Preparation method of melamine resin modified nitrogen-rich porous carbon fiber electrode material

A technology of porous carbon fiber and melamine resin, which is applied in the fields of fiber chemical characteristics, hybrid/electric double layer capacitor manufacturing, textile and papermaking, etc., can solve the problems of complicated production process and high production cost of porous nitrogen-containing carbon electrode materials, and achieve The effect of high specific capacitance per unit, improving production efficiency and high specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Add 5g of melamine into 15g of 37wt% formaldehyde solution, adjust the pH to about 9 with triethanolamine, stir in a water bath at 80°C for 40min, pour into cold methanol, precipitate out, filter, wash and dry.

[0028] Add 2g of polyacrylonitrile into 20g of N,N-dimethylformamide, dissolve and add 0.5g of the prepared melamine resin, and dissolve to obtain a spinning solution.

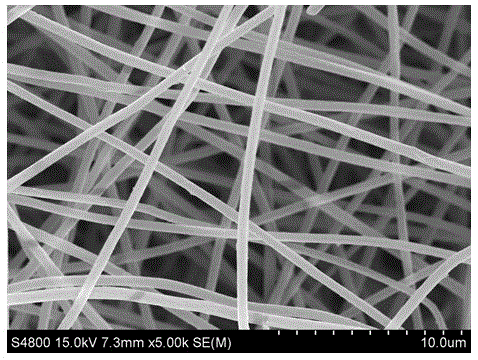

[0029] The melamine resin / polyacrylonitrile composite fiber was spun by high-voltage electrospinning technology, wherein the spinning voltage was 20kV, the injection speed was 0.3mm / min, the receiving distance was 17cm, the spinning temperature was 40°C, and the humidity was 30%.

[0030] The prepared composite fibers were pre-oxidized in an air atmosphere for 2 hours, the pre-oxidation temperature was 250°C, the heating rate was 5°C / min, and the cooling rate was 5°C / min.

[0031] The pre-oxidized fibers were carbonized for 2 hours under nitrogen or argon atmosphere, the carbonization temperat...

Embodiment 2

[0036] Add 5g of melamine into 15g of 37wt% formaldehyde solution, adjust the pH to about 9 with triethanolamine, stir in a water bath at 80°C for 40min, pour into cold methanol, precipitate out, filter, wash and dry.

[0037] Add 2 g of polyacrylonitrile into 18 g of N,N-dimethylformamide, dissolve it, add 1 g of the prepared melamine resin, and dissolve to obtain a spinning solution.

[0038] The melamine resin / polyacrylonitrile composite fiber was spun by high-voltage electrospinning technology, wherein the spinning voltage was 17kV, the injection speed was 0.1mm / min, the receiving distance was 20cm, the spinning temperature was 40°C, and the humidity was 30%.

[0039] The prepared composite fibers were pre-oxidized in an air atmosphere for 2 hours, the pre-oxidation temperature was 250°C, the heating rate was 5°C / min, and the cooling rate was 5°C / min.

[0040] The pre-oxidized fibers were carbonized for 2 hours under nitrogen or argon atmosphere, the carbonization tempera...

Embodiment 3

[0045] Add 5g of melamine into 15g of 37wt% formaldehyde solution, adjust the pH to about 9 with triethanolamine, stir in a water bath at 80°C for 40min, pour into cold methanol, precipitate out, filter, wash and dry.

[0046] Add 2 g of polyacrylonitrile into 18 g of N,N-dimethylformamide, dissolve it, add 1.5 g of the prepared melamine resin, and dissolve to obtain a spinning solution.

[0047] The melamine resin / polyacrylonitrile composite fiber was spun by high-voltage electrospinning technology, wherein the spinning voltage was 20kV, the injection speed was 0.5mm / min, the receiving distance was 20cm, the spinning temperature was 20°C, and the humidity was 30%.

[0048] The prepared composite fibers were pre-oxidized in an air atmosphere for 2 hours, the pre-oxidation temperature was 250°C, the heating rate was 3°C / min, and the cooling rate was 3°C / min.

[0049] The pre-oxidized fibers were carbonized for 2 hours under nitrogen or argon atmosphere, the carbonization tempe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com