Patents

Literature

41results about How to "Realize online repair" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

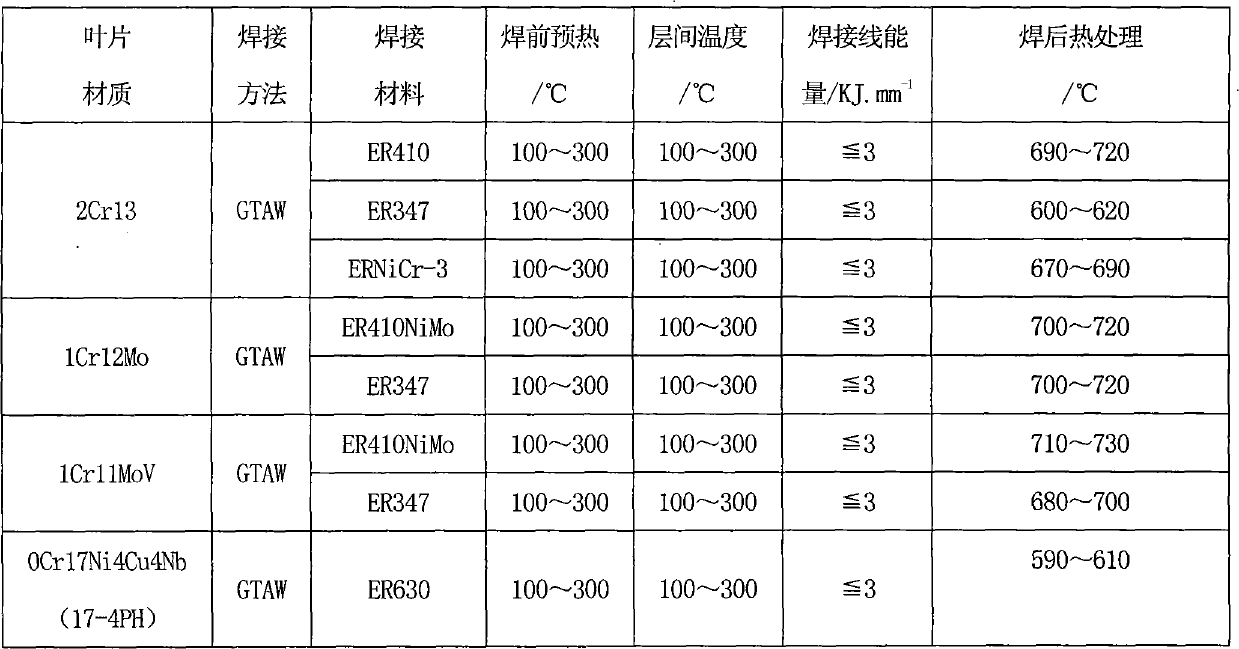

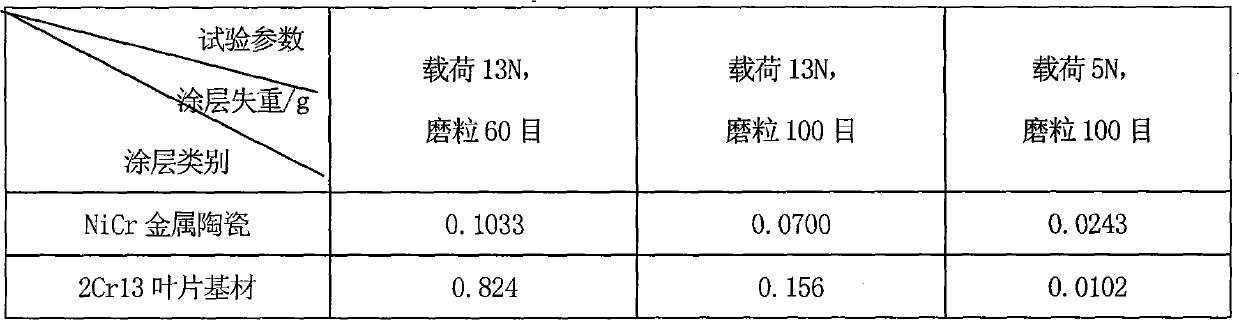

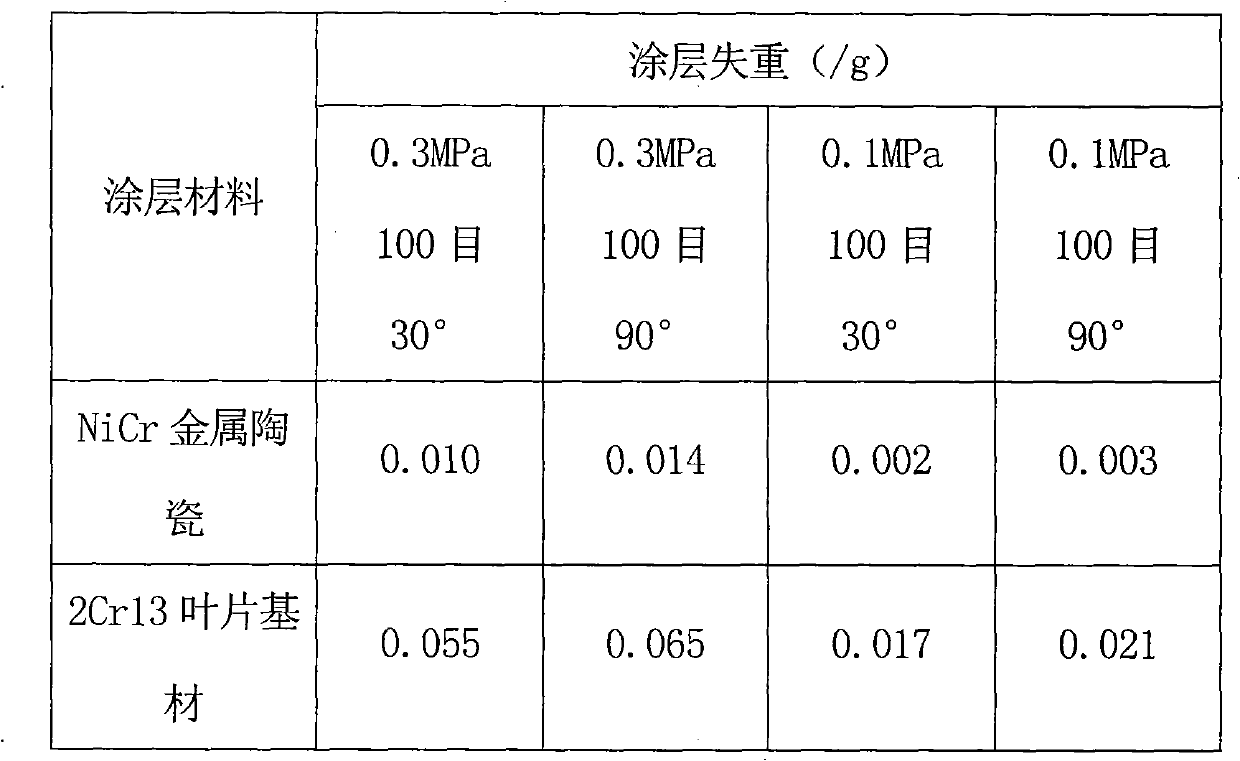

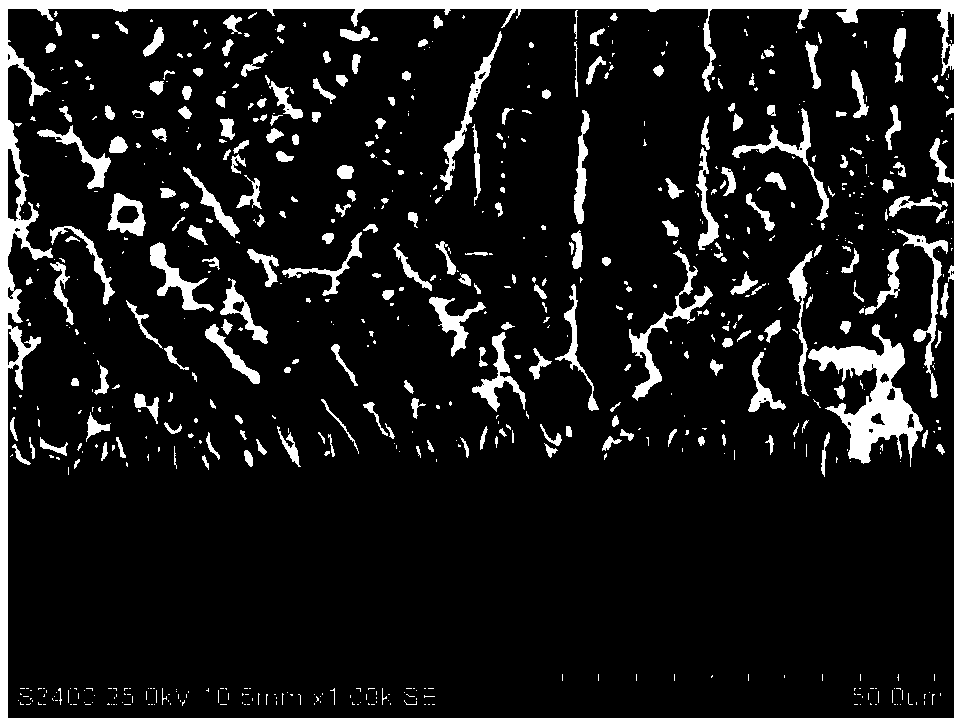

Process for repairing water erosion damage of flow passage component of steam turbine and protecting flow passage component of steam turbine

ActiveCN101767261AExtended service lifeNo change in vibration characteristicsMolten spray coatingPolishing machinesPower stationEconomic benefits

The invention discloses a process for repairing water erosion damage of a flow passage component of a steam turbine and protecting the flow passage component of the steam turbine. In the process, molded lines of the flow passage component of the steam turbine are repaired by adopting copy overlaying of manual argon tungsten arc welding aiming at the phenomenon of the water erosion damage existing in the flow passage component of the steam turbine. A water erosion resistant coating is prepared by supersonic speed flame spraying so as to achieve the purposes of repairing the molded lines of the flow passage component of the steam turbine and protecting the molded lines at large area on line and prolonging the service life of the flow passage component of the steam turbine. Through the process of the invention, the flow passage component of the steam turbine can be repaired and protected at large area on line in a short time without changing vibration characteristic, steam-driven characteristic and strength characteristic of the flow passage component of the steam turbine, so that the process has the advantages of high on-site operability, small deformation of the repaired workpiece, remarkable improvement on water erosion resistance and the like, can solve the common problem of water erosion in the flow passage component of the power station steam turbine in service on site, improves the running safety and efficiency of units and increases economic benefit of a power plant.

Owner:XIAN THERMAL POWER RES INST CO LTD

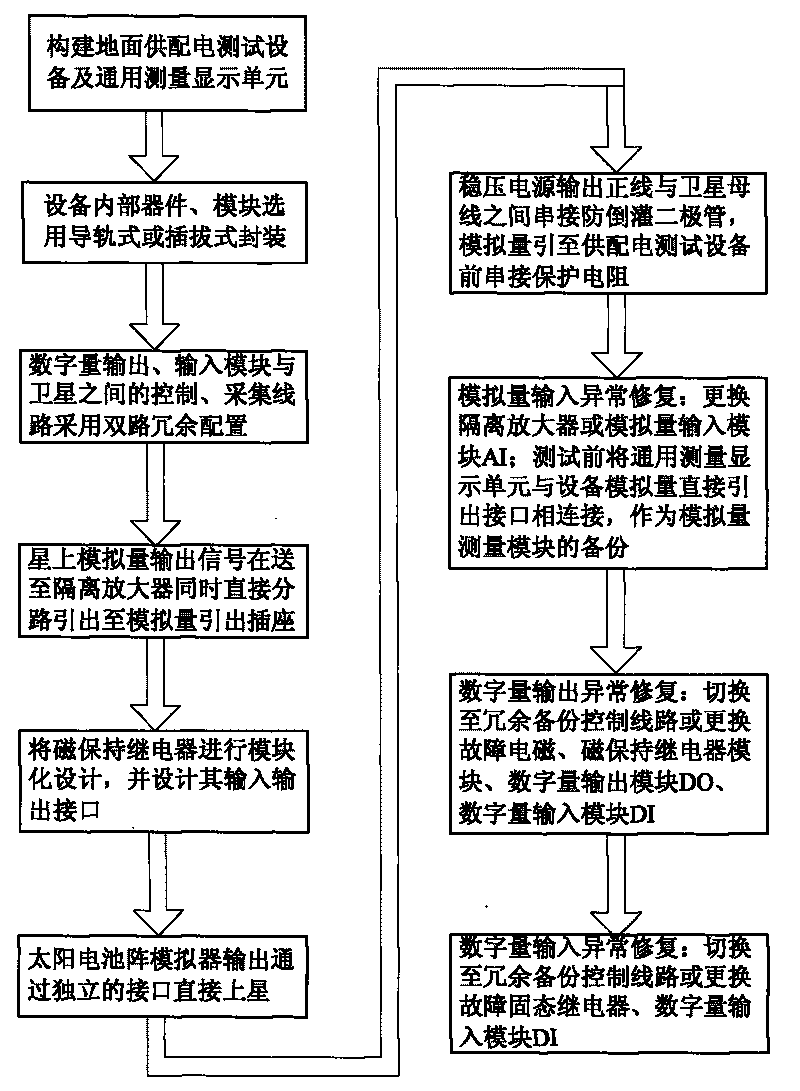

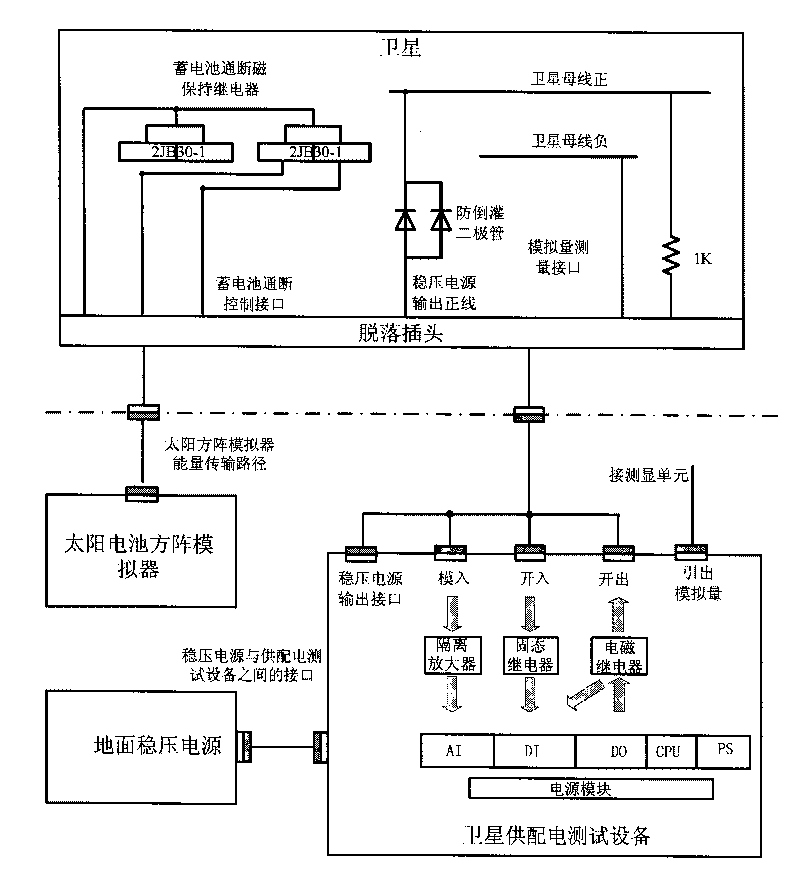

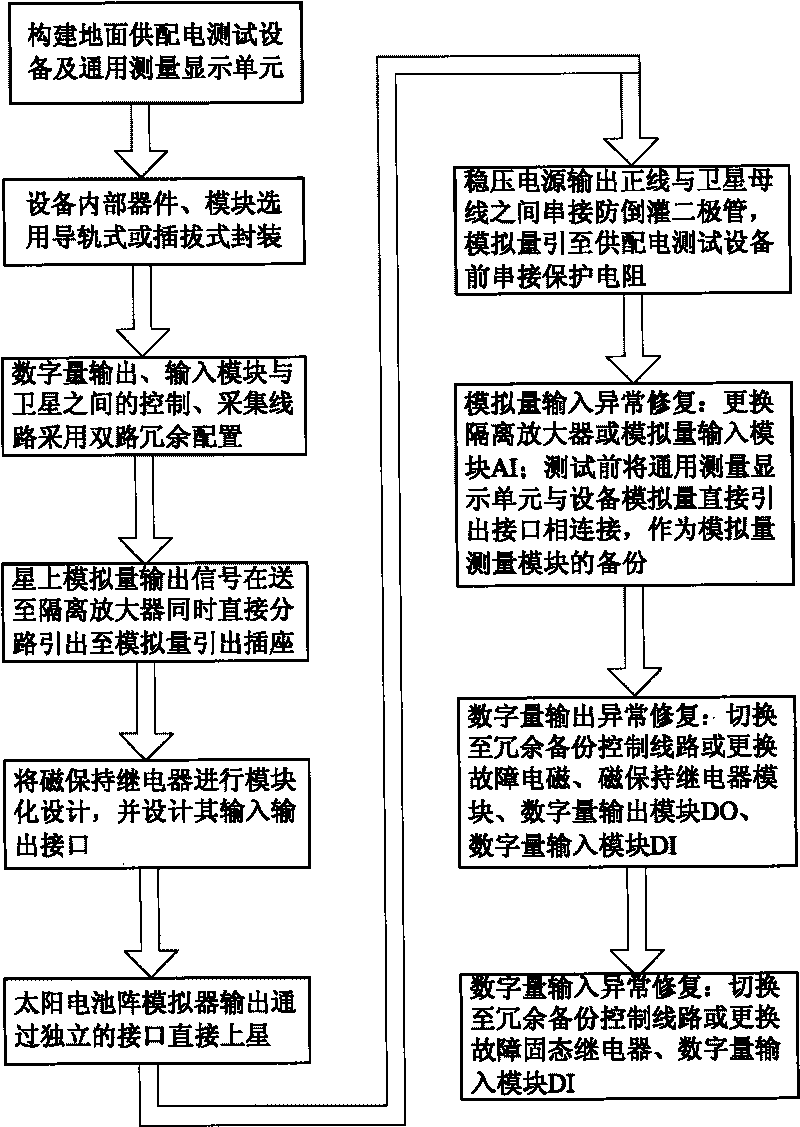

Fault on-line repairing method for satellite power supply and distribution test system

ActiveCN101713802AWith fault online repair functionFor quick replacementElectrical testingEngineeringSolar cell

The invention discloses a fault on-line repairing method for satellite power supply and distribution test system, which can fast repair the fault of power supply and distribution test equipments on line in thermal tests, aging tests and other tests in which the satellite needs continuous powering up. The internal components of the power supply and distribution test equipments are encapsulated in the plug-in or guide-way form, and simultaneously modular structure designing method is adopted to lead a magnetic latching relay can be fast replaced when in fault; the digital quantity output and input adopt dual redundant configuration, and the analog quantity output signals are displayed by a measurement display unit; the solar cell array simulator output is directly loaded on the satellite via independent interface; a flow backward resisting diode is connected in series between a voltage stabilization source power supply positive line, and an analog quantity outgoing line is connected with a protective resistor in series to prevent the on-satellite products from being influenced by cable plugging when the satellite is powered up; on the basis of satellite-ground synergic design, the redundant resources can be started by fast replacing the faulted modules one faults occur to the equipments to realize equipment on-line repairing.

Owner:AEROSPACE DONGFANGHONG SATELLITE

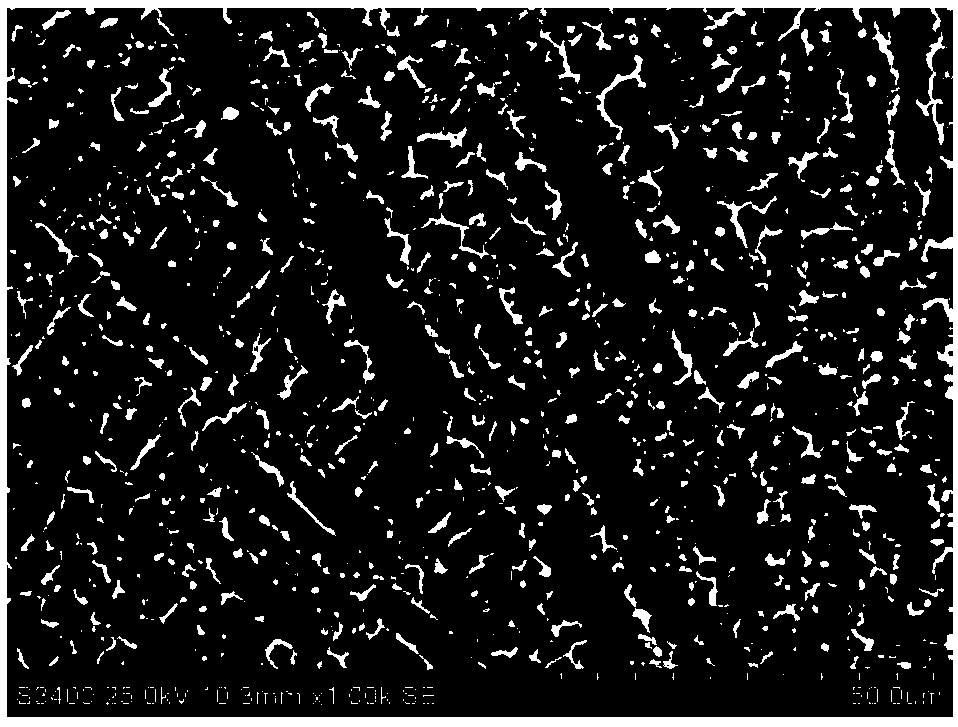

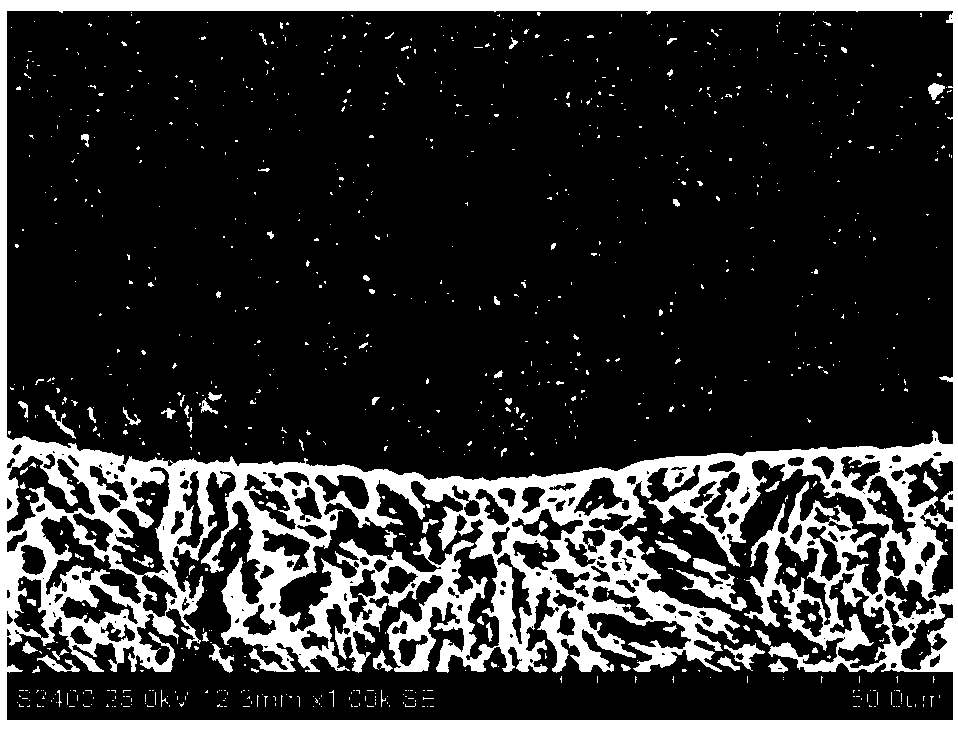

Powder for self-lubricating wear-resisting cobalt-base alloy clad through laser and technology method

ActiveCN108707894AGood molding effectNo crackMetallic material coating processesSurface strengthAlloy steel

The invention provides powder for a self-lubricating wear-resisting cobalt-base alloy clad through laser and a technology method. The powder comprises cobalt-base alloy powder and Ti3SiC2 powder. Thecobalt-base alloy powder comprises, by weight percent, 0.2-0.25% of C, 23.0-26.0% of Cr, 2.0-2.5% of Ni, 0.50-1.0% of Si, 4-5.5% of Mo, 0.55-0.65% of Mn and the balance Co. The powder comprises 85-95%of the cobalt-base alloy powder and 5.0-15.00% of the Ti3SiC2 powder. The laser cladding technology is adopted, a CO2 laser device is utilized for carrying out laser cladding to prepare a novel self-lubricating wear-resisting cobalt-base alloy cladding layer, the prepared cobalt-base alloy cladding layer is uniform in microscopic structure, is well combined with low-alloy steel, and has the beneficial effects of being high in surface strength and hardness and excellent in wear-resisting performance, the novel powder and the corresponding technology method are provided for preparing the self-lubricating wear-resisting cobalt-base alloy cladding layer through laser cladding, and the powder and the method can be widely applied to laser preparation and re-preparation of rolling rollers in themetallurgy industry.

Owner:SHENYANG POLYTECHNIC UNIV

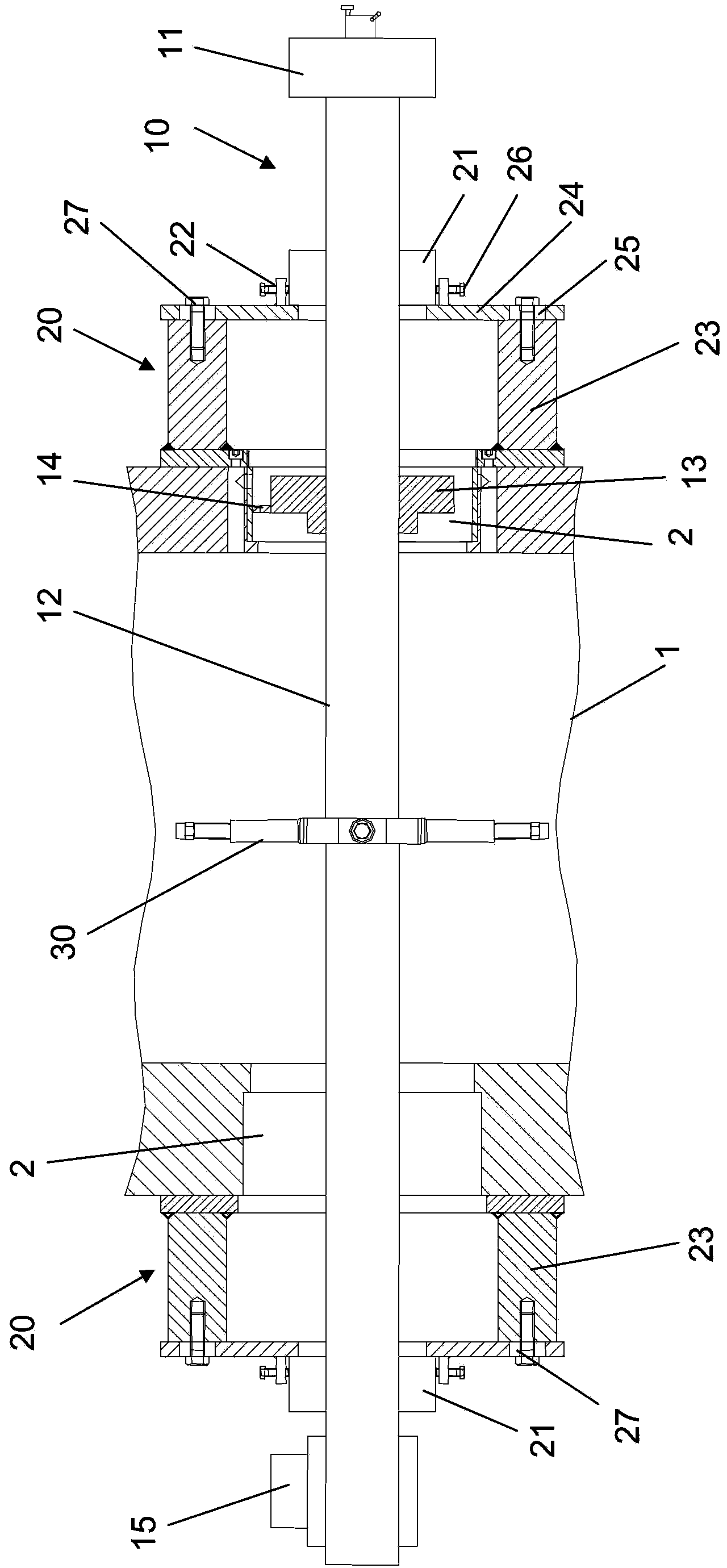

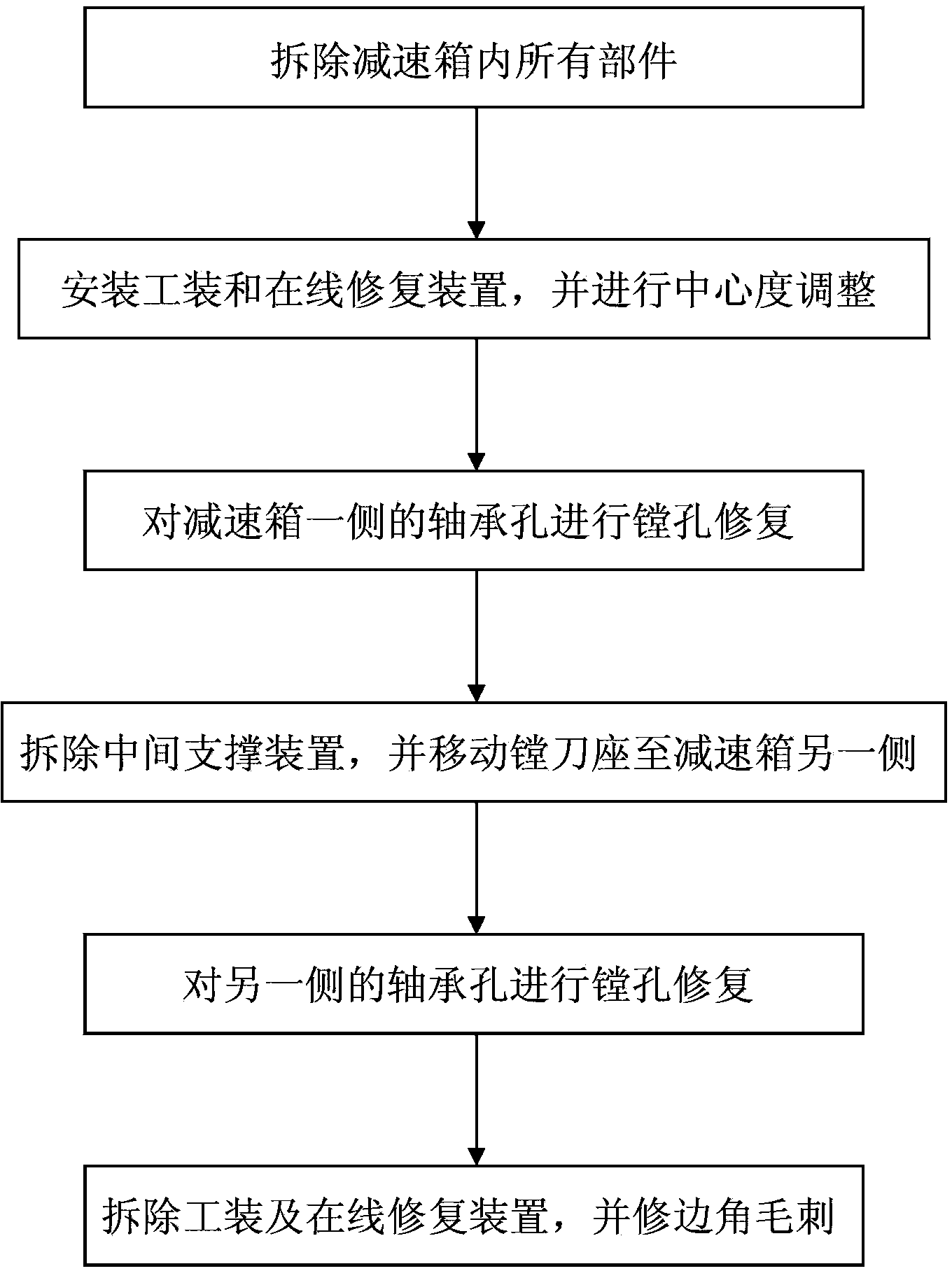

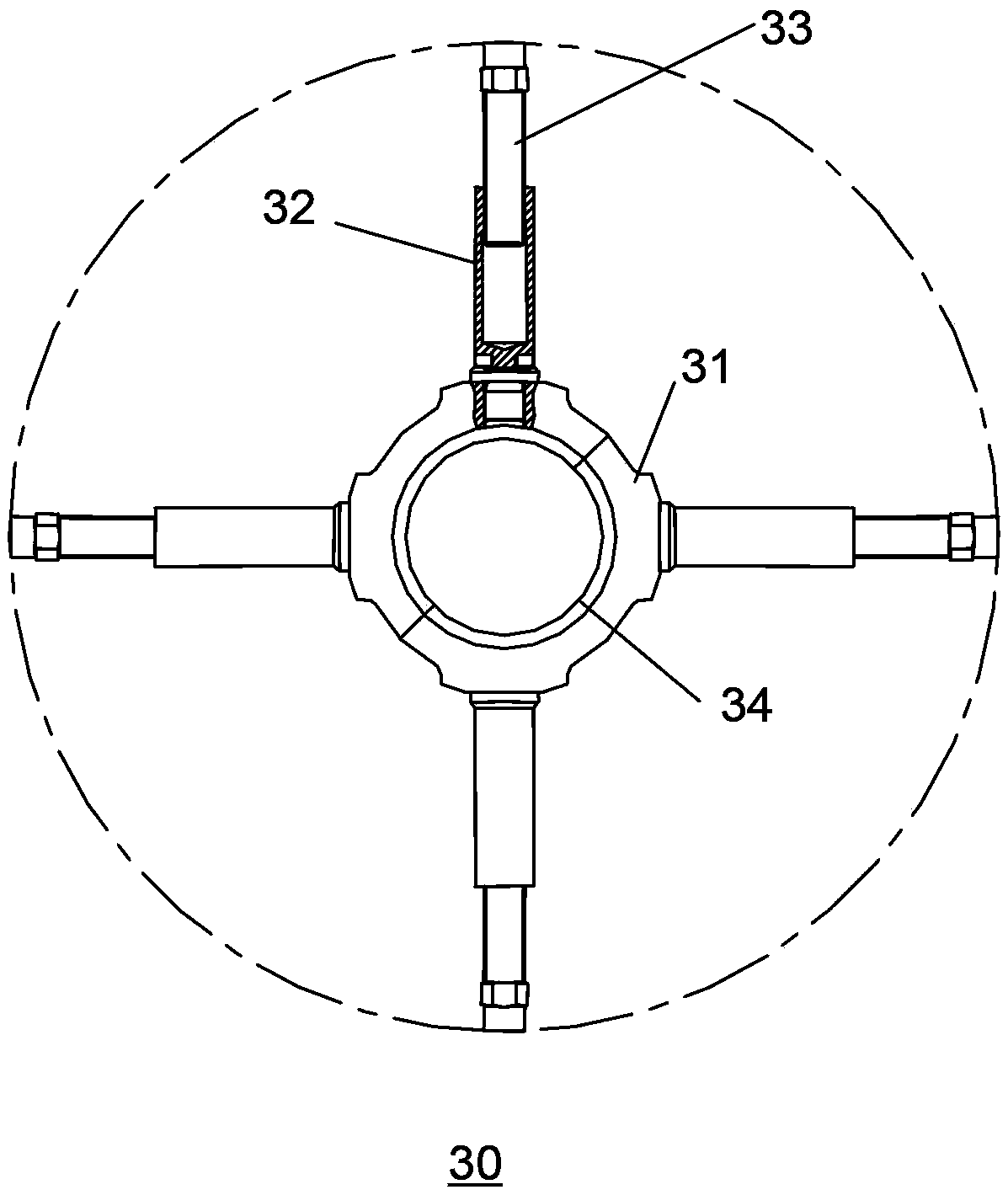

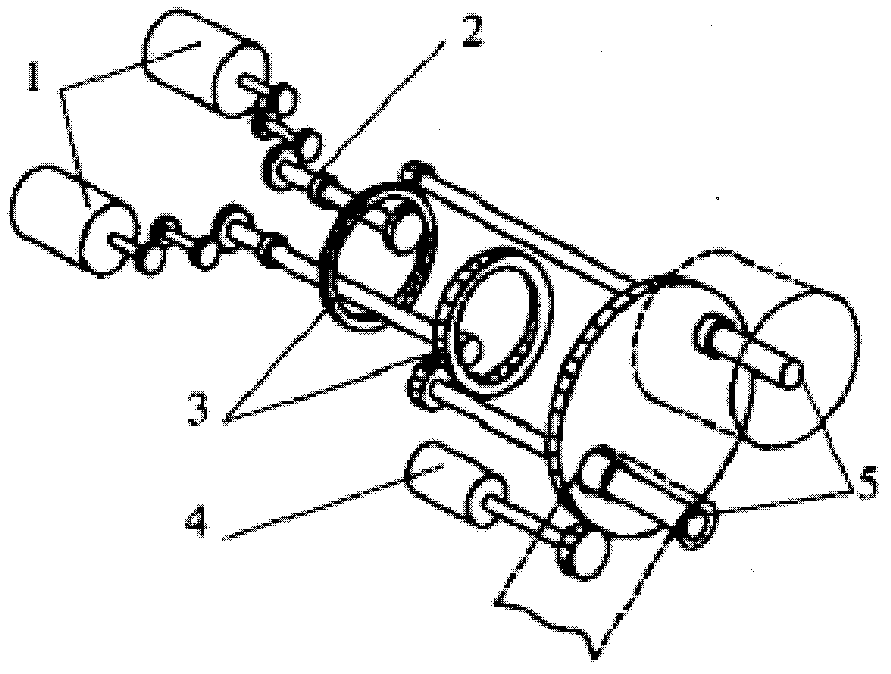

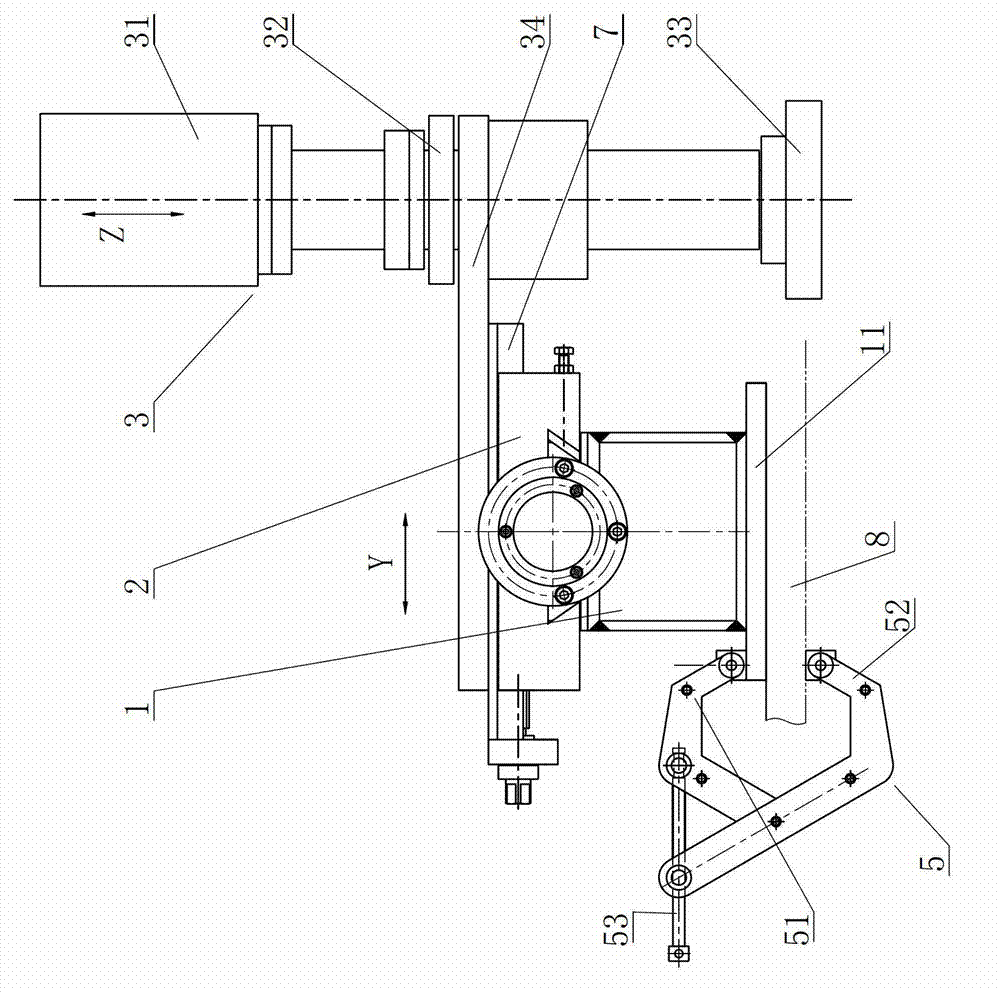

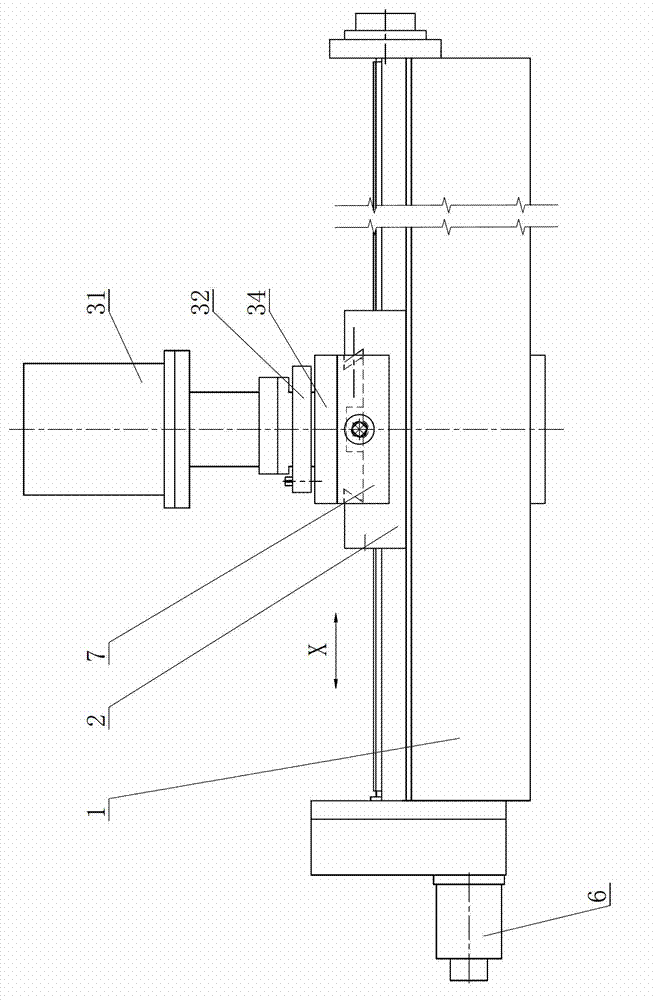

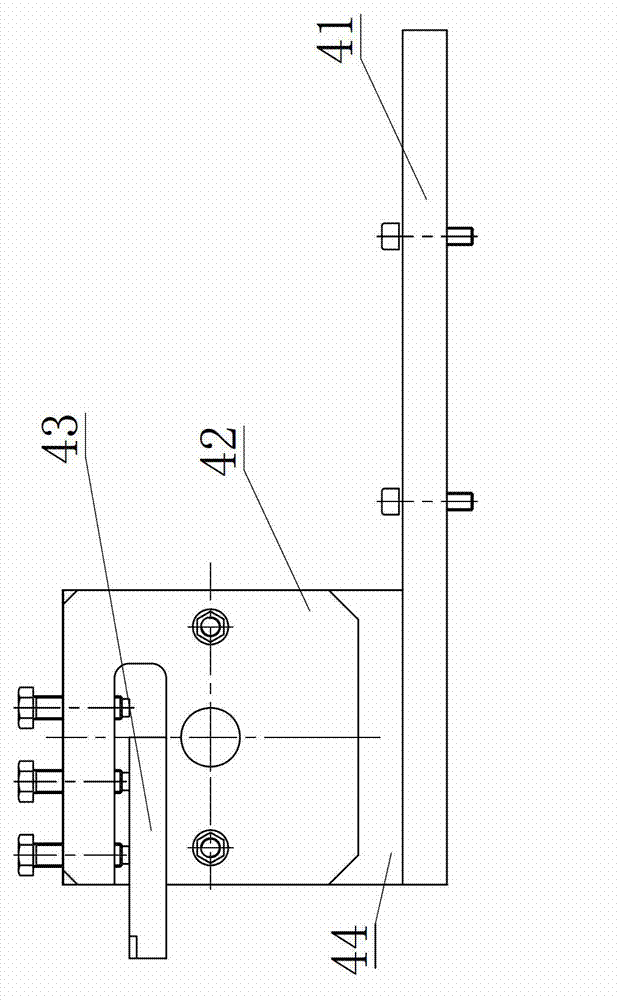

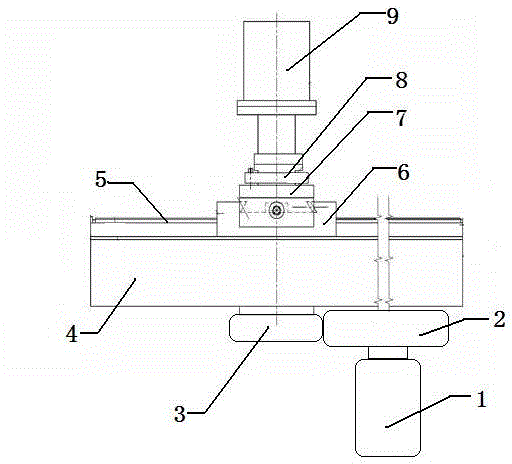

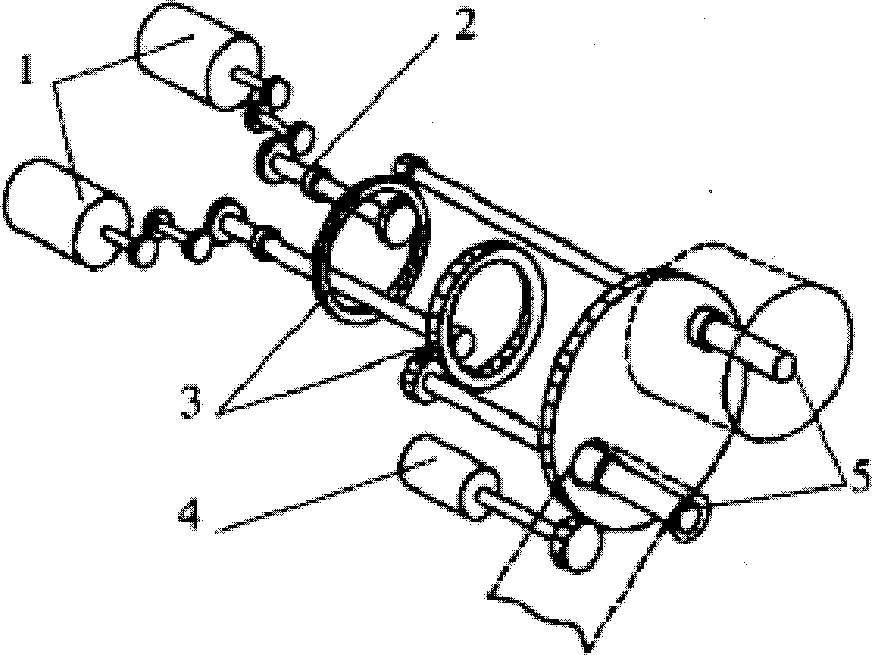

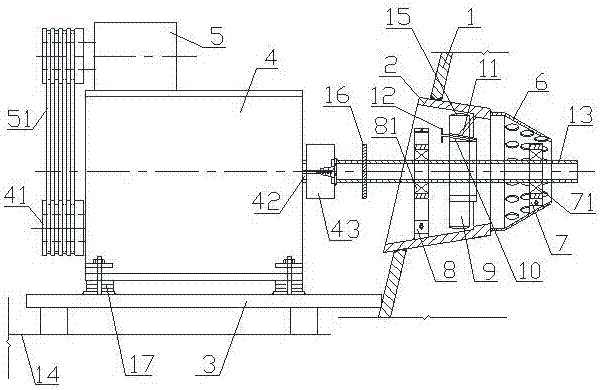

Device for online repairing of large reduction gearbox bearing hole abrasion and method thereof

ActiveCN103659146ARealize online repairHigh concentricity precisionMetal working apparatusPortable drilling machinesEngineeringStructural engineering

The invention discloses a device for online repairing of large reduction gearbox bearing hole abrasion and a method thereof. The device comprises a portable boring machine, a positioning device and a middle supporting device. By means of positioning of the positioning device, the middle supporting device and a reduction gearbox, the portable boring machine sequentially bores bearing holes in the two sides of the reduction gearbox, so that online repairing of the bearing holes is achieved, and size precision, geometric tolerance and roughness of the repaired bearing holes can fully meet the requirements of a drawing. Besides, the bearing holes in the two sides are bored through one cutter, coaxiality precision is high, and the device is convenient to use.

Owner:BAOSHAN IRON & STEEL CO LTD

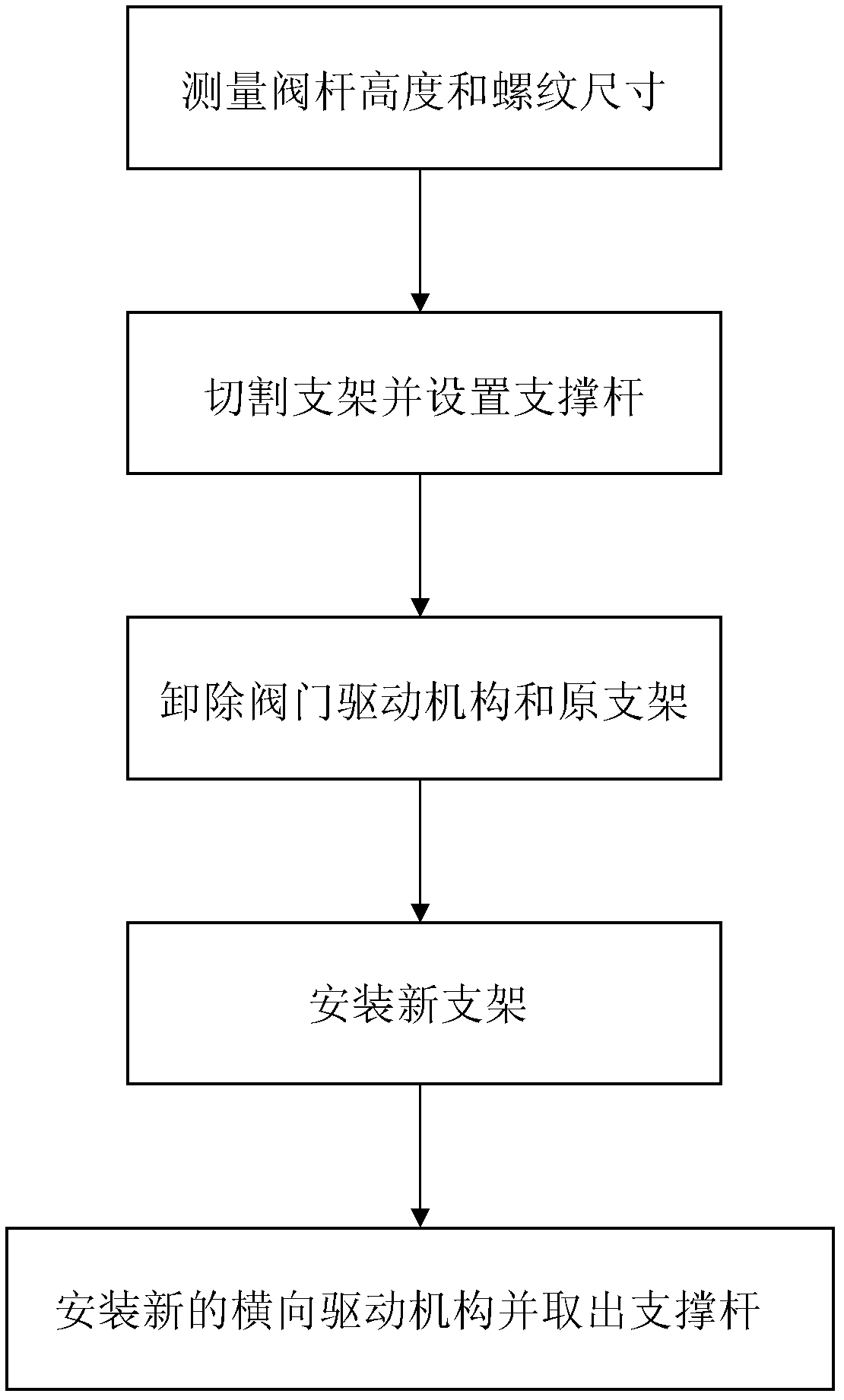

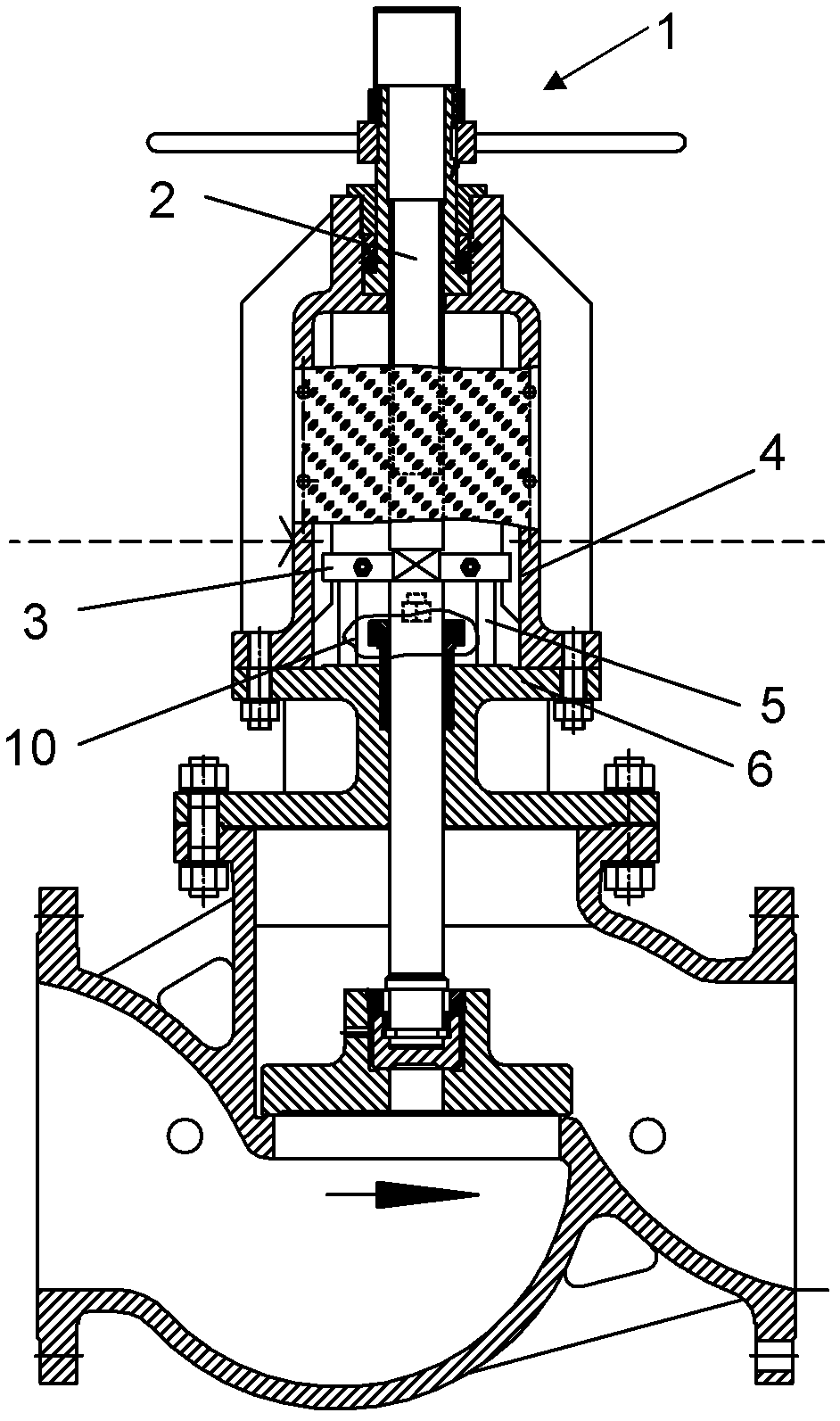

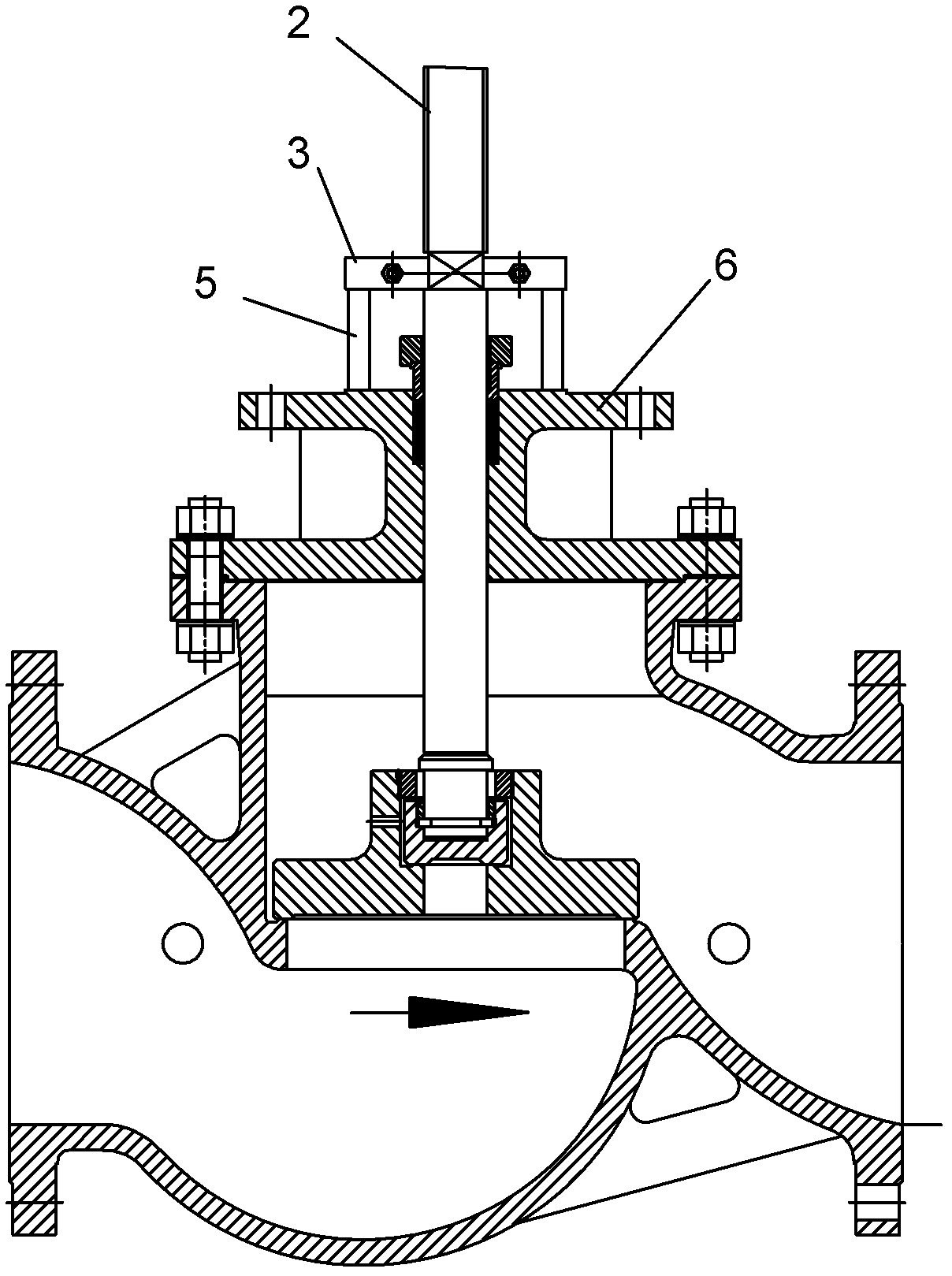

Oxygen valve online repairing method

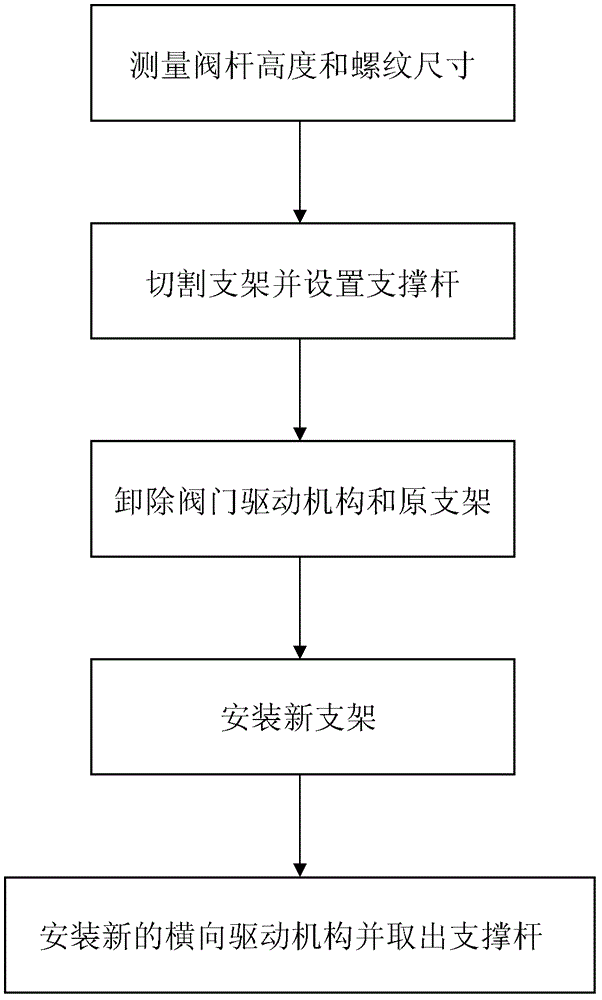

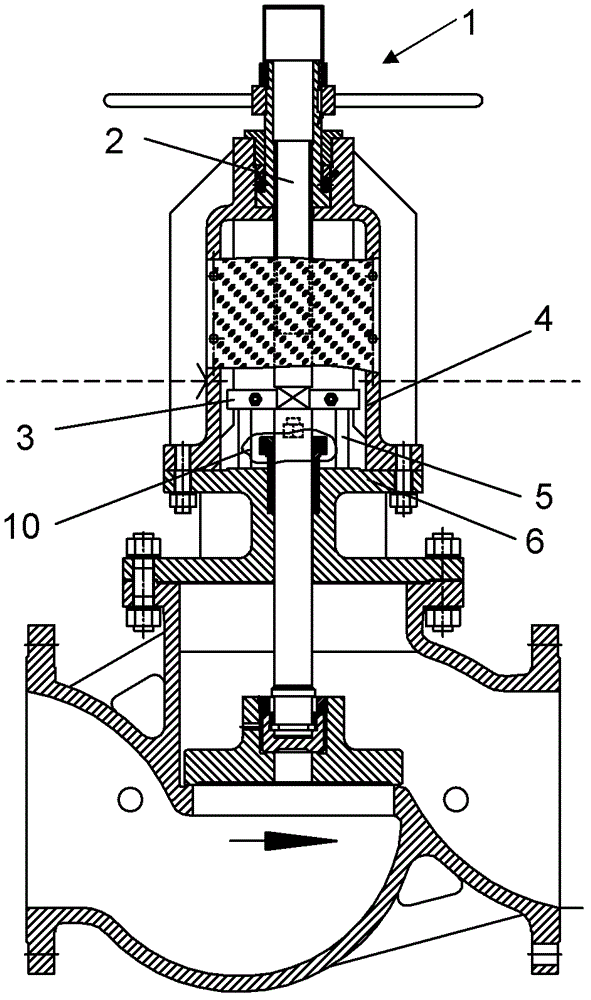

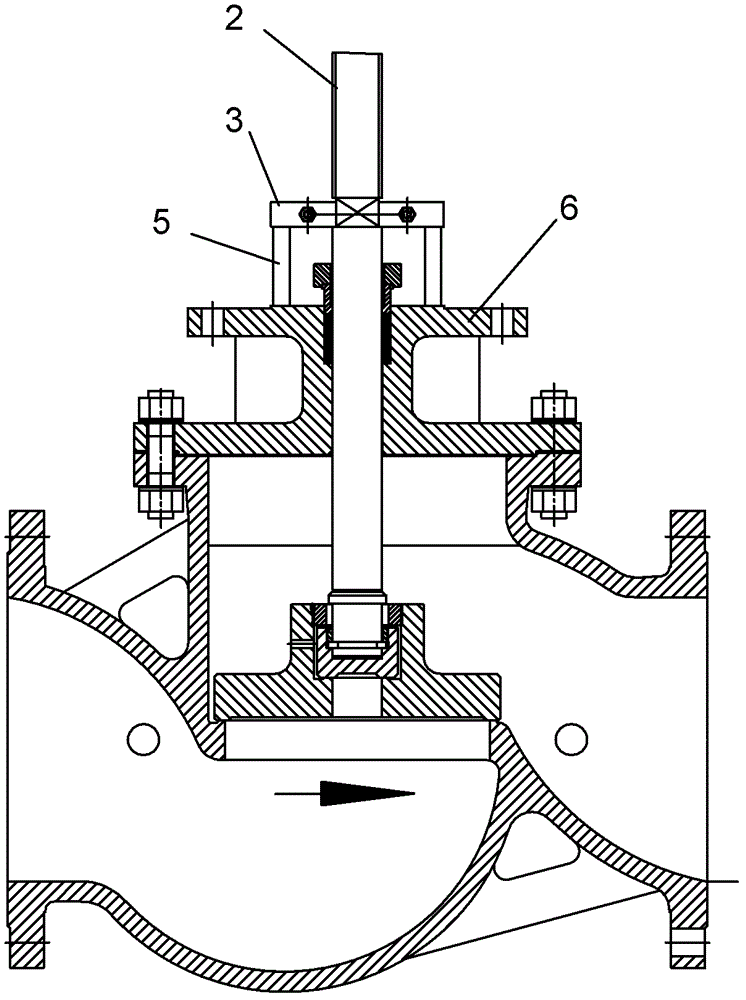

The invention discloses an oxygen valve online repairing method which comprises the following steps: measuring the height of the valve rod and the size of treads; cutting a bracket and arranging a supporting rod; discharging a disabled valve driving mechanism and the cut bracket; mounting a new bracket on a valve flange; mounting a new horizontal driving mechanism, taking out the supporting rod, and accomplishing steps such as debugging. By adopting the repairing method, online repairing is realized without shutting down a oxygen system and exchanging the whole valve, so that the repairing efficiency is improved, and the repairing cost is decreased.

Owner:BAOSHAN IRON & STEEL CO LTD

Management system for fixed asset information

InactiveCN106228297ADo automatic follow-upRealize online repairCo-operative working arrangementsResourcesManagement systemLibrary science

The invention discloses a management system for fixed asset information. The system is composed of a fixed asset management platform, a vacant code and a mobile client. The fixed asset management platform consists of a fixed asset editing platform module for editing fixed asset information, a fixed asset storage module for storing the fixed asset information, a vacant code generation module for generating a vacant code; and the vacant code being a two-dimensional code can be pasted on the fixed asset and can be scanned and then be stored into the fixed asset management storage module. The mobile terminal includes a vacant code scanning module for scanning the vacant code to realize information connection with the fixed asset storage module and a fixed asset editing mobile module for editing the fixed asset information stored by the fixed asset storage module. According to the management system, functions of fixed asset information management and timely repairing of the fixed assets can be realized.

Owner:余慧军

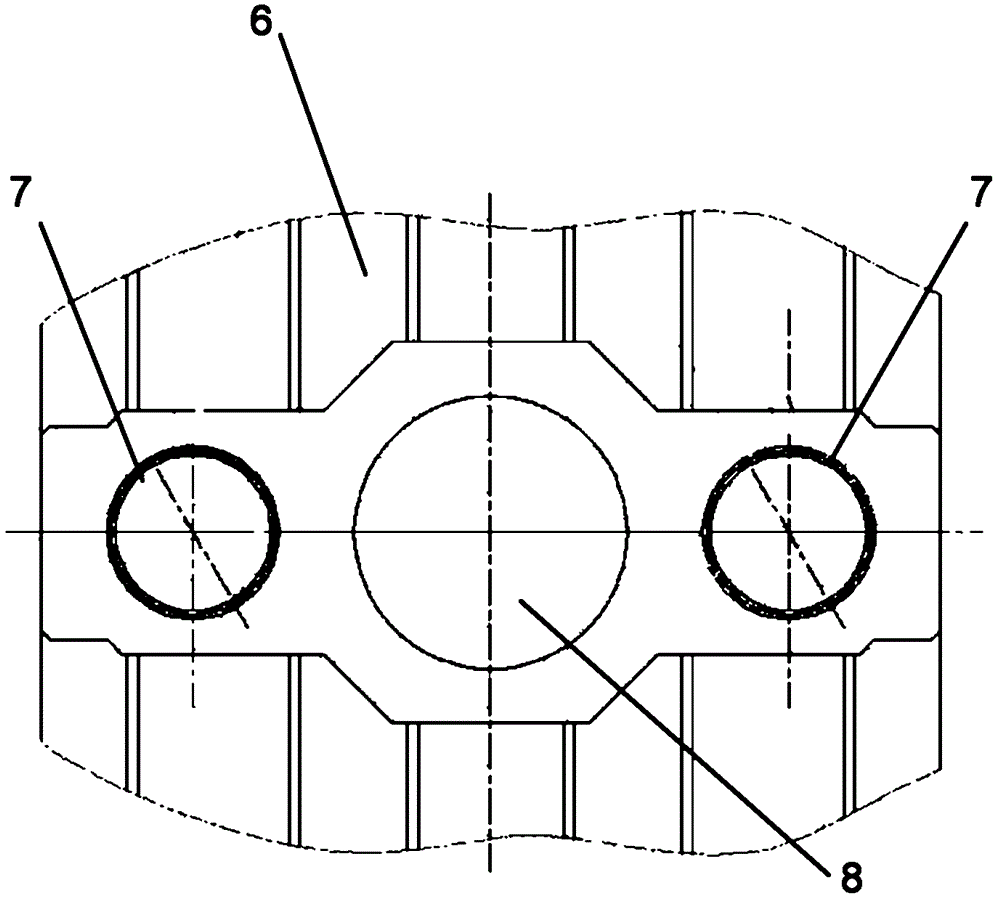

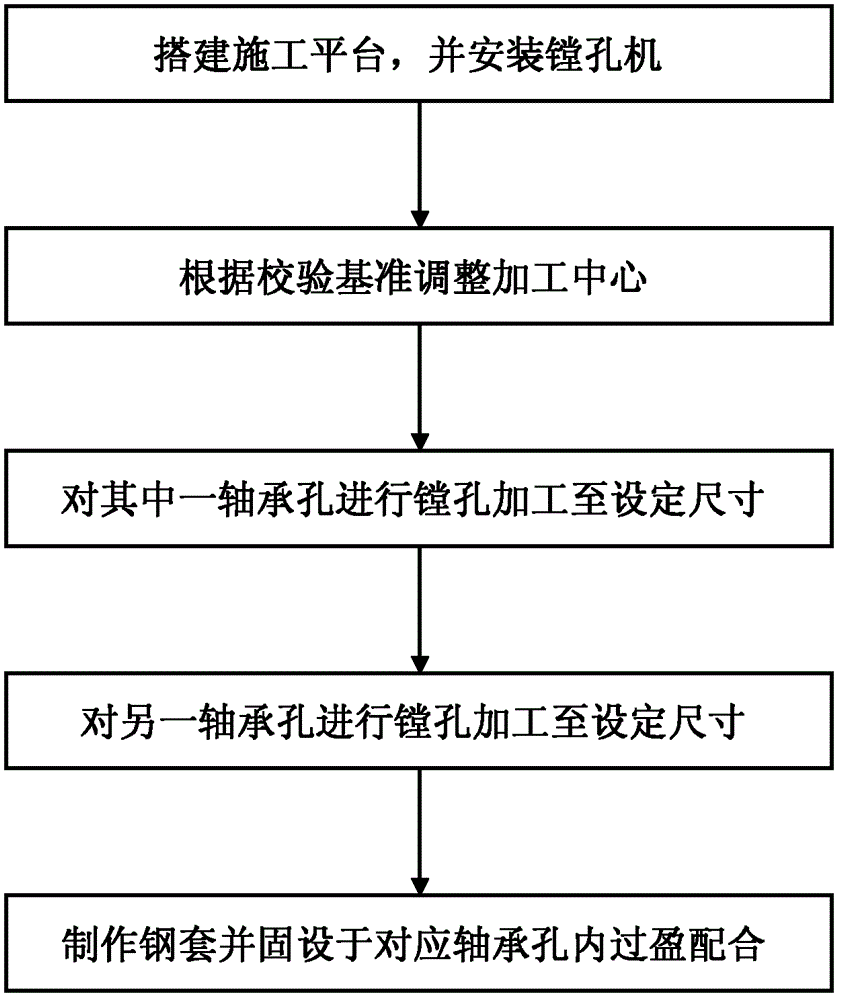

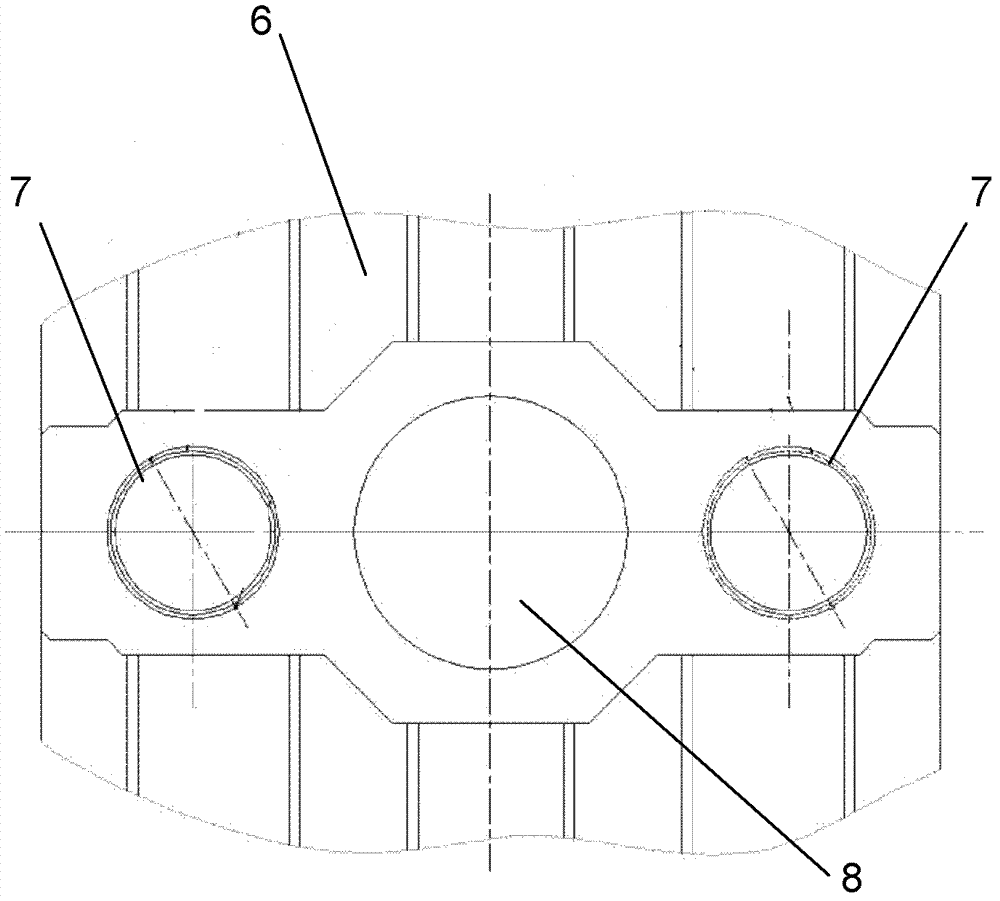

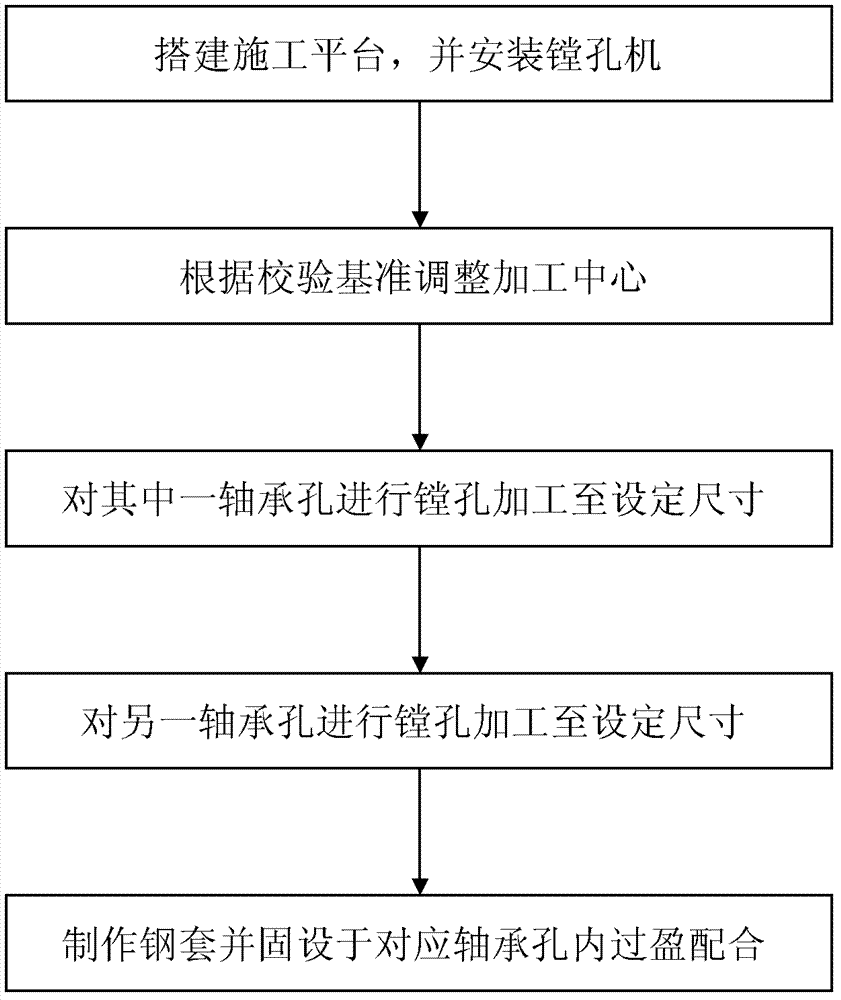

Recoiling machine reducer casing output shaft bearing hole abrasion repairing method

The invention discloses a recoiling machine reducer casing output shaft bearing hole abrasion repairing method. The repairing method includes that a hole drilling machine is installed on a tooling support through a building construction platform and the tooling support, twice hole drillings are respectively conducted on two bearing holes by adjusting a machining center, a steel jacket which is in an interference fit with the hole drilling is manufactured, and thereby according to the steel jacket which is in the interference fit with the hole drilling, on-line repairing of abrasion of a bearing hole is achieved and the existing accuracy of the bearing hole is guaranteed. After the steel jacket is again abraded, only the steel jacket needs to be replaced and maintenance is very convenient.

Owner:BAOSHAN IRON & STEEL CO LTD

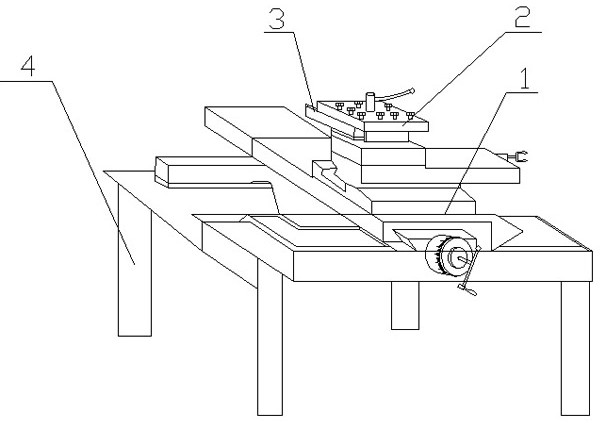

Large machinery equipment surface multifunction online processing and repairing device

InactiveCN103111849AImprove repair efficiencyRealize online repairFeeding apparatusOther manufacturing equipments/toolsHydraulic motorFeed drive

The invention relates to a large machinery equipment surface multifunction online processing and repairing device. The large machinery equipment surface multifunction online processing and repairing device comprises a lower sliding table and a cross sliding table which is connected with the lower sliding table in a sliding mode. One end of the lower sliding table is provided with a feed driving device. A base board is arranged at the bottom of the lower sliding table. The base board is connected with fixed base pieces of the large machinery equipment through a fast clamping device. The cross sliding table comprises a lower sliding board and an upper sliding board. The lower sliding board and the upper sliding board are connected in a mutual sliding mode. The lower sliding board and the lower sliding table are connected in a sliding mode. The sliding direction of the upper sliding board is vertical to the sliding direction of the lower sliding board. The upper sliding board is provided with a milling cutter assembly through a milling cutter assembly mounting plate or is provided with a turning cutter assembly through a turning tool assembly mounting plate. The feed driving device or a cutting power device is a hydraulic motor or a servo motor. The large machinery equipment surface multifunction online processing and repairing device has the advantages that through the large machinery equipment surface multifunction online processing and repairing device fixed on the repaired large machinery equipment, a turning cutter or a milling cutter is utilized to repair broken surfaces, and critical components of the large machinery equipments are not needed to be removed, and therefore, online repair to the large machinery equipment is achieved and repair efficiency is improved.

Owner:SINOMA TECH & EQUIP GRP

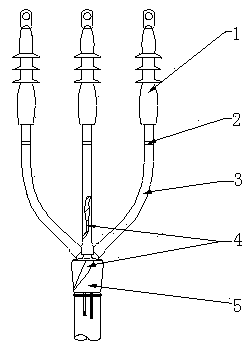

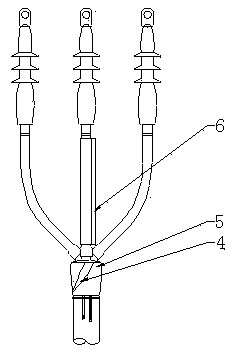

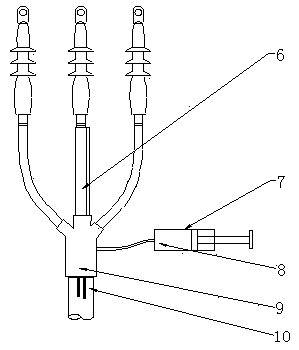

Cable accessory branching fingerstall restoration method

ActiveCN105375409ARealize online repairReduce maintenance costsApparatus for repairing insulation/armouring cablesInjection portRestoration method

The invention discloses a cable accessory branching fingerstall restoration method, and the method comprises three steps: prefabricating an injection mold and a buckle-type insulating tube, which are corresponding in shape and size; enabling a broken protection sleeve to be sleeved by the insulating tube, and placing room temperature vulcanized rubber in a slot and a joint; enabling a broken cable accessory branching fingerstall to be wrapped by the prefabricated injection mold, injecting the room temperature vulcanized rubber, and dismounting the mold after solidification. The injection mold is also provided with a mold housing, a sealing weir, and a glue injection port. The cross section structure of the buckle-type insulating tube is shaped like any one of omega, C and G. The material of the room temperature vulcanized rubber is preferably consistent with the base material of the buckle-type insulating tube and the base material of the cable accessory branching fingerstall. The method does not need to cut off the power for overall replacement, is low in overall cost, enables a maintenance mode to be changed into industrialization, standardization and modularization, is simple in operation, saves time and labor, is high in speed, guarantees that the insulating level and the service life are not reduced, and enables the reliability to meet the quality requirements of six sigma.

Owner:SHENZHEN WOER HEAT SHRINKABLE MATERIAL +1

Pumping-unit wellhead sealing filler with polished rod repairing capability

The invention relates to a pumping-unit wellhead sealing filler with polished rod repairing capability. The invention mainly solves the problem that the sealing effect of packing filler is seriously influenced due to excessive filler abrasion caused by uneven surface of an existing polished rod. The pumping-unit wellhead sealing filler with polished rod repairing capability comprises the followingcomponents in percentage by mass: 25-50% of rubber particles, 15-20% of epoxy resin, 5-20% of crude wax, 5-10% of super absorbent polymer (SAP) resin, 5-15% of vinyl chloride copolymer resin, 15-25%of a plasticizer, 3-5% of a dehumidifier, 1-2% of a foaming agent, 0.2-1.0% of a curing agent, 5%-15% of talcum powder, 5%-10% of molybdenum disulfide lithium-based lubricating grease and 3%-5% of base oil. According to the pumping-unit wellhead sealing filler with polished rod repairing capability, grooves of surface defects of the polished rod are basically filled, leveled and hardened, and a hot repairing effect is achieved, so that excessive filler abrasion caused by uneven surface of the polished rod is reduced, and the service life of the packing filler is prolonged.

Owner:PETROCHINA CO LTD +1

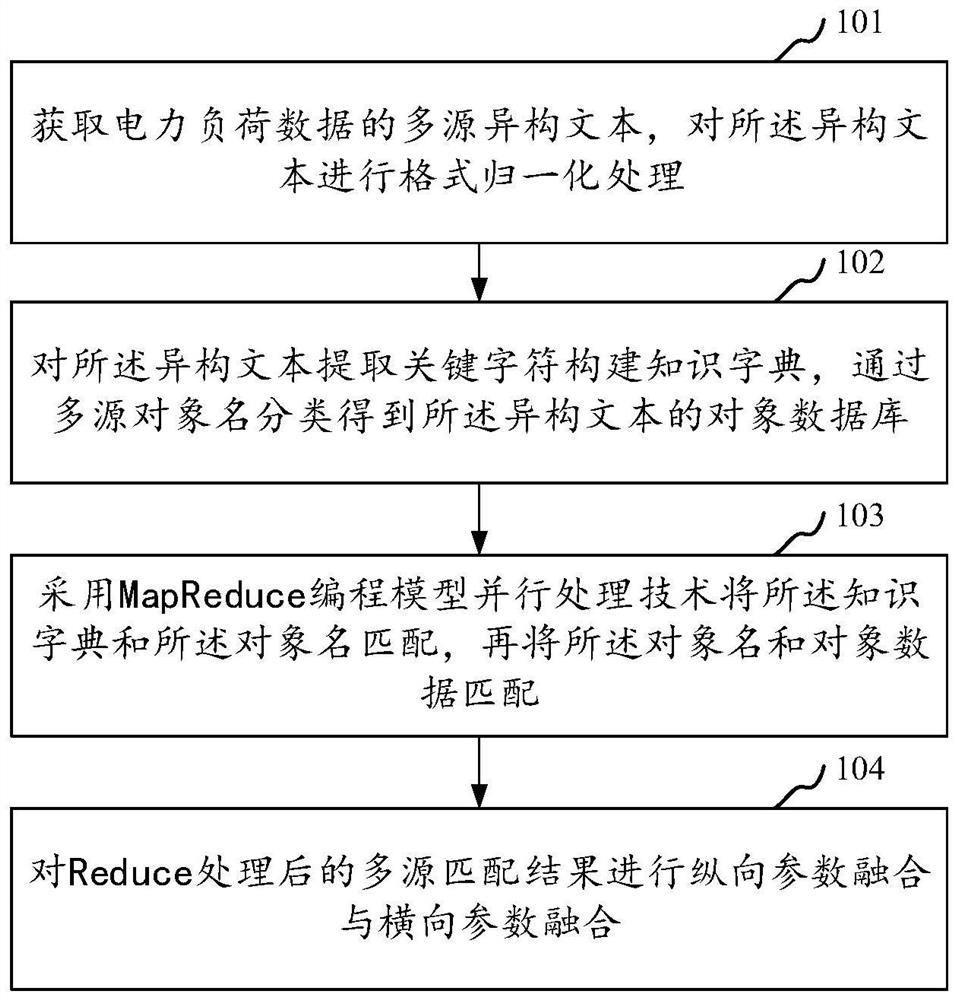

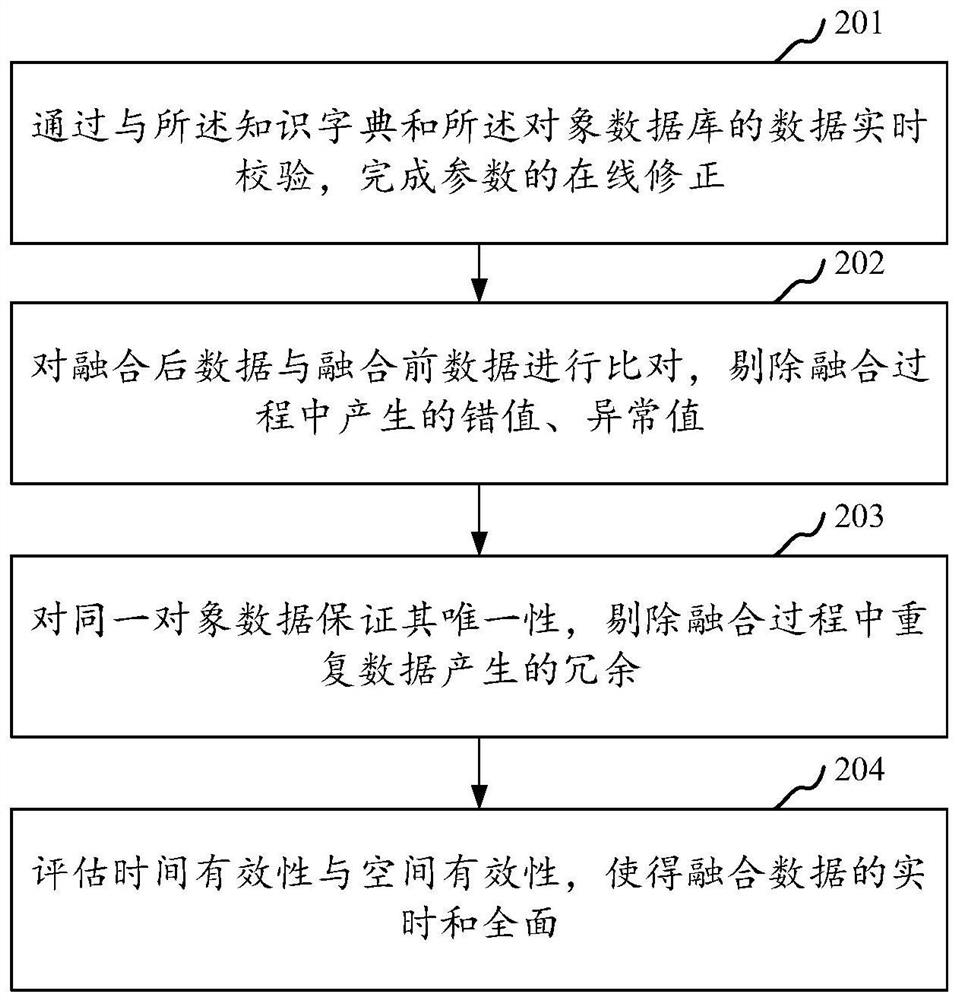

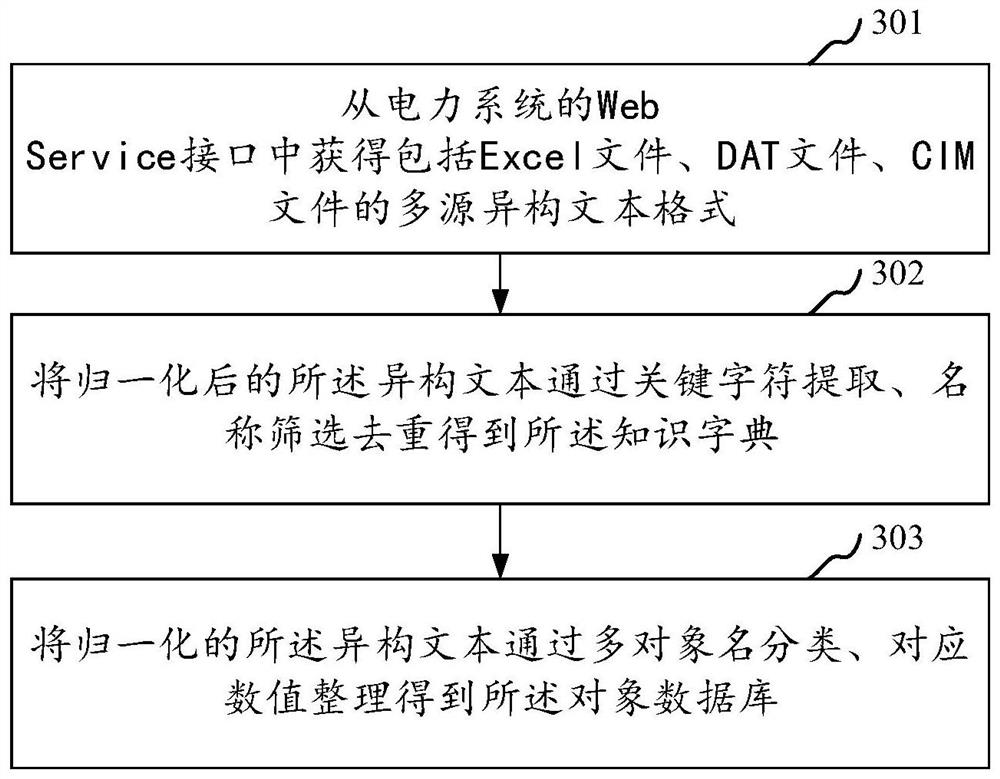

Multi-source heterogeneous power load data fusion method and device, equipment and storage medium

PendingCN113407723AImprove efficiencyPracticalResourcesSpecial data processing applicationsData matchingParallel processing

The invention relates to a multi-source heterogeneous power load data fusion method and device, equipment and a storage medium. The method comprises the steps of obtaining a multi-source heterogeneous text of power load data, and performing format normalization processing on the heterogeneous text; extracting key characters from the heterogeneous text to construct a knowledge dictionary, and obtaining an object database of the heterogeneous text through multi-source object name classification; matching the knowledge dictionary with the object name by adopting a MapReduce programming model parallel processing technology, and then matching the object name with the object data; and carrying out longitudinal parameter fusion and transverse parameter fusion on the multi-source matching result after Reduce processing. Through multi-level processing of multi-source heterogeneous power grid load big data, a whole set of electric power big data fusion strategy and evaluation from fusion to evaluation are provided, and data fusion is high in practicability and efficiency.

Owner:HUNAN WULING POWER TECH CO LTD +1

Surface treatment milling machine tool

InactiveCN105710421ARealize online repairAvoid bulkyMilling equipment detailsElectric machineryDrive motor

The invention provides a surface treatment milling machine tool. The surface treatment milling machine tool is characterized by comprising a driving motor, a first gear, a second gear, a sliding base, a slideway, a slide block, a milling cutter mounting joint, a knife rest and a milling power system, wherein the sliding base is connected with the slide block located at an upper side in a sliding connection manner, the other end of the sliding base is connected with a feed driving motor, the power-output shaft of the driving motor is connected with the first gear, the first gear is connected with the second gear in an externally-tangent mesh transmission manner, a transmission shaft of the second gear passes through the sliding base and is in fixed connection with the slide block, the milling cutter mounting joint is mounted above the slide block, and the knife rest and the milling power system are installed through the milling cutter mounting joint. The surface treatment milling machine tool has the advantages that surface repair of large mechanical equipment is realized without dismounting of key parts of the large mechanical equipment, so on-line repair of the large mechanical equipment is realized and repair efficiency is improved; the feed driving motor and a cutting power unit employ a hydraulic motor or servo motor, so the problem of heavy weight of a reduction box due to usage of a multi-stage reduction box for speed regulation in the prior art is avoided; and the size of the surface treatment milling machine tool is reduced and flexibility in usage is improved.

Owner:董博良

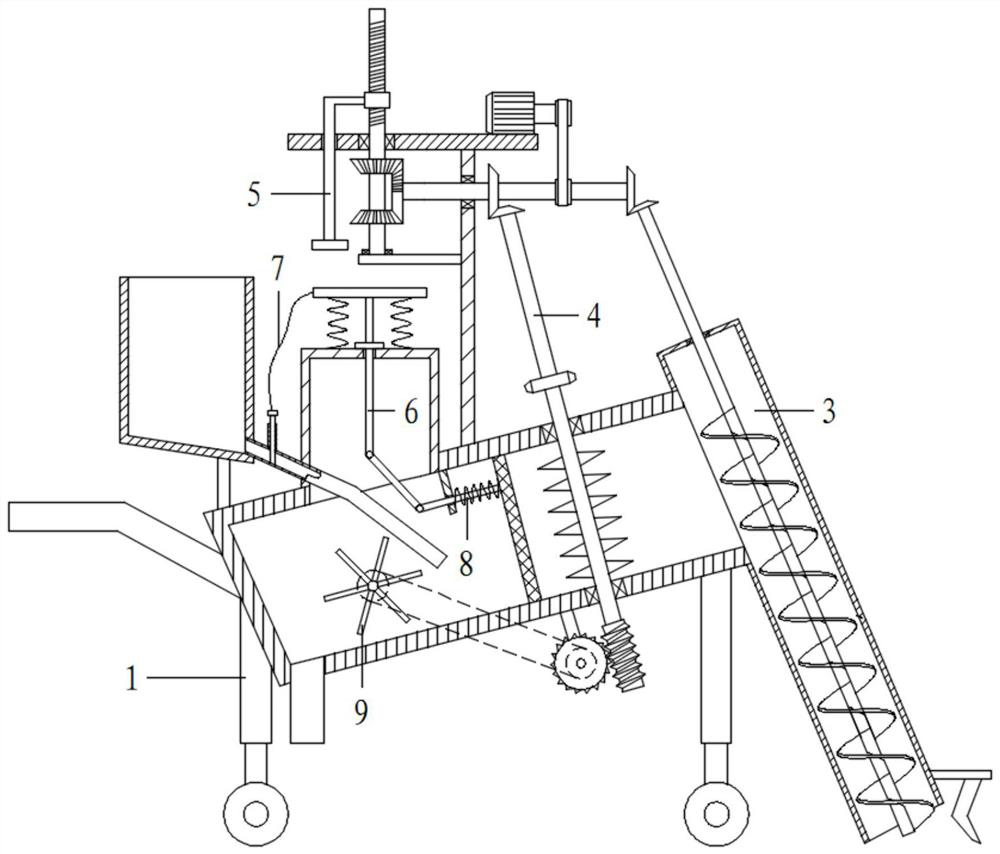

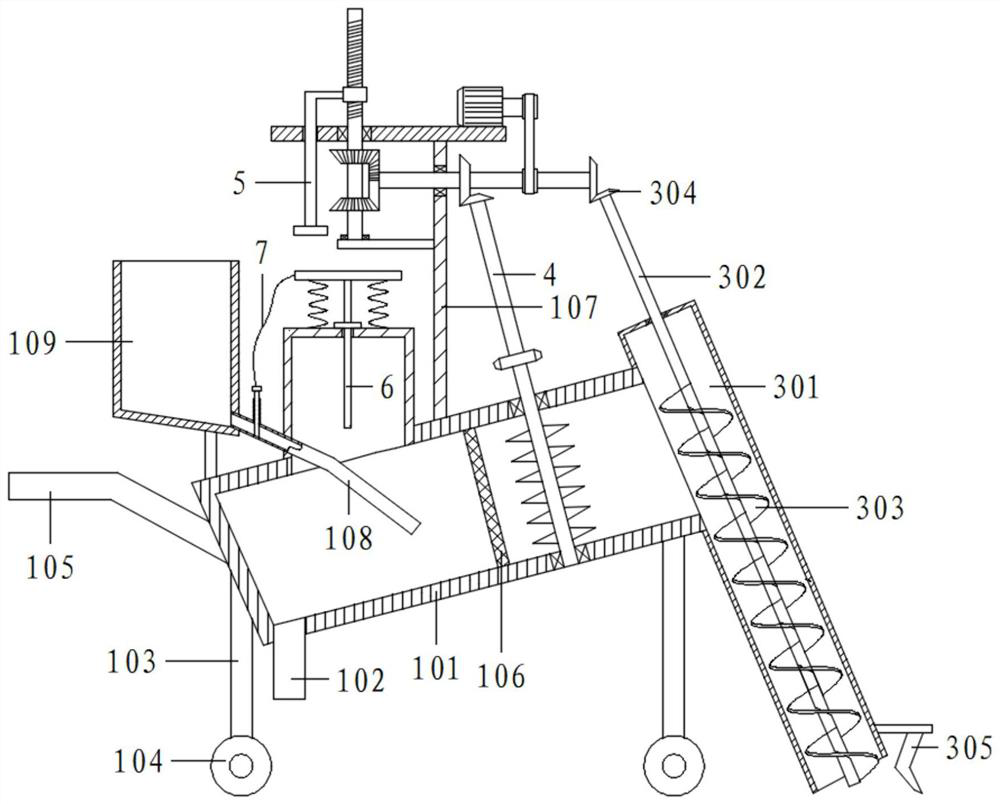

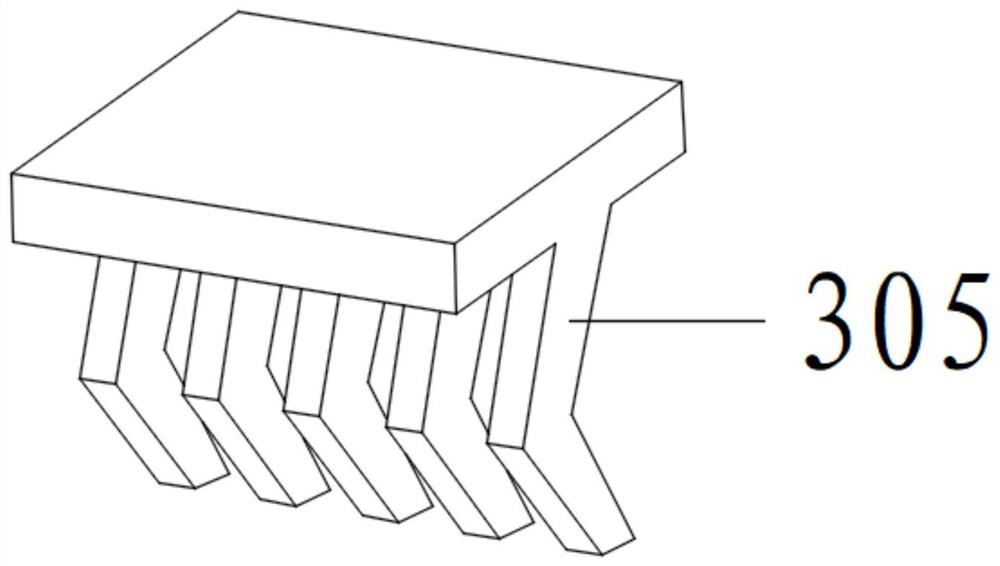

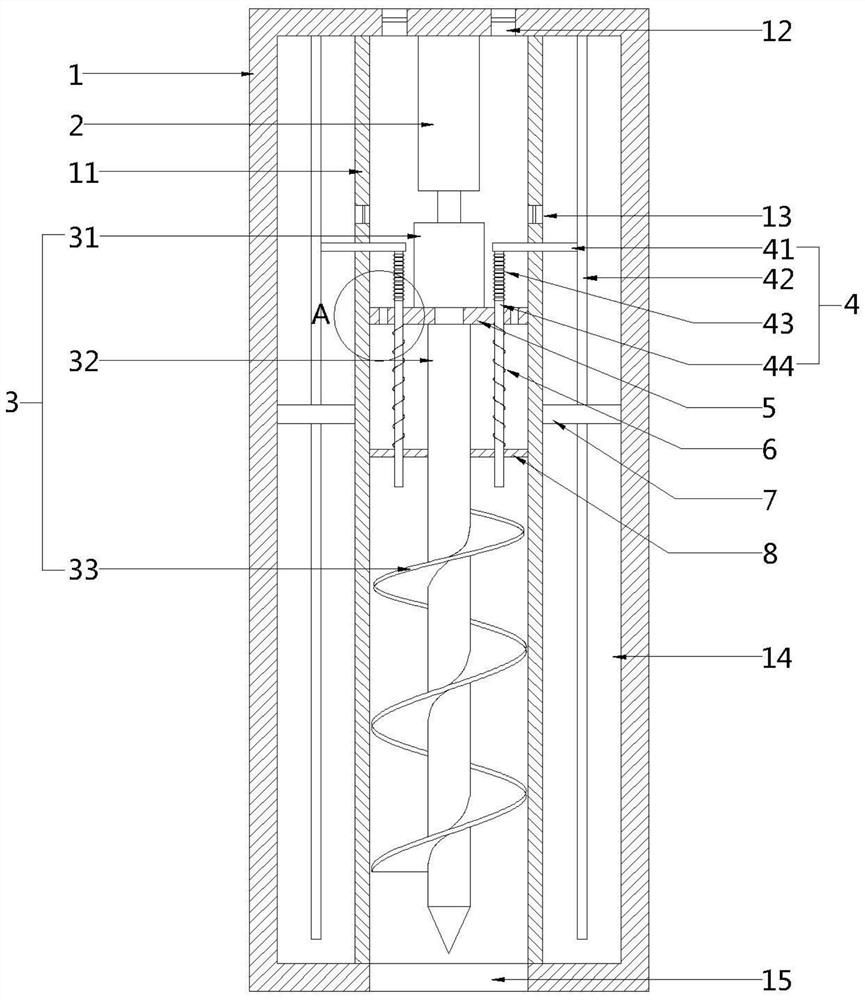

Hardened soil treatment and remediation system for greening

InactiveCN112567911ARealize automatic feedingEasy to moveSoil lifting machinesSpadesSoil scienceSoil treatment

The invention relates to the technical field of hardened soil treatment and remediation, and relates to a hardened soil treatment and remediation system for greening, in particular to a hardened soiltreatment and remediation vehicle for farmland planting. The system adopts a vehicle body design, and is convenient to move in a farmland; based on a transmission design, a soil turning device turns up hardened soil when the system advances, the turned-up soil is sucked into a soil inlet pipe and conveyed to the upper portion under the action of a spiral packing auger, then the turned-up soil is discharged into a main body barrel, and automatic feeding of the hardened soil is achieved; and the soil is crushed, plant ash is intermittently added into the crushed soil, and then the crushed soil is discharged back to the farmland through a soil discharge pipe, so that the online remediation of the hardened soil of the farmland is realized.

Owner:安徽亿擎网络科技有限公司

Repairing method for wear and tear of the bearing hole of the output shaft of the reduction box of the coiler

The invention discloses a recoiling machine reducer casing output shaft bearing hole abrasion repairing method. The repairing method includes that a hole drilling machine is installed on a tooling support through a building construction platform and the tooling support, twice hole drillings are respectively conducted on two bearing holes by adjusting a machining center, a steel jacket which is in an interference fit with the hole drilling is manufactured, and thereby according to the steel jacket which is in the interference fit with the hole drilling, on-line repairing of abrasion of a bearing hole is achieved and the existing accuracy of the bearing hole is guaranteed. After the steel jacket is again abraded, only the steel jacket needs to be replaced and maintenance is very convenient.

Owner:BAOSHAN IRON & STEEL CO LTD

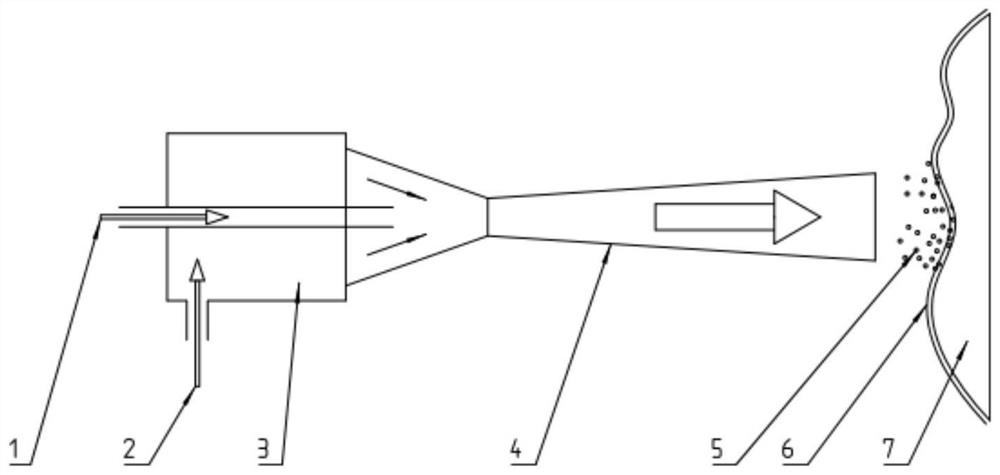

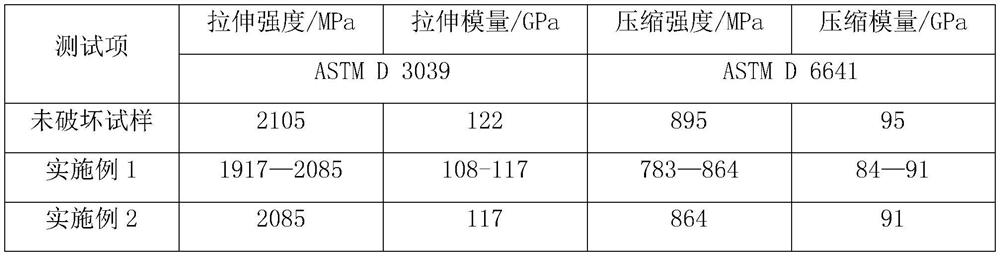

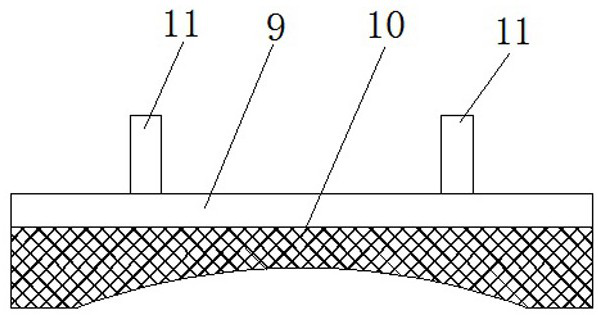

An Online Repair Process of Thermoplastic Composite Materials

The invention discloses an online repairing process for thermoplastic composite materials, which comprises the following steps: (1) performing surface treatment on the area to be repaired, and laying reinforcing fabrics on the area to be repaired after the treatment; (2) heating and pressing the resin powder, Then, under the action of high-pressure gas, the resin powder is sprayed onto the surface of the reinforced fabric. The resin powder particles impact the surface of the reinforced fabric, break up the fiber bundles and disperse into the fibers of the reinforced fabric, and at the same time, part of the resin powder passes through the reinforced fabric and impacts. To the area to be repaired, and enter the interior of the area to be repaired; (3) Stop spraying and then cool and solidify, so that some fibers and resin powder in the reinforcing fabric mesh with the resin matrix in the area to be repaired, and the online repair is completed after curing. The invention not only realizes the online repair of the thermoplastic composite material, but also improves the overall mechanical properties of the area to be repaired, and effectively prolongs the service life of the thermoplastic composite material.

Owner:SICHUAN UNIV

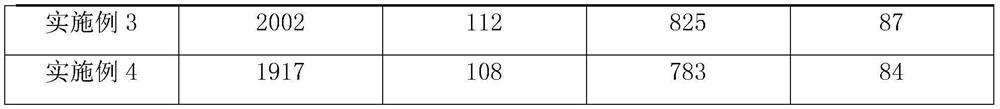

Maintenance and repair system for heating and ventilation

PendingCN106855956ARealize online repairRealize the whole process monitoring of serviceData processing applicationsBusiness processFull service

The invention provides a maintenance and repair system for heating and ventilation, which comprises a repair-side device, a maintenance-side device and a management center, wherein the repair-side device is held by a user and is in communication connection with the management center for carrying out repair and feedback on a heating and ventilation device; the maintenance-side device is held by a maintenance person and is in communication connection with the management center for managing and monitoring the maintenance person; the management center is composed of a server, and the server comprises a user information database, a maintenance information database and a communication module; the user information database is used for storing the information of the maintenance user; the maintenance information database is used for storing the information of the maintenance person and a maintenance process; and the communication module is used for receiving the repair information and the feedback information of the repair-side device and sending an instruction or information to the maintenance-side device. thus, online repair, remote order dispatching, and full service process monitoring can be realized, and the maintenance and repair service process is analyzed and optimized through a big data technology.

Owner:四川我爱舒适家优保信息技术有限公司

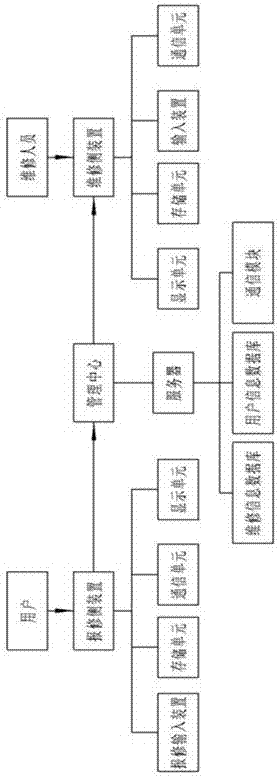

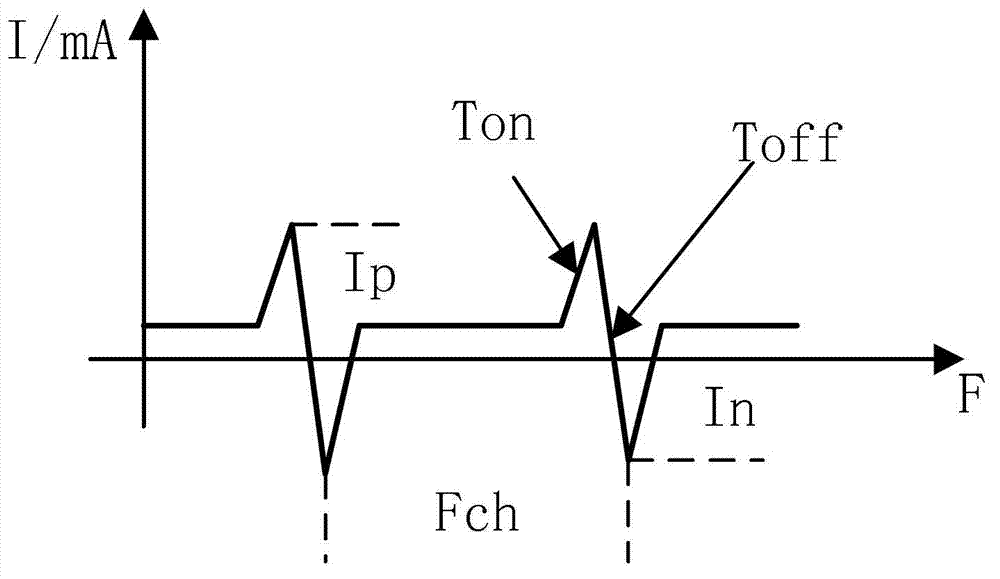

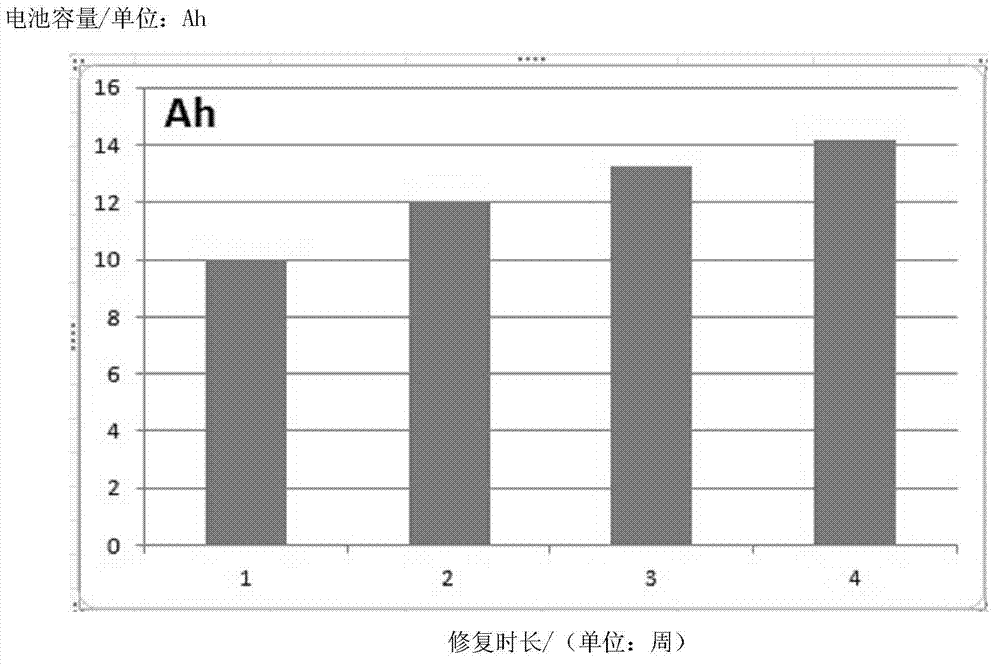

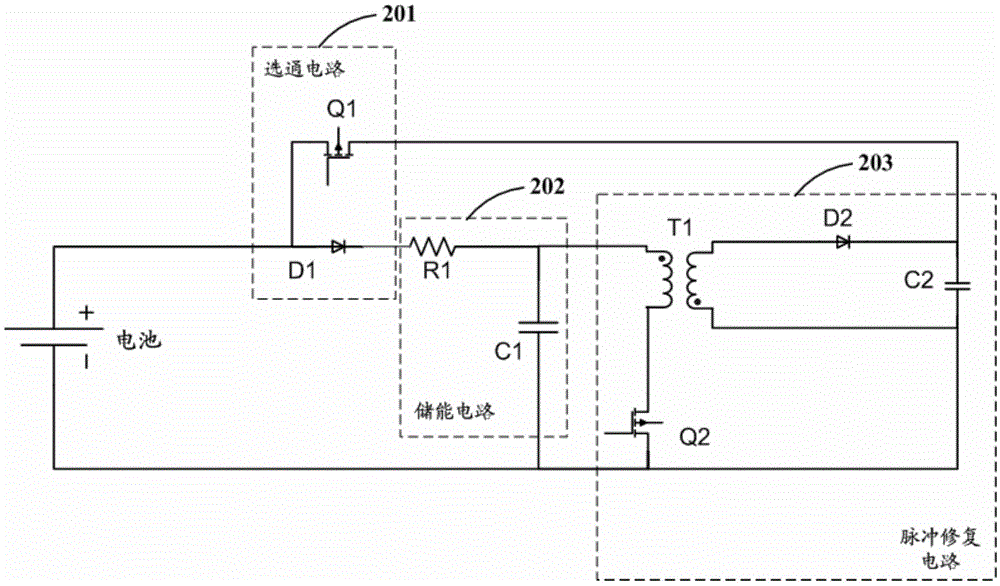

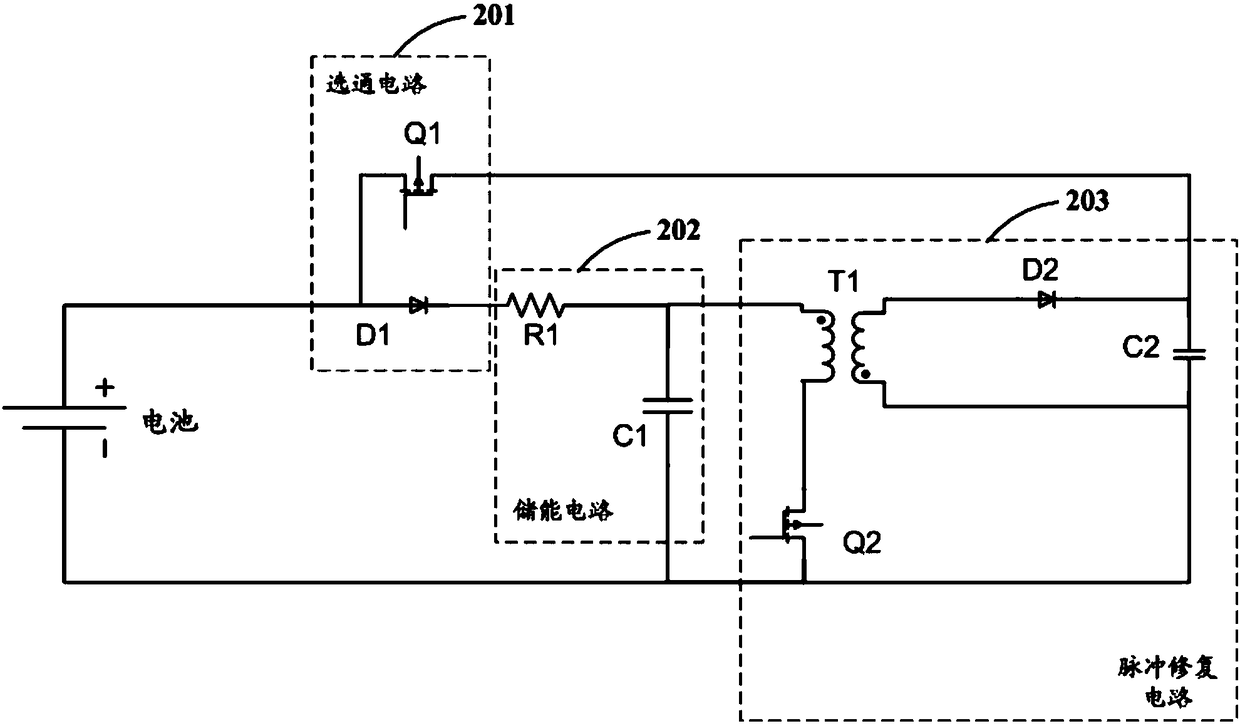

Device for on-line repair of storage battery

InactiveCN102903978ARealize online repairReduce energy lossBatteries circuit arrangementsElectric powerElectrical batteryLow voltage

The invention discloses a device for on-line repair of a storage battery. The device disclosed herein is characterized in that: according to a voltage signal provided by a detected external battery, the device controls a bipolar exciting current unit to output an adjustable bipolar exciting current, carries out on-line repair on the battery while uses the released partial electric energy to charge the battery, thus the energy loss of the battery is reduced, and the repair effect is obviously raised; in addition, the device has a low voltage threshold detection function, can effectively prevent the battery form overdischarge, thus the battery is protected. According to the invention, the repair process of the battery is simple, the repair conditions have strong applicability, the repair efficiency is high, on-line repair of the battery can be realized under any conditions, and the service life of the battery can be prolonged by 30-40%.

Owner:マイウェイ技研

Gas shielded welding wire for core bar local repair and welding technology

ActiveCN109277724AMeet the use requirementsImprove bindingArc welding apparatusWelding/cutting media/materialsImpurityMaterials science

The invention relates to a gas shielded welding wire for core bar local repair for an H13 seamless steel pipe. The gas shielded welding wire is prepared from, by mass, 0.04%-0.09% of C, 0.2%-0.5% of Si, 1.0%-1.8% of Mn, 1.5%-3.0% of Ni, 0.7%-1.90% of Mo, 0.0030%-0.0150% of S, 0.018% or less of P, 0.89%-1.0% of V, 1.0%-6.0% of Cr, 0.04%-0.2% of Cu, 0.055%-0.2% of Nb, 0.02%-0.04% of Als and the balance iron and inevitable impurities. The gas shielded welding wire has excellent welding manufacturability, is applicable to repair welding of a damaged core bar, and can prolong the service life of the repaired core bar.

Owner:ANGANG STEEL CO LTD

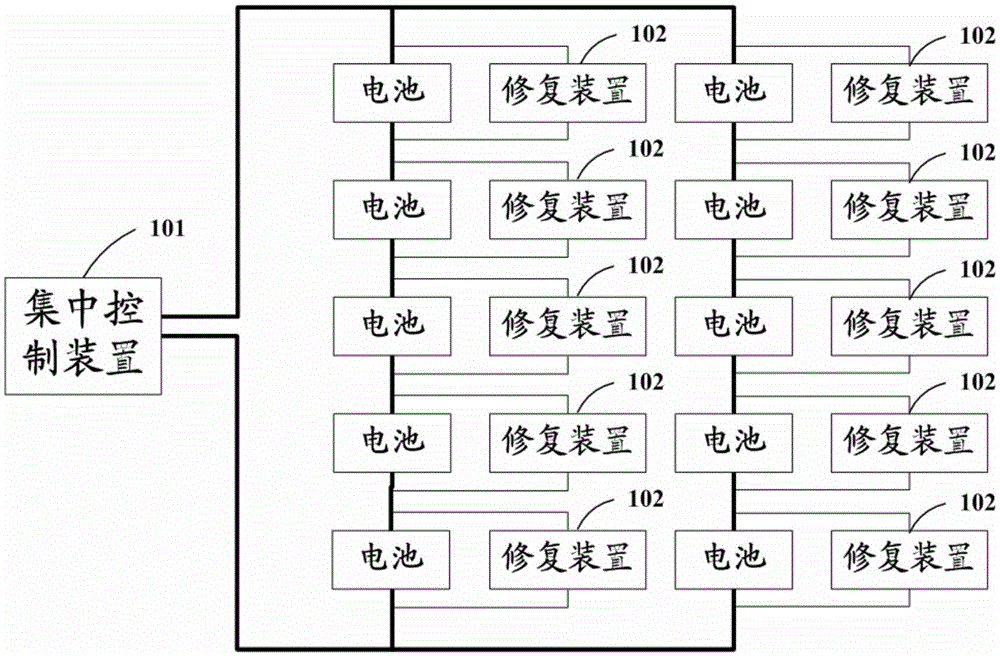

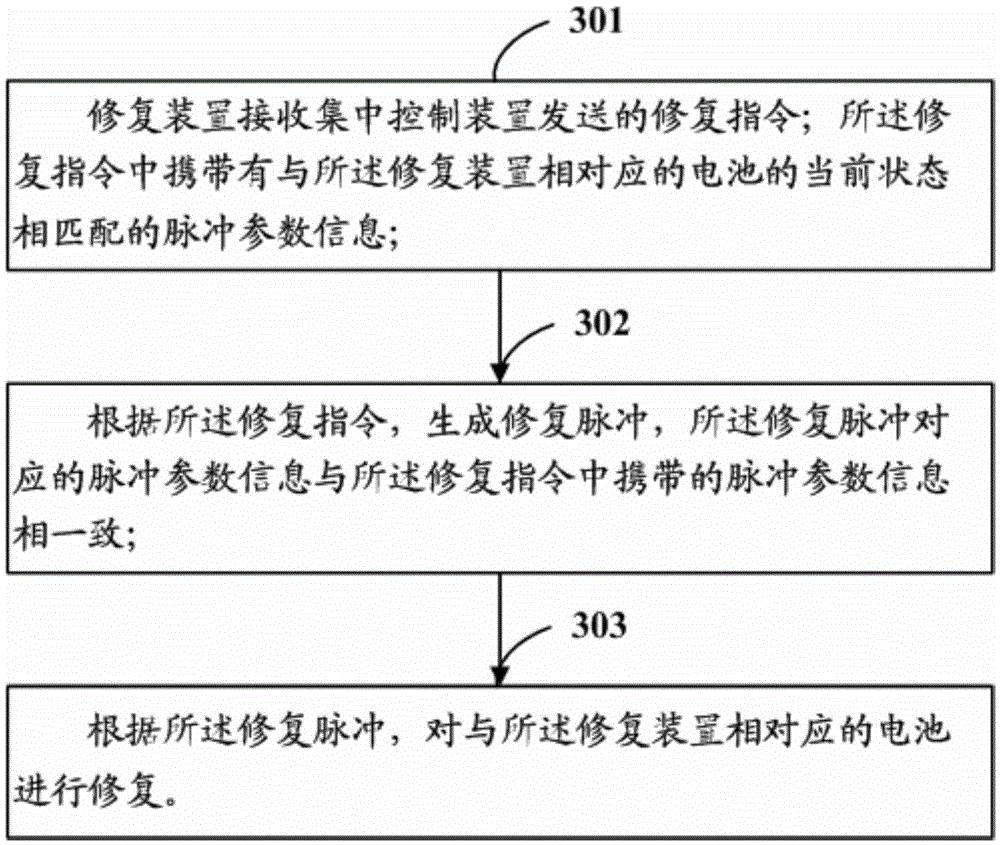

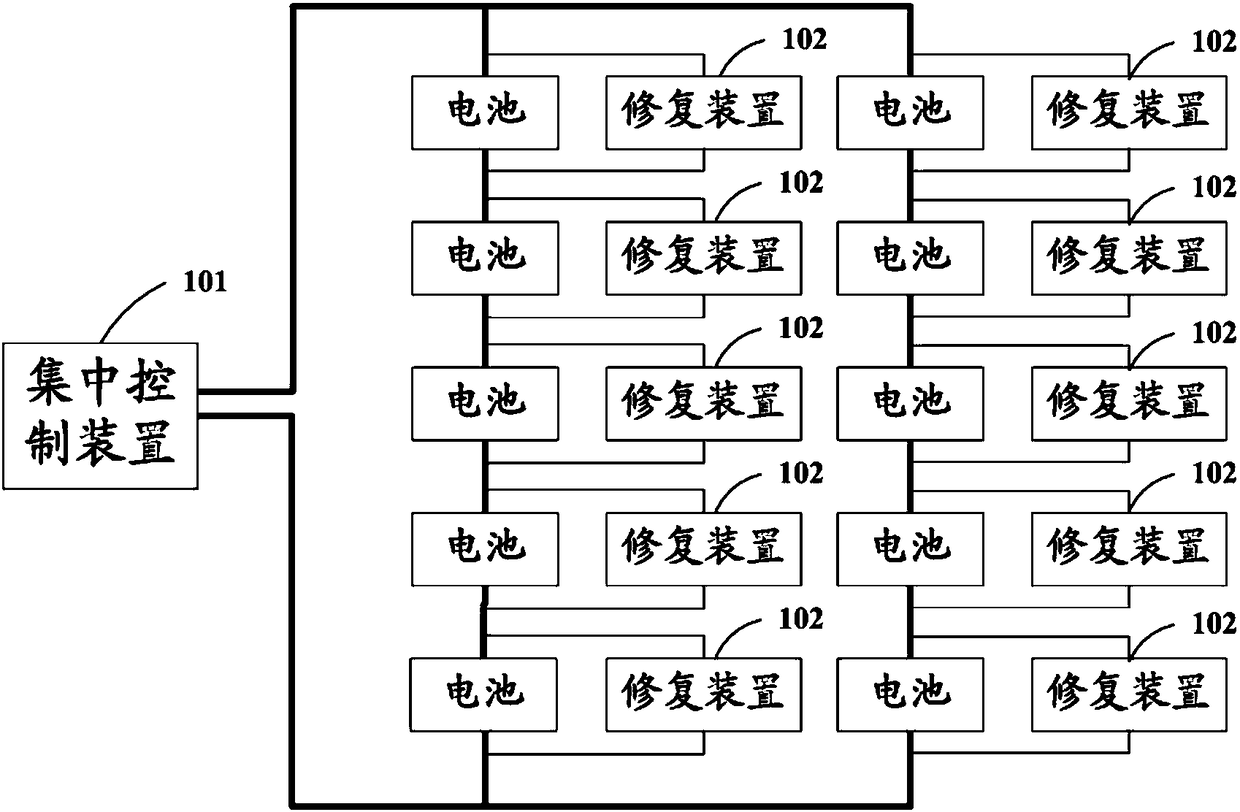

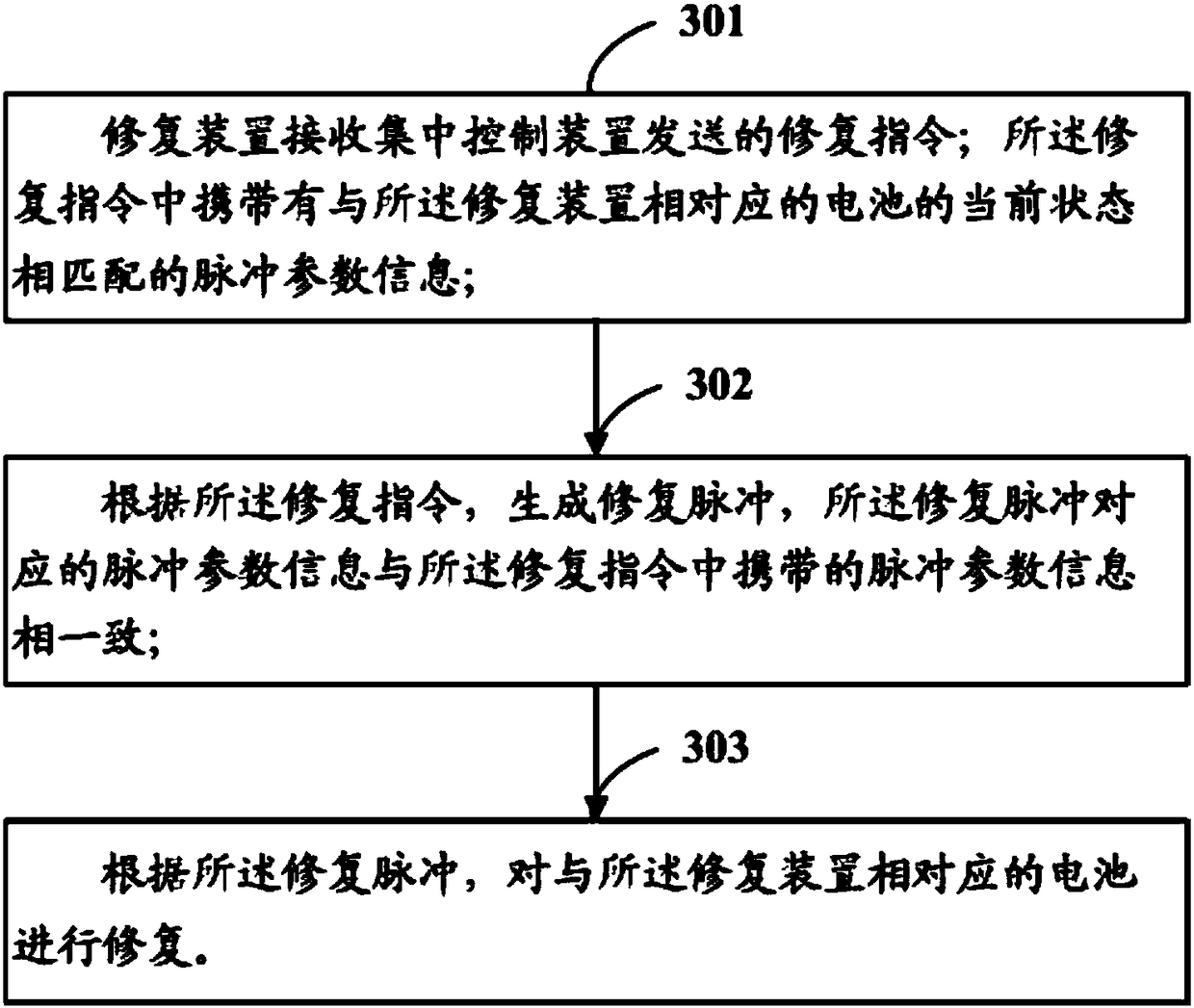

Battery repair system, method and device

ActiveCN105489953AImprove repair effectImprove efficiencyBatteries circuit arrangementsFinal product manufactureBattery systemMonomer

The invention discloses a battery repair system, method and device. Aiming at a battery system comprising at least one battery, each battery in the battery system can be repaired by arranging at least one repair device which is in one-to-one correspondence to the at least one battery in the battery system and a centralized control device for controlling each repair device; and according to the matching of a repair pulse generated according to a repair command sent from the centralized control device and the current state of the battery corresponding to the repair device, each monomer battery and a battery application system are not needed to be separated, each repair device can be used for carrying out differentiate repair on each monomer battery under the control of the centralized control device, thus, the battery repair effect is greatly improved, the repaired battery can be applied to the battery application system for use, on-line repair is achieved, and the application efficiency of the battery system is improved.

Owner:HUAWEI DIGITAL POWER TECH CO LTD

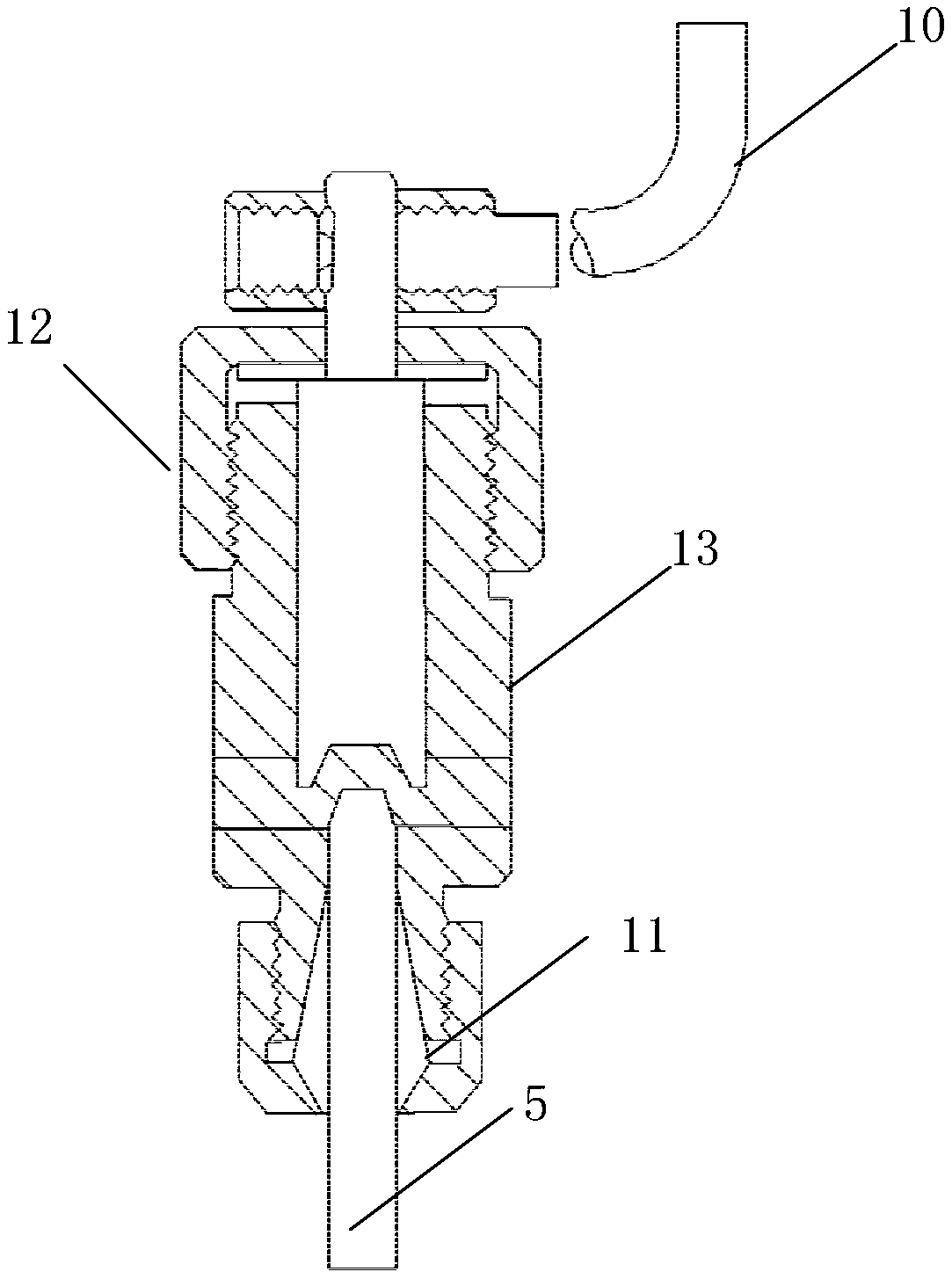

One-line repair device for inner holes of blast furnace tuyere-cooler casing

InactiveCN106929618AImprove repair efficiencyGuaranteed positioning accuracyTuyeresCouplingDrive motor

The invention discloses an one-line repair device for the inner holes of a blast furnace tuyere-cooler casing. According to the one-line repair device for the inner holes of a blast furnace tuyere-cooler casing, a base is arranged on a blast furnace tuyere platform, a reduction gearbox and a driving motor are arranged on the base, a rotating shaft is connected with the output shaft of the reduction gearbox through a coupler, a conical positioning ring is arranged on one side of the tuyere-cooler casing, the rotating shaft is located on the tuyere-cooler casing and the inner ring of the conical positioning ring through a first annular fixing block, a second annular fixing block and the corresponding rolling bearing, a cross positioning block is arranged on the rotating shaft and located inside the tuyere-cooler casing, a turning tool base, a turning tool and a turning tool rest are arranged on the cross positioning block in sequence, the end face of the turning tool base is a bevel, a tool feeding handle is arranged on the turning tool base, and the turning tool and the turning tool rest are driven by the tool feeding handle to move along the end face of the turning tool base. By using the one-line repair device for the inner holes of a blast furnace tuyere-cooler casing, the blast furnace tuyere-cooler casing can be repaired on line, the positioning accuracy of the center of the blast furnace tuyere can be guaranteed, affect caused by cutting operation on the furnace shell of a blast furnace is avoided, the efficiency of repair on the blast furnace tuyere-cooler casing is improved, and the equipment maintenance cost is reduced.

Owner:SHANGHAI BAOYE CONSTR INDAL FURNACE ENG TECH

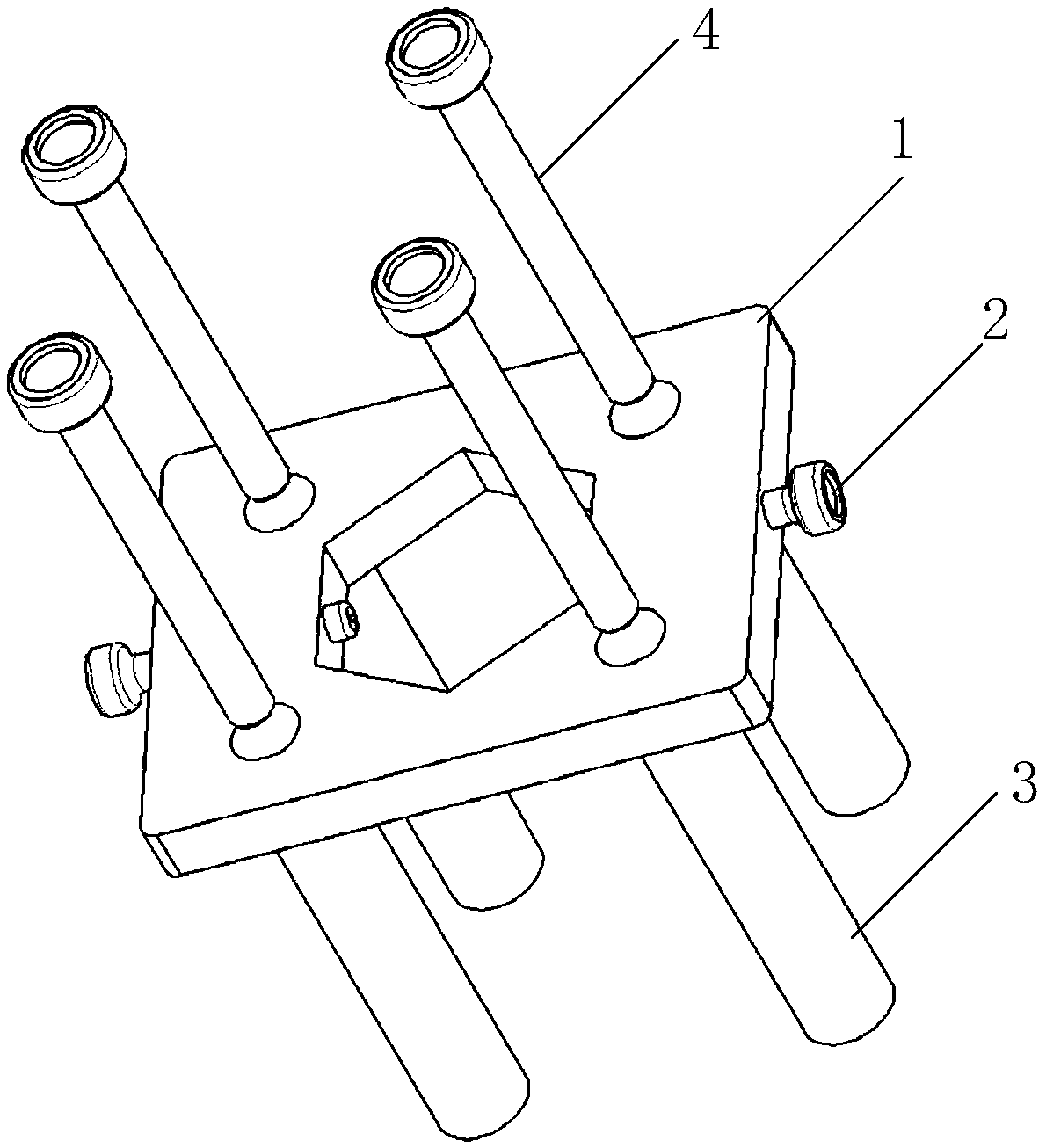

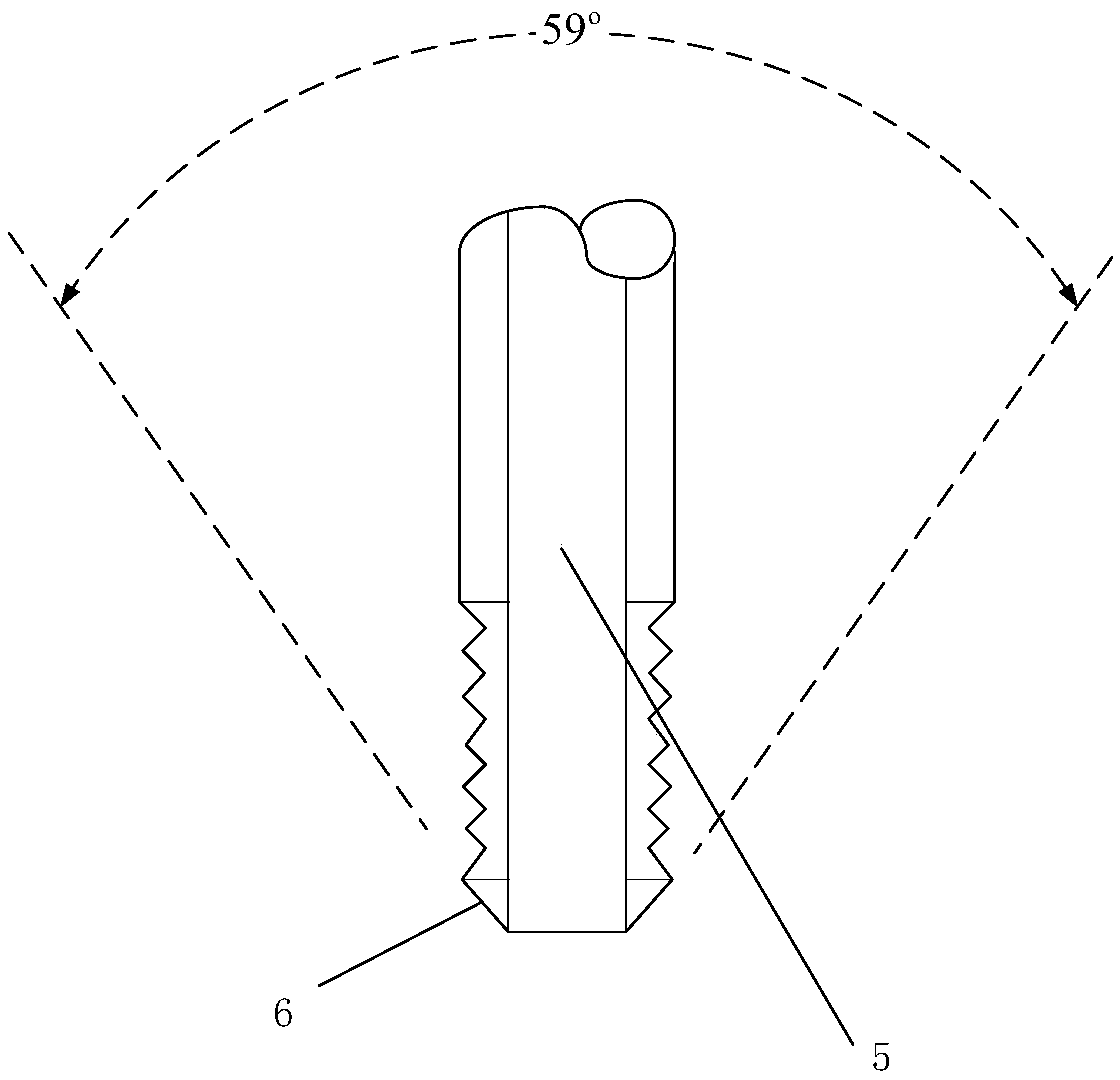

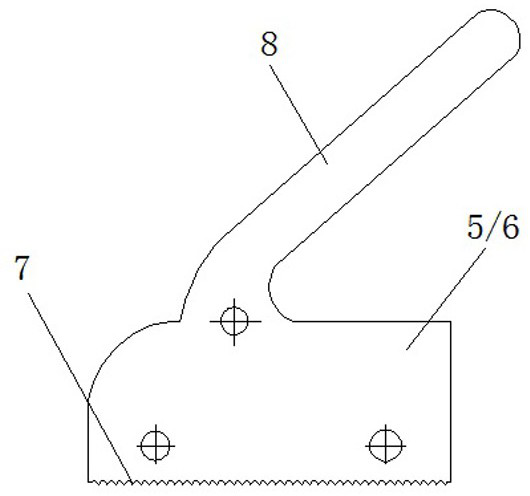

High pressure screw thread manual repair tool and repair method thereof

The invention provides a high pressure screw thread manual repair tool. The high pressure screw thread manual repair tool comprises a clamp fixing plate, the clamp fixing plate is provided with a first mounting hole, the first mounting hole penetrates through the body of the high pressure screw thread repair tool; four same second mounting holes are arranged around the first mounting hole; at least two same locking bolts penetrate through the side walls of the clamp fixing plate and against the body of the high-pressure screw thread repair tool; four same sleeves are connected between the bottom of the clamp fixing plate and an upper flange of a subsurface safety valve, the distance between the clamp fixing plate and the upper flange is limited; and four same fixing bolts penetrate throughthe second mounting hole, the sleeve and a control needle valve mounting hole, and are fixedly connected with the thread of the control needle valve mounting hole. The high pressure screw thread manual repair tool and repair method thereof also comprises a manual repair method for a high pressure screw thread. Through the high pressure screw thread manual repair tool of the invention, the sealingsurface repair tool of the high-pressure screw thread can repair the high-pressure screw thread online without removing the upper flange, the operation is easy and the cost of the oil field is greatly reduced.

Owner:MEIZUAN SHENHAI ENERGY TECH RES & DEV SHANGHAI CO LTD +1

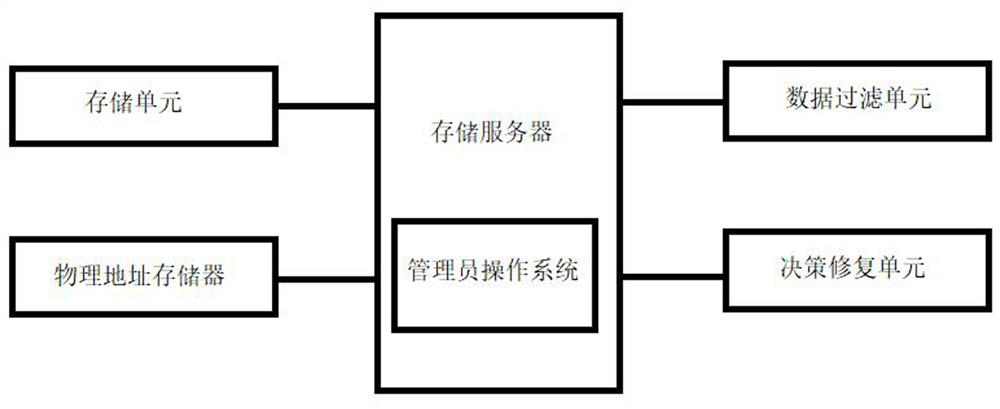

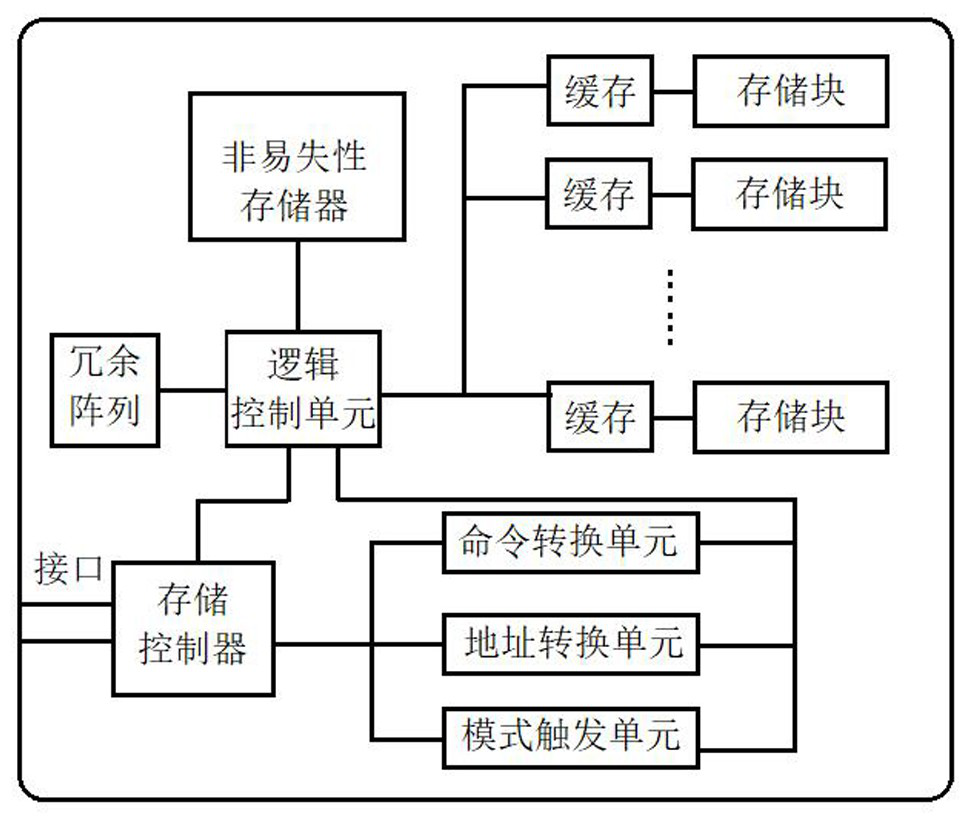

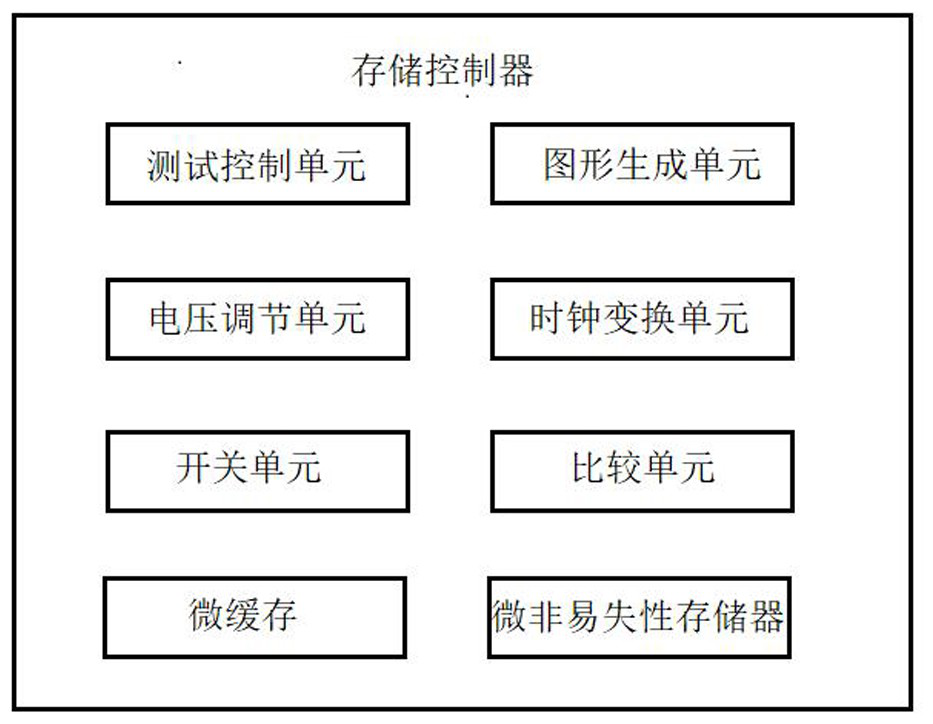

Storage server online repair system based on flash memory

The invention discloses a storage server online repair system based on a flash memory, which can realize online repair in remote areas, especially in harsh and severe environments by introducing the online repair system into the storage server based on the flash memory, and solves the problems of narrow space of a storage array, inconvenience in manual maintenance, low repair efficiency and the like. The efficiency is low; errors are easy to occur; and the maintenance cost is high.

Owner:杨孟林

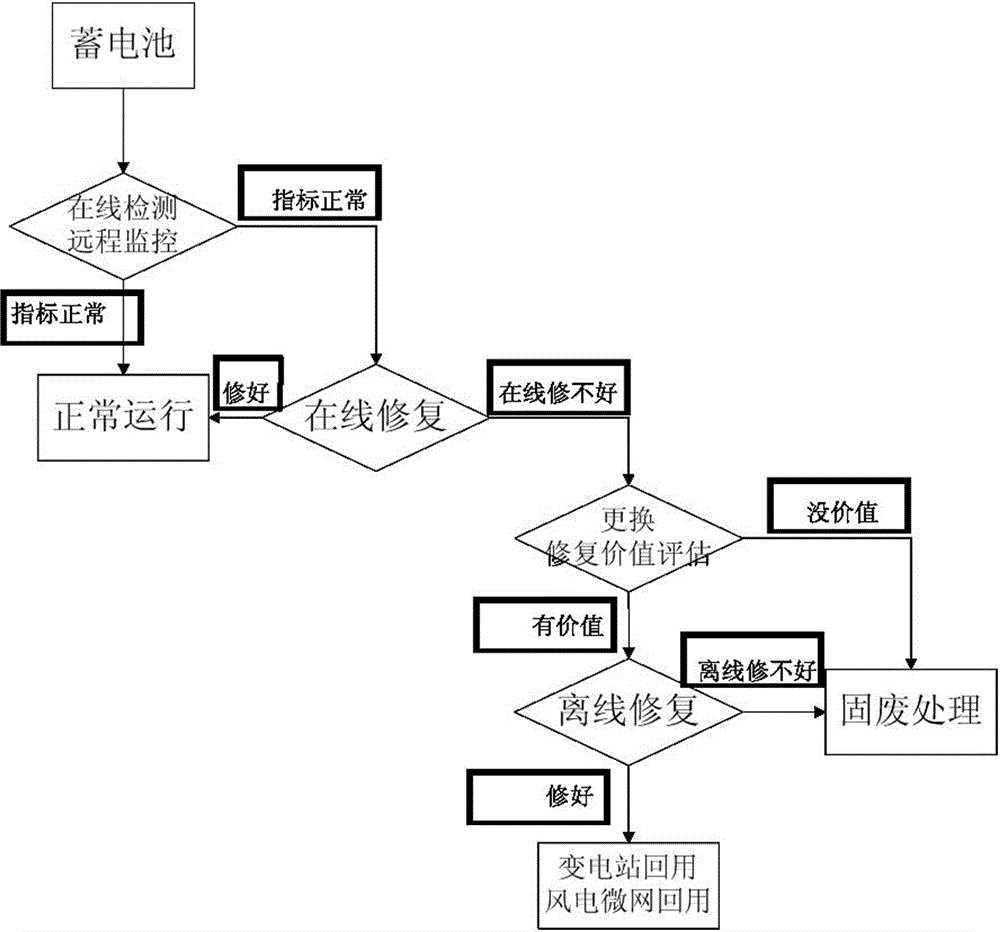

A method for battery on-line detection, repair and evaluation

ActiveCN104466278BRealize remote monitoringRealize remote dischargeSecondary cells servicing/maintenanceTransformerPrimary Indicator

The invention relates to a storage battery operation management system integrating online detection, online repairing and evaluation on operation service life and repairing value of a battery, and particularly relates to an online detection system of a transformer substation storage battery. By adopting the online detection system, an effective technical means is provided for the daily maintenance and detection of the transformer substation storage battery, and multiple functions such as comprehensive analysis, intelligent management, automatic alarming and network monitoring can be realized. An evaluation system for the operation service life and repairing value of the transformer substation storage battery is established, and the transformer substation storage battery is evaluated, distinguished and screened by utilizing the system according to main indexes of the battery such as application service life and repairing value; one or more methods for repairing and recycling the storage battery can be determined, the storage battery conforming to the repairing standard can be repaired, and the waste storage battery which does not conform to the repairing standard or is unnecessary to repair can be processed according to a national solid waste standard.

Owner:STATE GRID CORP OF CHINA +1

A Method for On-Line Repair of Commutator After Spark Fault of DC Motor

ActiveCN110336172BExtend the life cycleRealize online repairManufacturing dynamo-electric machinesCurrent collector maintenanceElectric machineMechanical engineering

A method for on-line repairing of the commutator after a spark fault of a DC motor: use a millivolt meter to find the zero potential point when the motor is stopped; fix the turning device for processing at the processing site; turn the entire surface of the commutator under electrification Processing until the accuracy requirements are met; cleaning the falling objects in the commutator groove when the motor is stopped; thinning the mica sheet with a sawtooth scraper when the motor is stopped; grinding the surface of the commutator in a charged state; dismantling The processing chip device fixed on the site; the motor runs without load under the rated voltage state; it is put into normal operation. The present invention finds the zero potential point of the commutator, and under the conditions of electrification of the motor and human-machine insulation, after turning and grinding the surface of the motor commutator online, not only can the surface finish of the processed commutator meet the requirements, but also make the motor The service life of the utility model can be increased from about half a year to more than two years, and personal safety is guaranteed.

Owner:SHANGHAI BAOSTEEL IND TECHNOLOGICAL SERVICE

Gas-shielded welding wire and welding process for local mandrel repair

ActiveCN109277724BMeet the use requirementsImprove bindingArc welding apparatusWelding/cutting media/materialsChemical compositionPipe

The invention relates to a gas-shielded welding wire for partially repairing mandrels for H13 seamless steel pipes. The chemical composition of the gas-shielded welding wire is: C 0.04%-0.09%; Si 0.2%-0.5%; Mn 1.0%- 1.8%; Ni 1.5%~3.0%; Mo 0.7%~1.90%; S 0.0030%~0.0150%; P≤0.018%; V 0.89%~1.0%; Cr 1.0%~6.0%; Nb 0.055% ~ 0.2%; Als 0.02% ~ 0.04%; the balance is iron and unavoidable impurities. The gas-shielded welding wire of the present invention has excellent welding manufacturability, is suitable for repairing and welding the mandrel after being damaged, and can improve the service life of the repaired mandrel.

Owner:ANGANG STEEL CO LTD

A battery repair system, method and device

ActiveCN105489953BImprove repair effectImprove efficiencyBatteries circuit arrangementsFinal product manufactureElectrical batteryBattery system

The invention discloses a battery repair system, method and device. For a battery system including at least one battery, at least one repair device corresponding to at least one battery in the battery system and a The centralized control device controlled by each repair device repairs each battery in the battery system, wherein, the repair pulse generated by each repair device according to the repair instruction sent by the centralized control device is the same as the current value of the battery corresponding to the repair device. The state of each single battery is matched, so that there is no need to separate each single battery from the battery application system, and each repair device can perform differentiated repairs on each single battery under the control of a centralized control device, which not only greatly improves the effect of battery repair , and make the repaired battery can be used immediately by the battery application system, realize online repair, and improve the use efficiency of the battery system.

Owner:HUAWEI DIGITAL POWER TECH CO LTD

Soil remediation device based on flowering plant planting

InactiveCN113926841ARealize online repairImprove repair effectContaminated soil reclamationSoil scienceSoil remediation

The invention provides a soil remediation device based on flowering plant planting, and belongs to the technical field of soil remediation, the soil remediation device comprises an outer box, an inner box, a driving part, a soil lifting part, a liquid medicine conveying part and a pressing plate, the inner box is arranged in the outer box, and a liquid medicine storage chamber is formed between the inner box and the outer box; and the pressing plate is movably arranged in the liquid medicine storage chamber, and the inner box is movably provided with a limiting disc. In the embodiment of the invention, during soil remediation, ground soil is lifted to one side of a limiting disc through a soil lifting part, at the moment, the limiting disc can move in the inner box so as to drive a pressing plate to move in a liquid medicine storage chamber, and liquid medicine in the liquid medicine storage chamber is conveyed to one side of the limiting disc from a liquid medicine conveying part, so that the soil in the liquid medicine storage chamber is purified and remedied; and compared with the prior art, online soil remediation can be achieved, and the method has the advantages of being good in soil remediation effect and high in remediation efficiency.

Owner:深圳市豪科园林有限公司

A self-healing reinforced polyarylether composite material and its preparation method

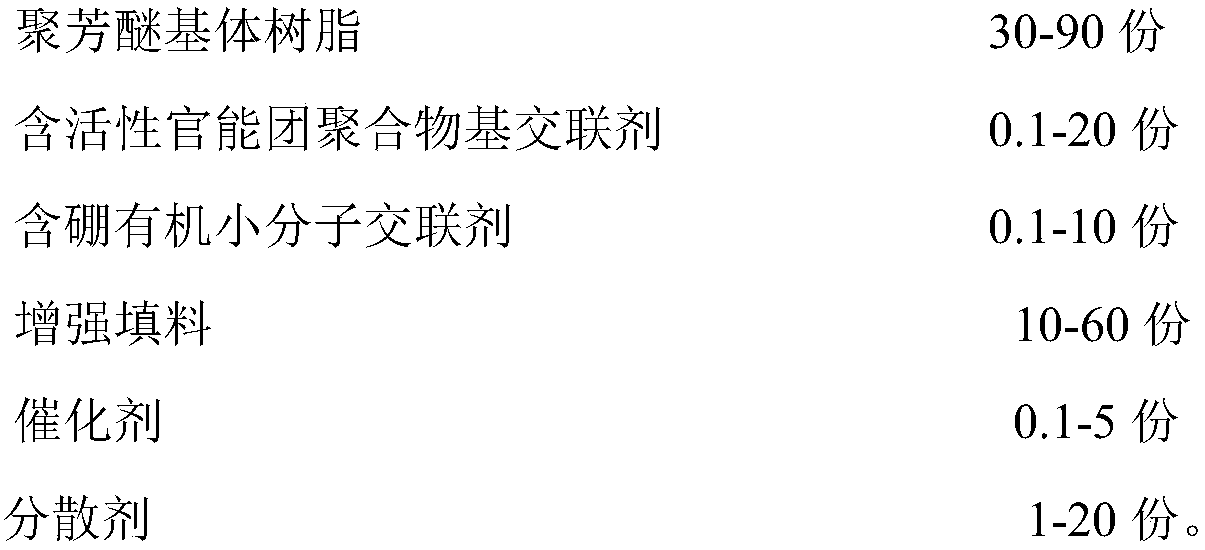

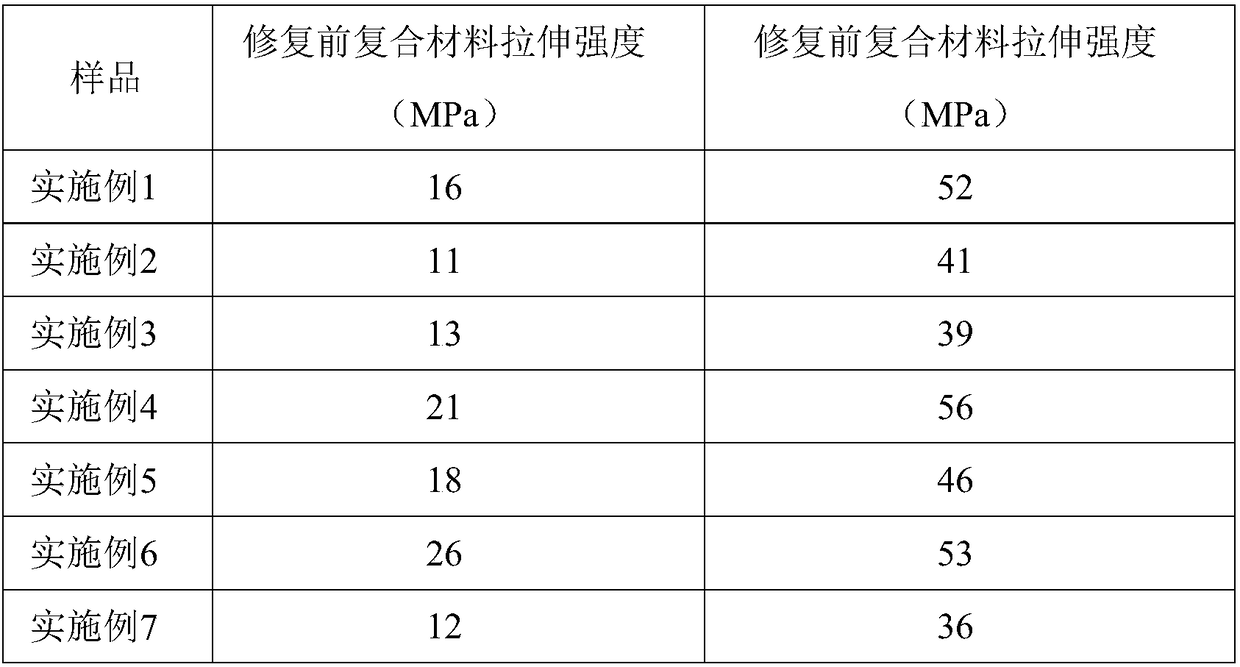

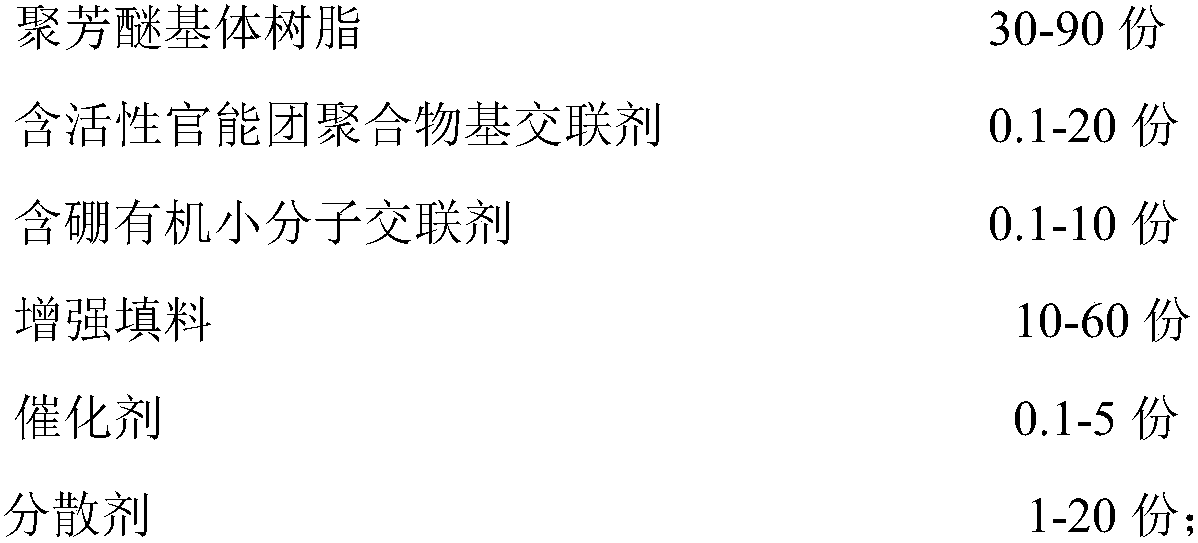

The invention discloses a self-repairing enhanced polyarylether composite material and a preparation method thereof, which is characterized in that 0.1-10 parts of a boron-containing organic small molecule crosslinking agent is dissolved in 1-20 parts of a dispersant to form a uniform mixture Liquid, this mixed solution and 30-90 parts of polyarylether base resin, 0.1-20 parts of polymer-based crosslinking agent containing active functional groups and 0.1-5 parts of catalyst are added to a high-speed mixer, and mixed at room temperature for 1-10min to obtain Masterbatch; the uniformly dispersed above-mentioned masterbatch is dried at a temperature of 30-80°C and a vacuum of 0.05-0.095MPa for 1-6h to obtain a mixed masterbatch; the masterbatch is added from the main feeding port of the twin-screw extruder, and the screw speed The temperature is 50-200rpm, the temperature is 270-380°C; at the same time, 10-60 parts of reinforcing fillers are added from the side feeding port of the twin-screw extruder, melted and blended for 2-10min, extruded, cooled, granulated, and dried to obtain Self-healing reinforced polyarylether composite material; injection molding it into a notched standard tensile spline, and testing its average tensile strength; comparing the tensile properties of the composite material before and after repairing to analyze its self-healing performance and effect.

Owner:安徽旭云商务咨询有限公司

An oxygen valve online repair method

The invention discloses an oxygen valve online repairing method which comprises the following steps: measuring the height of the valve rod and the size of treads; cutting a bracket and arranging a supporting rod; discharging a disabled valve driving mechanism and the cut bracket; mounting a new bracket on a valve flange; mounting a new horizontal driving mechanism, taking out the supporting rod, and accomplishing steps such as debugging. By adopting the repairing method, online repairing is realized without shutting down a oxygen system and exchanging the whole valve, so that the repairing efficiency is improved, and the repairing cost is decreased.

Owner:BAOSHAN IRON & STEEL CO LTD

A pumping unit wellhead sealing packing capable of repairing polished rods

The invention relates to a wellhead sealing packing of a pumping unit capable of repairing polished rods. It mainly solves the problem that the excessive abrasion of the packing caused by the uneven surface of the existing polished rod seriously affects the sealing effect of the packing of the packing. The pumping unit wellhead sealing packing capable of repairing polished rods has the following components and proportions in terms of mass percentages: 25-50% of rubber particles; 15-20% of epoxy resin; 5-20% of crude wax; 5% of SAP resin ‑10%; vinyl chloride copolymer resin 5‑15%; plasticizer 15‑25%; dehumidifier 3‑5%; foaming agent 1‑2%; curing agent 0.2‑1.0%; talcum powder 5‑15%; Molybdenum disulfide lithium base grease 5‑10%; base oil 3‑5%. The pumping unit wellhead sealing packing capable of repairing polished rods can basically fill and harden the grooves on the surface defects of polished rods, achieve the effect of hot repair, reduce the excessive wear of packing caused by the uneven surface of polished rods, and extend the Root filler lifespan.

Owner:PETROCHINA CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com