One-line repair device for inner holes of blast furnace tuyere-cooler casing

A technology of tuyere and large set, which is applied in the field of online repair device for the inner hole of large set of blast furnace tuyere, which can solve the problems of increasing equipment maintenance cost, increasing repair workload, uneven mixing, etc., so as to reduce equipment maintenance cost and ensure positioning The effect of improving accuracy and improving repair efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

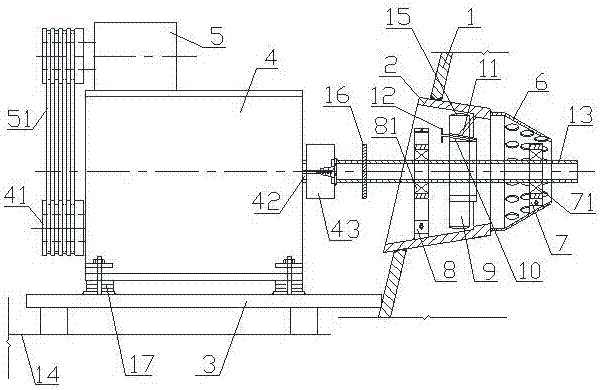

[0012] Example figure 1 As shown, the online repair device for the inner hole of the blast furnace tuyere large set of the present invention includes a blast furnace shell 1 and a large tuyere set 2 arranged on the blast furnace shell 1, and also includes a base 3, a reduction box 4, a driving motor 5, and a tapered positioning ring 6 , the first annular fixed block 7, the second annular fixed block 8, the cross positioning block 9, the turning tool base 10, the turning tool and the turning tool holder 11, the feed handle 12 and the rotating shaft 13, and the base 3 is located on the blast furnace tuyere platform 14 and one end is connected to the blast furnace shell 1, the reduction box 4 is arranged on the base 3, the drive motor 5 is arranged on the top surface of the reduction box 4 and the drive shaft is connected to the reduction box 4 through a belt 51 input shaft 41, one end of the tapered positioning ring 6 is arranged on the end face of the large tuyere sleeve 2, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com