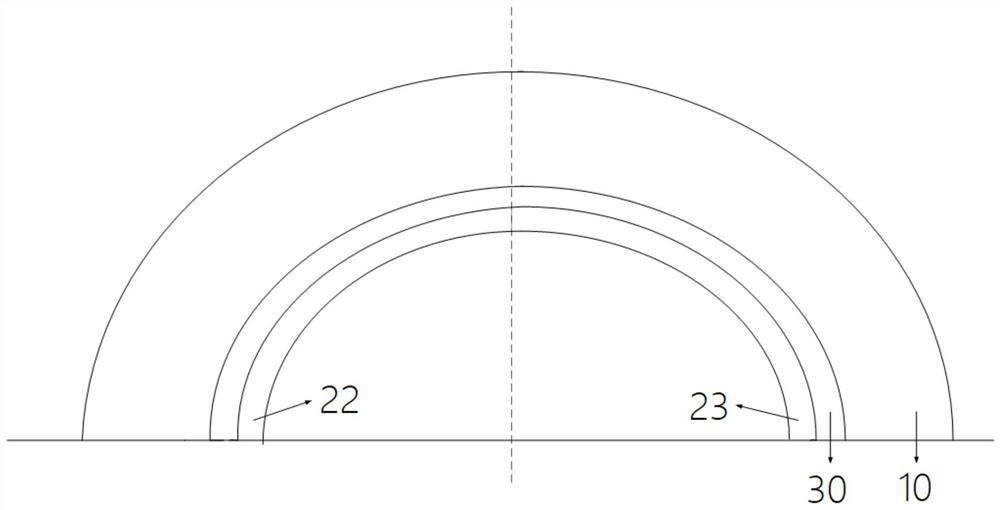

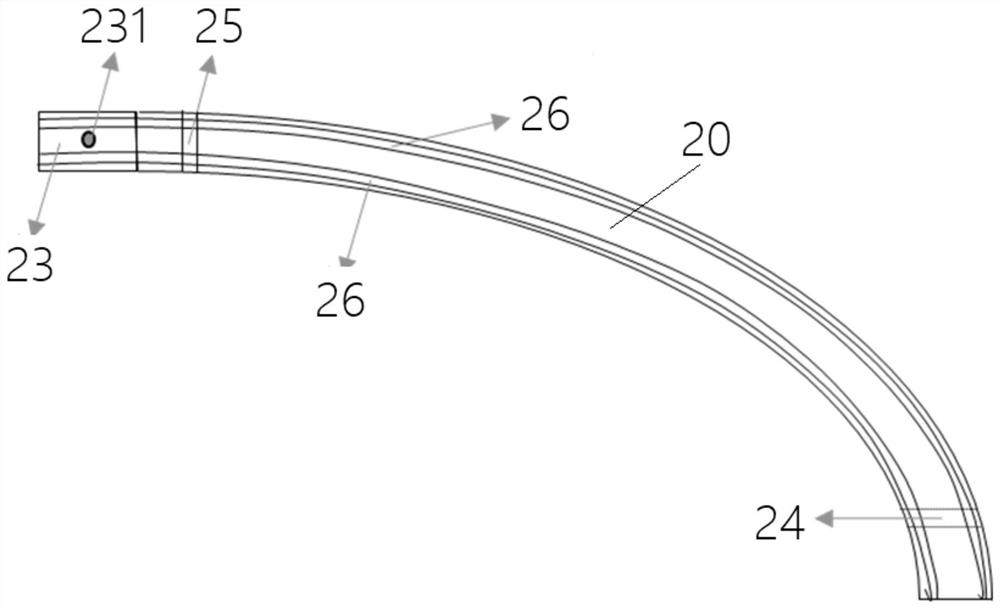

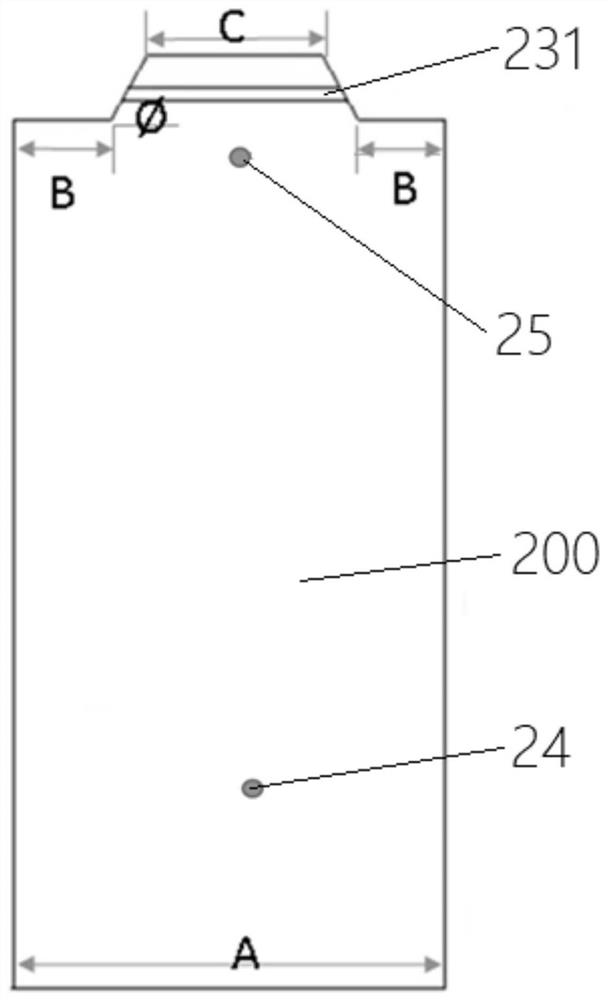

Prefabricated lining for tunnel reinforcement and installation method thereof

A lining and tunnel technology, applied in the field of tunnel reinforcement and repair construction, can solve problems affecting the normal operation of the tunnel, long-term traffic impact, closed tunnel, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] The idea, specific structure and technical effects of the present invention will be further described below in conjunction with the accompanying drawings, so as to fully understand the purpose, features and effects of the present invention.

[0052] Explanation of terms:

[0053] -------------------------------------------------- -------------------

[0054] Tunnel lining: In order to prevent the deformation or collapse of the surrounding rock, the permanent support structure is built with reinforced concrete and other materials along the periphery of the tunnel body. In most cases, a composite lining is used. Second lining) refers to the "original lining" described in this application. The prefabricated lining of the present invention is installed inside the secondary lining.

[0055] Anchor: It is a tension member that goes deep into the ground. One end of it is connected with the engineering structure, and the other end goes deep into the ground. The whole bolt is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com