Method for purifying sodium chloride and preparing doped carbon by pyrolyzing organic waste salt

A technology of sodium chloride and pyrolysis, applied in the preparation/purification of carbon, purification of alkali metal halides, etc., can solve the problems of occupation, waste salt is not effectively treated, waste of recyclable resources, etc., to achieve the realization of salt resources The effect of chemical utilization and promoting sustainable and coordinated development

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

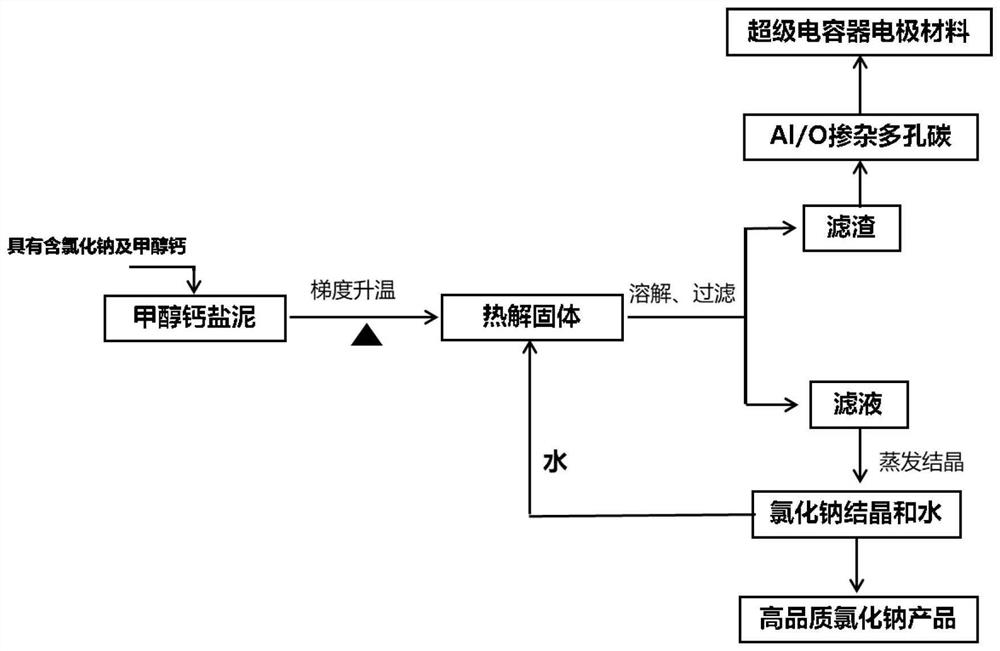

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] (1) Fully grind and sieve 5g of calcium methoxide waste salt (200 mesh);

[0037] (2) The calcium methoxide waste salt with uniform texture obtained in step (1) is placed in a tube furnace, and pyrolyzed in a nitrogen atmosphere at 350° C. for 2 hours;

[0038] (3) At room temperature of 24°C, cool the pyrolyzed solid obtained in step (2) to room temperature, weigh 4 g of the pyrolyzed solid, add 12 g of water to the weighed pyrolyzed solid, and stir thoroughly for 5 minutes, Make the waste salt fully dissolve completely, and then let it stand for 25 minutes to separate layers to obtain the upper and lower layers of liquid;

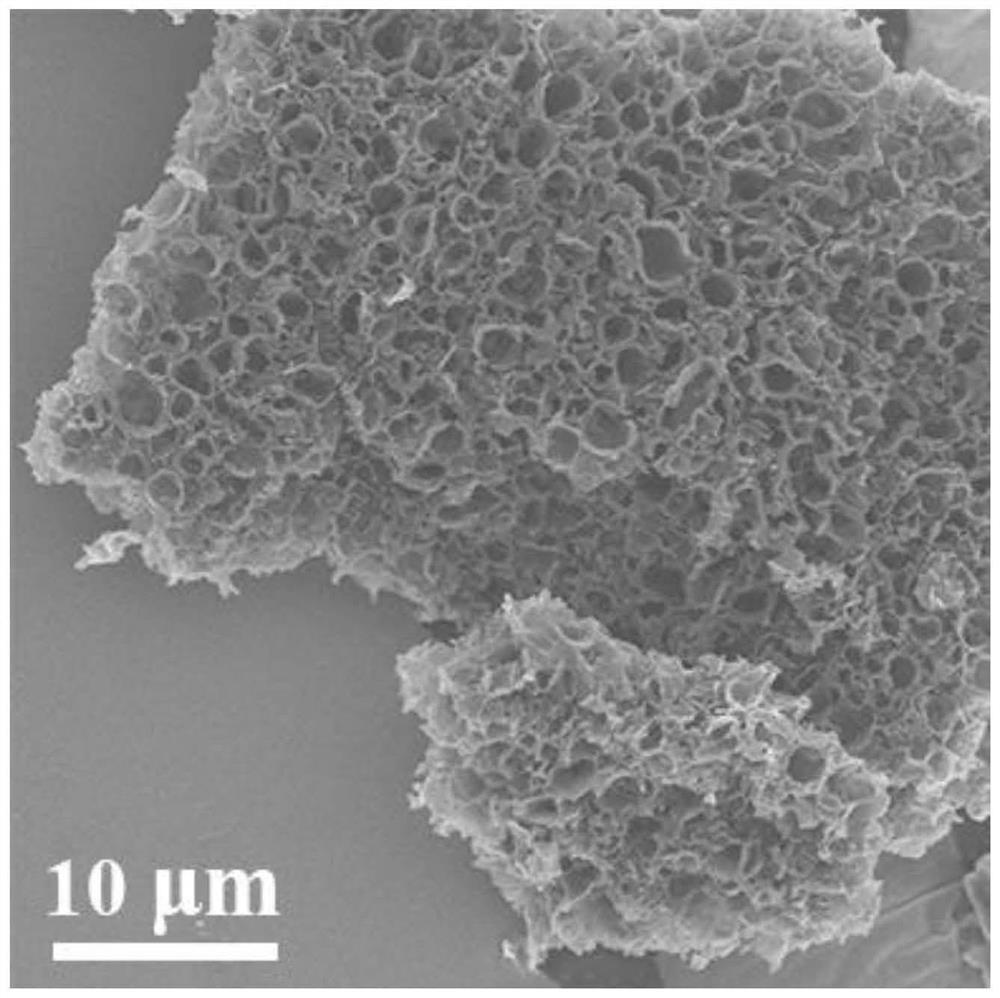

[0039] (4) filtering and separating the upper and lower layers of liquid obtained in step (3), drying the filter residue after filtering the upper layer of liquid, the drying temperature is 60°C, and reclaiming Al / O doped carbon material;

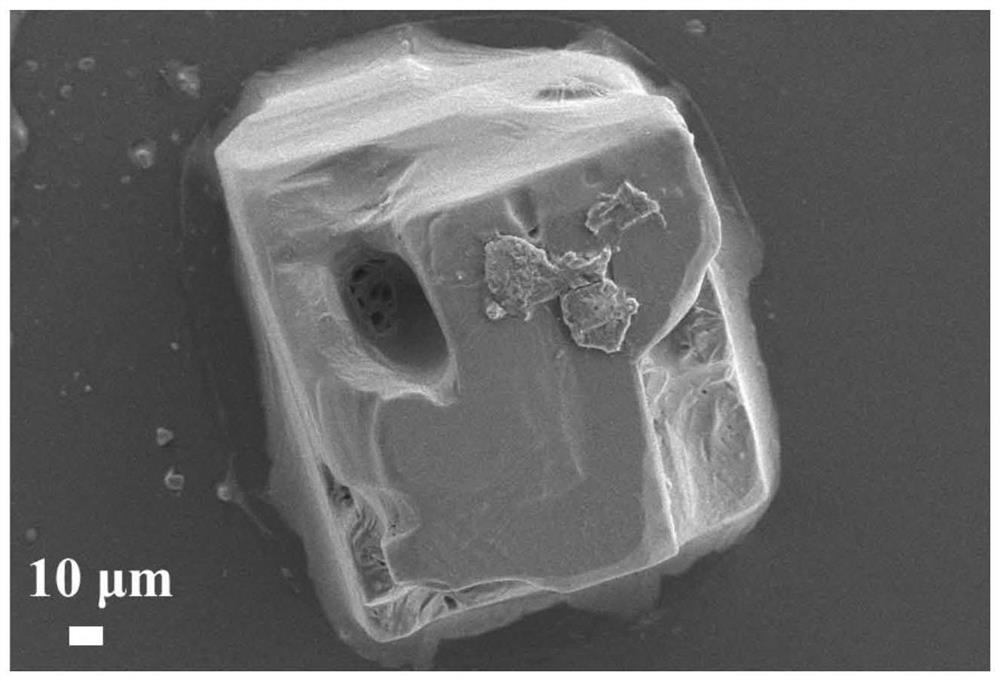

[0040] (5) Evaporate and crystallize the filtrate obtained in step (4) and the lower layer liquid in step (3...

Embodiment 2

[0044] (1) Fully grind and sieve 5g of calcium methoxide waste salt (150 mesh);

[0045] (2) The calcium methoxide waste salt slag obtained in step (1) is placed in a tube furnace, and pyrolyzed in a nitrogen atmosphere at 450° C. for 2 hours;

[0046] (3) At room temperature of 24°C, cool the pyrolyzed solid obtained in step (2) to room temperature, weigh 4 g of the pyrolyzed solid, add 20 g of water to the weighed pyrolyzed solid, and stir thoroughly for 5 minutes, Make the waste salt fully dissolve completely, and then let it stand for 35 minutes to separate layers to obtain the upper and lower layers of liquid;

[0047] (4) filtering and separating the upper and lower layers of liquid obtained in step (3), drying the filter residue after filtering the upper layer of liquid, the drying temperature is 70°C, and reclaiming Al / O doped carbon materials;

[0048] (5) Evaporate and crystallize the filtrate obtained in step (4) and the lower layer liquid in step (3) at 80° C., an...

Embodiment 3

[0052] (1) Fully grind and sieve 5g of calcium methoxide waste salt (100 mesh);

[0053] (2) The calcium methoxide waste salt slag with uniform texture obtained in step (1) is placed in a tube furnace, and pyrolyzed in an argon atmosphere at 550° C. for 2 hours;

[0054](3) At room temperature of 24°C, cool the pyrolyzed solid obtained in step (2) to room temperature, weigh 4g of the pyrolyzed solid, add 24g of water to the weighed pyrolyzed solid, and stir thoroughly for 5 minutes, Make the waste salt fully dissolve completely, and then let it stand for 45 minutes to separate layers to obtain the upper and lower layers of liquid;

[0055] (4) filtering and separating the upper and lower layers of liquid obtained in step (3), drying the filter residue after filtering the upper layer of liquid, the drying temperature is 80 ° C, and reclaiming Al / O doped carbon materials;

[0056] (5) evaporating and crystallizing the filtrate obtained in step (4) and the lower layer liquid of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com