Thermal cycle accurate temperature control gradient carbonization equipment and method for sludge treatment

A thermal cycle and equipment technology, applied in pyrolysis treatment of sludge, lighting and heating equipment, combustion methods, etc., can solve the problem of long-term operation stability of the drum carbonization furnace, and has not proposed the feasibility of sludge mixed with biomass, Lack of devices and methods for compounding biochar to achieve the effects of increasing calorific value, convenient maintenance, and thorough carbonization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0081] The present invention will be further described in detail below in conjunction with specific examples, but the embodiments of the present invention are not limited thereto, and for process parameters not specifically indicated, conventional techniques can be referred to.

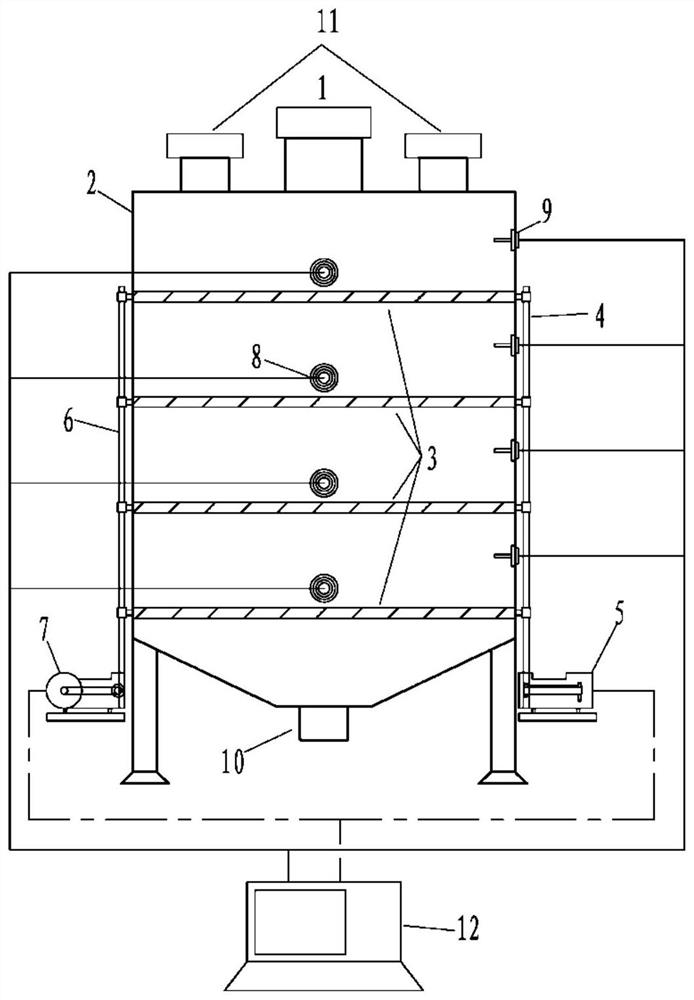

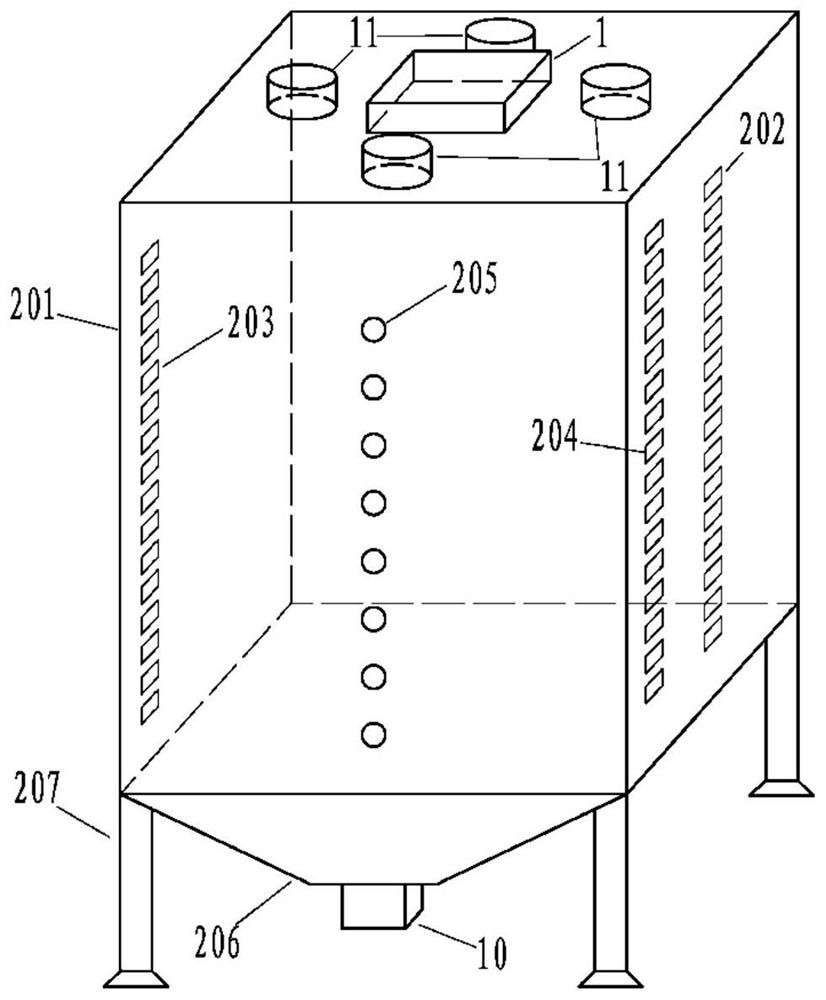

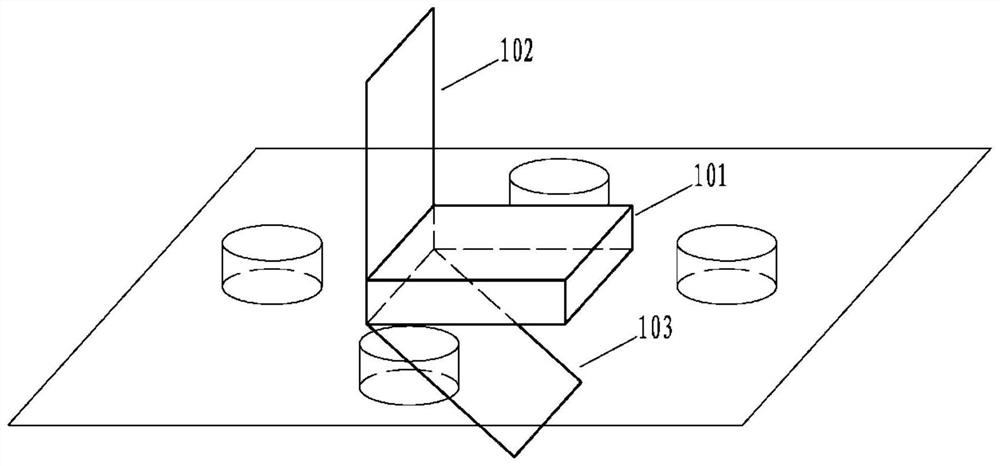

[0082] Such as Figure 1~Figure 12 As mentioned above, a kind of thermal cycle precise temperature control gradient carbonization equipment is provided with more than one vibrating flap 3 inside the equipment, and each vibrating flap 3 is arranged up and down, and a heating device, the heating port of the heating device is located on both sides of the vibrating flap 3; the vibrating flap 3 has the effect of vibrating and rolling the sludge on the plate surface; the heating device makes the temperature in the equipment have a gradient Transformation, the hot air flow in the equipment is internally circulated. The heating device is a burner 8 or a stainless steel electric heating tube, a ceramic electr...

Embodiment 1

[0093] The low-temperature carbonization process requires a treatment capacity of 850 kg / h for dry water body dredging sludge sludge biomass mixture (biomass content is 2%):

[0094] 1) The furnace body 2 of the vertical sludge carbonization equipment is equipped with 16 vibration flaps 3, 8 burners 8, and 8 temperature sensors 9; the central control system 12 controls the 8 burners 8 to start at the maximum power, and the opposite vertical sewage The furnace body 2 of the peatization equipment is preheated; the preheating target temperature is up to 300°C, and the eight burners 8 are started at the same time. When reaching 240°C, the second burner 8 is closed, and so on, until the temperature of the lowest two layers reaches 300°C, and the temperature in the carbonization furnace cavity 201 is fed back in real time by the temperature sensor 9;

[0095] 2) After the preheating temperature reaches 300°C, the temperature sensor 9 feeds back information to the central control sys...

Embodiment 2

[0104] The high-temperature rapid carbonization process requires a treatment capacity of 1200 kg / h for dry printing and dyeing sludge (the printing and dyeing sludge contains biomass, with a content of about 2%):

[0105] 1) Furnace body 2 of vertical sludge carbonization equipment is equipped with 6 vibration flaps 3, 6 burners 8, and 6 temperature sensors 9; the central control system 12 controls 6 burners 8 to start at maximum power, vertical sludge The preheating target temperature of the carbonization equipment furnace body 2 is up to 600°C, and the six burners 8 are started at the same time. When the temperature of the uppermost layer reaches 500°C, the uppermost burner 8 is turned off. Two burners 8 are closed, and so on, until the temperature of the lowest layer reaches 600 ° C, the vibration flap 3 is adjusted to a horizontal state and starts to oscillate, and the temperature in the carbonization furnace cavity 201 is fed back in real time by the temperature sensor 9; ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com