Method for rapidly maintaining converter lining

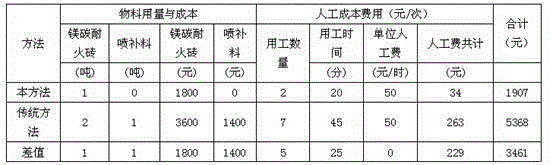

A converter lining and rapid maintenance technology, which is applied in the manufacture of converters and the improvement of process efficiency, etc., can solve the problems of long repairing time, rapid and stable production, short service life of converter lining, poor erosion resistance and erosion resistance, etc. Furnace time, saving refilling materials and labor costs, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Embodiment 1: The specific steps of this rapid maintenance method are as follows.

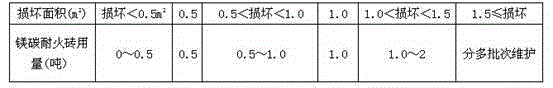

[0026] The feeding side area of repairing converter is 1m 2 damage. When the last furnace was smelted before repairing the furnace, the basicity of the slag was 3.7, the content of MgO was 11.21wt%, and the end temperature of blowing was 1665℃. tons (2% of the nominal ton), check that there is no steel left in the furnace; shake the converter mouth to the feeding side, add 1 ton of pre-prepared magnesia-carbon refractory bricks into the furnace, choose to use low speed to control the tilting of the converter, and slowly turn the converter Shake it up, shake it to about 55 degrees, repeat the movement twice in a small range, observe the magnesia-carbon refractory bricks in the furnace and stop tilting the converter. Stand still in this state for 10 minutes to check the effect of repairing the furnace. The mixture of magnesia-carbon refractory bricks and slag is better pasted at the re...

Embodiment 2

[0027] Embodiment 2: The specific steps of this rapid maintenance method are as follows.

[0028] The bottom area of the repaired converter is 1m 2 damage. When the last furnace was smelted before repairing the furnace, the basicity of the slag was 3.9, the content of MgO was 12.61wt%, and the end temperature of blowing was 1671℃. tons (4% of the nominal ton), check that there is no steel left in the furnace; shake the converter mouth to the feeding side, add 1 ton of pre-prepared magnesia-carbon refractory bricks into the furnace, choose to use low speed to control the tilting of the converter, and slowly turn the converter Shake it up, shake it to about 0 degree position, repeat the movement 3 times back and forth in a small range, observe the magnesia-carbon refractory bricks in the furnace and stop tilting the converter. Stand in this state for 10 minutes to check the effect of repairing the furnace. The mixture of magnesia-carbon refractory bricks and slag has a good ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com