Novel fly ash efficient resource utilization system and method

A recycling and fly ash technology, which is applied in the field of new fly ash efficient resource utilization system, can solve the problems of inability to achieve detoxification, continuous production, dioxin regeneration, high equipment requirements, etc., to improve the processing capacity of a single furnace, Increase the uniformity of heating and the effect of uniform heating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

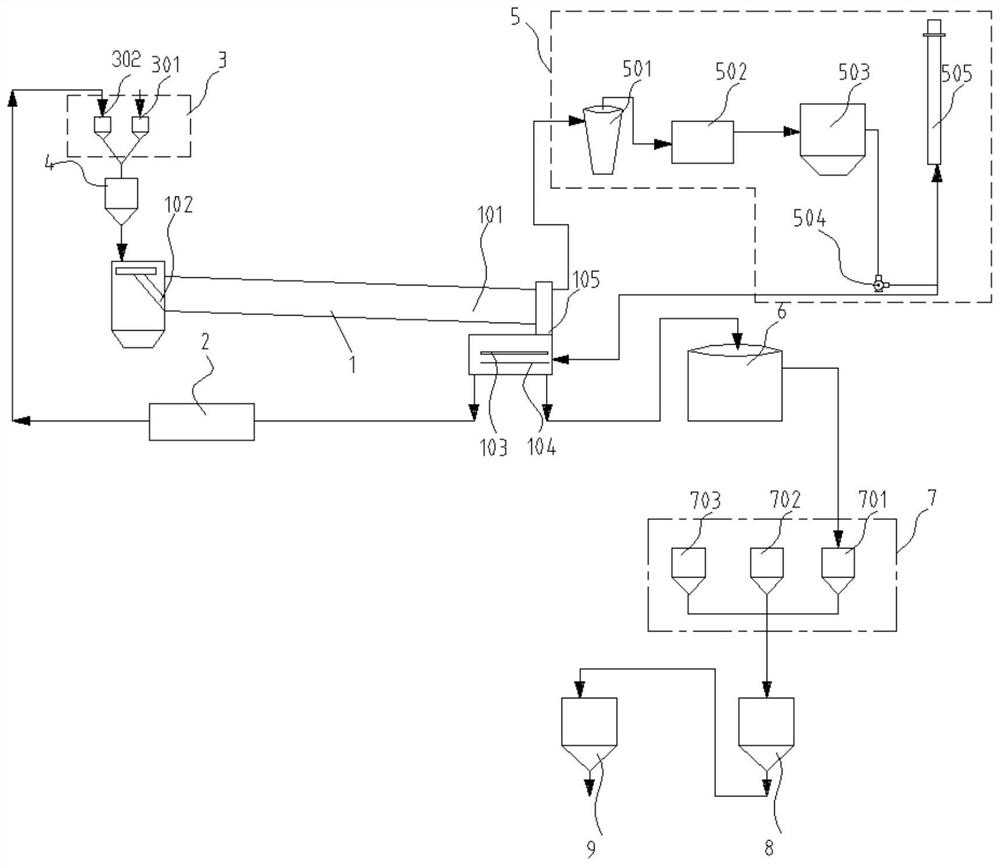

[0072] use figure 1 The high-efficiency continuous fly ash heat treatment system treats waste incineration fly ash. The specific process is as follows:

[0073] Put the waste incineration fly ash into the fly ash bin 301, turn on the heating system in the preheater 2 to preheat the heat storage ball, send the preheated heat storage ball into the heat carrier storage bin 302, and turn on the return The external heating chamber of the mixed pyrolysis reactor preheats the back-mixed pyrolysis reactor. The heat storage ball and the waste incineration fly ash are mixed according to the volume ratio of 1.5-2:1. The heat storage ball adopts a spherical ceramic ball with a size of φ20-40mm. Rotate the back-mixing pyrolysis reactor, and control the temperature of the pyrolysis reactor at 700±15°C by adjusting the amount of gas (combustible gas supplied from outside) and the amount of air. After the temperature of the heat storage ball rises to 600±10°C, the waste incineration fly as...

Embodiment 2

[0093] use figure 1 The high-efficiency continuous fly ash heat treatment system treats waste incineration fly ash. The specific process is as follows:

[0094] Put the waste incineration fly ash into the fly ash bin 301, turn on the heating system in the preheater 2 to preheat the heat storage ball, send the preheated heat storage ball into the heat carrier storage bin 302, and turn on the return The external heating chamber of the mixed pyrolysis reactor preheats the back-mixed pyrolysis reactor. Heat storage balls and waste incineration fly ash are mixed according to the volume ratio of 2:1. Rotate the back-mixing pyrolysis reactor, and control the temperature of the pyrolysis reactor at 800±10°C by adjusting the amount of gas and air. After the temperature of the heat storage ball rises to 500±10°C, the waste incineration fly ash and the heat storage ball are transferred to the mixing bin 4, and after mixing evenly under the action of the stirring device, they are fed in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com