Large machinery equipment surface multifunction online processing and repairing device

A large-scale mechanical and multi-functional technology, applied in positioning devices, feeding devices, metal processing equipment, etc., can solve problems that affect production, long cycle time, and high cost, and achieve the effects of improving flexibility, reducing volume, and improving repair efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

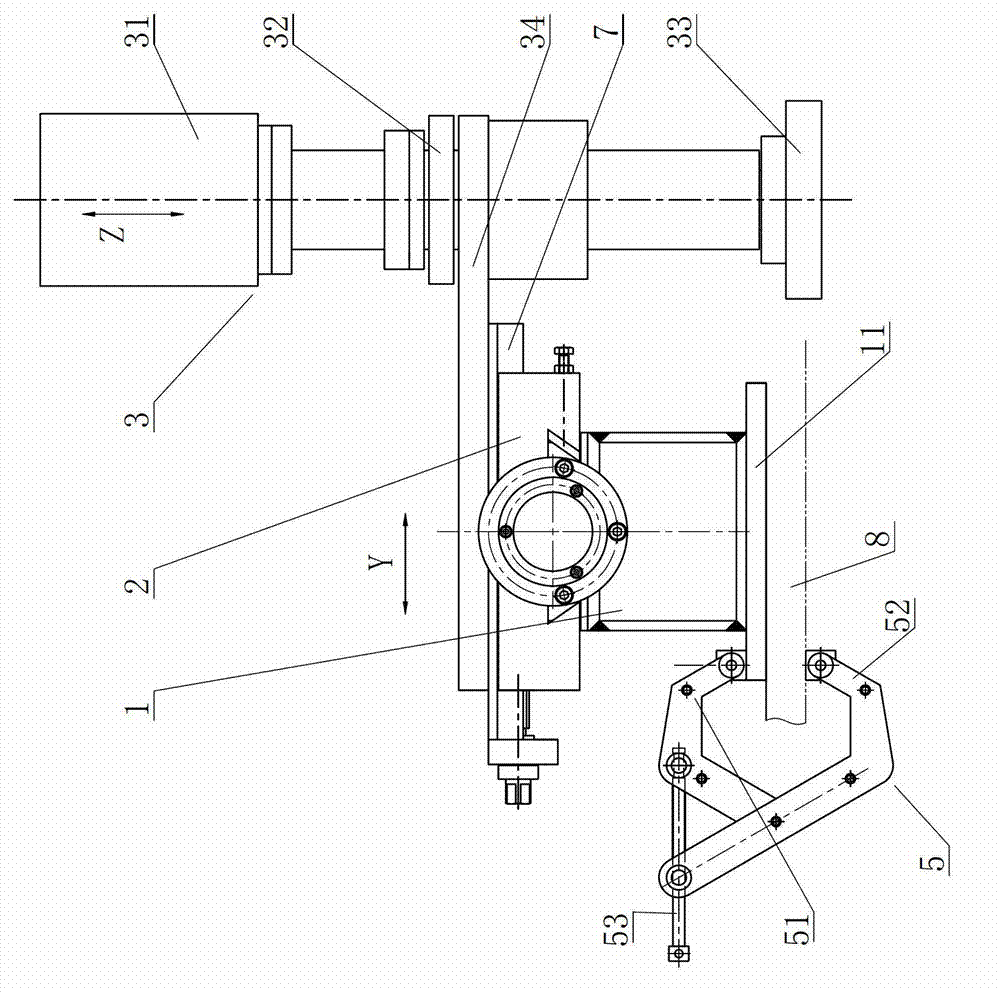

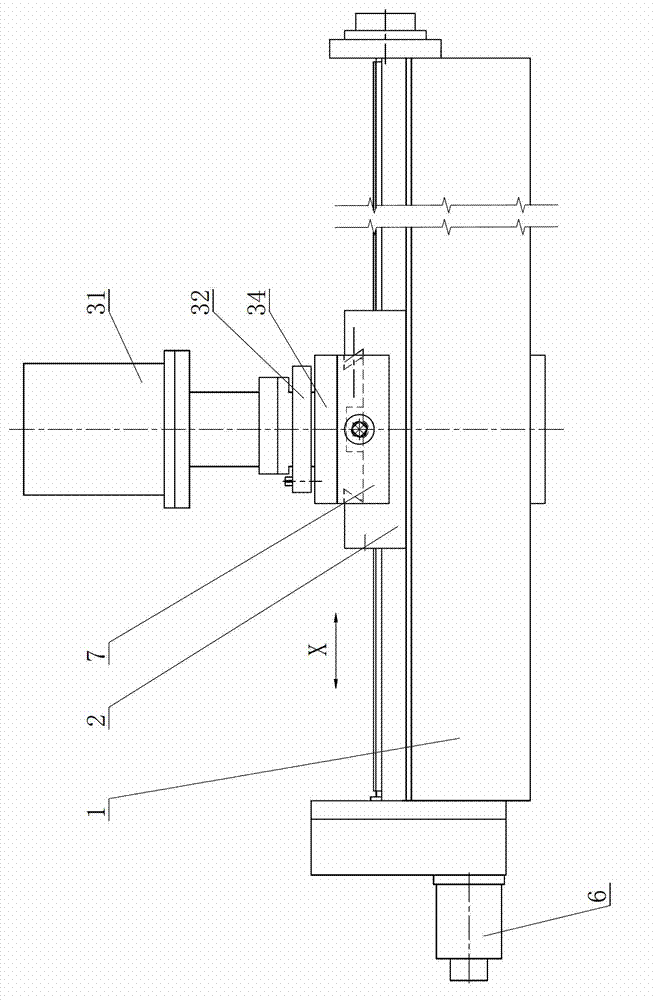

[0019] see figure 1 and figure 2 , a multifunctional online processing and repairing device for the surface of large-scale mechanical equipment, including a sliding table and a cross sliding table 2, the cross sliding table is connected with the sliding table in a sliding connection, in the form of a dovetail groove in this embodiment, the sliding table A feed drive device 6 is provided at one end of the sliding table, and a bottom plate 11 is provided at the bottom of the sliding table, which is connected with the fixed base 8 of large-scale mechanical equipment through a quick clamping device 5. Sliding plate, wherein the sliding plate 2 is slidingly connected with the sliding table, the sliding direction of the upper sliding plate 7 on the lowering plate is perpendicular to the sliding direction of the lowering plate on the sliding table, and the milling cutter assembly is installed on the upper sliding plate through the milling cutter assembly mounting plate 34 3. The m...

Embodiment 2

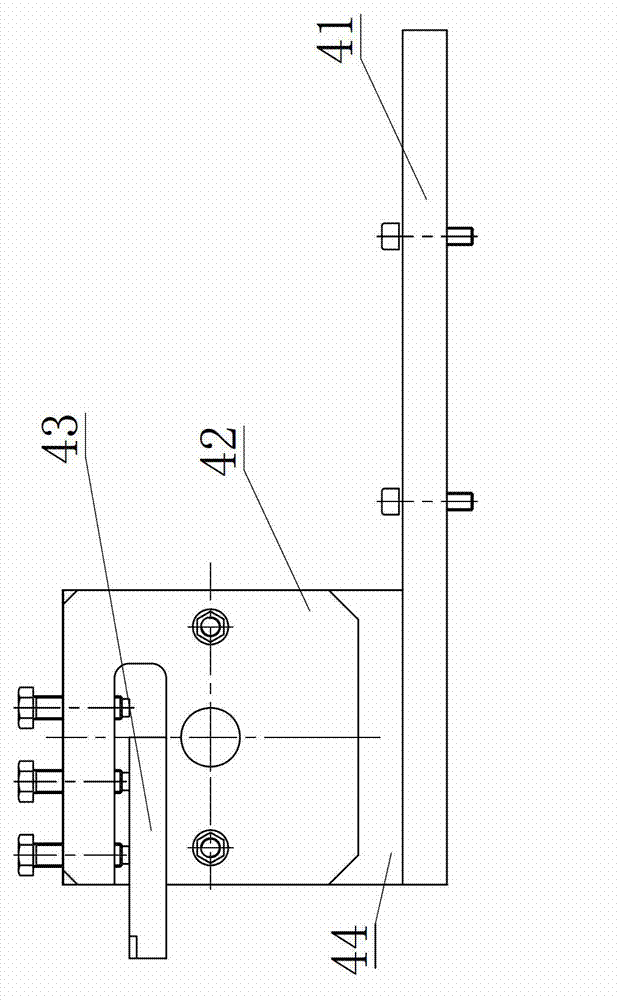

[0022] Such as image 3 , Figure 4 As shown, the difference between this embodiment and Embodiment 1 is that the tool assembly is not a milling cutter, but a turning tool is used. Specifically, the tool assembly is a turning tool assembly, which includes a turning tool installed at one end of the upper slide. Knife assembly mounting plate 41, the tool seat 42 installed on the turning tool assembly mounting plate, the tool seat 42 installed on the rotary seat 44 and the turning tool 43 fixed on the tool seat by screws in a manner of circumferential rotation connection .

[0023] When changing from using a milling cutter to a turning tool as a cutting tool, remove the milling cutter assembly mounting plate from the upper slide plate, replace the turning tool assembly mounting plate and the turning tool assembly, and use bolts to secure the turning tool assembly The installation plate and the upper slide plate are fixed, and the tool replacement work is completed. This device...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com