A kind of harmful gas dynamic purification reactor and purification method thereof

A harmful gas and reactor technology, applied in chemical instruments and methods, separation methods, calcium/strontium/barium halides, etc., can solve problems such as easy generation of dioxins, incomplete combustion of chlorine-containing waste, and achieve manufacturing costs Low, simple structure, high clearance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

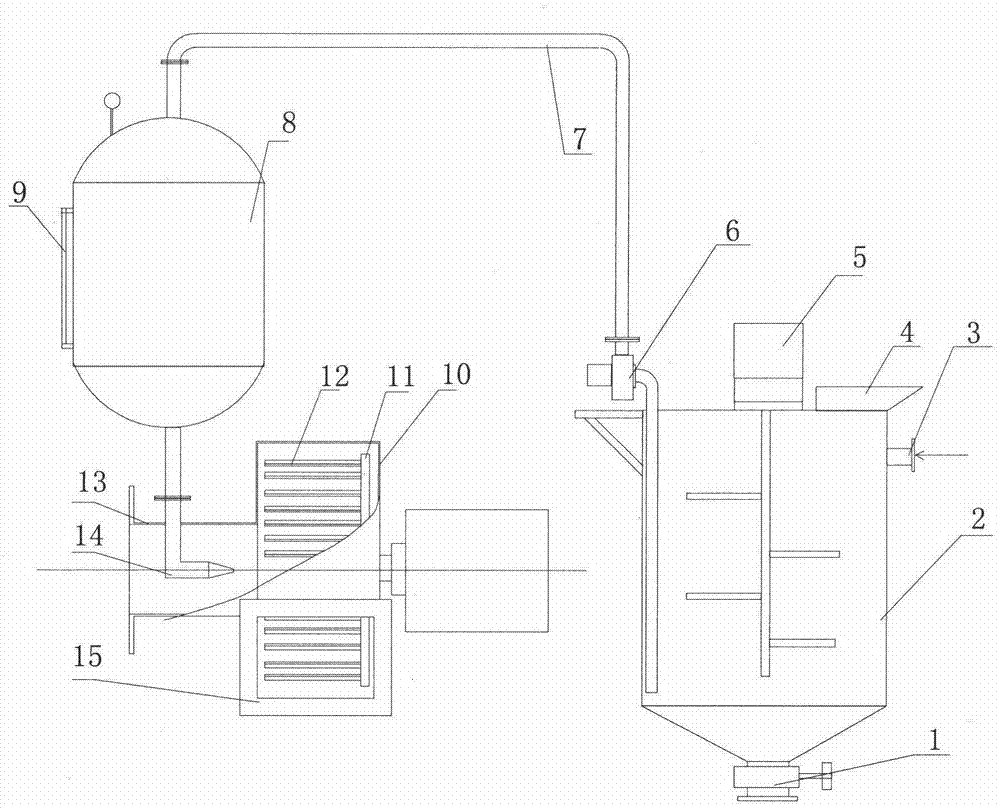

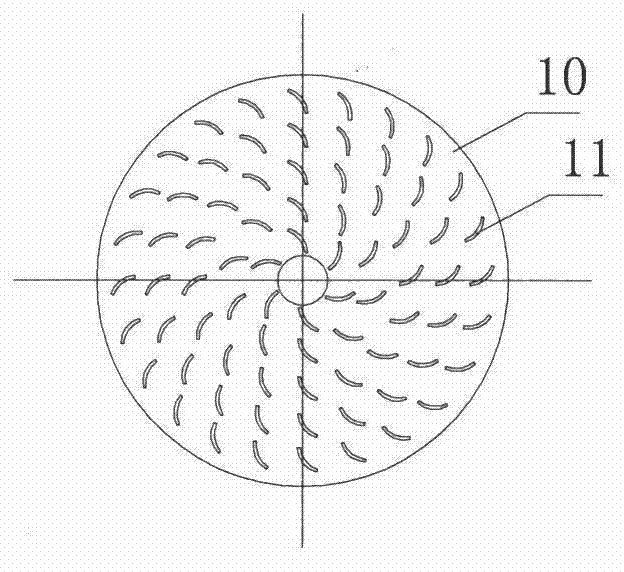

[0026] The working principle of the harmful gas dynamic purification reactor of the present invention is as follows: as introduced in the background technology, the main source of dioxin is caused by the combustion of chlorine-containing plastic waste in a low-temperature and anoxic state, and the chlorine-containing plastic waste in a low-temperature and anoxic state When burning at a temperature lower than 800°C, first, chlorine is decomposed into gaseous chloride ions, and carbon and hydrogen generate carbon dioxide, water or small molecular weight compounds. Dioxin can be synthesized with other small molecular weight organic compounds at ℃ temperature. Experiments have proved that even if chlorine-containing plastics are burned and decomposed at 1000℃, dioxin can also be synthesized when the temperature is naturally cooled to 400-800℃ in the flue. It is the root cause that no matter how high the temperature of waste incineration is, it cannot completely remove dioxins. Acc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com