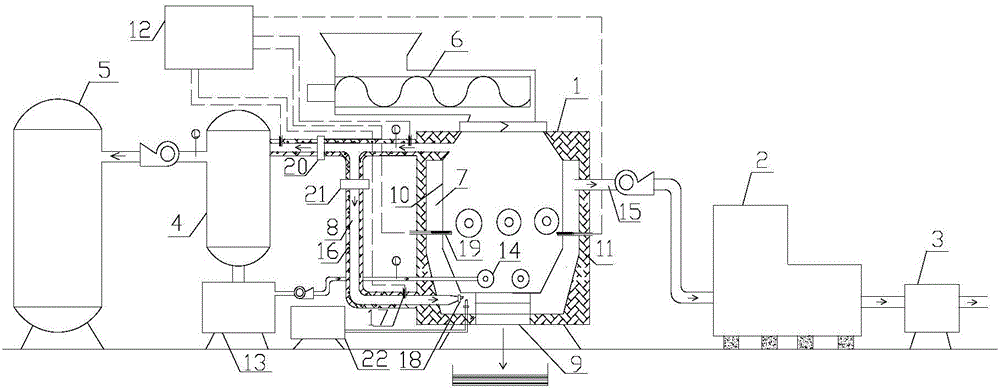

Household garbage pyrolysis and gasification processing system

A technology of pyrolysis gasification and treatment system, which is applied in the field of high-efficiency domestic waste pyrolysis and gasification treatment system, can solve the problems of high cost of external heating sources, pollution caused by domestic waste pyrolysis and gasification, etc., so as to improve heat utilization efficiency and reduce capacity. Significant weight reduction and the effect of reducing dependence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in detail below in conjunction with the drawings.

[0022] This technical solution is applied to the harmless treatment of urban domestic garbage. The start-up heat source and auxiliary heat source of the pyrolysis gasifier adopt the method of oil heating. After the pyrolysis gasifier operates stably, the main heat source is the pyrolysis gas produced by combustion Gas. The domestic waste is screened and dried and then enters the pyrolysis gasification furnace. The pyrolysis gasification gas with higher calorific value is introduced to the bottom of the furnace through a special pyrolysis gasification gas pipeline, and the pyrolysis gasification gas is burned into the furnace body Provides the heat required for the reaction, the generated high-temperature flue gas is used to heat the furnace body through the flue gas channel before being discharged, and the temperature in the furnace and the pyrolysis gas pipeline is controlled by th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com