Hardened soil treatment and remediation system for greening

A repair system and soil technology, applied in the direction of soil lifting machinery, application, soil crushing machine, etc., can solve the problems of consumption, affecting absorption, water and soil loss, etc., and achieve the effect of easy use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

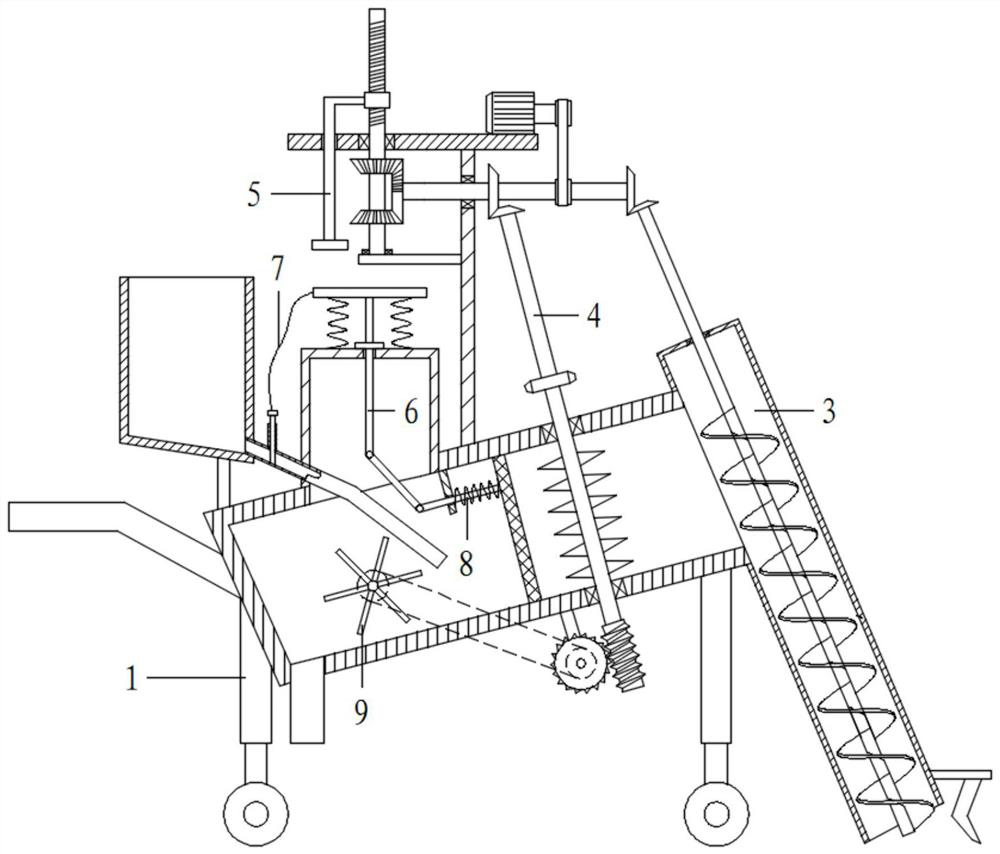

[0071] With reference to the accompanying drawings, a compacted soil treatment and restoration system for greening includes a car body assembly 1, a drive assembly 2, a soil entry assembly 3, a crushing assembly 4, a lifting assembly 5, a pull-down assembly 6 and an ash assembly 7;

[0072] The vehicle body assembly 1 includes a main body cylinder 101, a soil discharge pipe 102, a foot 103, a wheel 104, a push handle 105, a screen 106, a vertical support plate 107, an ash discharge pipe 108 and an ash storage bucket 109; the main body cylinder 101 is low on the left and high on the right. Inclined setting, the bottom is connected to the right wheel 104 through the leg 103; the left side of the main body cylinder 101 is connected with a push handle 105, and the bottom of the left end is connected with a soil discharge pipe 102; the middle part of the main body cylinder 101 is equipped with a screen 106; Above the left end, ash discharge pipe 108 is connected to the bottom, and t...

Embodiment 2

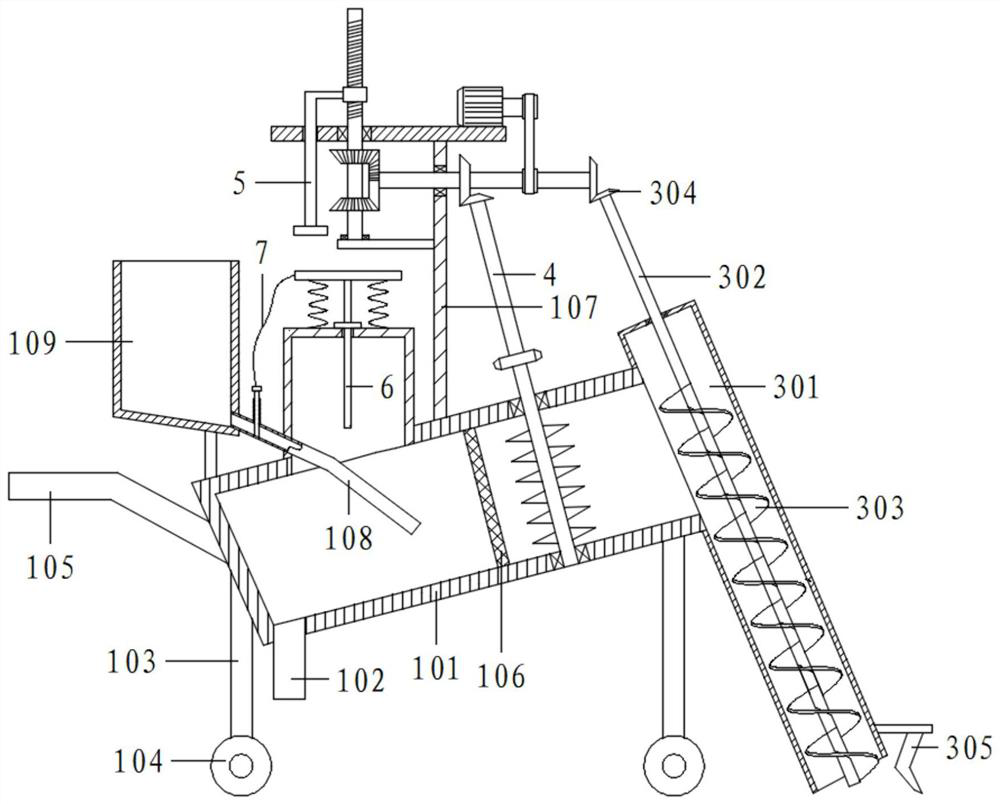

[0075] With reference to the accompanying drawings, a compacted soil treatment and restoration system for greening includes a car body assembly 1, a drive assembly 2, a soil entry assembly 3, a crushing assembly 4, a lifting assembly 5, a pull-down assembly 6 and an ash assembly 7;

[0076] The vehicle body assembly 1 includes a main body cylinder 101, a soil discharge pipe 102, a foot 103, a wheel 104, a push handle 105, a screen 106, a vertical support plate 107, an ash discharge pipe 108 and an ash storage bucket 109; the main body cylinder 101 is low on the left and high on the right. Inclined setting, the bottom is connected to the right wheel 104 through the leg 103; the left side of the main body cylinder 101 is connected with a push handle 105, and the bottom of the left end is connected with a soil discharge pipe 102; the middle part of the main body cylinder 101 is equipped with a screen 106; Above the left end, ash discharge pipe 108 is connected to the bottom, and t...

Embodiment 3

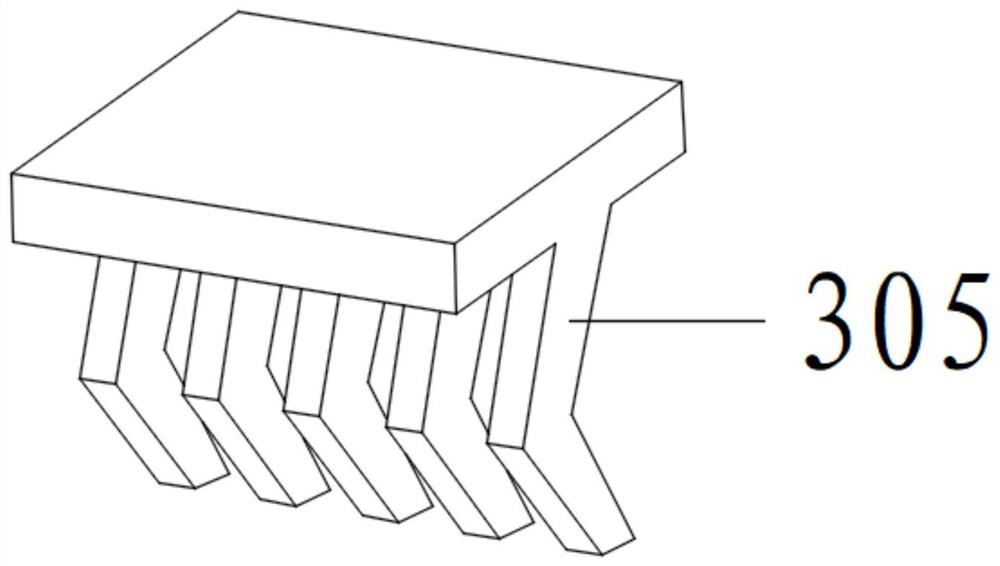

[0101] On the basis of embodiment 2,

[0102] It also includes a rebound assembly 8; the rebound assembly 8 includes No. 3 connecting rod 801, No. 4 connecting rod 802, guide plate 803 and compression spring 804;

[0103] The screen 106 is slidably arranged in the main cylinder 101; the inner top of the main cylinder 101 corresponds to the left side of the screen 106 and is fixedly connected with a guide plate 803, and a compression spring 804 is connected between the guide plate 803 and the screen 106; the No. 4 connecting rod 802 runs through The right end of the guide plate 803 is connected to the top of the screen 106, and the left end is hinged to the bottom of No. 3 connecting rod 801; the top of No. 3 connecting rod 801 is hinged to the bottom of the vertical bar 602.

[0104] Specifically, when the top plate 604 is lifted by the magnet 507, the vertical rod 602 also moves up, and the fourth connecting rod 802 is pulled by the third connecting rod 801 to move to the lef...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com