Fluidized bed plasma garbage-gasifying equipment and gasifying process thereof

A technology of fluidized bed gasification and fluidized bed gasifier, which is applied in granular/powder fuel gasification, petroleum industry, manufacture of combustible gas, etc. and other problems, to achieve the effect of improving gasification efficiency and throughput, improving gasification efficiency and reducing adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

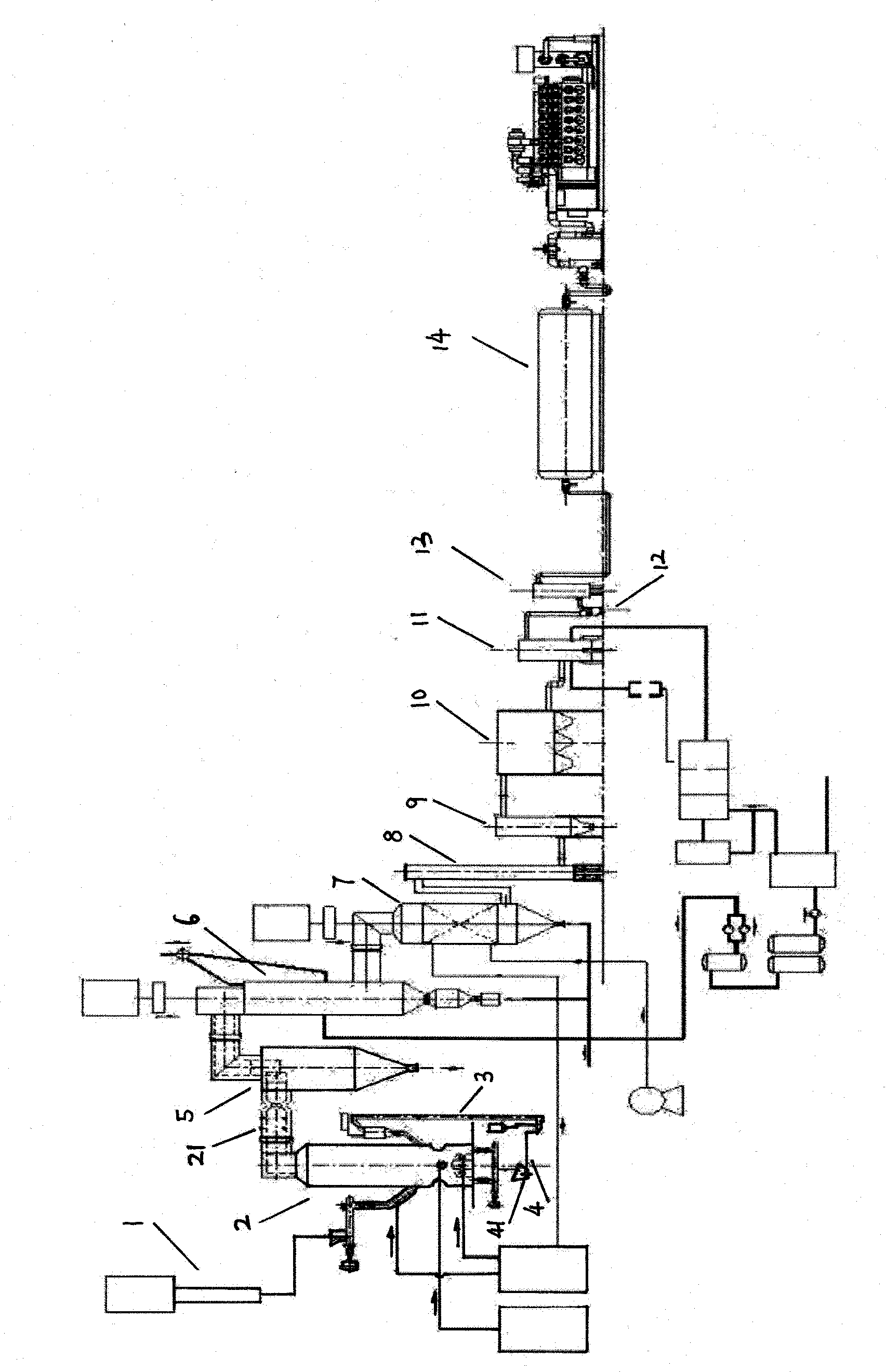

[0053] A fluidized bed gasification garbage equipment, including a feeding system 1, a plasma gasification fluidized bed 2, a feeding system 3, a slag discharge system 4, a cyclone separator 5, a rapid cooling waste heat boiler 6, a rapid cooling tower 7, a cooling tower 8, adsorption tower 9, bag type dust removal device 10, sulfur removal device 11, water ring compressor 12, steam-water separator 13, gas storage and distribution cylinder 14, and equipment control system, such as figure 1 shown;

[0054] The feeding system 1 is composed of a double auger feeder. The two augers are placed side by side and can move laterally. When the auger jams the material, it can be separated automatically so that the jammed material continues to move forward.

[0055] The plasma gasification fluidized bed 2 includes a furnace wall, an air distribution plate, and a plasma torch 21;

[0056] The furnace wall is composed of a three-layer structure, the innermost layer is made of corundum cast...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com