A method for co-resource utilization of urban solid waste and carbon dioxide

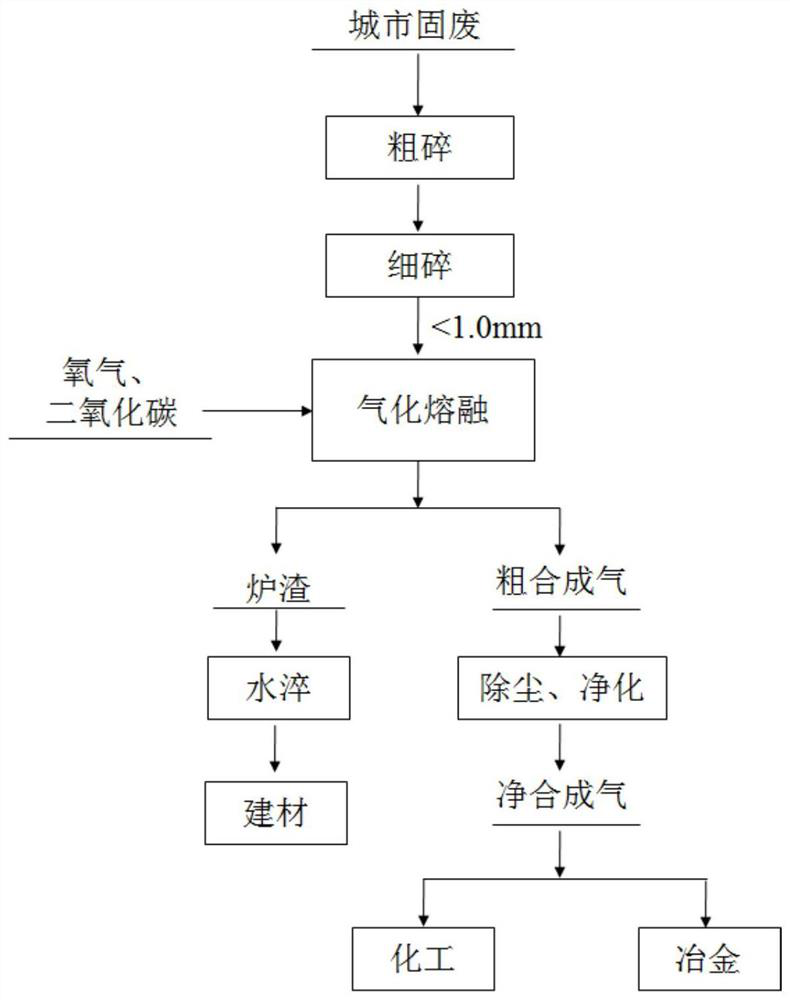

A carbon dioxide, recycling technology, applied in gasification process, combustible gas purification, removal of gas pollutants, etc., can solve the high pyrolysis and gasification reaction rate of waste-derived fuel, waste incineration power generation processing capacity can not meet the requirements, The problem of high cost of secondary pollutant treatment can achieve the effect of rapid and efficient gasification and melting, reducing the NIMBY effect and reducing the difficulty of site selection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] For the mixed solid waste collected by the urban sanitation system (pre-removed kitchen waste), the waste sorting system separates recyclables, bricks and tiles, harmful substances, etc., and the remaining part is mixed and sent to the shear crusher for coarse crushing When the particle size is less than 50mm, the crushed material is sent to a low-temperature heating device for heating. The heating is carried out under an inert protective atmosphere. The heating temperature is 400°C, and the heating time is 50 minutes, and then cooled. The whole process completes the removal of moisture and the improvement of brittleness. The cooled material is crushed and screened by a high-speed shear crusher to obtain finely divided materials with a particle size of less than 1.0 mm. The sensible heat of the crude synthesis gas is recovered by a heat exchanger and the oxygen-carbon dioxide mixture is preheated. After preheating, the temperature of the mixed gas reaches 500°C, and the ...

Embodiment 2

[0049] For other garbage collected by the urban sanitation system that adopts the "four-point method", bricks, tiles, metals, etc. are removed through the garbage classification system, and the remaining part is mixed and sent to the shear crusher for coarse crushing until the particle size is less than 50mm. In order to co-dispose wastes in rural and forestry areas, agricultural and forestry wastes are added to urban solid wastes. Agricultural and forestry wastes also need to be coarsely crushed and mixed with coarsely crushed urban solid wastes. The proportion of agricultural and forestry wastes 10%. The mixed coarsely crushed material is sent to a low-temperature heating device for heating. The heating is carried out under an inert protective atmosphere. The heating temperature is 350°C, and the heating time is 60 minutes. The material is crushed and screened by a high-speed shear crusher to obtain finely divided materials with a particle size of less than 1.0 mm. The sens...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com