Driving device for mineral aggregate transport car

A technology of driving device and transport vehicle, which is applied in the direction of transportation and packaging, wheels, trolleys, etc. It can solve the problems of large manpower requirements, poor stability, single structure, etc., and achieve the effect of fast maintenance, low cost and strong flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, so that the advantages and features of the present invention can be more easily understood by those skilled in the art, so as to define the protection scope of the present invention more clearly.

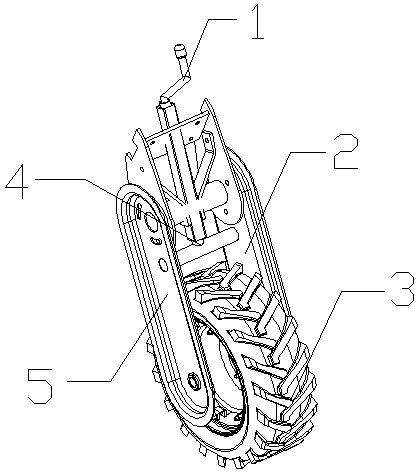

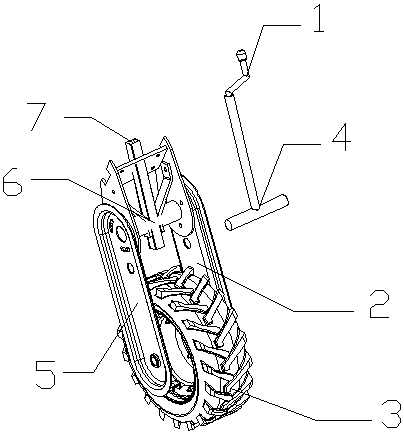

[0017] see Figure 1-2 As shown, a driving device for a mineral material transport vehicle includes a direction control rod 1 and a transmission rod 4 connected to the direction control rod 1, and the direction control rod 1 passes through the middle fixed shaft 6 through a fixing hole 7; Both sides of the middle fixed shaft 6 are connected to the left fixed plate 2 and the right fixed plate 5 respectively; the ends of the left fixed plate 2 and the right fixed plate 5 are equipped with rollers 3 .

[0018] As a technical optimization solution of the present invention, there are two symmetrical triangular structures on the intermediate fixed shaf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com