Waste incineration treatment process

A waste incineration and treatment process technology, applied in the direction of incinerator, combustion method, combustion type, etc., can solve the problem of limited fly ash treatment effect, achieve the effect of reducing poor curing effect, reducing volume expansion ratio, and good adsorption and curing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] A waste incineration treatment process, comprising the following steps:

[0036] Incineration: The garbage in the garbage pool is lifted into the incinerator for incineration, and the deodorization treatment is carried out during the lifting process of the garbage, and oxygen is introduced into the incinerator at the same time;

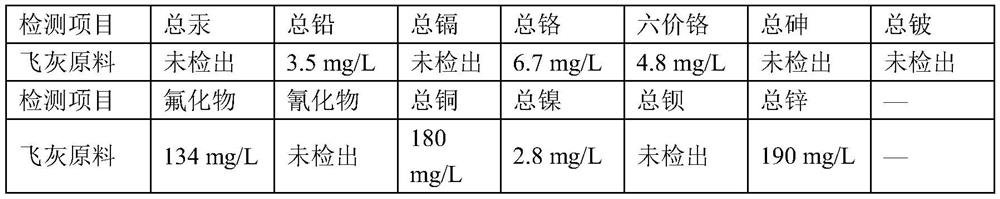

[0037] Flue gas treatment: the flue gas enters the semi-dry spray reaction tower, and the lime slurry is sprayed in the tower for acid removal operation to obtain fly ash residue. Flue gas and incineration fly ash to be discharged;

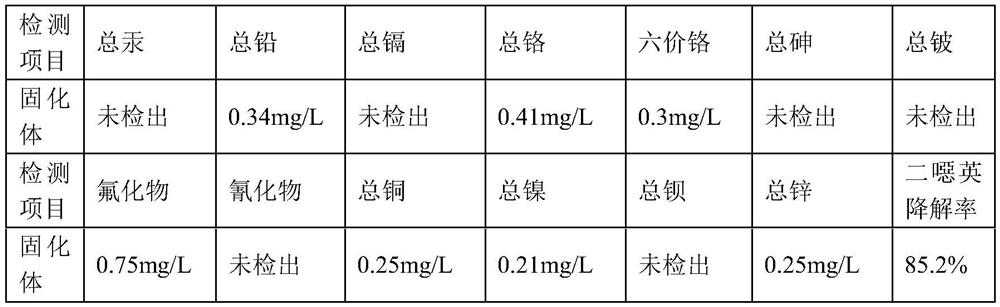

[0038] Incineration fly ash treatment: Mix and stir the incineration fly ash and the treatment agent under the irradiation of a mercury lamp, add the cementitious material, and finally add water and stir to form a block to obtain a solidified body, and then perform landfill post-treatment;

[0039] Wherein, the addition amount of treatment agent is 5wt% of the mass of incineration fly ash, the addition amount of c...

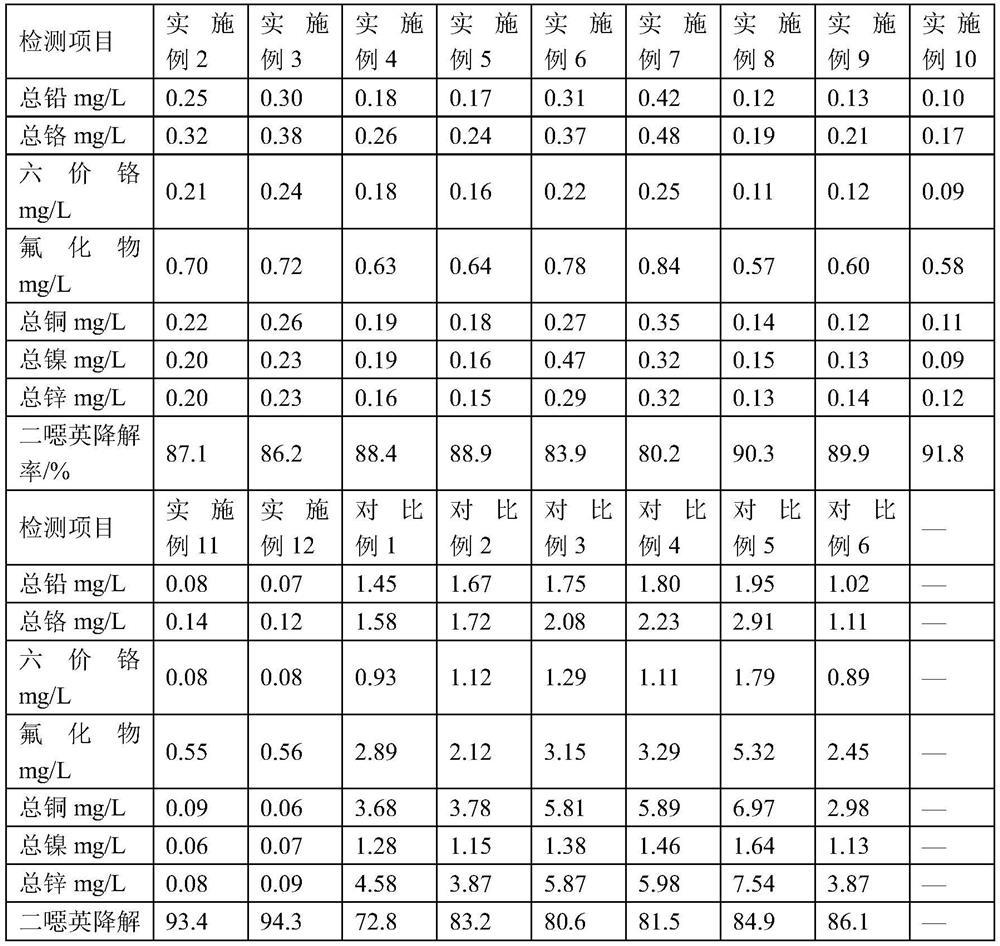

Embodiment 2

[0045]A waste incineration treatment process, carried out according to the method in Example 1, the difference is that the addition of the treatment agent is 8wt% of the mass of the incineration fly ash, and the addition of the cementitious material is 18wt% of the mass of the incineration fly ash, The amount of water added is 32wt% of the incineration fly ash mass;

[0046] The cementitious material is cement and water glass with a mass ratio of 1:0.4;

[0047] Prepare the biochar loaded with graphene oxide according to the following steps:

[0048] Dissolve 30kg of graphene oxide in water of 2 volume multiples, then soak 30kg of biochar in the graphene oxide solution for 30 minutes, and dry at 50°C for 30 minutes to obtain graphene oxide-loaded biochar.

[0049] The treatment agent is made by the following steps:

[0050] Get 30kg of biochar, 20kg chelating agent, 10kg hydrotalcite and 8kg nano-titanium dioxide that are loaded with graphene oxide that 30kg above-mentioned ...

Embodiment 3

[0052] A waste incineration treatment process, carried out according to the method in Example 1, the difference is that the addition of the treatment agent is 12wt% of the mass of the incineration fly ash, and the addition of the cementitious material is 22wt% of the mass of the incineration fly ash, The amount of water added is 35wt% of the incineration fly ash mass;

[0053] The cementitious material is cement and water glass with a mass ratio of 1:0.5;

[0054] Prepare the biochar loaded with graphene oxide according to the following steps:

[0055] Dissolve 35kg of graphene oxide in water of 3 volume multiples, then soak 35kg of biochar in the graphene oxide solution for 40 minutes, and dry at 60°C for 20 minutes to obtain graphene oxide-loaded biochar.

[0056] The treatment agent is made by the following steps:

[0057] Get 35kg of biochar loaded with graphene oxide prepared in the above steps, 25kg of chelating agent, 15kg of hydrotalcite and 12kg of nano-titanium dio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com