Cable accessory branching fingerstall restoration method

A technology of cable accessories and branch finger sleeves, which is applied in the fields of installation and maintenance, design and manufacture of cable accessories, can solve the problems of reduced electrical stress control ability of cable accessories, high overall cost, shortened service life, etc., and achieves insulation level and service life. The effect of reduction, low social operating cost and low maintenance cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

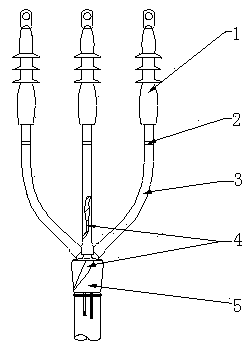

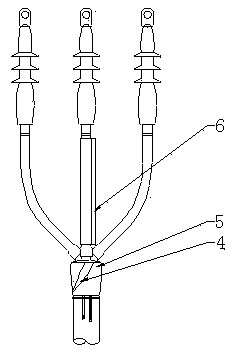

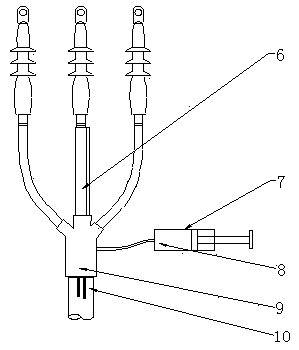

[0027] In order to explain in detail the technical content, structural features, achieved purpose and effect of a cable accessory branch finger cot repair method of the present invention, the following will be further explained in conjunction with examples and accompanying drawings.

[0028] Such as Figure 1 to Figure 4 As shown, an example of a method for repairing a branch finger cot of a cable accessory of the present invention is disclosed, including three steps of "a, b, c":

[0029] a. Prefabricate the injection mold 9 and snap-fit insulating tube 6 of corresponding shape and size according to the external dimensions of the cable accessory branch finger sleeve 5 and the sheath tube 3;

[0030] b. Cover the damaged part 4 of the sheath tube 3 with a snap-fit insulating tube 6, and use liquid to toothpaste room temperature vulcanized rubber 8 to manually fill the slot and seam of the snap-fit insulating tube 6. The vulcanized rubber 8 is cured as one;

[0031] c. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com