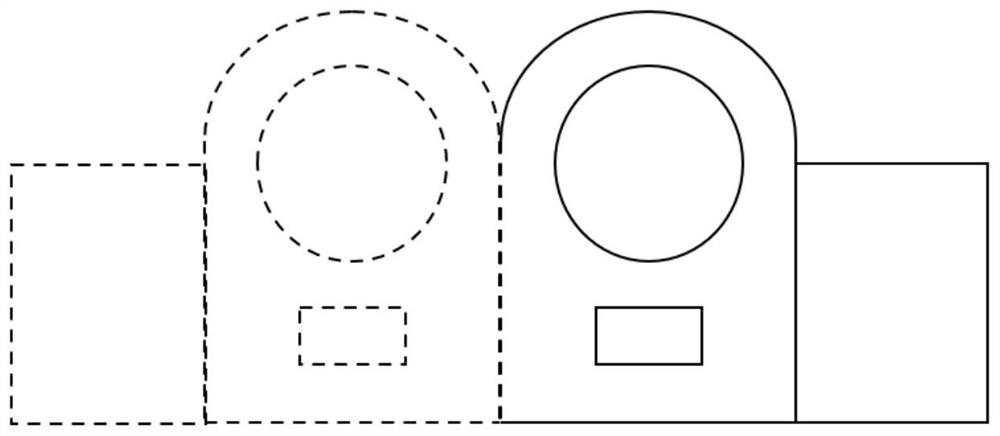

Method and device for continuously preparing vanadium-nitrogen alloy

The invention discloses a method for continuously preparing vanadium-nitrogen alloy. The method includes the first step of preparation, the second step of blending and blank manufacturing, the third step of adding, the fourth step of preheating and prereduction, the fifth step of carbonization and nitridation sintering, and the sixth step of discharging. A device for preparing vanadium-nitrogen alloy according to the method comprises a vertical boiler, a top feeding bin (1) and a continuous automatic discharging device (2), wherein the vertical boiler is composed of a preheating section (4), a calcination section (4) and a cooling section (5); the lower end of the vertical boiler is connected with the continuous automatic discharging device (2) through a pipeline; the tail end of the continuous automatic discharging device is connected with a finished product trolley (20) through a discharge pipe (18); the bottom of the vertical boiler is provided with a nitrogen inlet (21). The method has the advantages that the process and the device are compact, the production process is short, electric energy is saved, little investment is required, yield is high, continuous production is really achieved, and the industrialized and scale production requirement is met.

Owner:SICHUAN ZHANXIANG SPECIAL ALLOY TECH

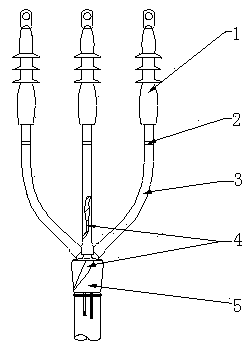

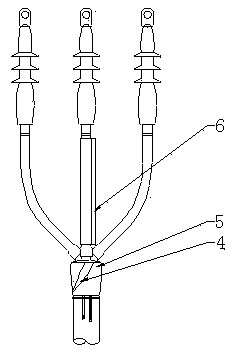

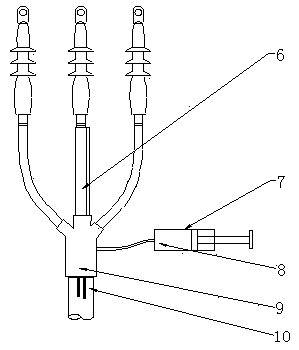

Cable accessory branching fingerstall restoration method

ActiveCN105375409ARealize online repairReduce maintenance costsApparatus for repairing insulation/armouring cablesInjection portRestoration method

The invention discloses a cable accessory branching fingerstall restoration method, and the method comprises three steps: prefabricating an injection mold and a buckle-type insulating tube, which are corresponding in shape and size; enabling a broken protection sleeve to be sleeved by the insulating tube, and placing room temperature vulcanized rubber in a slot and a joint; enabling a broken cable accessory branching fingerstall to be wrapped by the prefabricated injection mold, injecting the room temperature vulcanized rubber, and dismounting the mold after solidification. The injection mold is also provided with a mold housing, a sealing weir, and a glue injection port. The cross section structure of the buckle-type insulating tube is shaped like any one of omega, C and G. The material of the room temperature vulcanized rubber is preferably consistent with the base material of the buckle-type insulating tube and the base material of the cable accessory branching fingerstall. The method does not need to cut off the power for overall replacement, is low in overall cost, enables a maintenance mode to be changed into industrialization, standardization and modularization, is simple in operation, saves time and labor, is high in speed, guarantees that the insulating level and the service life are not reduced, and enables the reliability to meet the quality requirements of six sigma.

Owner:SHENZHEN WOER HEAT SHRINKABLE MATERIAL +1

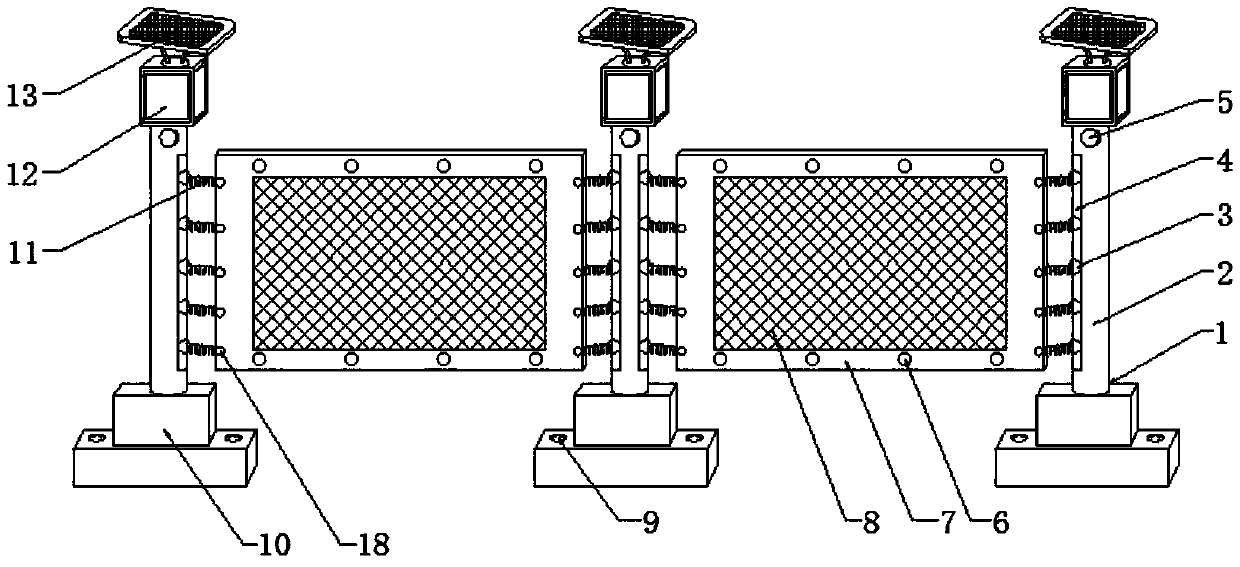

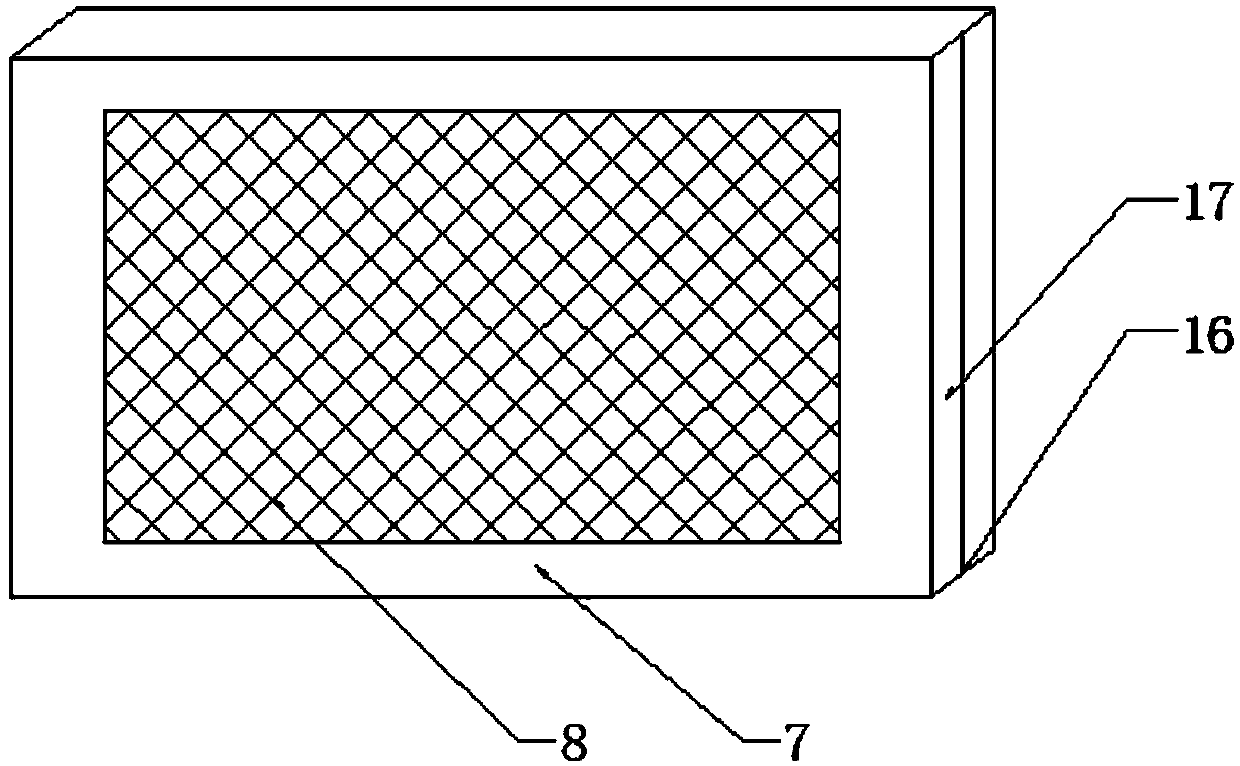

Guard bar structure

InactiveCN109653089ASimplified installation stepsIncrease elasticityBridge structural detailsTraffic signalsTraffic accidentEngineering

The invention discloses a guard bar structure. The guard bar structure comprises a guard bar main body, wherein the guard bar main body consists of a protecting support arranged on the bottom of the guard bar main body, a protecting supporting column arranged on the top of the protecting support and an anti-collision plate arranged on one side of the guard bar main body. The mounting steps of theroad bridge guard bar are simple, maintaining and disassembling are facilitated, by arrangement of LED lamps, traffic accident times are reduced, the guard bar is good in elasticity, a vehicle can bebuffered by arrangement of the anti-collision plate, springs, an air bag restraint system and an elastic steel wire gauze, thus, the vehicle can move backwards by a certain safe distance, the buffer layer in the anti-collision plate can further buffer and protect the vehicle, the circumstance that the bridge guard bar is broken by collision is avoided, and severe damage of the guard bar and the vehicle are also avoided. The guard bar structure is high in structural strength and good in elastic effect, and has wide application prospect in the future.

Owner:GUIZHOU UNIV

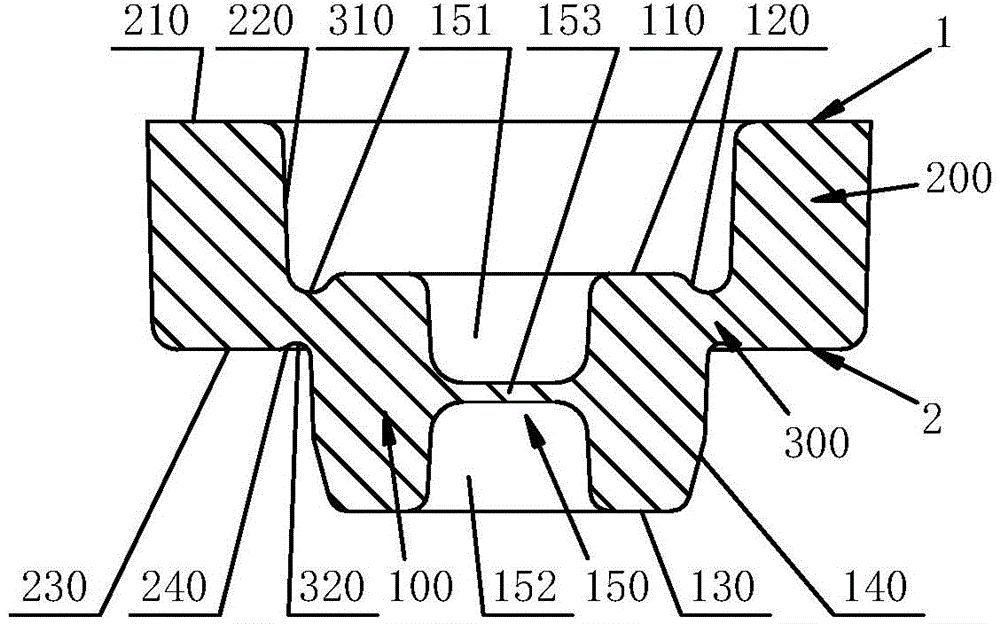

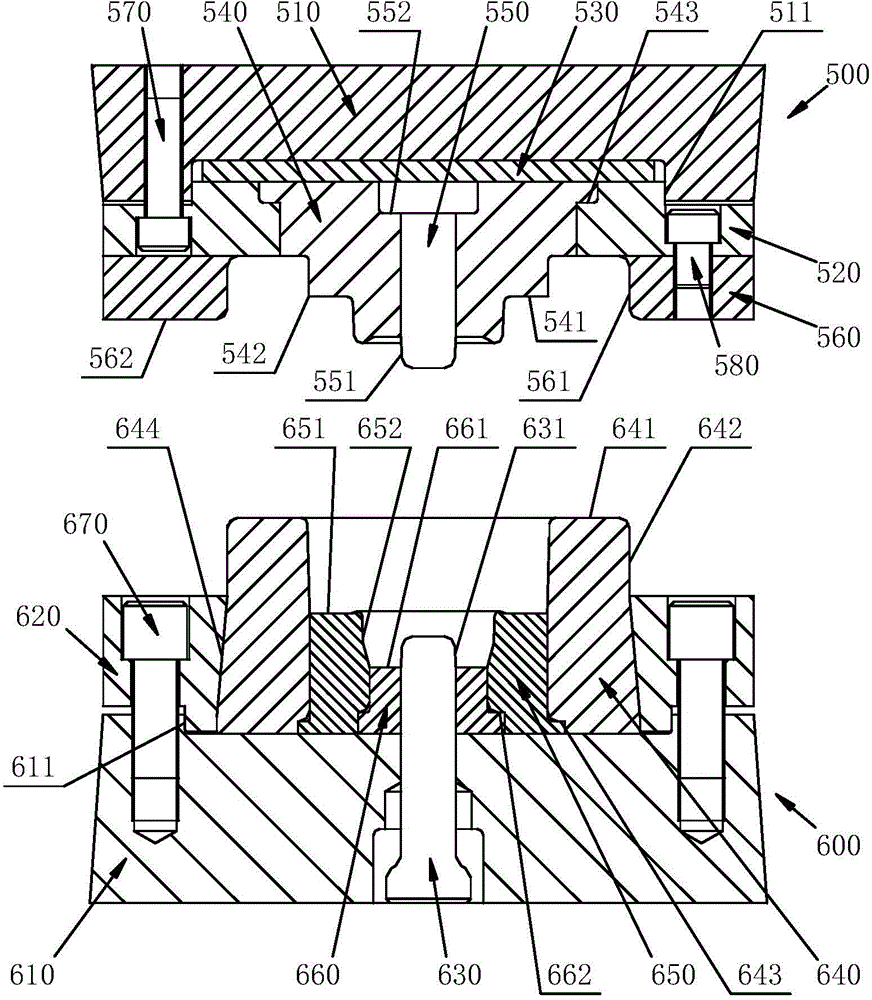

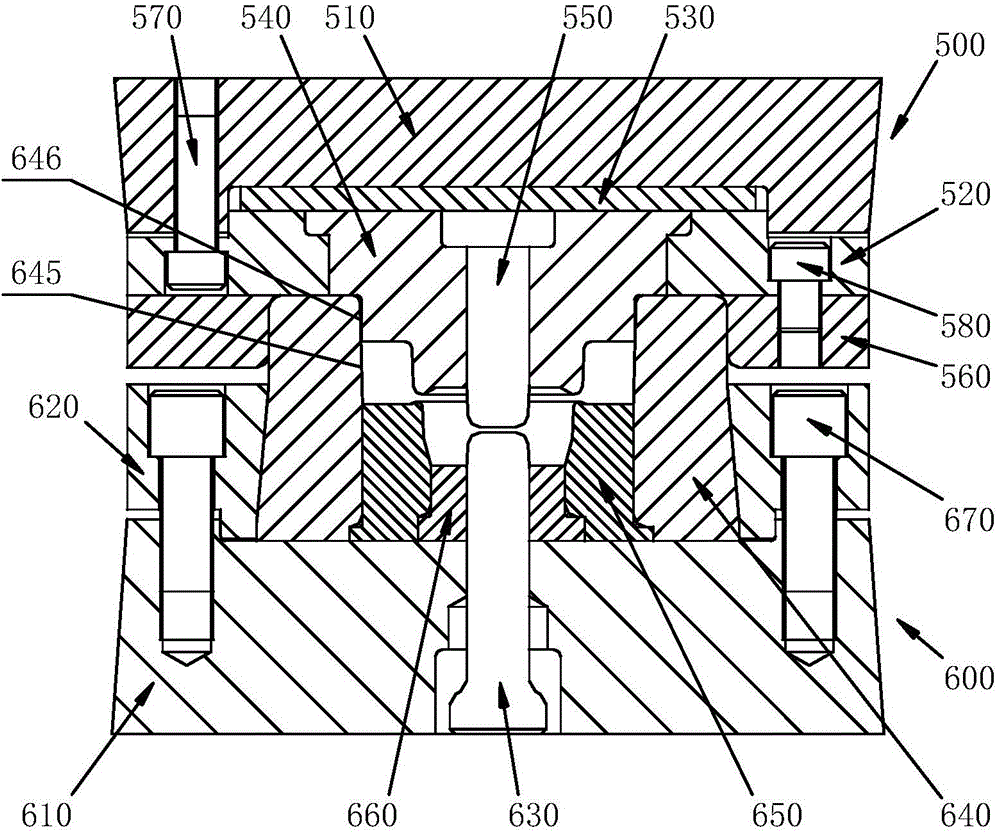

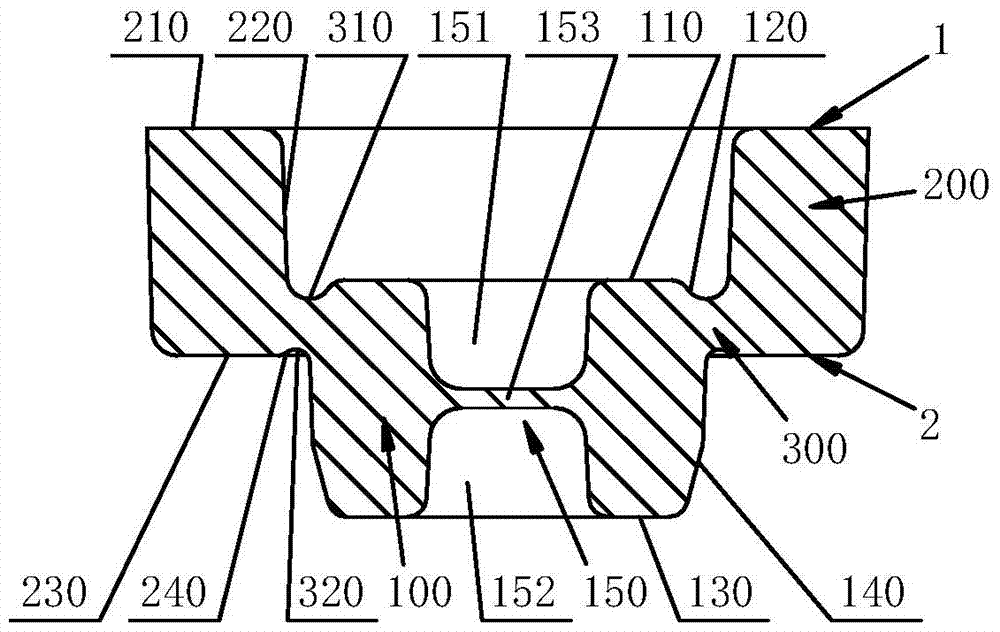

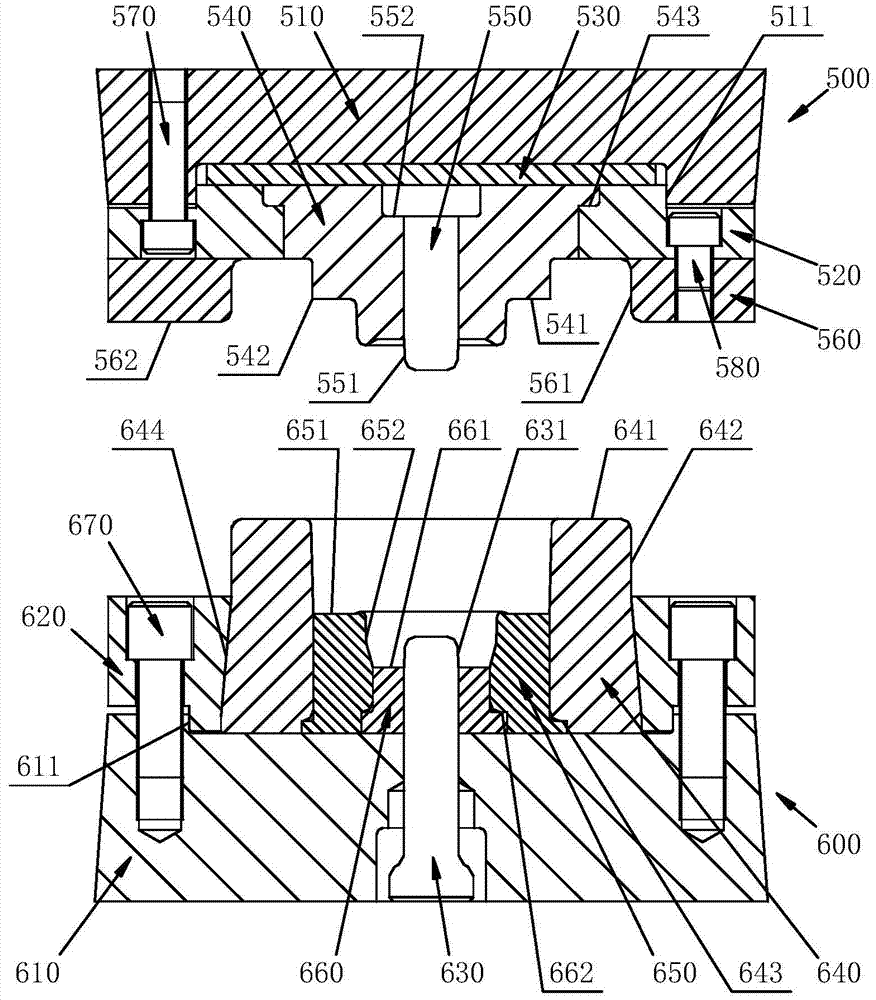

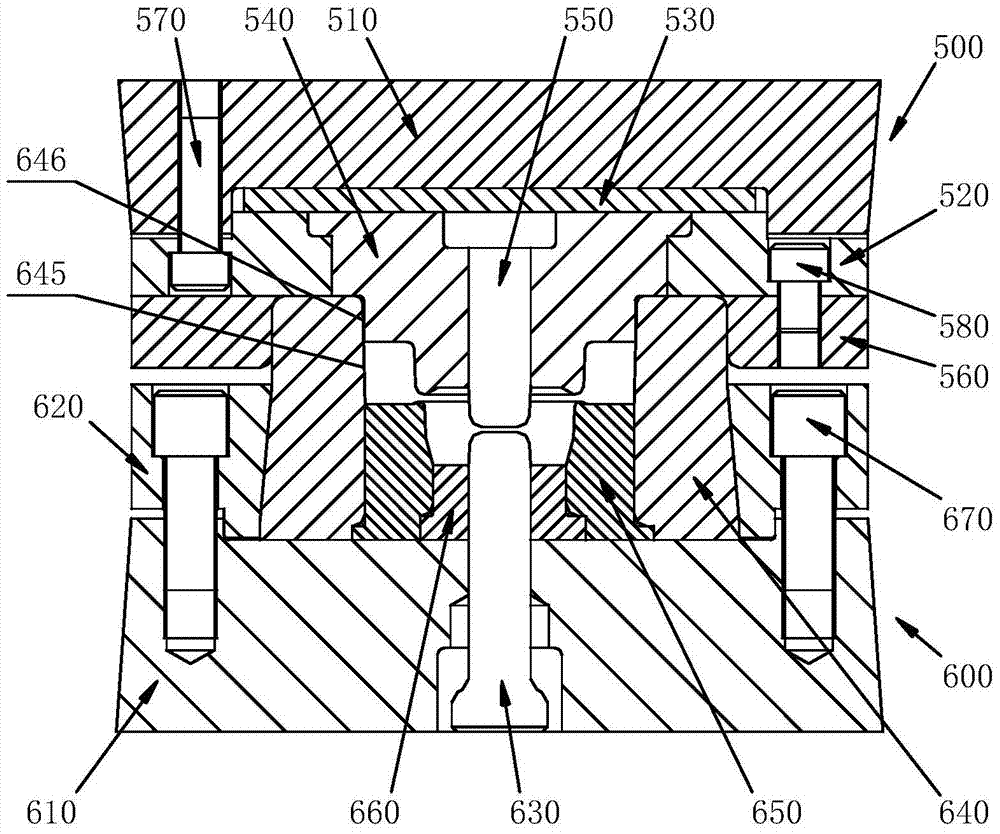

Inner rzeppa shell and outer rzeppa shell connected forging and forging die for same

ActiveCN105317861AIncrease profitIncrease productivityYielding couplingForging/hammering/pressing machinesEngineeringRaw material

The invention provides an inner rzeppa shell and outer rzeppa shell connected forging. The upper end surface of the forging comprises an outer rzeppa shell upper end surface, an outer rzeppa shell upper side inner wall, a connecting part upper end surface, an inner rzeppa shell upper side outer wall and an inner rzeppa shell upper end surface; the lower end surface of the forging comprises an outer rzeppa shell lower end surface, an outer rzeppa shell lower side inner wall, a connecting part lower end surface and an inner rzeppa shell lower side outer wall; the forging further comprises an inner rzeppa shell central hole. The invention further provides a forging die for manufacturing the forging. An upper die assembly of the die comprises a split type male die formed by a male die ring and a male die core, the lower end of the male die ring forms a forming surface of the upper end surface of the forging, and the lower end of the male die core forms a forming surface of the upper side wall of the central hole of the inner rzeppa shell; a lower die assembly comprises an ejection rod and a split type female die formed by a female die outer ring, a female die middle ring and a female die inner ring, the upper end of the split type female die forms forming surfaces of the lower end surface of the forging and the outer side wall of the outer rzeppa shell, and the upper end of the ejection rod forms a forming surface of the lower side wall of the central hole of the inner rzeppa shell. The utilization rate of raw materials of the forging is high, and the production cost of the inner rzeppa shell and the outer rzeppa shell is low.

Owner:SHANGHAI GKN DRIVE SYST

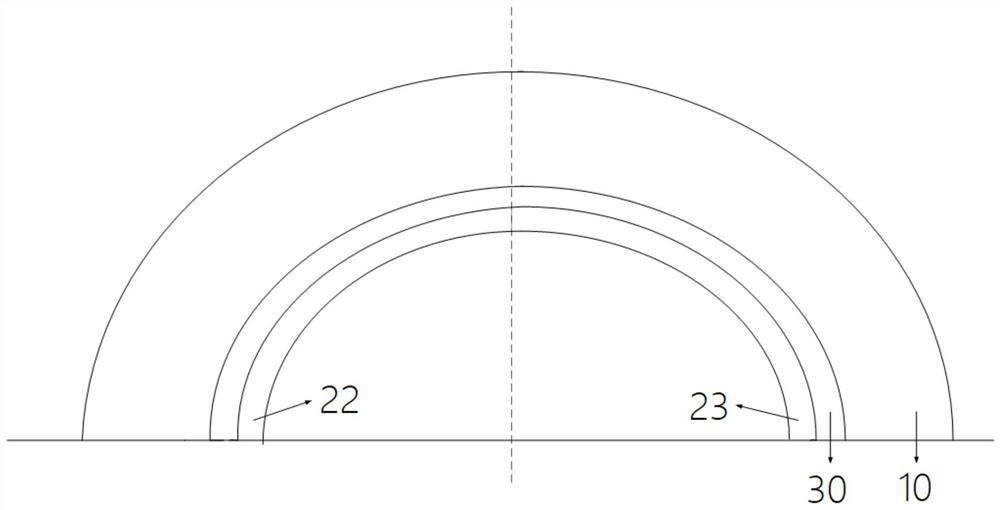

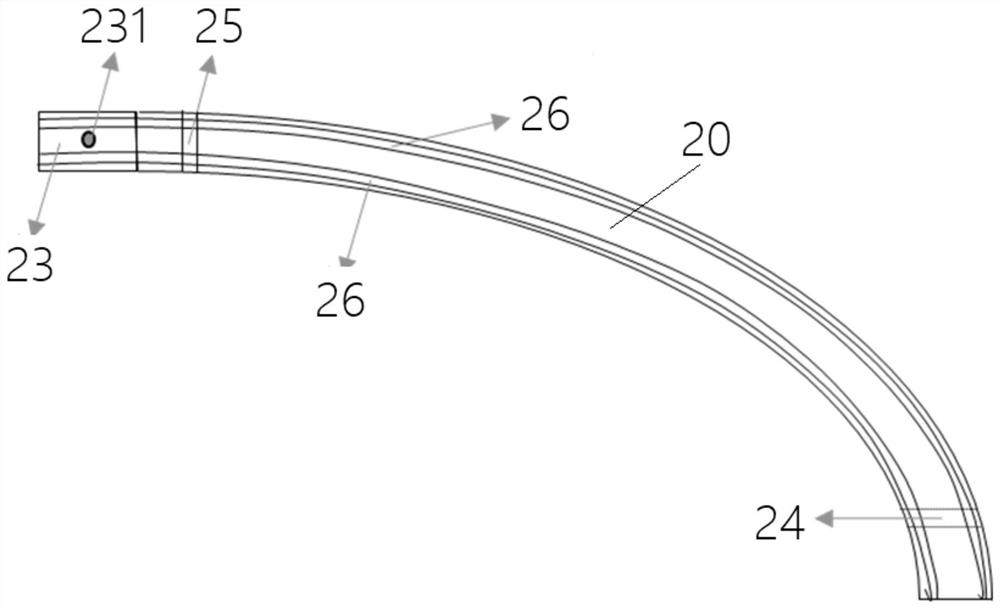

Prefabricated lining for tunnel reinforcement and installation method thereof

ActiveCN111828038ADoes not affect normal operationAvoid damageUnderground chambersTunnel liningShotcreteButt joint

The invention relates to a prefabricated lining for tunnel reinforcement and an installation method thereof. The prefabricated lining is installed on the inner side of an original lining of a tunnel and comprises a left prefabricated lining body and a right prefabricated lining body, wherein the section of the left prefabricated lining body and the section of the right prefabricated lining body are both arc; the left prefabricated lining body and the right prefabricated lining body are symmetrical about the central axis of the tunnel and are in butt joint at the top of the tunnel; a grouting layer is arranged between the prefabricated lining and the original lining of the tunnel; the left prefabricated lining body and the right prefabricated lining body are each composed of a plurality ofsub-linings with the same width; the sub-linings are arranged in the extending direction of the tunnel and connected with one another; the butt joint position of the left prefabricated lining body andthe right prefabricated lining body is in tooth-shaped connector type butt joint; tooth-shaped connectors are each of a trapezoidal structure and positioned in the middles of the tops of the sub-linings; each tooth-shaped connector is axially provided with a bolt hole, and the tooth-shaped connectors are connected through bolts; and the thickness H of the prefabricated lining is delta Dmin-T. Inthe construction process, only corresponding lanes need to be closed, and normal passing of the other lanes is not affected. The installation process is rapid, easy and convenient, concrete pouring orspraying is not needed, grooving in an original structure is not needed, the difficulty of reinforcement construction can be greatly lowered, and the time of reinforcement construction can be greatlyshortened.

Owner:TONGJI UNIV +1

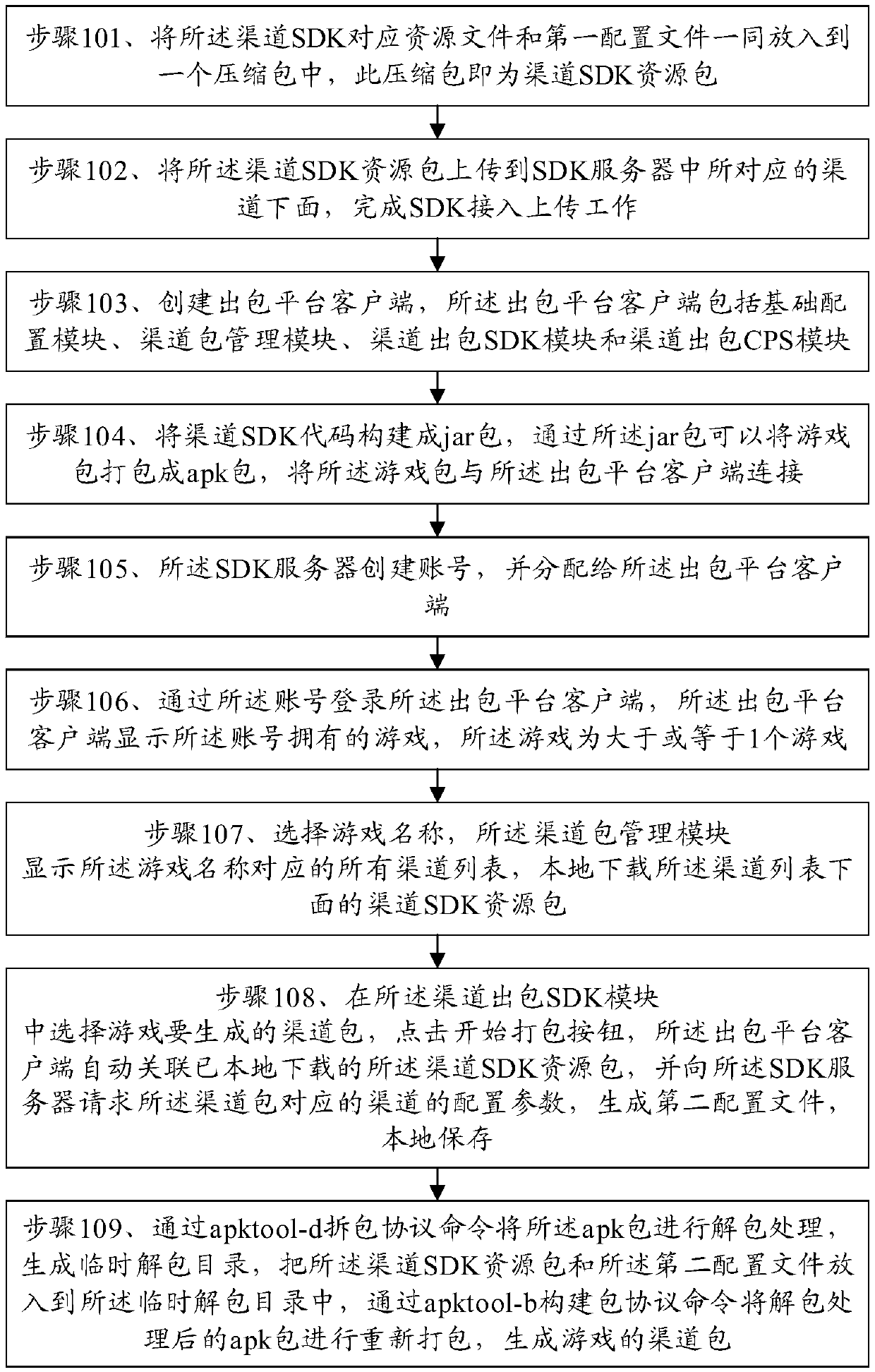

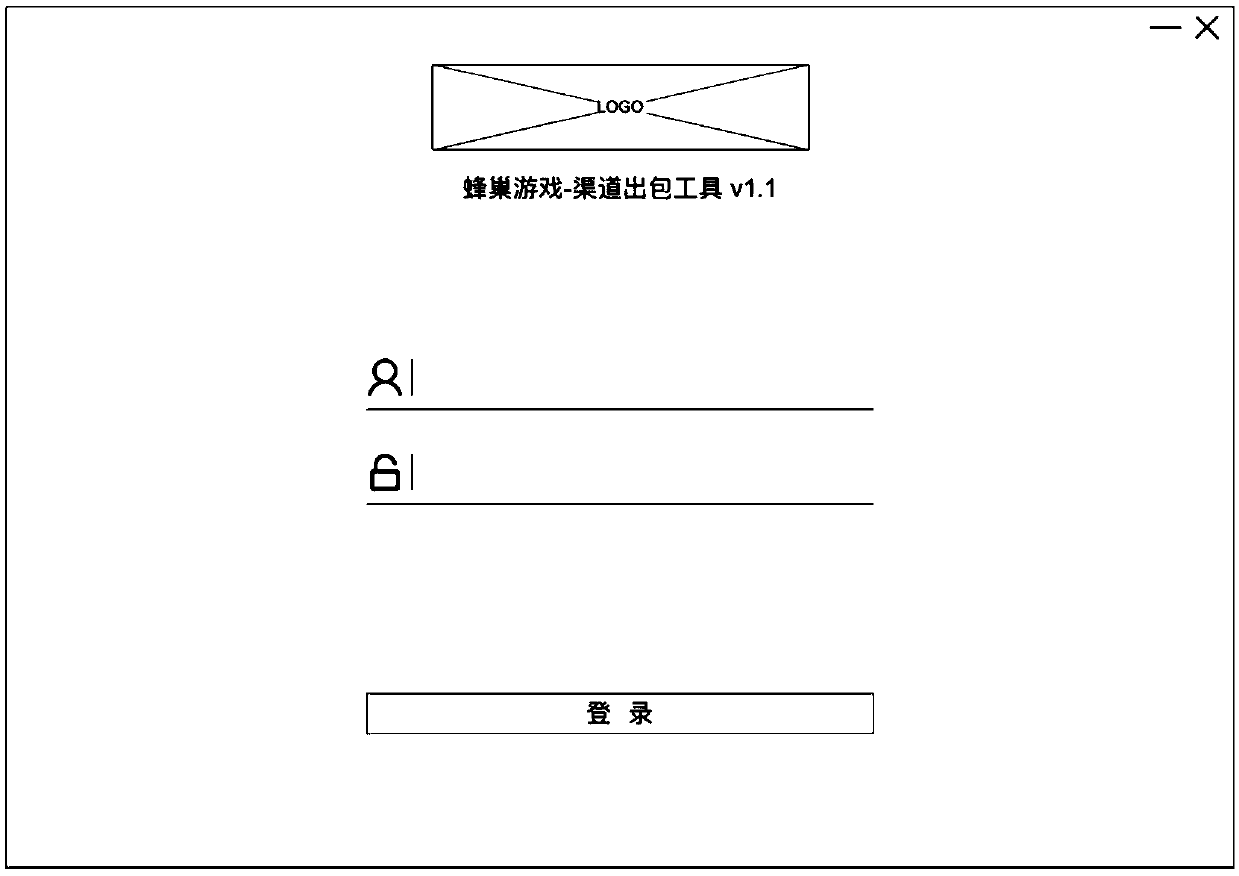

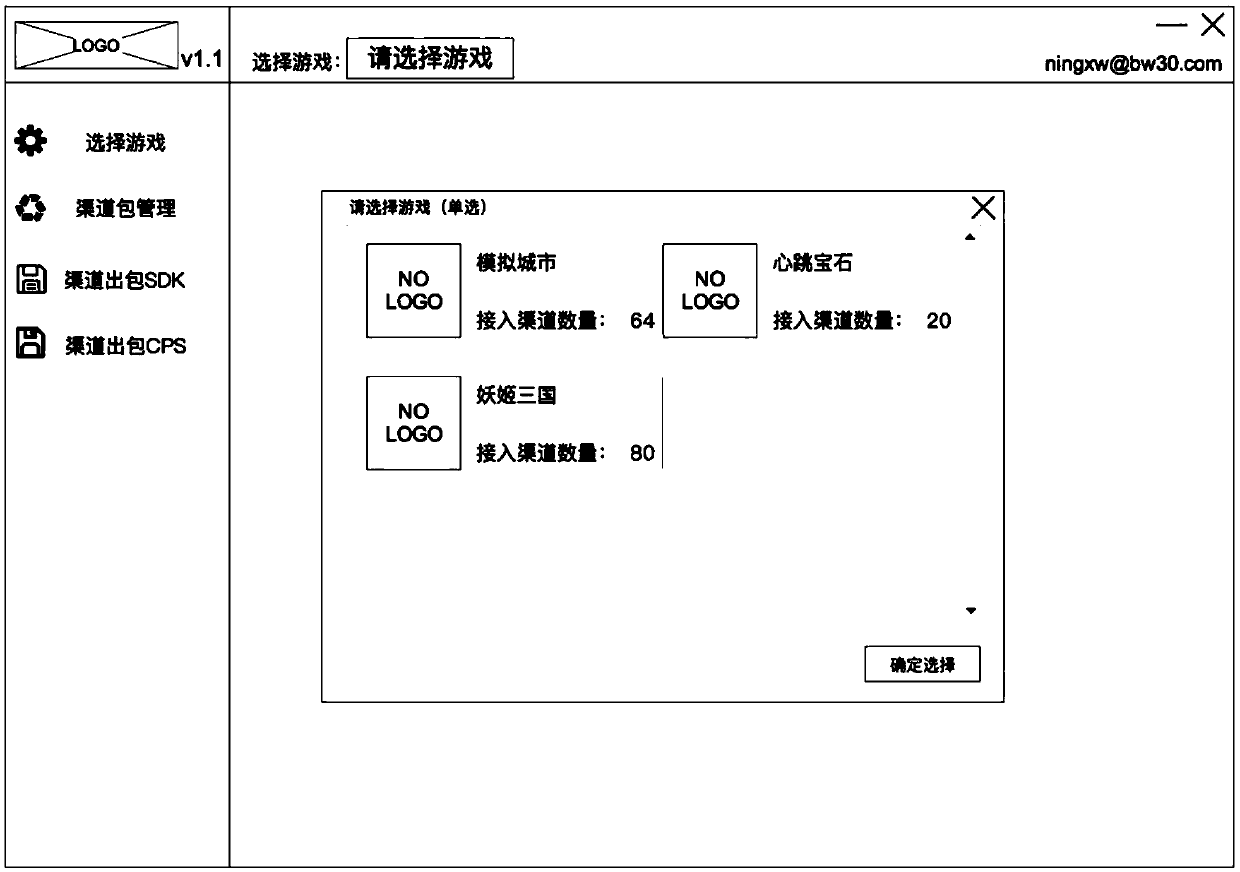

Platform package delivery method for generating a plurality of game channel packages based on one key

ActiveCN109522030AAvoid red tapeRealize automated outsourcingVersion controlSoftware deploymentStart buttonDelivery efficiency

The invention discloses a platform package delivery method for generating multiple game channel packages based on one key, which comprises the following steps of: uploading a channel SDK resource package to the lower part of a corresponding channel in an SDK server to finish SDK access uploading work; Creating a package delivery platform client; Logging in the package delivery platform client through the account; Selecting a game name, and locally downloading a channel SDK resource package under the channel list; Selecting a channel package to be generated by a game in a channel package discharging SDK module, and clicking a package starting button; And carrying out unpacking processing on the apk packet to generate a temporary unpacking directory, putting the channel SDK resource packet and the second configuration file into the temporary unpacking directory, and carrying out repacking to generate a channel packet of the game. According to the invention, automatic package delivery isrealized, the development time is shortened, and the package delivery efficiency is improved. Game channel packages of all the selected channels can be automatically generated at a time, the package output amount is large, and multiple package output tasks can be completed at a time.

Owner:北纬通信科技南京有限责任公司

IT equipment operation and maintenance management system and method

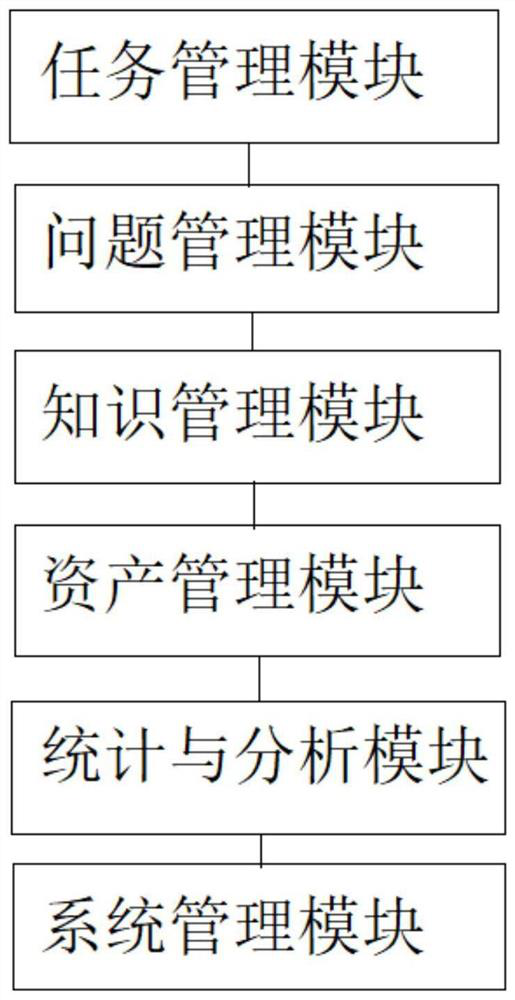

InactiveCN112200326AFast maintenanceImprove work efficiencySemantic analysisResourcesManagement planningSystems management

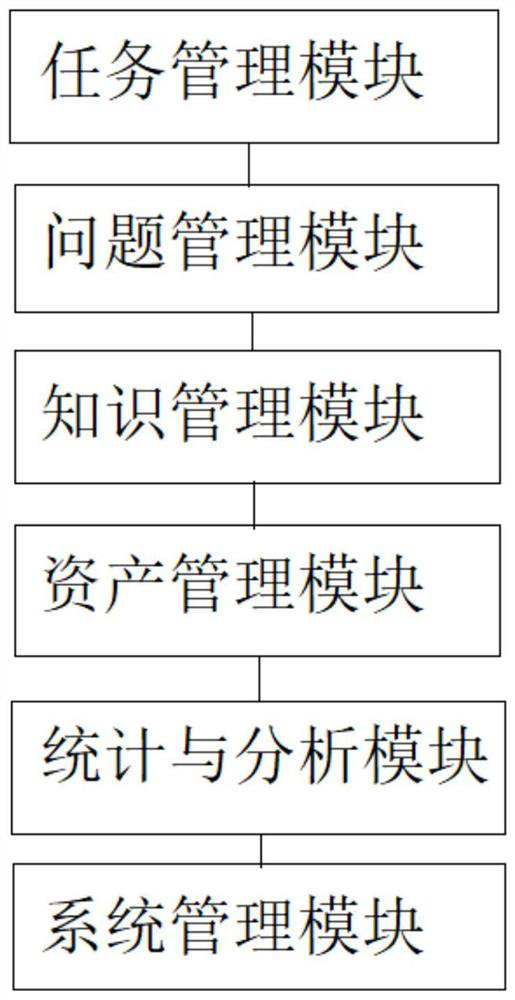

The invention discloses an IT equipment operation and maintenance management system and method. The IT equipment operation and maintenance management system comprises a task management module, a problem management module, a knowledge management module, an asset management module, a statistics and analysis module and a system management module. The task management module is used for equipment technical state management, planned task, temporary task and equipment maintenance account management; the knowledge management module is used for knowledge collection, knowledge query and knowledge updating; the asset management module is used for asset account management, printing bar code functions, inventory functions, configuration management, change management, asset allocation, asset rejection and assets disposal; and the statistics and analysis module is used for query statistics and performance assessment. The IT equipment maintenance system has the advantages that the IT equipment can beprotected by the system according to preset settings, the IT equipment maintenance speed is high, the working efficiency is high, solutions in the knowledge base can be searched when the IT equipmentis maintained, and the blindness of IT equipment maintenance is reduced.

Owner:广州厉行科技有限公司

A method and equipment for continuously preparing vanadium nitrogen alloy

The invention discloses a method for continuously preparing vanadium-nitrogen alloy. The method includes the first step of preparation, the second step of blending and blank manufacturing, the third step of adding, the fourth step of preheating and prereduction, the fifth step of carbonization and nitridation sintering, and the sixth step of discharging. A device for preparing vanadium-nitrogen alloy according to the method comprises a vertical boiler, a top feeding bin (1) and a continuous automatic discharging device (2), wherein the vertical boiler is composed of a preheating section (4), a calcination section (4) and a cooling section (5); the lower end of the vertical boiler is connected with the continuous automatic discharging device (2) through a pipeline; the tail end of the continuous automatic discharging device is connected with a finished product trolley (20) through a discharge pipe (18); the bottom of the vertical boiler is provided with a nitrogen inlet (21). The method has the advantages that the process and the device are compact, the production process is short, electric energy is saved, little investment is required, yield is high, continuous production is really achieved, and the industrialized and scale production requirement is met.

Owner:SICHUAN ZHANXIANG SPECIAL ALLOY TECH

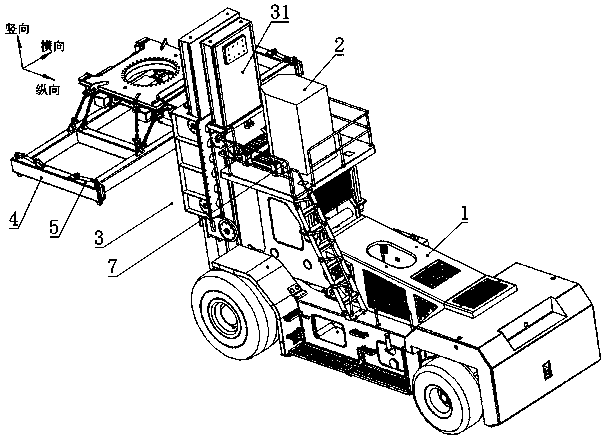

Oil-burning and electrically drive two-purpose forklift

InactiveCN101088907BAvoid accidentsAutomatic chargingGas pressure propulsion mountingLifting devicesVehicle frameAutomatic control

The oil-burning and electrically driven two-purpose forklift includes a frame, a power system, a gear box, a walking system, a hydraulic pump station, a hydraulic system, an operation system, an automatic control system, a cable reel, a reel oil motor and a walking oil motor. The power system includes one oil-burning engine and one AC motor; the hydraulic pump station includes one engine driven hydraulic pump station and one motor driven hydraulic pump station connected via a two-position three-way valve to the hydraulic system; the motor driven hydraulic pump station provides hydraulic oil to the reel oil motor and the walking oil motor, while the engine drives the input shaft of the gear box; and the automatic control system controls the forklift under the driving of the motor. The present invention can save fuel oil, reduce environmental pollution caused by oil burning tail gas and lower operation cost.

Owner:安培

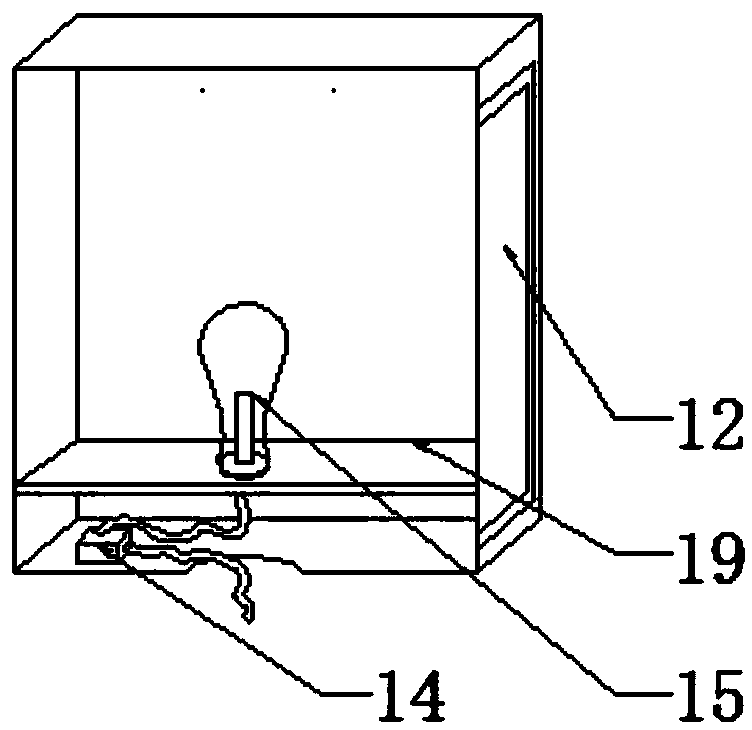

Intelligent conveniently maintained traffic lamp

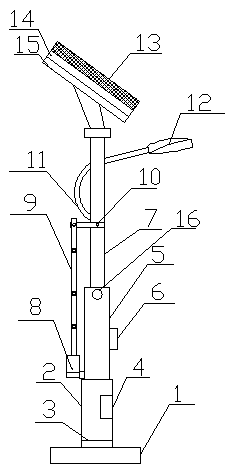

InactiveCN108895384ADetection firmnessReduce riskMechanical apparatusLighting support devicesEngineeringPressure sensor

The invention discloses an intelligent conveniently maintained traffic lamp. The intelligent conveniently maintained traffic lamp comprises a street lamp base, a containing cavity, a pressure sensor,a controller, a first lamp pole, a buzzer, a second lamp pole, an electric telescopic rod, a four-bar linkage, a fixing bolt, a lamp arm, a lamp body, a solar panel, an inverter, a storage battery anda rotating shaft, wherein the top end of the street lamp base is provided with the containing cavity, the inner bottom end of the containing cavity is provided with the pressure sensor, the inner wall of the containing cavity is provided with the controller, the top end of the containing cavity is provided with the first lamp pole, one side of the first lamp pole is provided with the buzzer, thetop end of the first lamp pole is provided with the second lamp pole, the second lamp pole is provided with the four-bar linkage, one side of the bottom end of the first lamp pole is provided with theelectric telescopic rod, one side of the second lamp pole is provided with the lamp arm, one side of the lamp arm is provided with the lamp body, the top end of the second lamp pole is provided withthe solar panel, the bottom end of the solar panel is provided with the inverter, and the bottom end of the inverter is provided with the storage battery; the intelligent conveniently maintained traffic lamp has reasonable design and a simple structure.

Owner:芜湖致新信息科技有限公司

Maintenance method of converter bottom of top-bottom combined blowing converter

ActiveCN110317920AReduce quality impactSimple stepsManufacturing convertersProcess efficiency improvementSlagNitrogen

The invention provides a maintenance method of a converter bottom of a top-bottom combined blowing converter. Low-pressure and low-flow nitrogen are blown into the converter through an oxygen lance, and heat of converter gas in the converter is timely replaced and discharged, so that a small amount of converter slag left in the converter is rapidly cooled so as to be chilled, solidified and adhered to the converter bottom; and after steel scraps or iron blocks are added, the heat of the converter slag and the added steel scraps or iron blocks are further subjected to heat exchange, so that thecooling and solidification of the converter slag are accelerated, therefore the converter bottom is rapidly patched with the slag, and the purpose of maintaining the converter bottom is achieved; themaintenance method does not need modification of equipment and process, and is simple and practical in steps and low in cost, on the premise of ensuring operation safety and maintenance effect, the cost investment of refractory materials such as converter fettling materials is not needed, and adverse effects on converter fettling and molten steel pollution problems caused by too long or too shortsintering time no longer exist; and the maintenance method has the characteristics of being fast in maintenance speed, good in fettling effect, little in influence on the molten steel quality, low inmaintenance cost, simple, practical, safe and environmental-friendly, and the like.

Owner:山东钢铁集团有限公司

IT equipment allocation management and control system and allocation method thereof

InactiveCN111612341AFast maintenanceImprove work efficiencyOther databases queryingResourcesManagement planningSystems management

The invention discloses an IT equipment allocation management and control system and an allocation method thereof. The IT equipment allocation management and control system comprises a task managementmodule, a problem management module, a knowledge management module, an asset management module, a statistics and analysis module and a system management module; the task management module is used fortechnical state management, planned task, temporary task and equipment maintenance ledger management of the equipment; the knowledge management module is used for knowledge collection, knowledge query and knowledge updating; the asset management module is used for asset standing book management, a bar code printing function, a checking function, configuration management, change management, assetallocation, asset scrapping and asset disposal; and the statistics and analysis module is used for query statistics and performance assessment. The IT equipment allocation management and control system has the advantages that the IT equipment can be protected by the system according to preset settings, the IT equipment maintenance speed is high, the working efficiency is high, solutions in the knowledge base can be searched when the IT equipment is maintained, and the blindness of IT equipment maintenance is reduced.

Owner:广东鹄志人才服务有限公司

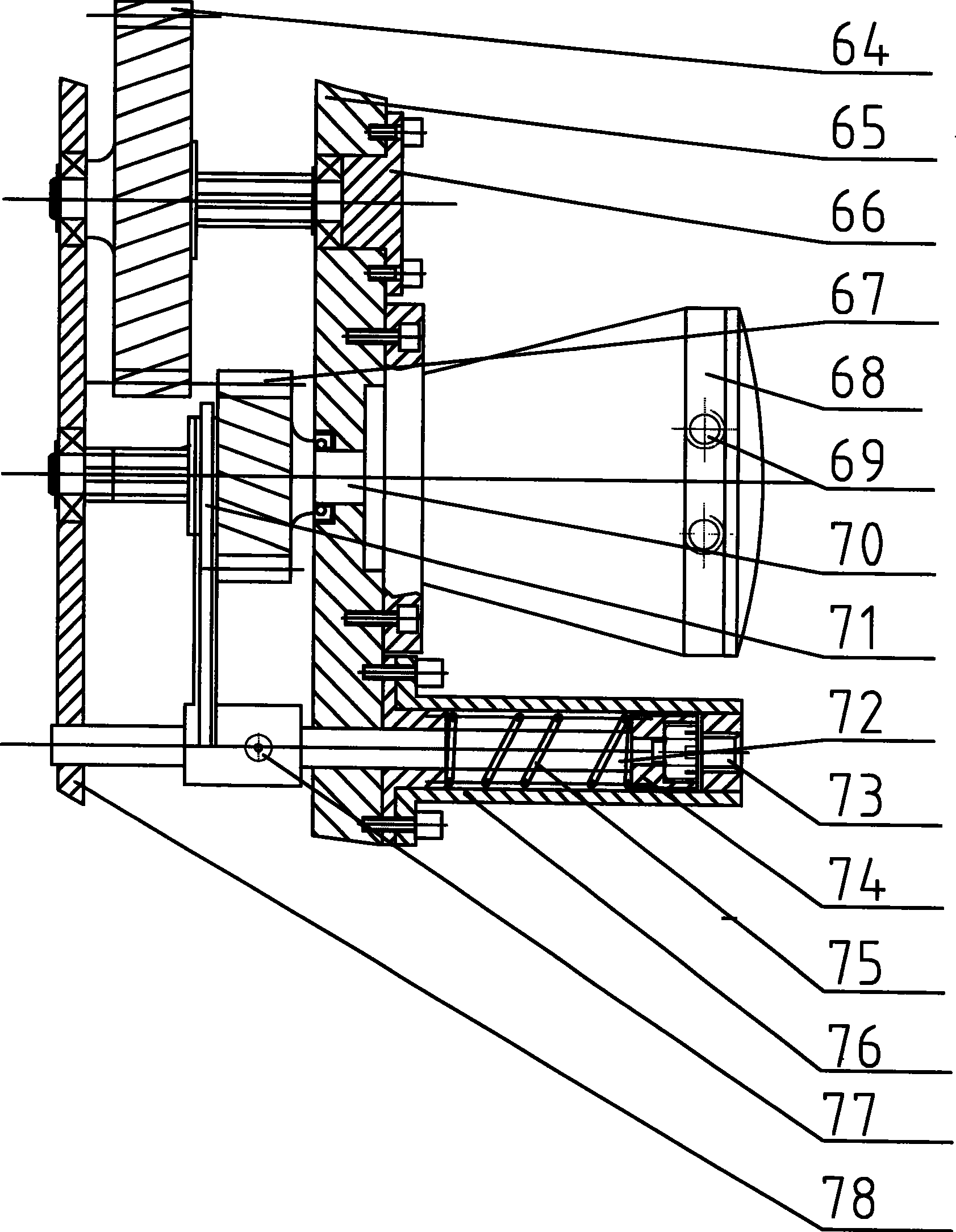

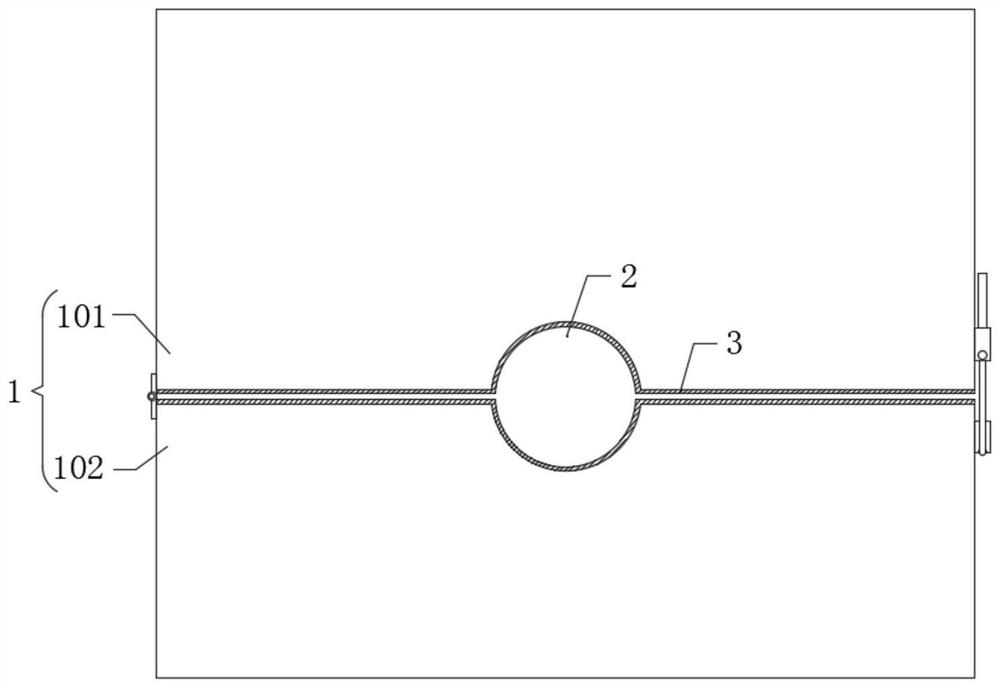

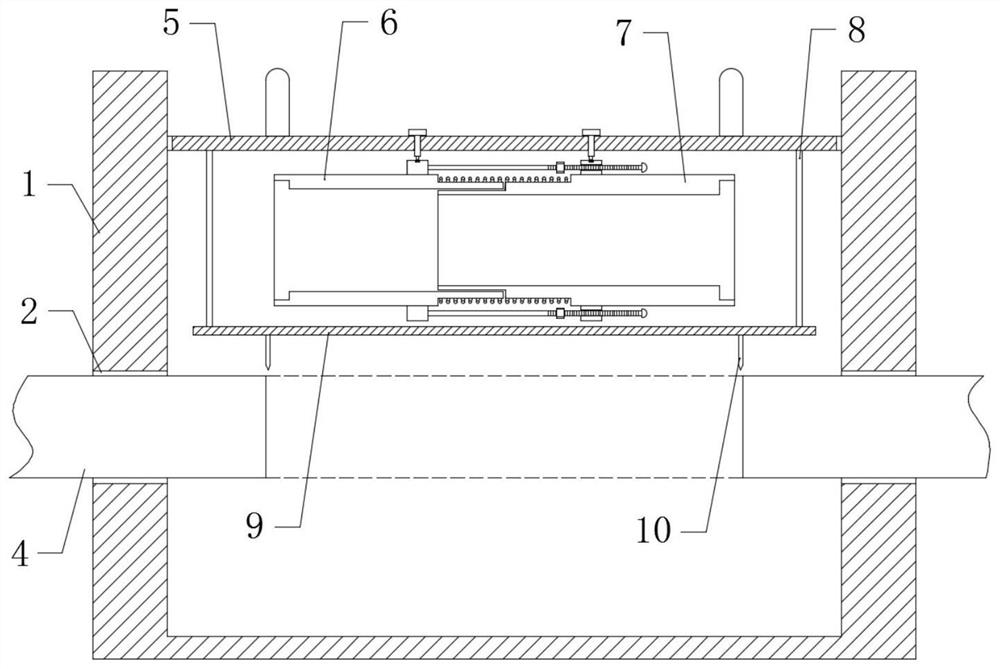

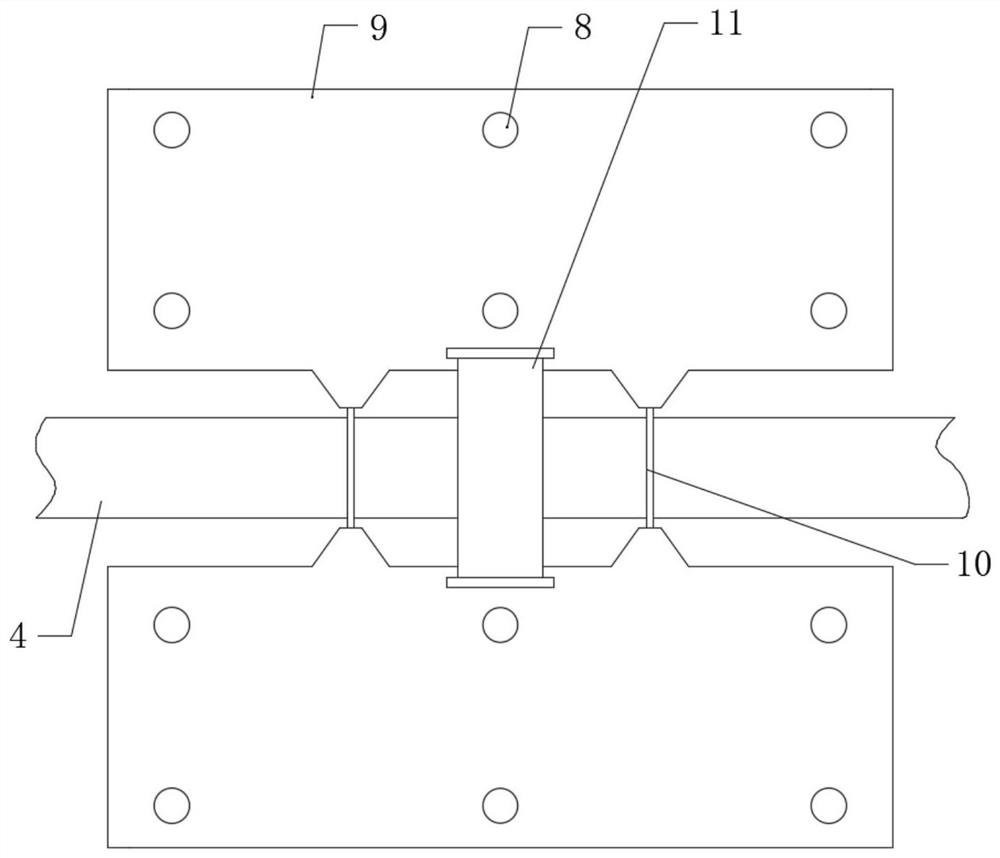

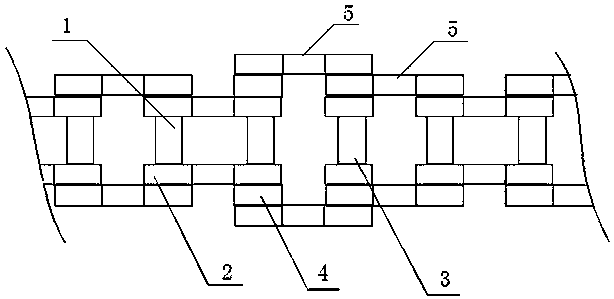

Multi-dimensional sling for container

PendingCN110790163AAccuracy adjustment has defects to make upSimple designCranesLoad-engaging elementsStructural engineeringTransaxle

Owner:荣成中磊科技发展有限公司

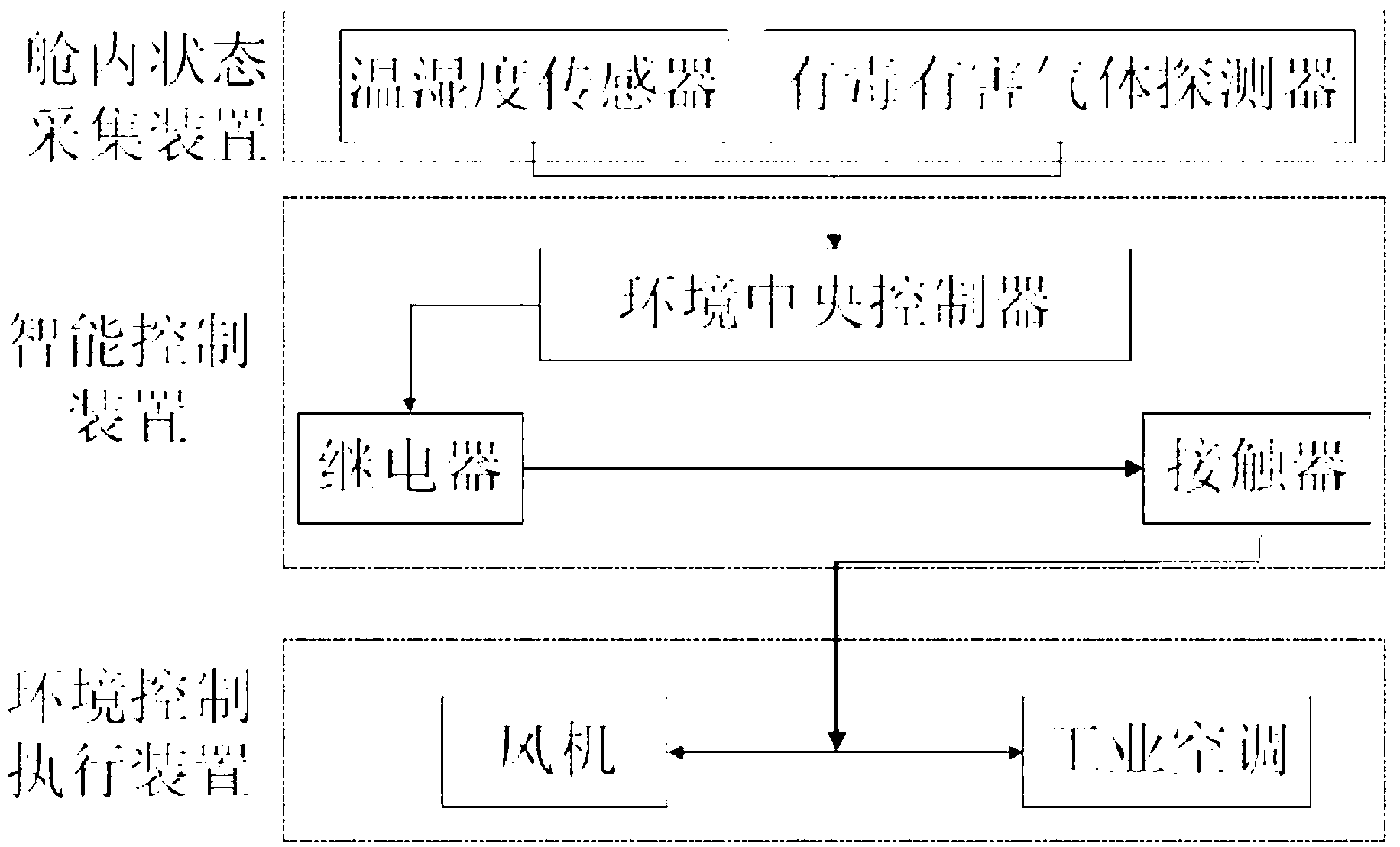

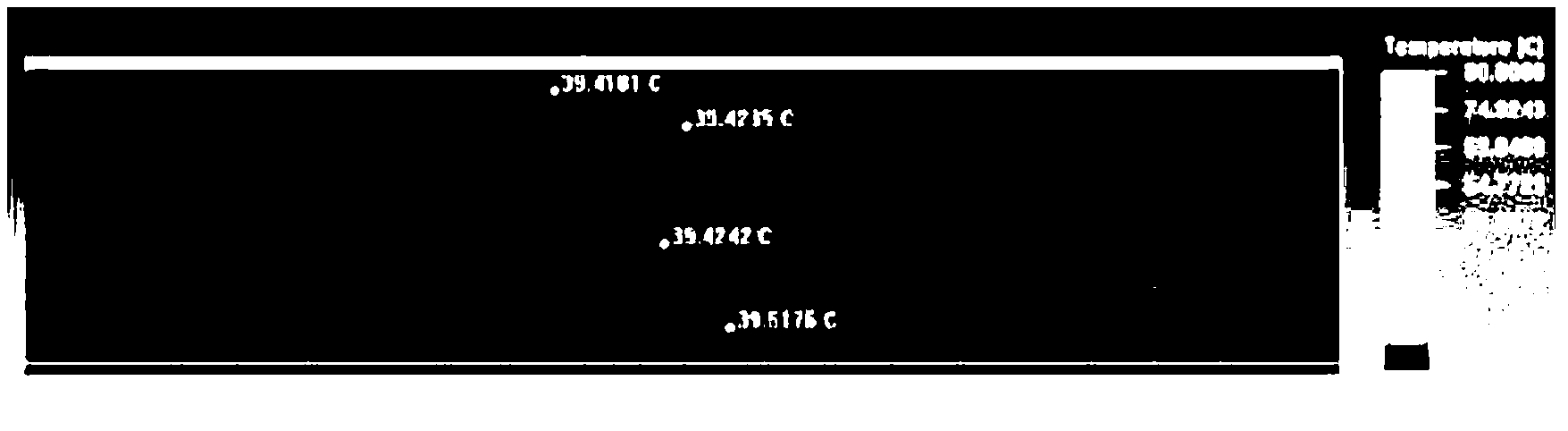

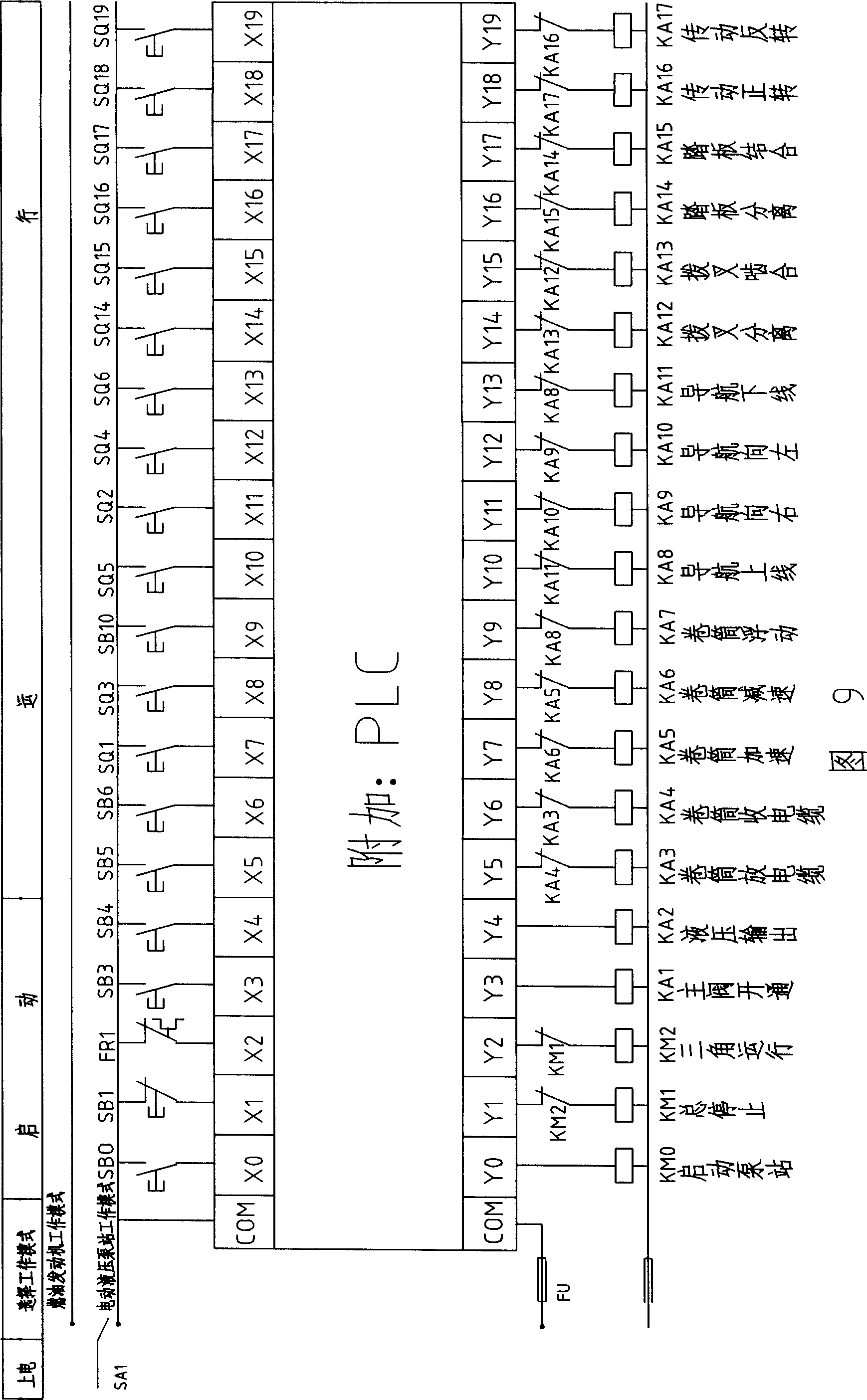

Prefabricated equipment compartment intelligent environment control system and control method thereof

ActiveCN103307708AReduce environmental control costsReduce operating energy consumptionSpace heating and ventilation safety systemsLighting and heating apparatusIntelligent environmentControl system

The invention discloses a prefabricated equipment compartment intelligent environment control system and a control method thereof. The system comprises an in-compartment state acquisition device, an intelligent control device and an environment control executive device, wherein the in-compartment state acquisition device comprises a plurality of temperature and humidity sensors; the intelligent control device comprises an environment central control unit, a relay and a contactor; the environment control executive device comprises a fan and an industrial air conditioner; the temperature and humidity sensors are connected with the environment central control unit; the environment central control unit is respectively connected with the relay and the contactor; and both the fan and the industrial air conditioner are connected with the environment central control unit through the relay and the contactor. The working principle of system is to control the relay and the contactor to start or stop the fan or the air conditioner through a central control program according to different acquired information. The system adopts an interactive operation control mode by taking the fan as a main body and the industrial air conditioner as an auxiliary body, and integrally utilizes the advantages of long service life, energy economization and low cost of the fan and the characteristics of strong conditioning effect and capacity of the air conditioner.

Owner:南京瑞吾电气有限公司

Fuel oil and electric dual-purpose bulldozer

InactiveCN101126244BAvoid accidentsAutomatic chargingMechanical machines/dredgersHydraulic pumpFuel oil

The invention provides a fuel-electricity dual-purpose bulldozer, which comprises a chassis, a power system, a transmission case, a running system, a hydraulic power station, a hydraulic system, an operating system, a control circuit, a cable drum, an oil motor for a drum, a driving oil motor, a driving transmission case of the power system and a hydraulic pump station. The output shaft of the transmission case drives the running system, the hydraulic pump station provides pressure oil for the hydraulic system which drives the operating system; the power system comprises a fuel engine and an AC motor; the hydraulic pump station comprises a hydraulic pump station driven by the fuel engine and an electric hydraulic pump station driven by the AC motor, the two hydraulic pump stations are connected with the hydraulic system through a two-position three-way valve; the electric and hydraulic pump station provides pressure oil for the drum oil motor and the driving oil motor; the fuel enginedrives the input shaft of the transmission case; the driving oil motor drives the intermediate shaft of the transmission case through an engaging and disengaging device; a cable drum is used for drawing or releasing the cable and the drum oil motor drives the cable drum to draw or release the cable; a control circuit controls the bulldozer when the bulldozer is driven by the AC motor. The invention can effectively save fuel, reduce the pollution to the environment by the exhaust gas of the fuel and can considerably reduce the operation cost.

Owner:安培

High-voltage pulse track circuit receiver

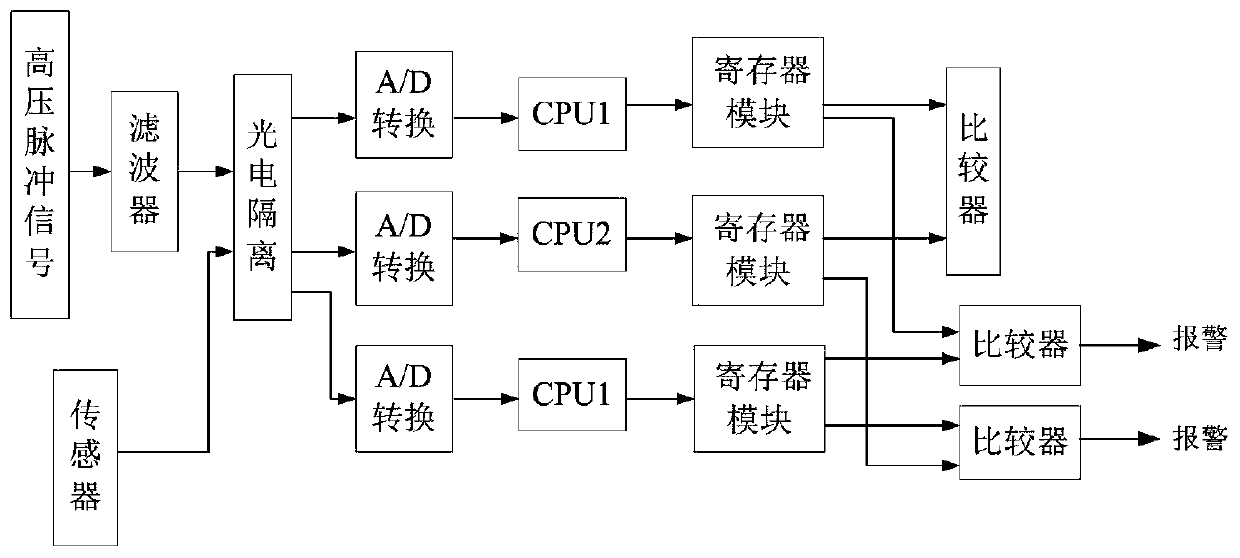

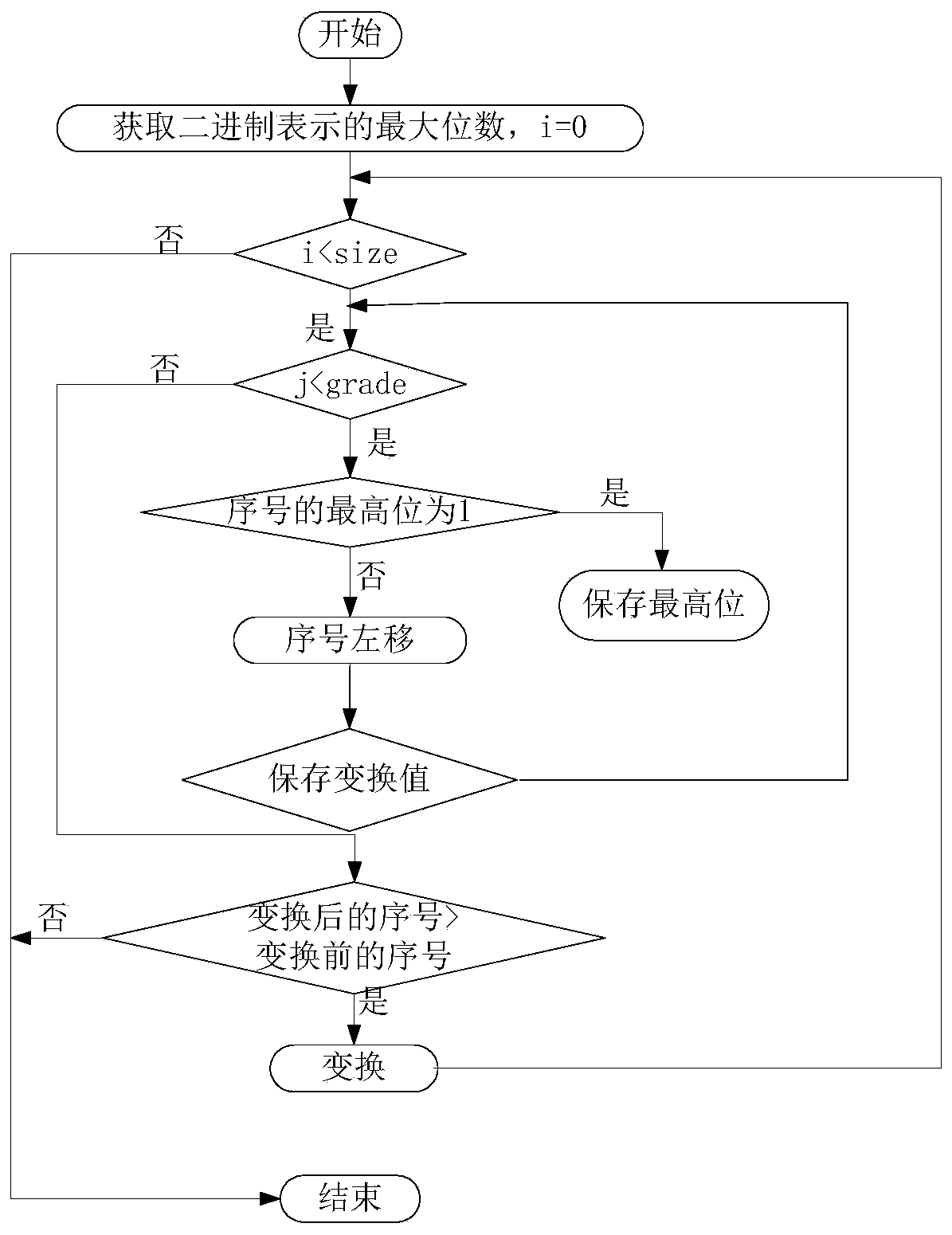

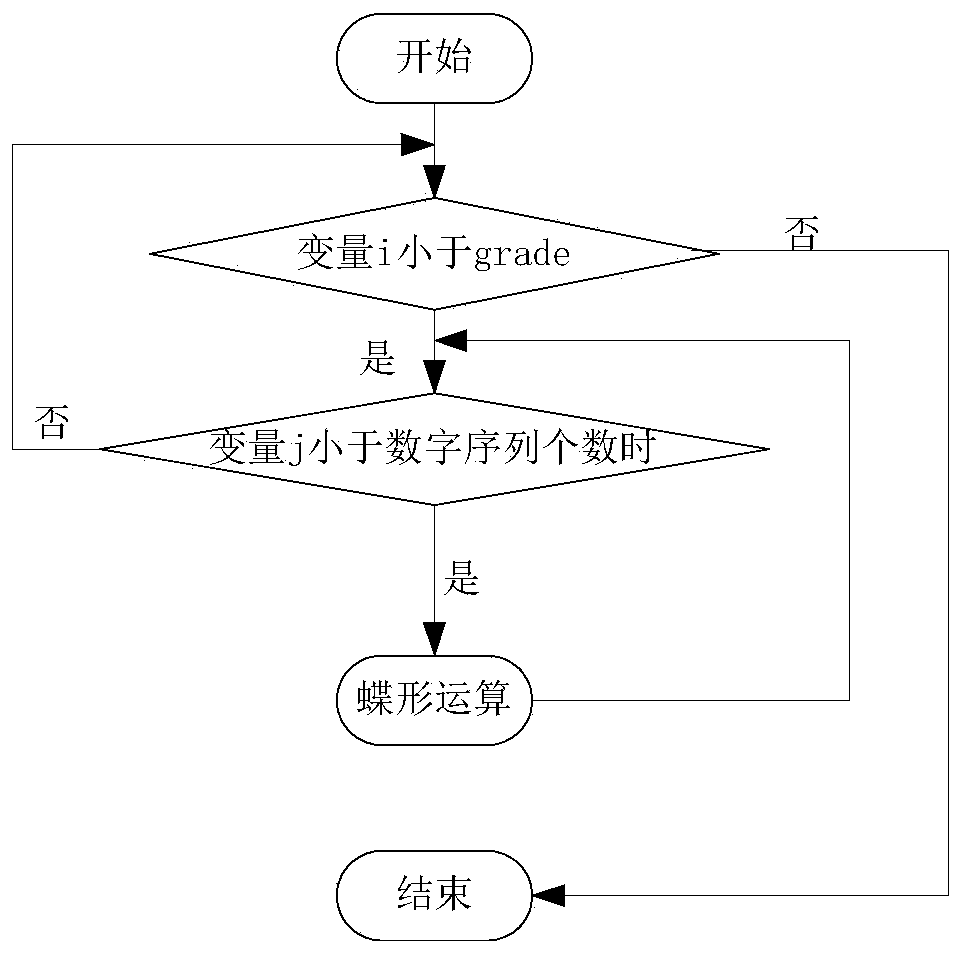

InactiveCN110979391AImprove processing speedImprove processing precisionVehicle route interaction devicesVoltage pulseHigh voltage pulse

A high-voltage pulse track circuit receiver belongs to the technical field of track circuits. The high-voltage pulse track circuit receiver comprises three acquisition channels, two signal processingunits and three storage units, the acquisition channel I and the acquisition channel III share the signal processing unit I, two output signals are respectively stored in two of the three storage units, the acquisition channel II is connected with the signal processing unit II, the output signal of the acquisition channel II is stored in another storage unit, and the three storage units form a two-out-of-three structure and are respectively connected to corresponding comparators. According to the high-voltage pulse track circuit receiver, two CPUs are mainly used for effectively acquiring andidentifying high-voltage pulse signals, the two CPUs respectively adopt different processing identification methods, the pulse signals are processed by the CPUs, and the operation results are comparedto be consistent by the comparators, so that whether a vehicle is occupied in an interval or not can be judged, and the reliability and the safety of the equipment are improved.

Owner:HUNAN VOCATIONAL COLLEGE OF RAILWAY TECH

Safe and reliable platform

Owner:刘丰源

Fuel oil and electric dual-purpose special type engineering machinery

InactiveCN100582499CWith automatic navigation functionReduce duplicationMachines/enginesFluid-pressure actuator componentsVehicle frameHydraulic pump

The invention relates to a special-purpose fuel and electric engineering machine, which comprises a self-travelling carriage, on which a central rotary table, a power system, a traveling system, a hydraulic pump station, and a work system are provided. The power system drives the hydraulic pump station and the traveling system, the hydraulic pump station supplies pressure oil to the hydraulic system, which drives the work system. On the carriage, additionally a control circuit, a cable drum and a drum oil motor are provided. Wherein, the power system comprises a fuel engine and an AC motor; the hydraulic pump station comprises a hydraulic pump station driven by the fuel engine and an electro-hydraulic pump station driven by the AC motor; the electro-hydraulic pump station and the hydraulic pump station driven by the fuel engine are connected with the hydraulic system through a 2-position 3-way valve; the electro-hydraulic pump station supplies pressure oil to the oil motor of the drum; the cable drum is for accommodating the cable connected with the AC motor; the oil motor of the drum drives the cable drum to take up and retract the cable; the control circuit controls the special-purpose engineering machine to work under driving of the AC motor. The invention can effectively save fuel, reduce the environmental pollution from the tail gas of fuel, and can also greatly reduce the operation cost.

Owner:安培

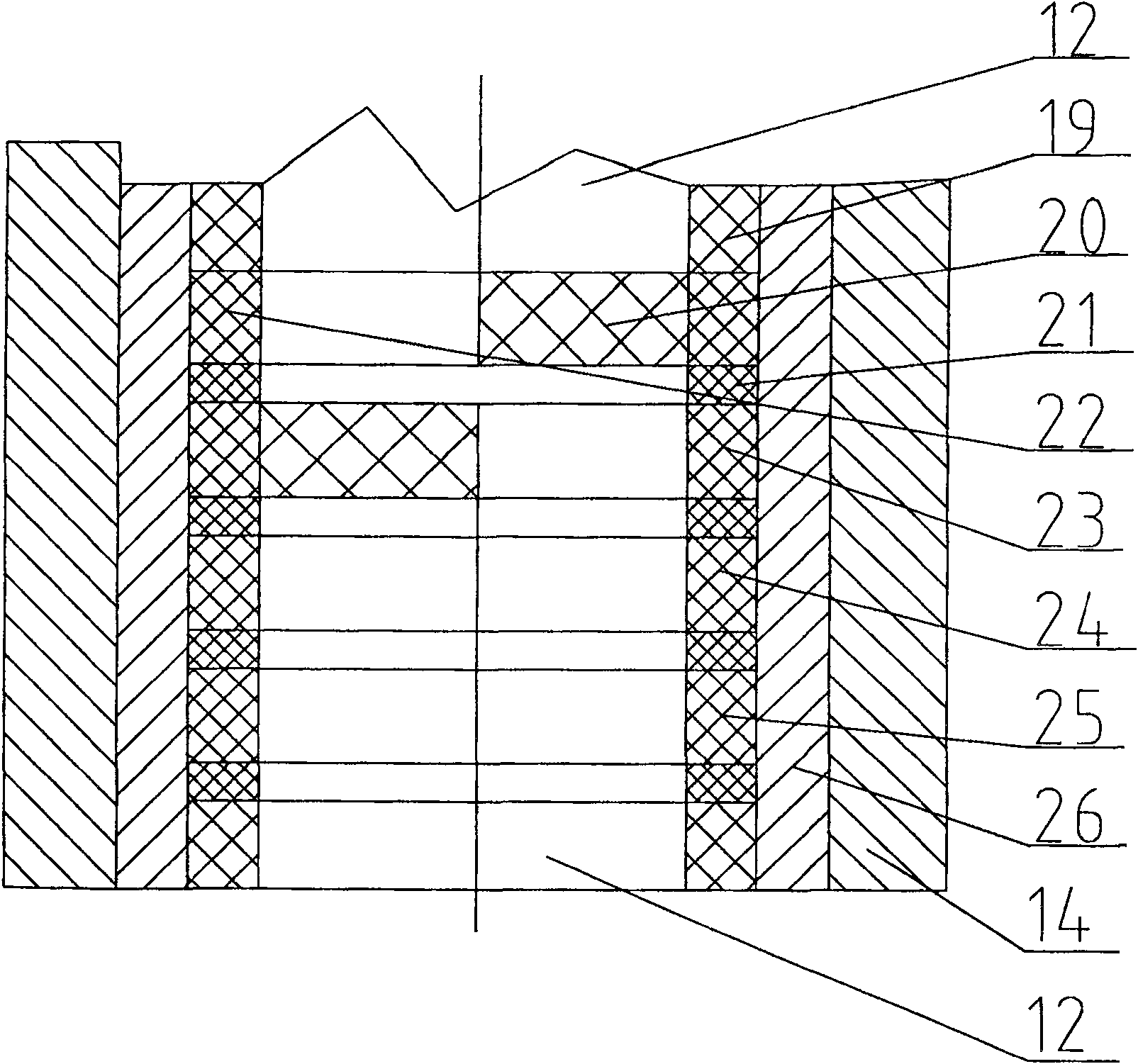

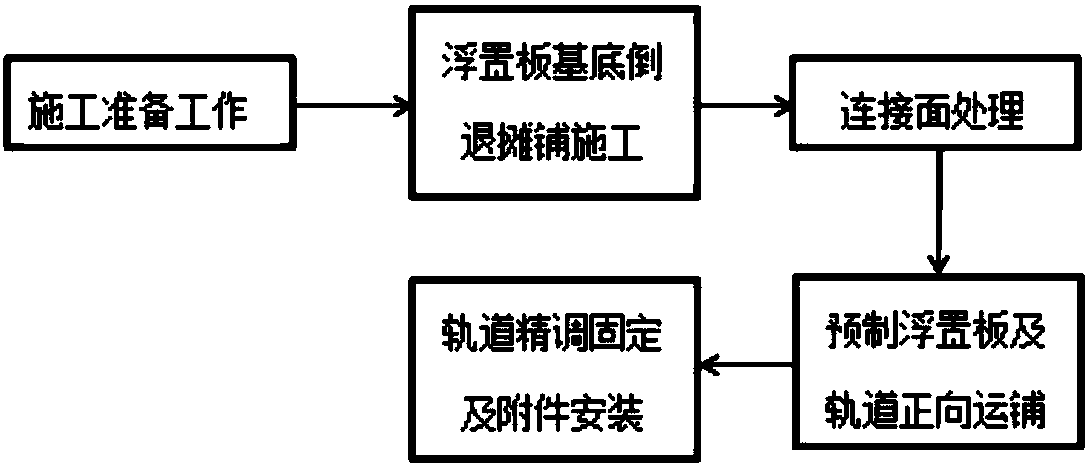

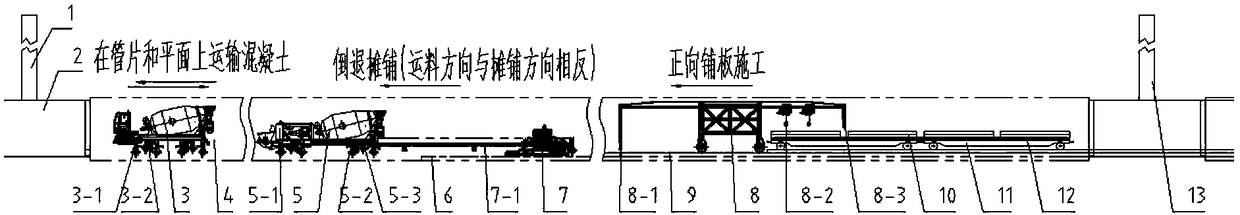

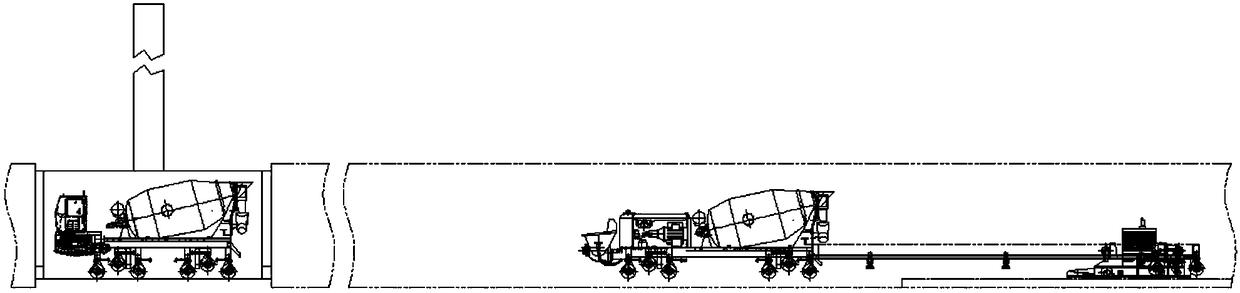

Construction method of subway slab track bed

The invention relates to a construction method for a plate ballast bed of a metro. The method comprises the steps of a basement backward paving construction step, in which a truck mixer transports concrete from a front material feeding well segment to a material storage truck to and fro via a pump or a belt conveyer in a backward moving manner, the material storage truck moves backward to an area to be paved and discharges concrete, and a paver paves; and a plate pathway conveying and paving steps, in which a back pathway and floating plates are transported to a construction area by using a flatcar, a plate paver is used for sequentially discharging the floating plates from the flatcar and paving the same to a predetermined area; and then the pathway is discharged from the flatcar and paved on the floating plates. According to the method provided by the invention, building of a temporary pathway is not needed, the damage to tunnel segments caused by the temporary pathway when the temporary pathway is supported and fixed is reduced, and the construction speed is rapid; in a tunnel, both the truck mixer and the material storage truck can move on a plane as well as a hook face for conveying the concrete, so that the concrete transportation cost is low, and the adaptability is good; the backward paving construction can be operated with subsequent construction in parallel, so that the construction efficiency is high.

Owner:CHINA RAILWAY ENG MASCH RES & DESIGN INST CO LTD +1

Inner and outer spherical cage conjoined forgings and forging dies

ActiveCN105317861BIncrease profitIncrease productivityYielding couplingForging/hammering/pressing machinesManufactured materialStructural engineering

The invention provides an inner and outer ball cage conjoined forging, the upper end surface of which includes the upper end surface of the outer ball cage, the upper inner wall of the outer ball cage, the upper end surface of the connecting part, the upper outer wall of the inner ball cage, the upper end surface of the inner ball cage, and the lower end surface It includes the lower end surface of the outer ball cage, the lower inner wall of the outer ball cage, the lower end face of the connecting part, and the lower outer wall of the inner ball cage; the forging also includes the central hole of the inner ball cage. The present invention also provides a forging die for manufacturing the forging. The upper die assembly of the die includes a split punch consisting of a punch ring and a punch core. The forming surface of the upper side wall of the center hole of the inner ball cage is formed; the lower die assembly includes a ejector rod and a split die consisting of the outer ring of the die, the middle ring of the die and the inner ring of the die, and the upper end of the split die forms the lower part of the forging. The end face, the forming surface of the outer side wall of the outer cage, and the upper end of the ejector rod form the lower side wall forming surface of the center hole of the inner cage. The invention makes the utilization rate of the raw material of the forging high, and makes the production cost of the inner and outer ball cages low.

Owner:SHANGHAI GKN DRIVE SYST

Maintenance method of a transmission chain

The invention discloses a repair method of a transmission chain. The repair method includes the steps that 1, an inner link and a pair of outer chain plates connected with the inner link are removed;2, the removed inner link is cut along the middles of inner chain plates and ground into a round barrel, wherein the circle radius of the round barrel is the radiuses of the outer circumferences of the chain plates where the round barrel is located; 3, two half inner chain plates on the inner link left in the step 2 are taken down from a sleeve and ground into two round rings, wherein the circle radiuses of the round rings are the radiuses of the outer circumferences of the chain plates where the round rings are located; and 4, the round barrel is inserted between the pair of suspended outer chain plates, the two round rings are mounted at the two ends of the exposed inner link, then the pair of removed outer chain plates are used for fixing from the two sides through pin shafts, and chains are combined. When no accessories are available, repair can be rapidly achieved with the method, only one inner link is removed on the aspect of the length, the steps are simple, and the repair speed is high.

Owner:武克学

A maintenance method for the furnace bottom of a top-bottom combined blowing converter

ActiveCN110317920BFor quick maintenanceReduce the temperatureManufacturing convertersProcess efficiency improvementThermodynamicsProcess engineering

This application provides a maintenance method for the furnace bottom of the top-bottom combined blowing converter, blowing in low-pressure, low-flow nitrogen through the oxygen lance, replacing and discharging the heat of the furnace gas in the furnace in time, so that the small amount of slag left in the furnace can be quickly cooled After cooling and solidification, it adheres to the bottom of the furnace. After adding scrap steel or iron nuggets, the heat of the slag and the added scrap steel or iron nuggets further undergo heat exchange, which accelerates the cooling and solidification of the slag, thereby realizing rapid slag repairing of the furnace bottom and reaching the bottom of the furnace. The purpose of maintenance; this application does not require the transformation of equipment and processes, the steps are simple, practical, and low in cost. On the premise of ensuring the operation safety and maintenance effect, there is no need to invest in refractory materials such as furnace materials, and there is no longer sintering time If it is too long or too short, it will have adverse effects on furnace repair and molten steel pollution. It has the characteristics of fast maintenance, good furnace repair effect, little impact on molten steel quality, low maintenance cost, simple and practical, safe and environmentally friendly.

Owner:山东钢铁集团有限公司

Hot maintenance method at joint of rising pipe and bridge pipe

PendingCN110055088AAvoid feesSave moneyCoke oven safety devicesCoke oven detailsPhosphoric acidMaterial resources

The invention discloses a hot maintenance method at a joint of a rising pipe and a bridge pipe. The method includes the steps: (1) preparing a feeding pallet; (2) opening a coal port after a final stage of coking; (3) blowing dust at the joint of the rising pipe and the bridge pipe by compressed air until cleanness, and compressing the air; (4) kneading slightly hard mud materials doped phosphoricacid into circular dough according to needed depths, and placing the circular dough on the feeding pallet to spray slurry on the circular dough to convey the circular dough; (5) pushing the mud materials to a position needing to be wiped and filled by a wiping and filling shovel and leaning the mud materials, and recovering the feeding pallet; (6) secondly conveying the mud materials to the upperportions of the firstly wiped and filled mud materials by the feeding pallet; (7) repeatedly operating the steps five times to complete operation. The hot maintenance method has the advantages that disassembly and assembly of the rising pipe and the bridge pipe are omitted, replacing costs after fusing are avoided, a lot of labor, material resources and production time are saved, benefits are great considerable, and the hot maintenance method has the advantages that time and labor are saved, maintenance speed is high, and hanging time is long.

Owner:SHANDONG TAISHAN STEEL GROUP

Co-production type metal powder preparation device and preparation method

The invention discloses a co-production type metal powder preparation device, and relates to the field of industrial production, and the device comprises a distillation heating unit, a side purification furnace unit, a waste heat collection unit and a smoke emission unit which are arranged in sequence. Wherein the distillation heating unit comprises a heating bin, an ignition, gas valve and temperature feedback control integrated device positioned at the lower part of the heating bin, and a condenser and powder screening module integrated device; and the side purification furnace unit comprises a melting furnace and a medium-rotating furnace. The melting furnace is connected with the intermediate converter through a liquid flow guide pipe, and the distillation heating unit is connected with the intermediate converter through a flow guide pipe. Waste heat generated by the heating bin is connected into the waste heat collecting unit and serves as a heat source for air heating. According to the method, high zinc powder production yield, short production period, low raw material requirement, low loss and high maintenance speed can be achieved, the evaporation device can be recycled, energy conservation and environmental protection are achieved, and the fine powder rate can reach 90-95% when the fine powder rate is 400 meshes or above according to practice.

Owner:沈协江

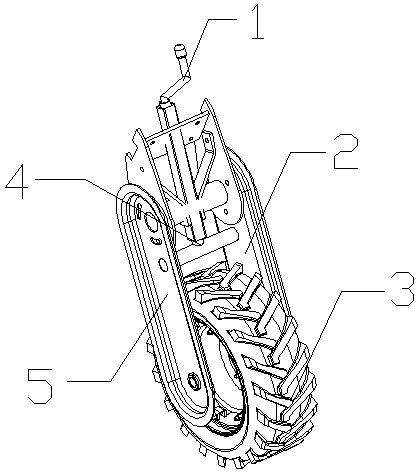

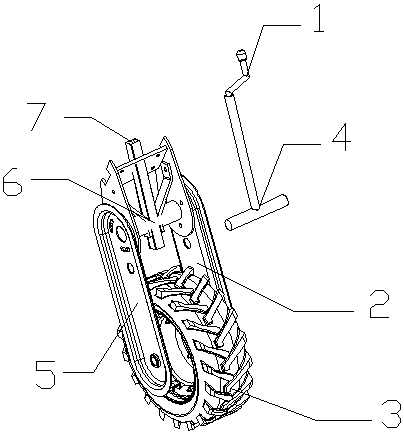

Driving device for mineral aggregate transport car

InactiveCN107776328ASimple structureLow costWheel protectionHand carts with one axisDrive wheelEngineering

The invention discloses a driving device for a mineral aggregate transport car. The device comprises a direction control rod, a left-side fixing board, a roller, a driving rod, a right-side fixing board, a middle fixing shaft and a fixing hole. The device is simple in structure, low in cost and good in practicability. The direction control rod passes through the fixing hole and penetrates throughthe middle fixing shaft to be connected with the driving rod. The left-side fixing board and the right-side fixing board are fixed on two sides of the roller. Two sides of the driving rod are respectively and movably connected with the left-side fixing board and the right-side fixing board. By rotating the direction control rod, the driving rod is stressed such that fixing boards on two sides deviate at the same angle. Therefore, the roller can change forward direction. The direction control rod employs a lever principle so that force is saved. Additionally, the driving device independently rotates and can also be combined with multiple similar driving devices in order to form dual-wheel drive, three-wheel drive, four-wheel drive and the like. Each device can independently steer. Therefore, the driving device is more adapted to the complicated environment in a mine.

Owner:李思模

An emergency repair device for pipelines in water conservancy projects

The invention discloses a pipeline emergency repair device for water conservancy engineering, which includes a repair box, the repair box includes an upper frame body and a lower box body, and the upper frame body and the lower box body are rotatably connected, and the upper frame body and the lower box body are rotatably connected. The side walls of the lower box are symmetrically provided with two semicircular card slots, the four semicircular card slots and the contact surface of the upper frame and the lower box are fixedly installed with sealing rubber pads, and the inner side wall of the upper frame An operation panel is slidably installed on the upper side, and a plurality of fixing rods are fixedly installed on the lower bottom surface of the operation panel. The invention cuts off the broken water pipe and replaces the first repair pipe and the second repair pipe through the cutter mechanism and the pipe changing mechanism. The repair speed is fast and the operation is simple. The first fixing block, the second fixing block, the threaded rod and the adjusting nut realize the tight socket connection between the first repairing pipe, the second repairing pipe and the water pipe, thereby increasing the pressure resistance of the device.

Owner:济南市水利建筑勘测设计研究院有限公司

Repair method of transmission chain

The invention discloses a repair method of a transmission chain. The repair method includes the steps that 1, an inner link and a pair of outer chain plates connected with the inner link are removed;2, the removed inner link is cut along the middles of inner chain plates and ground into a round barrel, wherein the circle radius of the round barrel is the radiuses of the outer circumferences of the chain plates where the round barrel is located; 3, two half inner chain plates on the inner link left in the step 2 are taken down from a sleeve and ground into two round rings, wherein the circle radiuses of the round rings are the radiuses of the outer circumferences of the chain plates where the round rings are located; and 4, the round barrel is inserted between the pair of suspended outer chain plates, the two round rings are mounted at the two ends of the exposed inner link, then the pair of removed outer chain plates are used for fixing from the two sides through pin shafts, and chains are combined. When no accessories are available, repair can be rapidly achieved with the method, only one inner link is removed on the aspect of the length, the steps are simple, and the repair speed is high.

Owner:武克学

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com