Chelating agent for treating medical waste incineration fly ash and preparation method thereof

A technology for incinerating fly ash and medical waste, which is applied in the direction of protective devices against harmful chemicals, etc. It can solve the problems of inability to decompose or stabilize fly ash dioxins, and long time, so as to reduce the content and cost of heavy metals and dioxins Low, burden-reducing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

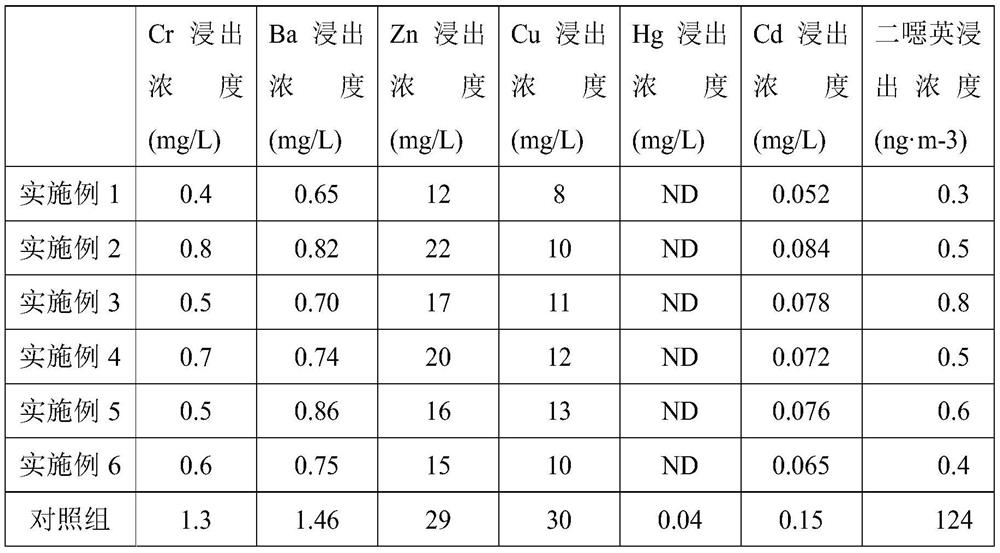

Examples

Embodiment 1

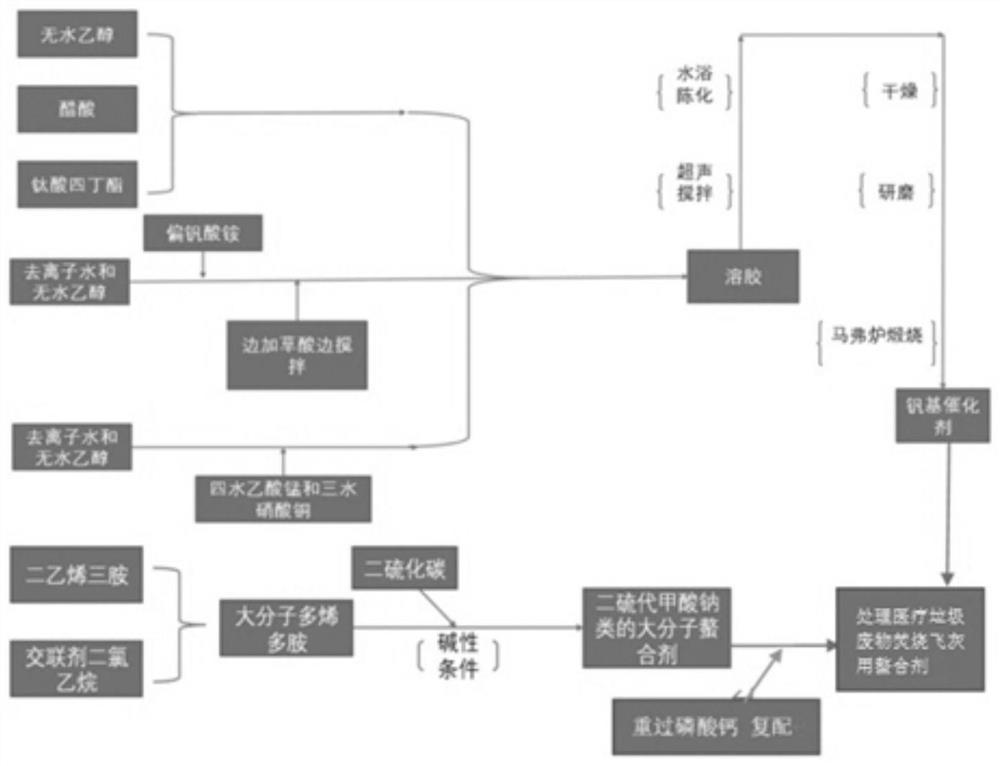

[0033] Such as figure 1 As shown, the present embodiment provides a method for preparing a chelating agent for processing medical waste waste incineration fly ash, comprising the following steps:

[0034] S1. Preparation of organic chelating agent: 10 parts of diethylenetriamine and 5 parts of dichloroethane are mixed and reacted to obtain macromolecular polyene polyamine, and macromolecular polyene polyamine is reacted with 5 parts of carbon disulfide under alkaline conditions. Get sodium dithioformate;

[0035] S2. Preparation of vanadium-based catalyst:

[0036] S21. Stir 5 parts of absolute ethanol, 5 parts of acetic acid and 10 parts of tetrabutyl titanate evenly to obtain solution 1;

[0037] S22. Put 10 parts of ammonium metavanadate solution in a mixed solution of deionized water and absolute ethanol, then add 2 parts of oxalic acid dropwise to the mixed solution while stirring to obtain solution 2;

[0038] S23. Add 5 parts of manganese acetate tetrahydrate and 10 ...

Embodiment 2

[0043] The present embodiment provides a kind of preparation method of chelating agent for processing medical waste waste incineration fly ash, comprising the following steps:

[0044] S1. Preparation of organic chelating agent: 10 parts of diethylenetriamine and 5 parts of dichloroethane are mixed and reacted to obtain macromolecular polyene polyamine, and macromolecular polyene polyamine is reacted with 5 parts of carbon disulfide under alkaline conditions. Get sodium dithioformate;

[0045] S2. Preparation of vanadium-based catalyst:

[0046] S21. Stir evenly 10 parts of absolute ethanol, 2 parts of acetic acid and 5 parts of tetrabutyl titanate to obtain a solution 1;

[0047] S22. Put 5 parts of ammonium metavanadate solution in a mixed solution of deionized water and absolute ethanol, then add 5 parts of oxalic acid dropwise to the mixed solution while stirring to obtain solution 2;

[0048] S23. Add 8 parts of manganese acetate tetrahydrate and 5 parts of copper nitra...

Embodiment 3

[0053] Referring to Example 1, this example differs from Example 1 in that the mass parts of each raw material in step S21 are as follows: absolute ethanol: 2 parts, acetic acid: 10 parts, tetrabutyl titanate 4 parts.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com