Catalyst for removing dioxin in kiln flue gas through catalytic oxidation and preparation method of catalyst

A catalytic oxidation and catalyst technology, which is applied in the field of environmental protection and catalysts, can solve the problems of high decomposition temperature, difficult industrial production, and low decomposition efficiency, and achieve the effects of high decomposition efficiency, easy molding, and simple preparation methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

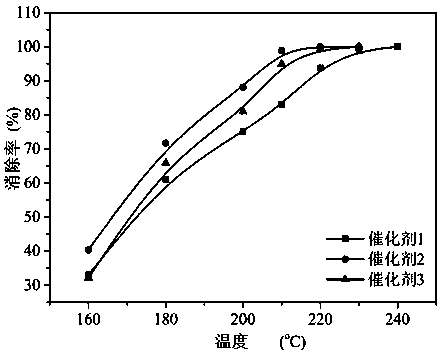

Examples

Embodiment 1

[0025] (1) Fully dissolve 0.64 g of ammonium metavanadate, 0.54 g of ammonium metatungstate and 0.35 g of tin tetrachloride in a mixed solution of 10 g of deionized water and 3 g of monoethanolamine, and record it as solution A;

[0026] (2) Add 8.75 g of titanium dioxide to solution A, disperse fully and evenly, and record the obtained solution as solution B;

[0027] (3) Add 0.12 g of ammonium molybdate into 3 g of deionized water, stir to fully dissolve it, and obtain C solution;

[0028] (4) Slowly add solution C and 0.5 g ammonia water to solution B under vigorous stirring to obtain solution D;

[0029] (5) Keep stirring solution D for 5 hours in a water bath at 40°C; after the above mixed solution evaporates to dryness to form a paste mixture, put the mixture in a blast drying oven for further drying at a drying temperature of 100°C. The time is 12 hours;

[0030] (6) Calcining the dried block in a muffle furnace, the calcination temperature is 400°C, the heating rate ...

Embodiment 2

[0032] (1) Fully dissolve 1.15 g of ammonium metavanadate, 0.54 g of ammonium metatungstate and 0.08 g of stannous chloride in a mixed solution of 15 g of deionized water and 2 g of monoethanolamine, and record it as solution A;

[0033] (2) Add 8.5 g of titanium dioxide to solution A, disperse fully and evenly, and record the obtained solution as solution A;

[0034] (3) Add 0.13 g of cerium nitrate to 3 g of deionized water, stir to fully dissolve it, and obtain C solution;

[0035] (4) Slowly add solution C and 1.0 g ammonia water to solution B under vigorous stirring to obtain solution D;

[0036] (5) The D solution was continuously stirred for 4 hours under the condition of a water bath at 50°C. After the above mixed solution was evaporated to dryness to form a paste mixture, the mixture was put into a blast drying oven for further drying. The drying temperature was 80°C, and the drying time was for 20 hours;

[0037] (6) Calcining the dried block in a muffle furnace, t...

Embodiment 3

[0039] (1) Fully dissolve 1.02 g of ammonium metavanadate, 0.37 g of ammonium paratungstate and 0.23 g of tin tetrachloride in a mixed solution of 20 g of deionized water and 1 g of monoethanolamine, and record it as solution A;

[0040] (2) Add 8.7 g of titanium dioxide into solution A, stir to dissolve it fully, and obtain solution B;

[0041] (3) Add 0.26 g of lanthanum nitrate to 5 g of deionized water, stir to fully dissolve it, and obtain C solution;

[0042] (4) Slowly add solution C and 1.5 g ammonia water to solution B under vigorous stirring to obtain solution D;

[0043] (5) The D solution was continuously stirred for 7 hours under the condition of a water bath at 30°C. After the water in the above mixed solution was evaporated to dryness to form a paste mixture, the mixture was placed in a blast drying oven for further drying. The drying temperature was 80°C and the drying time was for 15 hours;

[0044] (6) The dried block is placed in a muffle furnace for calci...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com