An oxygen valve online repair method

A repair method and valve technology, applied in the field of test fixtures, can solve problems such as failure to open normally, high risk, accidents, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

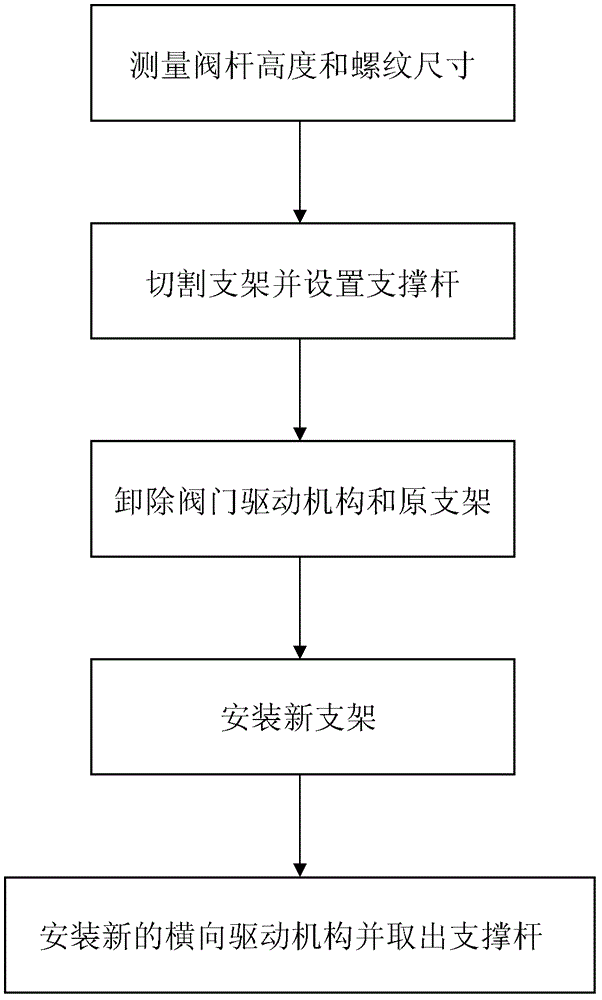

[0025] see figure 1 As shown, the oxygen valve online repair method of the present invention mainly includes the following steps:

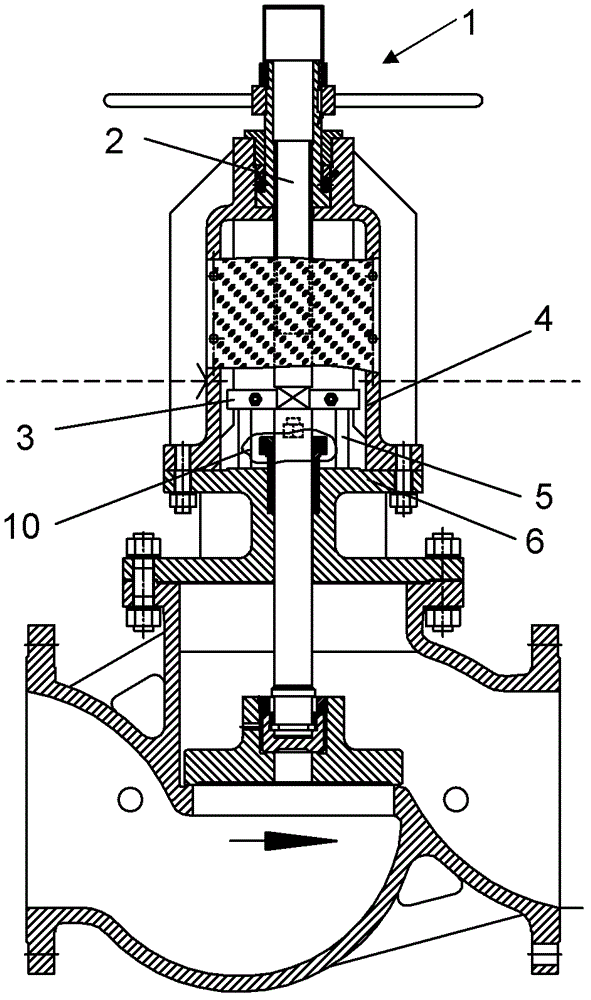

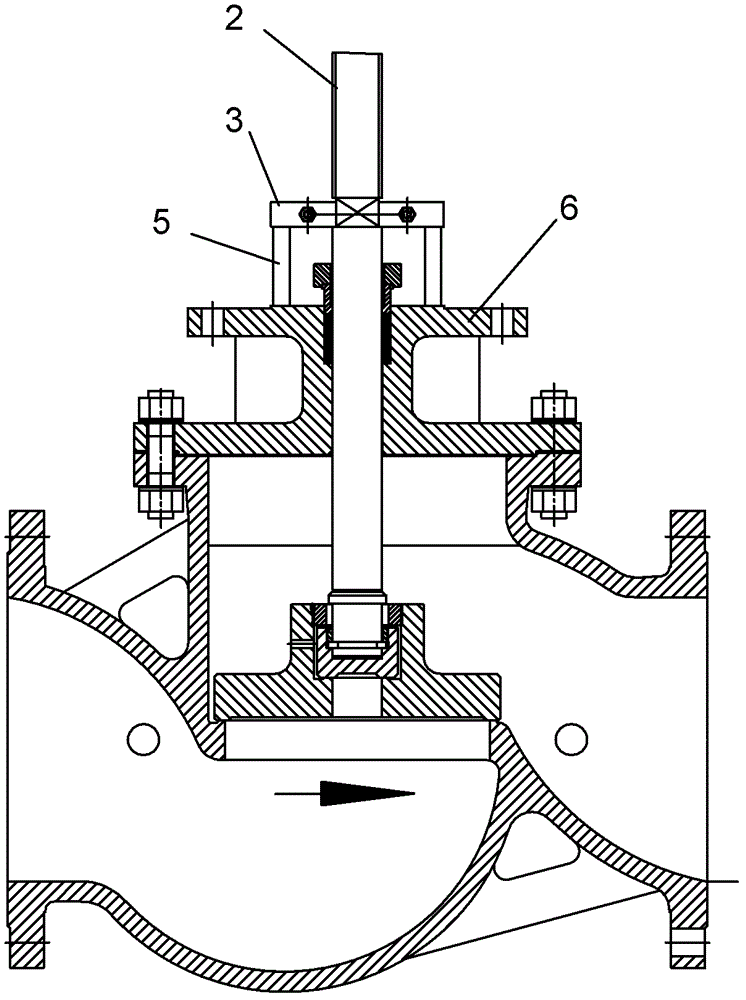

[0026] A. Please combine figure 2 As shown, measure and calculate the height of the valve stem 2 of the oxygen valve whose drive mechanism 1 has failed and the thread size of the valve stem 2, and provide the basis for the production size of the new bracket and drive mechanism.

[0027] B. Cut the bracket 4 at a position higher than the valve opening indicator block 3, cut off both sides of the bracket 4 and set a support rod 5 between the valve opening indicator block 3 and the valve flange; the cutting location (ie figure 1 The horizontal dotted line in ) should be about 5cm higher than the valve opening indicator block 3, so as to ensure that the indicator block 3 will not be touched when t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com