Superheater for waste heat boiler of waste incineration system

A technology for waste incineration and waste heat boilers, applied in incinerators, steam superheating, combustion methods, etc., can solve the problems of unfavorable exhaust gas treatment, no waste heat boilers, and a large amount of dioxins, so as to ensure steam supply and reduce difficulty. , the effect of improving heat conversion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

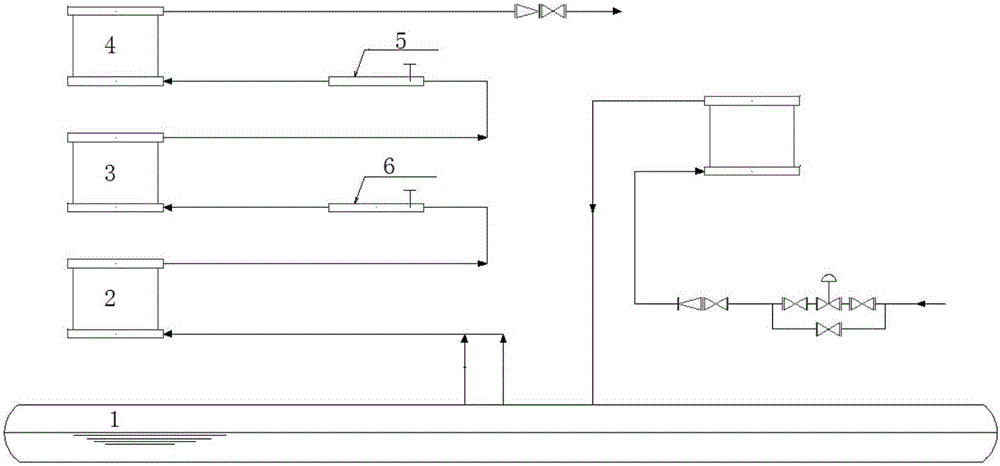

[0015] The superheater for the waste heat boiler in the waste incineration system is installed in the flue. 4 components, by setting three sets of superheaters, it is possible to control the steam temperature and prevent the flue gas temperature from dropping too fast, so as to avoid the generation of dioxin.

[0016] Such as figure 1 As shown, the inlet header of the first superheater 2 is connected to the saturated steam output pipe of the steam drum 1, the outlet header of the first superheater 2 is connected to the inlet header of the second superheater 3 through the first desuperheater 6, and the first The outlet header of the second superheater 3 is connected to the inlet header of the third superheater 4 via the second desuperheater 5, and the outlet header of the third superheater 4 is connected to the main steam pipeline. Between the outlet header and the inlet header is the pipe for the superheater.

[0017] The main flue above the combustion chamber is connected t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com