A small domestic waste low-temperature pyrolysis furnace flue gas purification device

A low-temperature pyrolysis technology for domestic waste, which is applied in combined devices, gas treatment, steam condensation, etc., can solve the problems of difficulty in meeting dioxin emission standards, high tar content in flue gas, and easy blockage of flue gas pipes, etc., to achieve tar removal Good effect, low consumption and low investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] In order to better understand the present invention, the present invention will be further described below in conjunction with the accompanying drawings, but the embodiments of the present invention are not limited thereto.

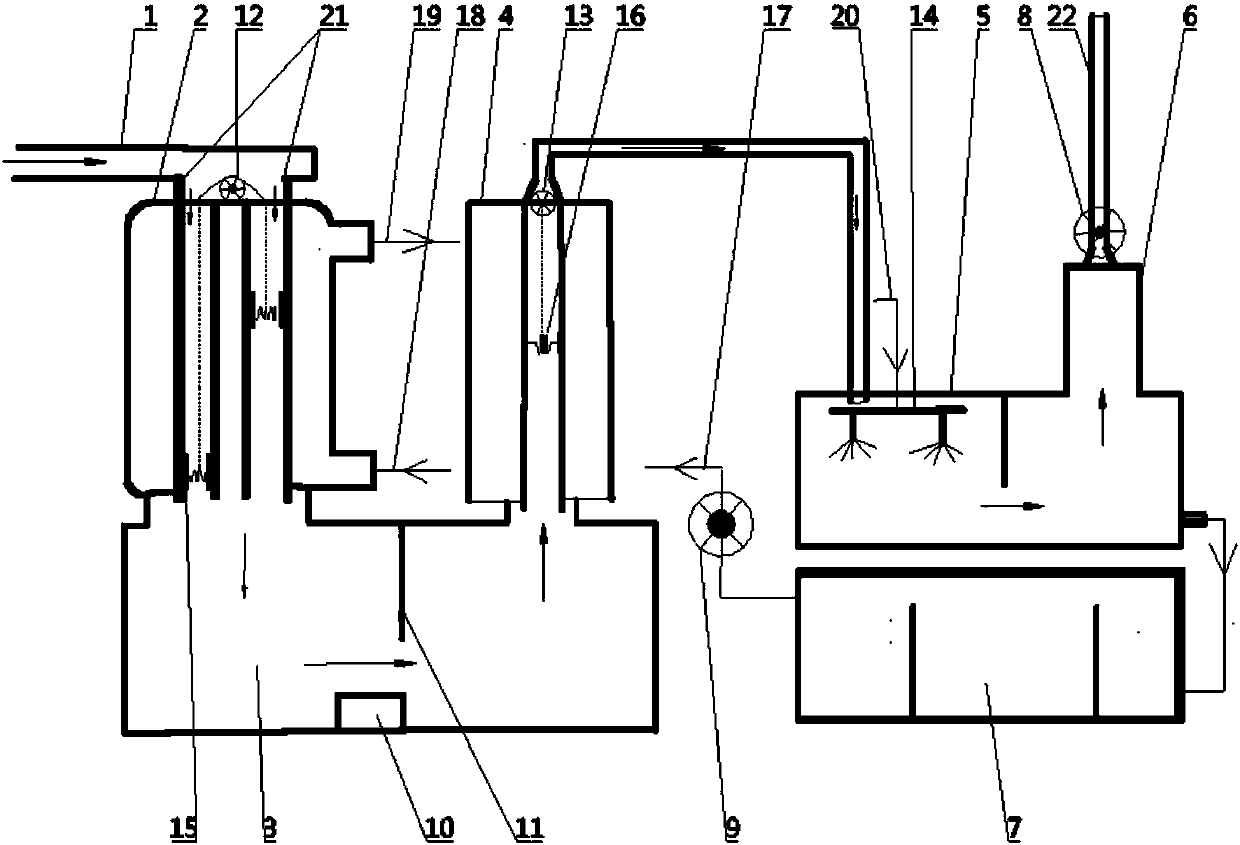

[0036] Such as figure 1 As shown, a small domestic waste low-temperature pyrolysis furnace flue gas purification device includes a tar condenser 2, a tar collection box 3, an electrostatic decoker 4, a wet scrubber 5, a dioxin adsorption bed 6 and a three-stage sedimentation pool 7; the tar condenser 2 and the electrostatic decoker 4 are arranged above the tar collection box 3, and communicate with the tar collection box 3; the electrostatic decoker 4 is connected to the wet scrubber 5 through pipelines; the dioxin adsorption bed 6 It is arranged at the upper end of the wet scrubber 5 and communicates with the wet scrubber 5, and the lower end of the wet scrubber 5 communicates with the tertiary sedimentation tank 7.

[0037] The tar condenser 2 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com