Device for online repairing of large reduction gearbox bearing hole abrasion and method thereof

A repairing method and reduction box technology, applied in boring/drilling, drilling/drilling equipment, portable drilling rigs, etc., can solve the problems of high repair cost, no time to disassemble, long repair time, etc., and achieve concentricity high precision effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

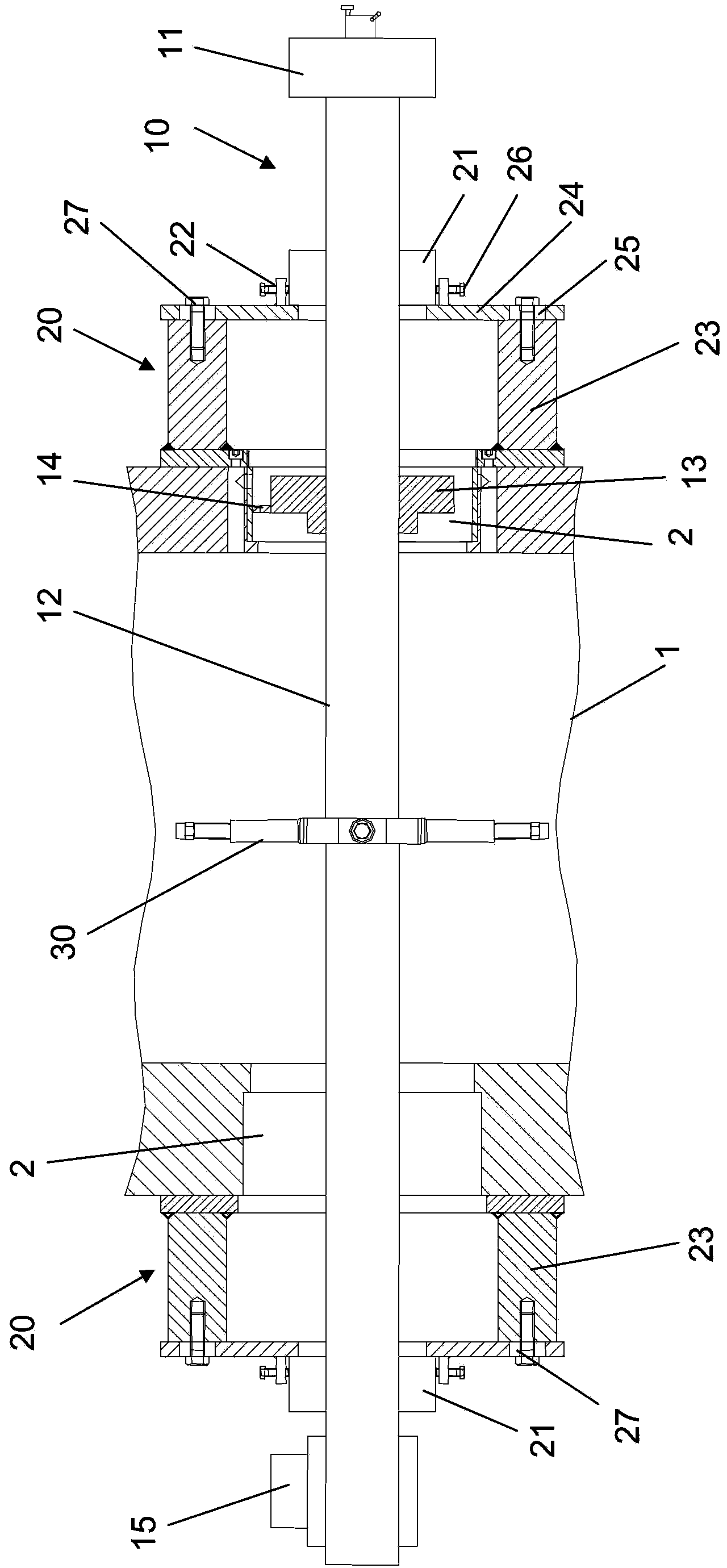

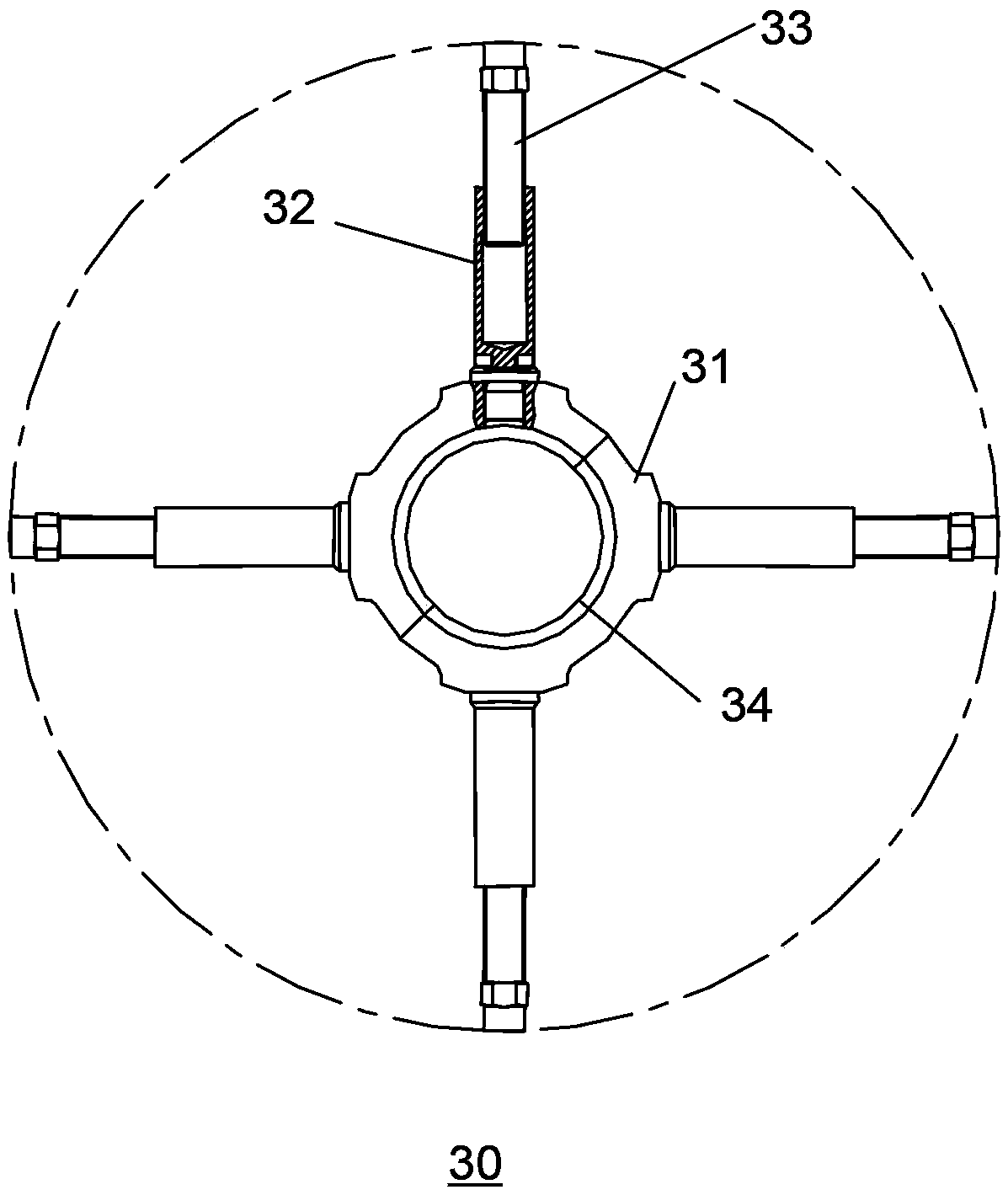

[0033] see figure 1 As shown, the on-line repair device of the bearing hole wear of large reduction box of the present invention includes a portable boring machine 10, a positioning device 20 and an intermediate support device 30, and the portable boring machine 10 includes an axial feed device 11, a boring bar 12, a boring The hole device and the rotary drive device 15, the axial feed device 11 is set at one end of the boring bar 12, and the two positioning devices 20 are set respectively on both sides of the boring bar 12 to be fixed to the left and right sides of the reduction box 1 Each positioning device 20 is also provided with a support bearing 21 and a center adjustment device 22 sleeved on the boring bar 12. The boring device includes a boring tool holder 13 sleeved on the boring bar 12 and a boring tool holder 13. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com