Surface treatment milling machine tool

A surface treatment and milling technology, which is applied in the direction of milling machine equipment, milling machine equipment details, metal processing equipment, etc., can solve the problems of incomplete release of stress, vibration, noise, high cost, etc., to improve flexibility, reduce volume, and improve repair efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

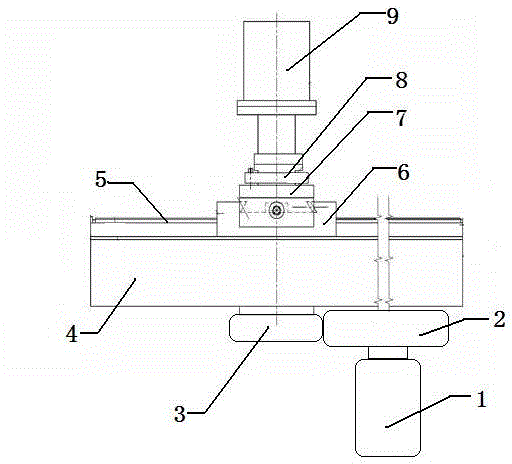

[0012] This embodiment provides a surface treatment milling machine tool, characterized in that: the surface treatment milling machine tool includes a drive motor (1), a first gear (2), a second gear (3), a sliding table (4), Slideway (5), slider (6), milling cutter installation connection (7), tool holder (8), milling power system (9);

[0013] Among them: the sliding table (4) is connected with the slider (6) on the upper side in a sliding connection, the other end of the sliding table (4) is provided with a feed drive motor (1), and the power output shaft of the driving motor (1) Connected to the first gear (2), the first gear (2) is in circumscribed meshing transmission with the second gear (3), and the transmission shaft of the second gear (3) passes through the slide table (4) and is fixedly connected to the slider (6 ), a milling cutter installation connection (7) is installed above the slider (6), and a tool holder (8) and a milling power system (9) are installed throu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com