Process for repairing water erosion damage of flow passage component of steam turbine and protecting flow passage component of steam turbine

A technology for flow-through parts and water erosion damage, applied in the field of material science, can solve problems such as complex equipment, unsuitable on-site repairs, uneven cladding layer surface, etc., to improve safety and efficiency, increase economic benefits of power plants, and resist water erosion Significant effect on performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

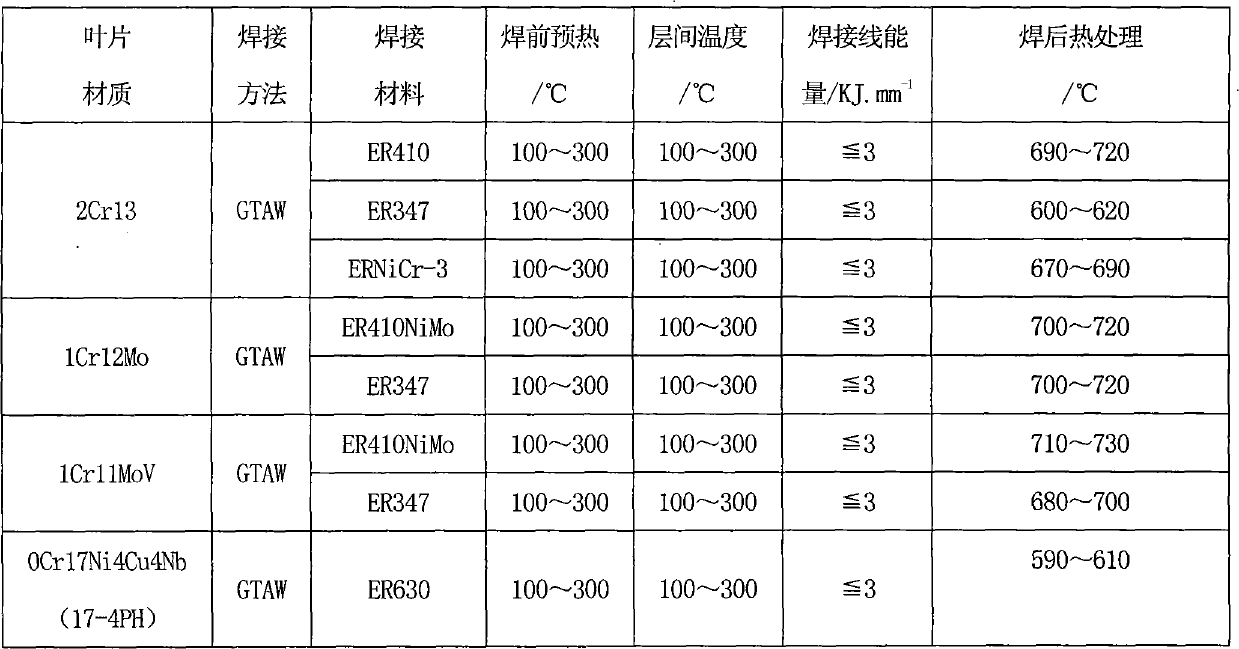

[0052] Concrete process of the present invention is as follows:

[0053] 1) Before the repair, use a direct-reading spectrometer to identify the material of the flow-through parts on site, test the static frequency of the blade and the molded line of the repaired area, and make a molded line model according to the test data. The molded line model is made of flexible thin iron sheet, which can truly reflect the steam turbine. Spatial profile of flow-through parts;

[0054] 2) Use macroscopic inspection, magnetic particle inspection or penetrant inspection to check the distribution and size of blade defects, and use manual mechanical methods to clean up water erosion defects;

[0055] 3) Macroscopic inspection and re-inspection of non-destructive flaw detection to confirm that the defects in the area to be repaired have been completely eliminated;

[0056] 4) Prepare a V-shaped groove in the area to be repaired. The angle of the groove is related to the thickness of the blade. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com