High-speed preparation method for producing large-tow carbon fibers

A technology of tow carbon fiber and large tow, which is applied in the field of high-speed preparation of large tow carbon fiber, can solve the problems of lack of large tow carbon fiber technology, discrete fiber indicators, and difficult pre-oxidation, etc., to improve the scale of enterprises Production efficiency, reduce unit production consumption, and ensure performance effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

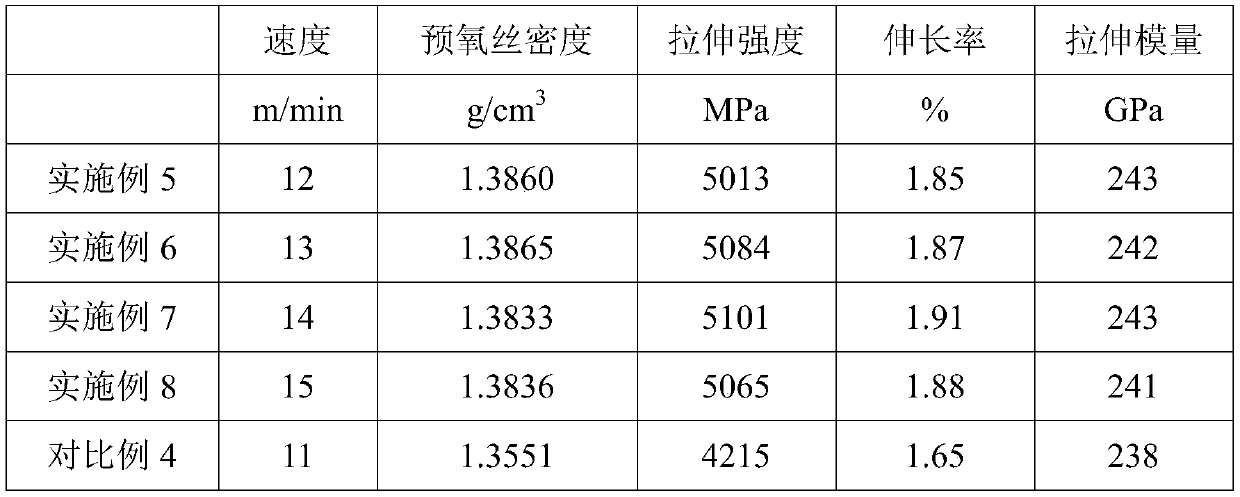

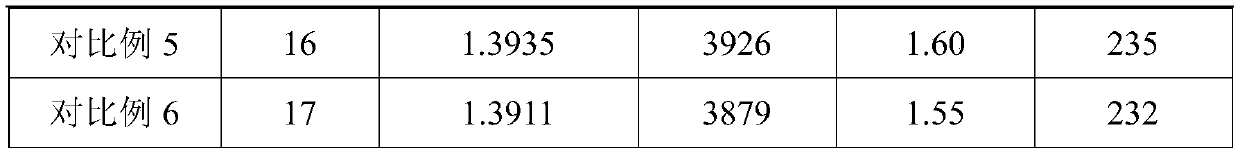

Embodiment 1

[0019] Choose the 25K large-tow polyacrylonitrile copolymer fiber (precursor) produced by Jilin Carbon Valley Company produced by wet spinning, the PAN copolymer fiber containing more than 90% acrylonitrile monomer components, in the air medium, the speed is 12m / Under the conditions of 230°C, 238°C, 247°C, 255°C, 261°C, and 270°C, six-stage pre-oxidation furnaces were used for treatment under the condition of 270°C. The oxidation time was 50 minutes, and the draw ratio was 1.01, resulting in a density of 1.3844g / cm 3 Then, under the protection of nitrogen, the pre-oxidized wire was carbonized at 800°C for 63s at a low temperature, with a draft ratio of 1.01; at a high temperature of 1200°C, with a draft ratio of 0.97, and a high temperature carbonization time of 63s, and then passed through the surface Processing, sizing, and drying to obtain 25K large-tow carbon fibers.

[0020] The prepared large-tow carbon fiber was prepared with Beihua resin A / Beihua resin B / acetone (1:0....

Embodiment 2

[0022] Choose the 25K large tow polyacrylonitrile copolymer fiber (precursor) produced by Jilin Carbon Valley Company produced by wet spinning, the PAN copolymer fiber containing more than 90% acrylonitrile monomer components, in air medium, the speed is 13m / Under the condition of 235°C, 243°C, 252°C, 260°C, 264°C, and 273°C, six gradient pre-oxidation furnaces were used for treatment, the oxidation time was 45min, the draw ratio was 1.01, and the density was 1.3850g / cm 3 Then, under the protection of nitrogen, the pre-oxidized wire was carbonized at 800°C for 63s at a low temperature, with a draft ratio of 1.01; at a high temperature of 1200°C, with a draft ratio of 0.97, and a high temperature carbonization time of 63s, and then passed through the surface Processing, sizing, and drying to obtain 25K large-tow carbon fibers.

[0023] The prepared large-tow carbon fiber was prepared with Beihua resin A / Beihua resin B / acetone (1:0.34:12) to prepare a mixed resin, dipped and cu...

Embodiment 3

[0025] Choose the 25K large tow polyacrylonitrile copolymer fiber (precursor) produced by the Jilin Carbon Valley Company produced by wet spinning, the PAN copolymer fiber containing more than 90% acrylonitrile monomer components, in the air medium, the speed is 14m / Under the condition of 240°C, 248°C, 256°C, 266°C, 269°C, and 276°C, the six-stage gradient pre-oxidation furnace was used for treatment under the condition of 240°C, the oxidation time was 42.9min, the draw ratio was 1.01, and the density was 1.3812g / cm 3 Then, under the protection of nitrogen, the pre-oxidized wire was carbonized at 800°C for 63s at a low temperature, with a draft ratio of 1.01; at a high temperature of 1200°C, with a draft ratio of 0.97, and a high temperature carbonization time of 63s, and then passed through the surface Processing, sizing, and drying to obtain 25K large-tow carbon fibers.

[0026] The prepared large-tow carbon fiber was prepared with Beihua resin A / Beihua resin B / acetone (1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Tensile modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com