Device for reducing dioxins discharge during steel smelting in electric furnace and method thereof

An electric furnace steelmaking and dioxin technology, which is applied in the field of iron and steel smelting to achieve the effect of reducing steelmaking costs and saving energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

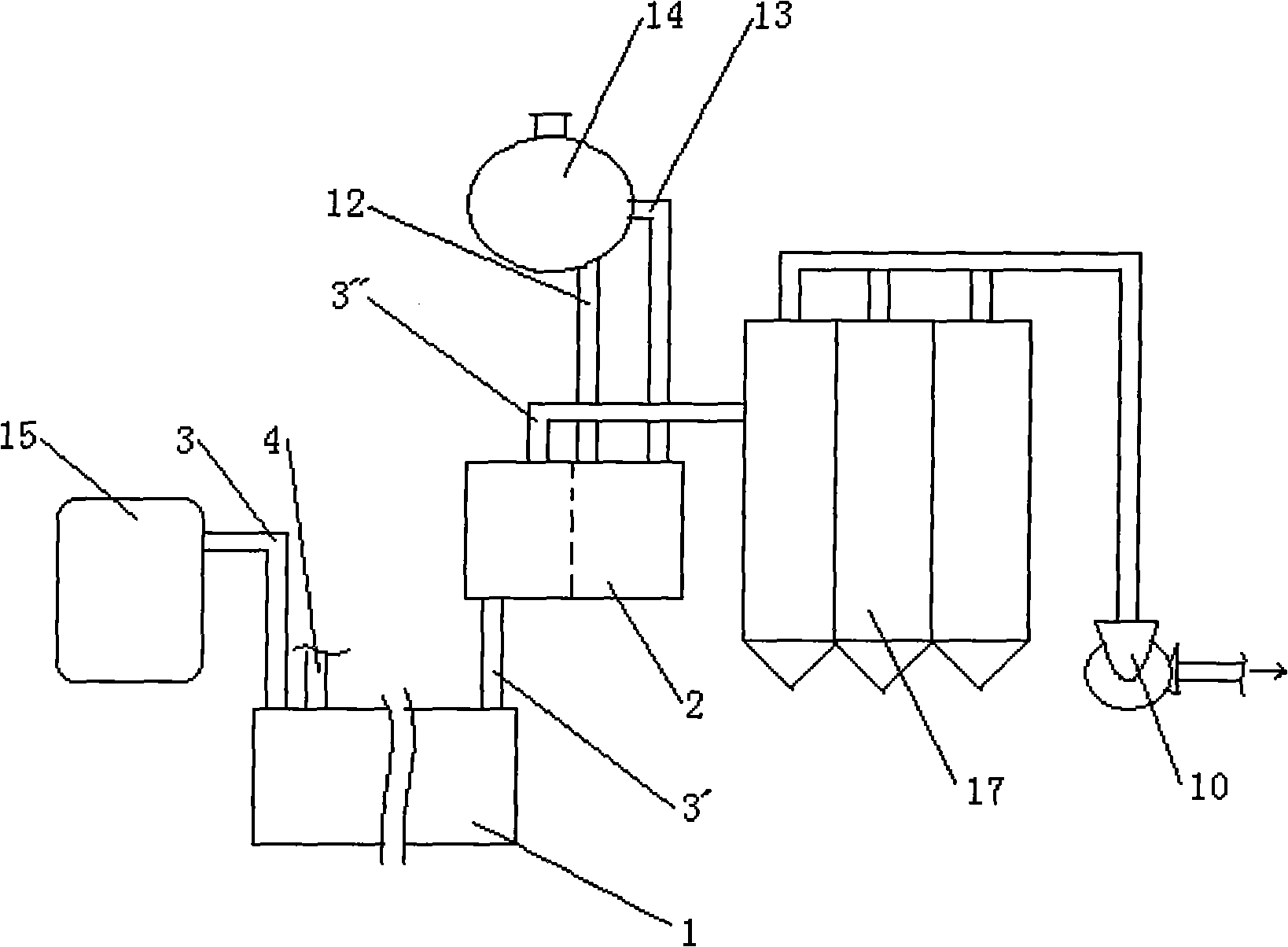

[0019] Such as figure 1 As shown, the device for reducing dioxin emissions from electric furnace steelmaking includes a bag filter 17 and a negative pressure device 10 connected to the electric furnace 15 through the flue gas pipeline, and the pipeline between the electric furnace 15 and the bag filter 17 is sequentially It is connected with a combustion settling chamber 1 and a cooling device 2 .

[0020] still as figure 1 As shown, the combustion settling chamber 1 is a cuboid, and the inlet and outlet of the flue gas ducts 3, 3' are respectively arranged on the upper parts of the two ends of the combustion settling chamber 1 in the direction of the long axis, and the upper part of the combustion settling chamber 1 is also provided with an air inlet duct 4. The outer walls of the combustion settling chamber 1 and the flue gas pipes 3, 3' are provided with an insulating layer (not shown).

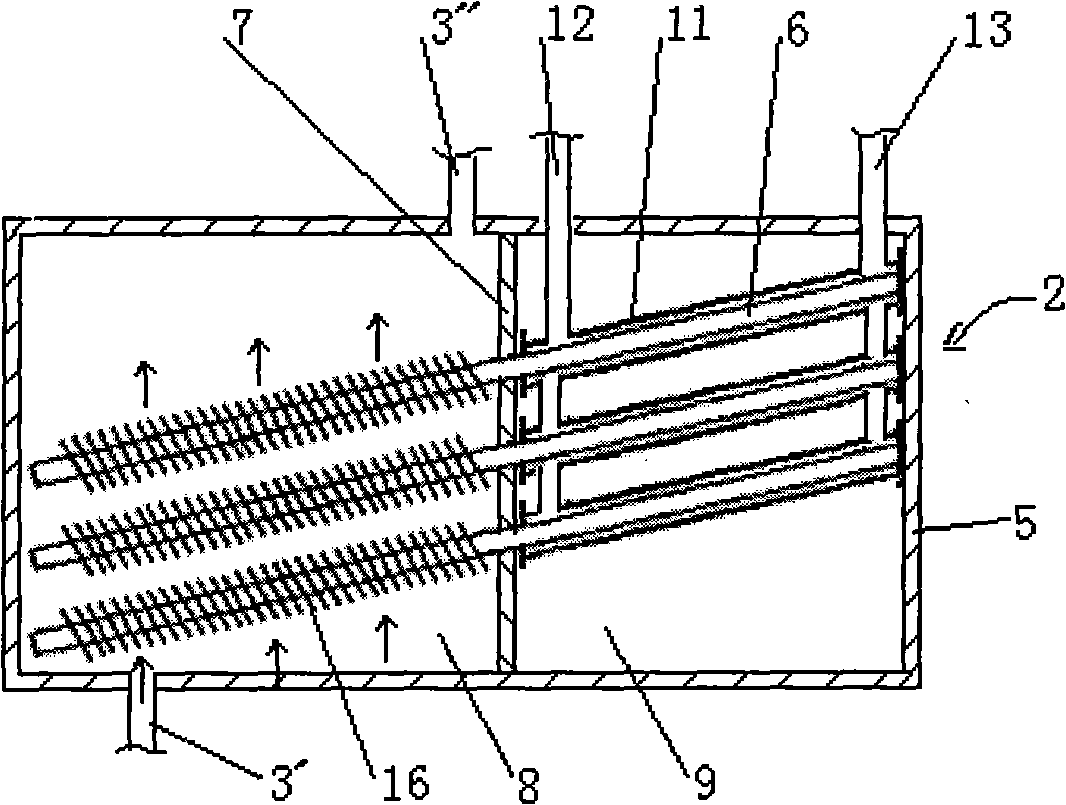

[0021] Such as figure 2 As shown, the cooling device 2 is composed of a housing 5 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com