Fuel oil and electric dual-purpose bulldozer

An electric dual-purpose, fuel engine technology, applied to mechanically driven excavators/dredgers, etc., can solve the problems of fuel engine exhaust and noise pollution, failure to meet the use requirements, environmental pollution, etc., to achieve fuel saving and maintenance cycle Long-term, anti-pollution effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

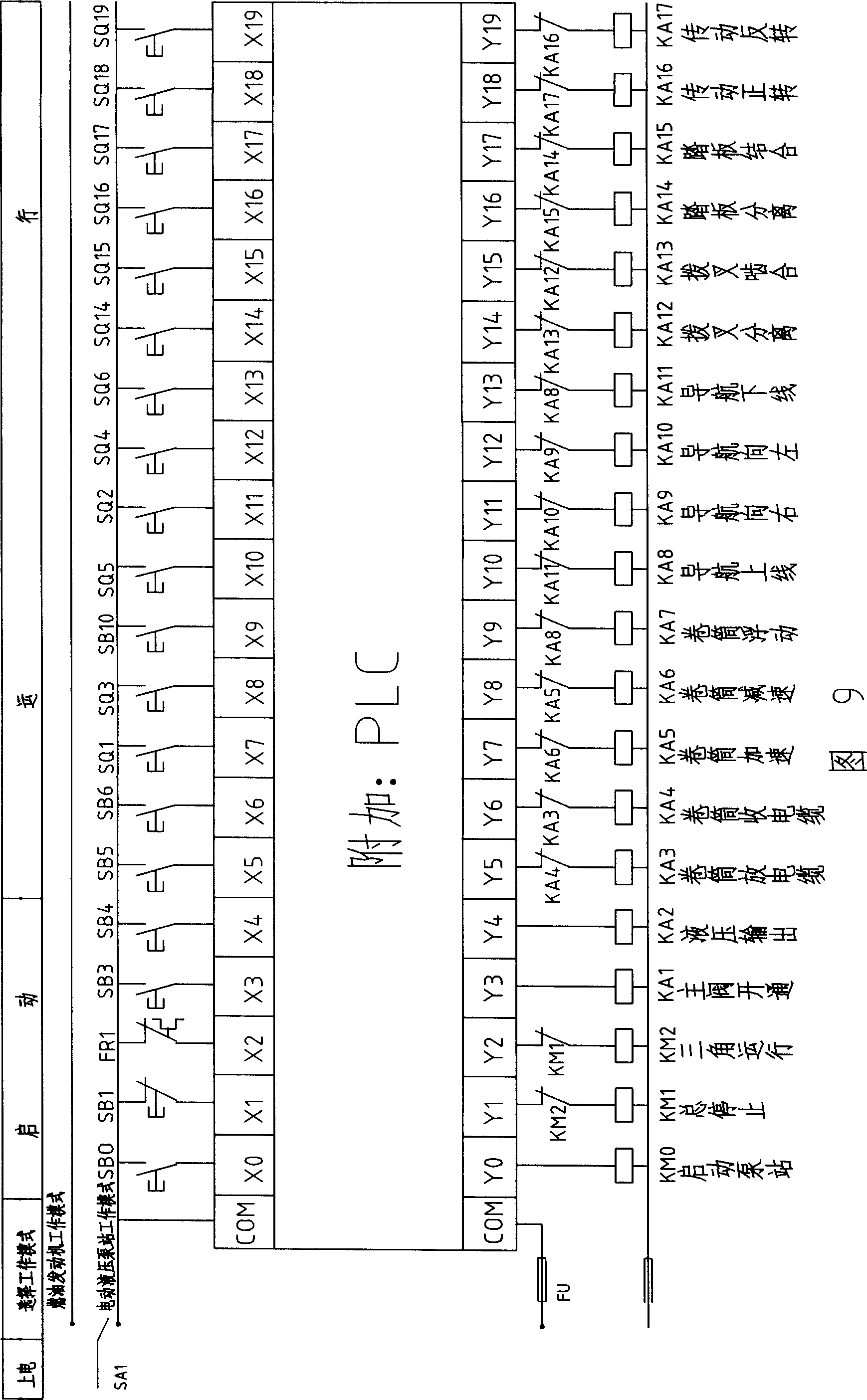

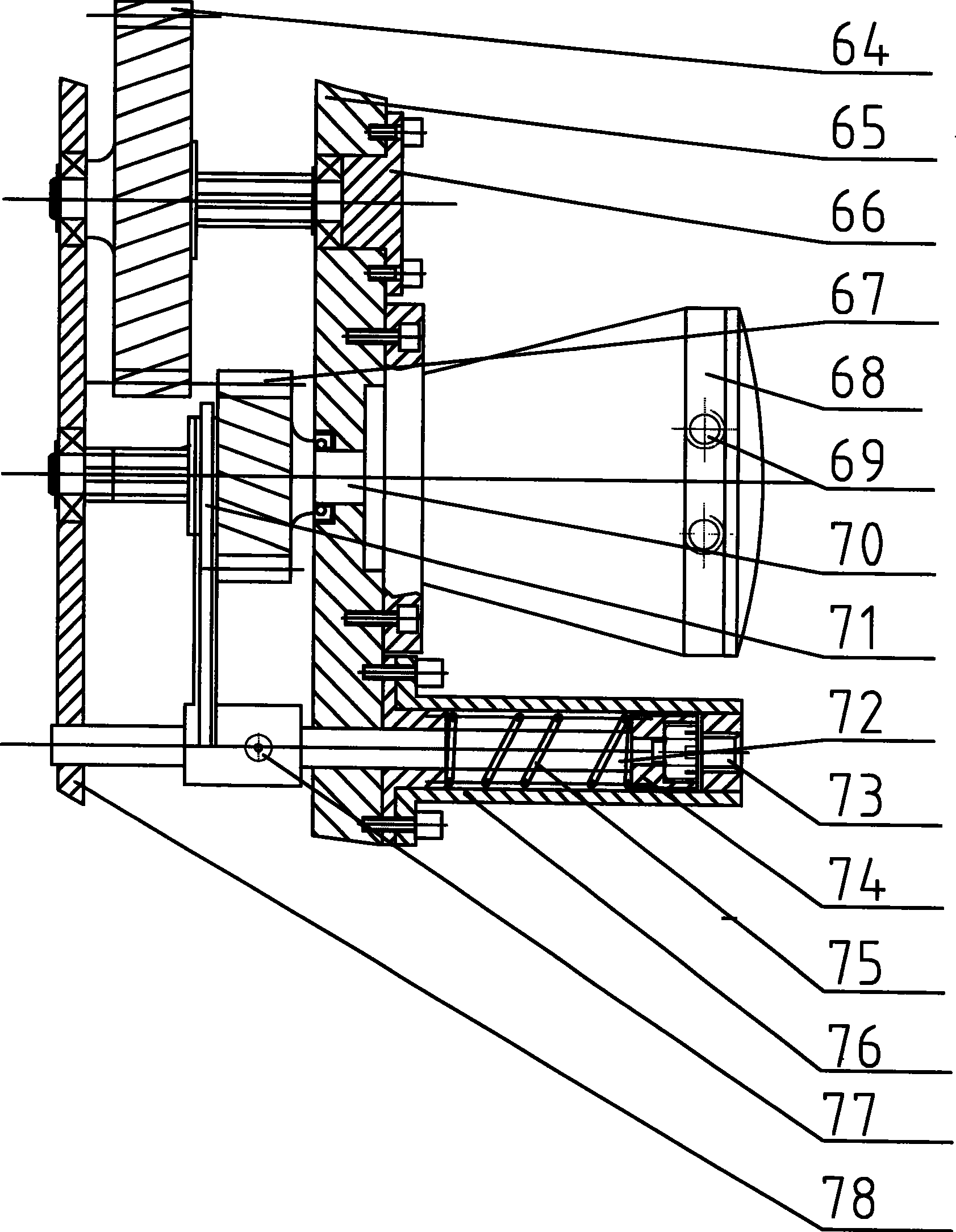

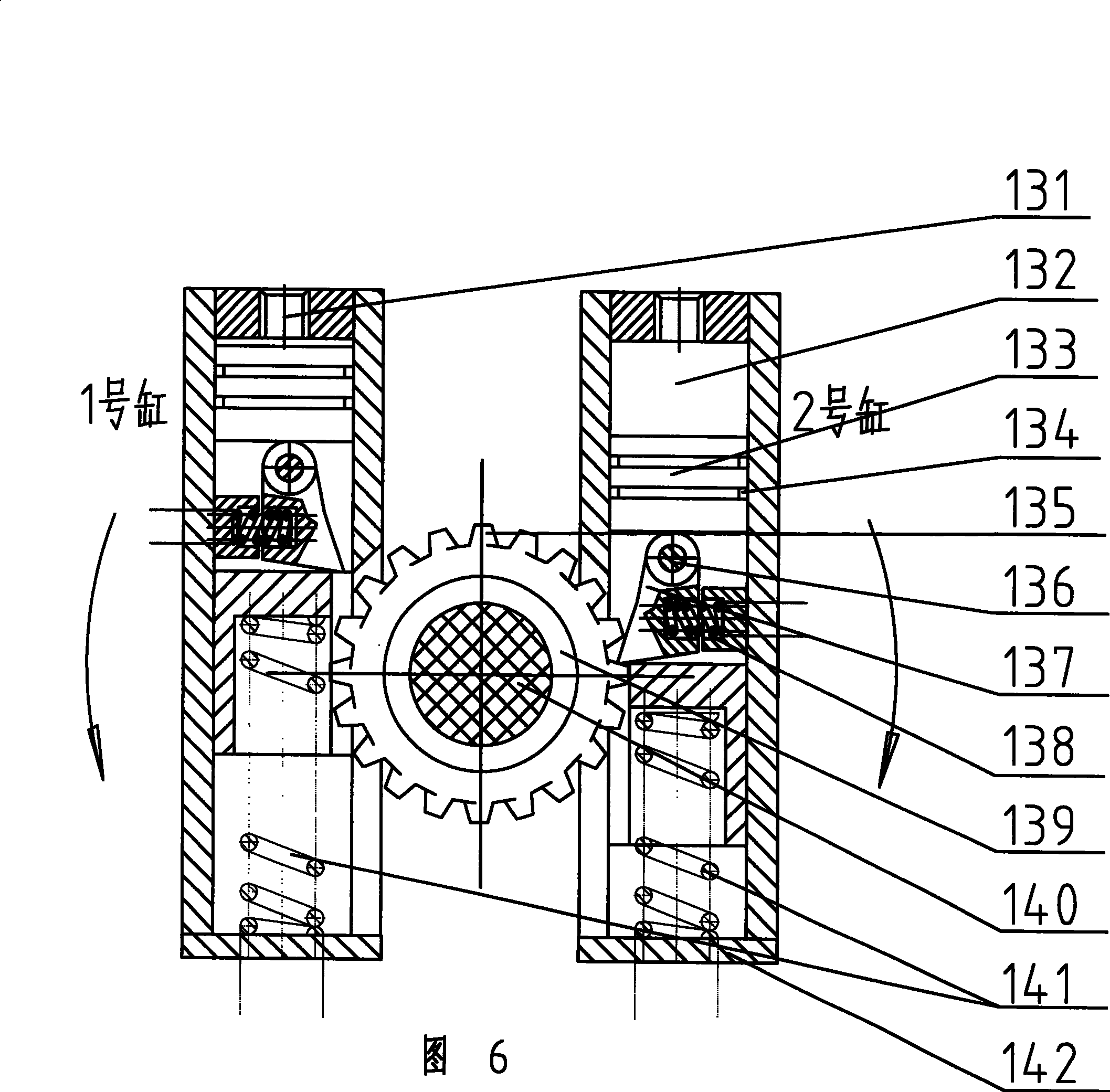

[0030] See figure 1 . The present invention is a fuel-electric dual-purpose bulldozer, which includes a chassis 10, which is equipped with a power system composed of a fuel engine 13 and an AC motor, a gearbox, a walking system including drive wheels 8, a hydraulic pump station, a hydraulic System, the operating system including the shovel arm 12 and the oil cylinder 14 and the push shovel 15, the cable reel 5, the reel oil motor 7, the transmission oil motor, and the control circuit. Among the figure: 4 sensing devices, 6 internal electric brushes, 11 driver's cab, 16 pull cable rings, 17 cable clamps, 18 reel supports, 19 gear levers, 20 joysticks, 21 accelerators. in:

[0031] The fuel engine 13 drives the input shaft of the gearbox. The AC motor 9 is connected to the cable 3 and connected to or disconnected from the power source 1 through the plug 2 . The hydraulic pump station includes a fuel hydraulic pump station driven by a fuel engine 13 and an electric hydraulic ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com