High-temperature hearth carbonizing furnace

A carbonization furnace and furnace technology, which is applied in coke ovens, by-product vaporization, chemical instruments and methods, etc., can solve the problems of low utilization rate of carbonized by-products, not very good effect, energy waste, etc., to avoid energy gas waste, The effect of shortening carbonization time and reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

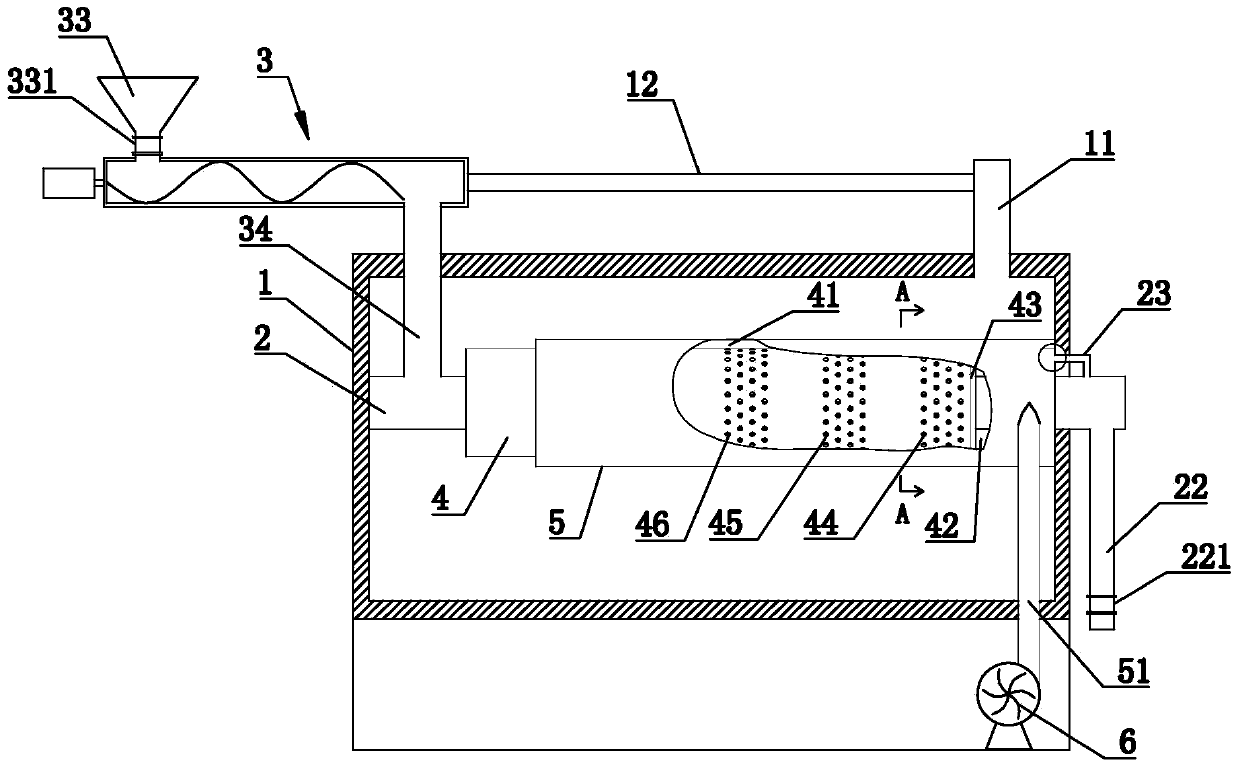

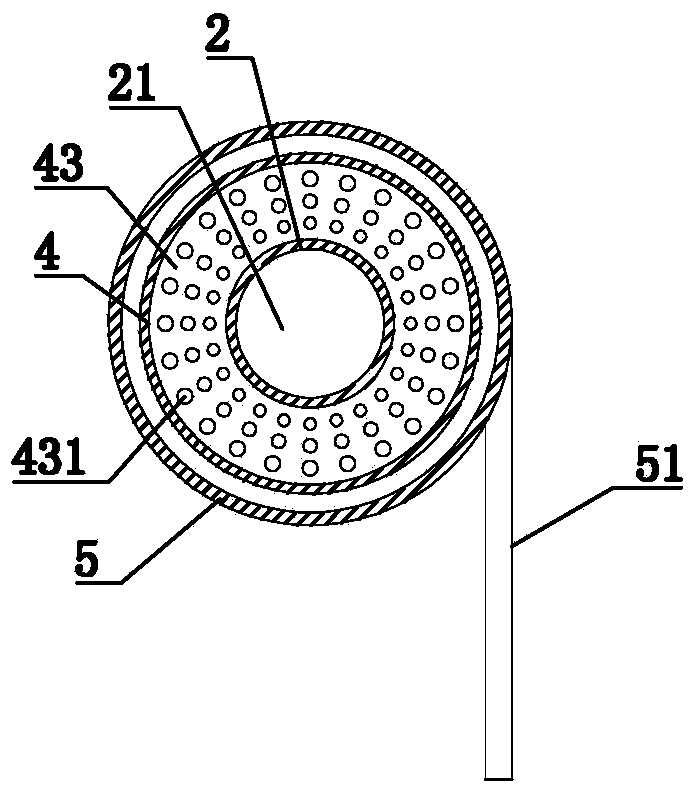

[0024] Such as figure 1 and figure 2 As shown, the high-temperature hearth carbonization furnace includes a furnace body shell 1, the space surrounded by the furnace body shell 1 is the furnace hearth, the furnace body shell 1 is provided with a smoke exhaust port 11, and the inner wall of the furnace body shell 1 is provided with silicate insulation material to avoid heat loss in the carbonization furnace.

[0025] The furnace is provided with a carbonization chamber 21 surrounded by carbonization tubes 2. One end of the carbonization tube 2 protrudes from the furnace shell 1 and is provided with a carbon particle outlet 22. The furnace shell 1 is also connected with a feeding device.

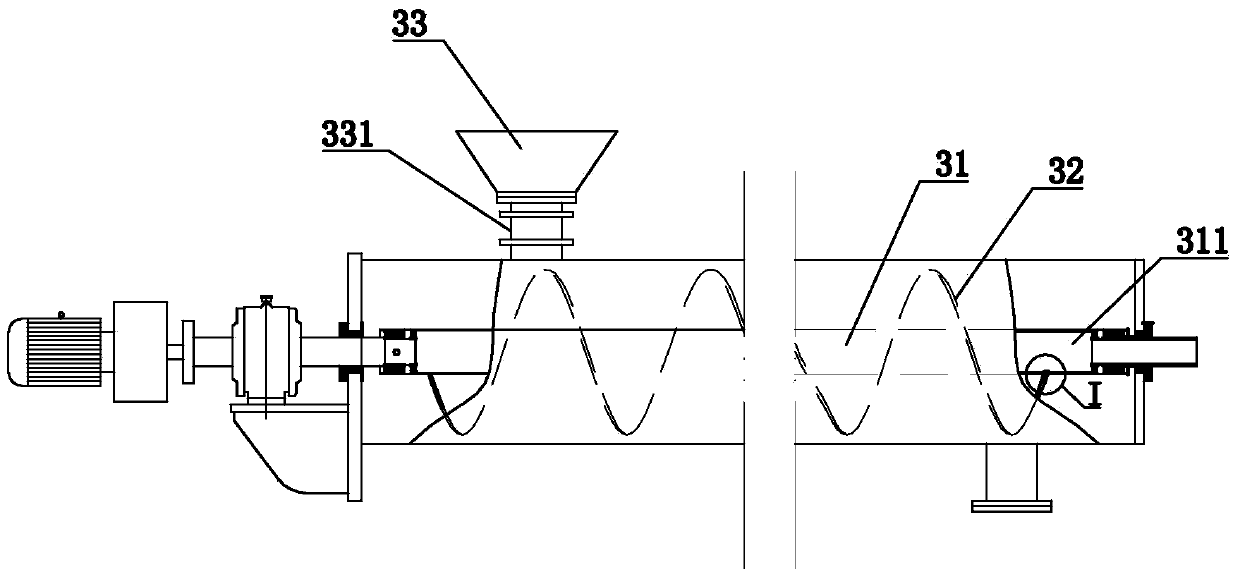

[0026] Preferably, the feeding device is a screw feeding device 3, such as image 3 and Figure 4 Commonly shown, the inside of the screw feeding device 3 is provided with a rotating shaft 31 driven by a power unit, and a screw blade 32 installed on the rotating shaft 31. The inside of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com