A Method for On-Line Repair of Commutator After Spark Fault of DC Motor

A DC motor and commutator technology, applied in the field of metal processing, can solve problems such as commutator surface burns, difficult to solve spark faults, commutator surface finish and concentricity cannot be guaranteed, and achieve the effect of personal safety guarantee

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be described in detail below in conjunction with accompanying drawing:

[0032] Explanation: The following devices and tools are used in the examples:

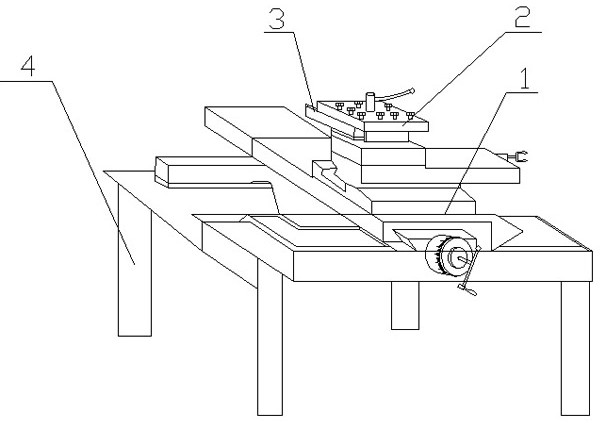

[0033] Turning device: a simple turning tool holder composed of a carriage 1, a tool holder 2 connected to the carriage 1, and a tool 3 on the carriage 2; a support frame 4 is connected to the lower end surface of the carriage 1 by bolts; Frame 4 is fixedly connected with the site by means of bolts or welding.

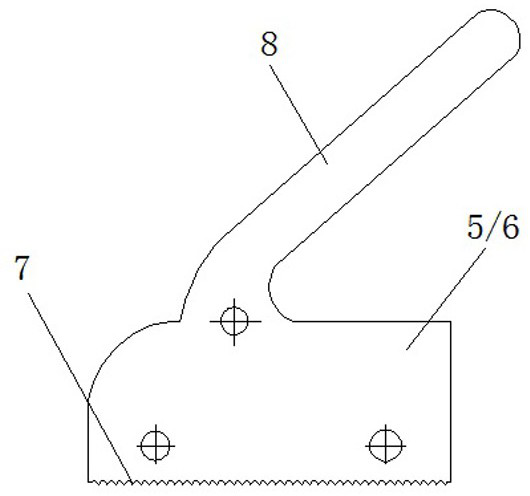

[0034] Saw-toothed scraper: consists of splint 1 5, splint 2 6, saw blade 7 between splint 1 5 and splint 2 6, and a handle 8 that is welded or bolted to splint 1 5 or / and splint 2 6.

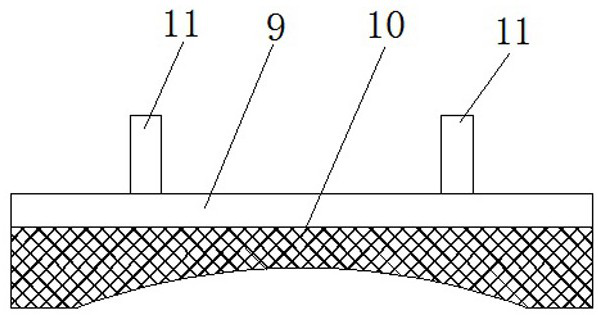

[0035] Grinder: consists of a fixed plate 9, a grinding layer 10 connected to the fixed plate 9 by embedding or bonding, and a handle 11 connected to the upper surface of the fixed plate 9 by welding or bolts; the working surface of the grinding layer 10 The shape matches the shape of the workpiece pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com